Rare earth zirconium-based composite oxide with core-shell structure, and preparation method and application thereof

A technology of composite oxides and rare earth oxides, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, separation methods, etc., can solve problems such as high energy consumption, complicated process, and expensive manufacturing cost , to achieve good oxygen storage capacity, avoid ammonia nitrogen wastewater, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

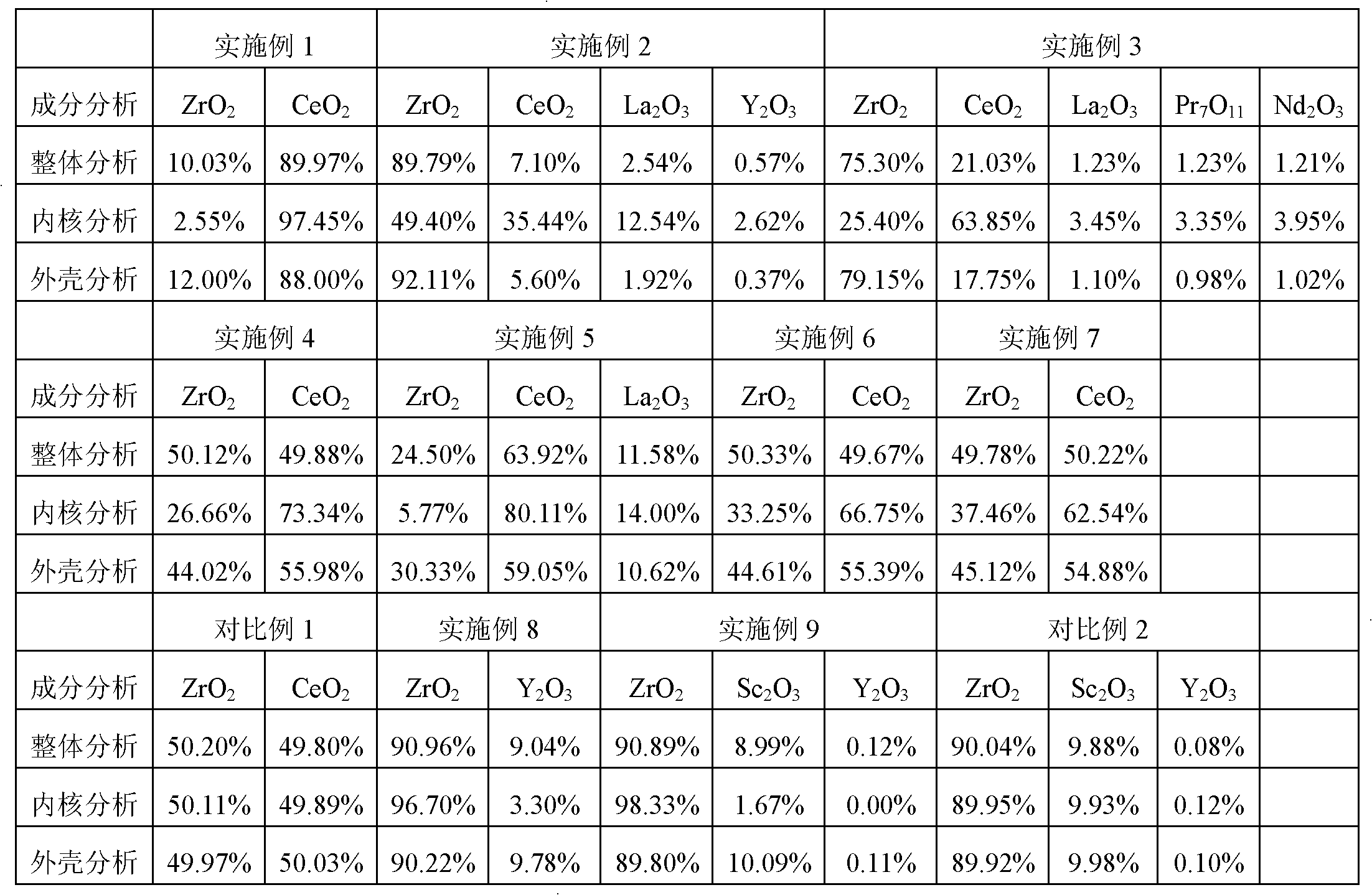

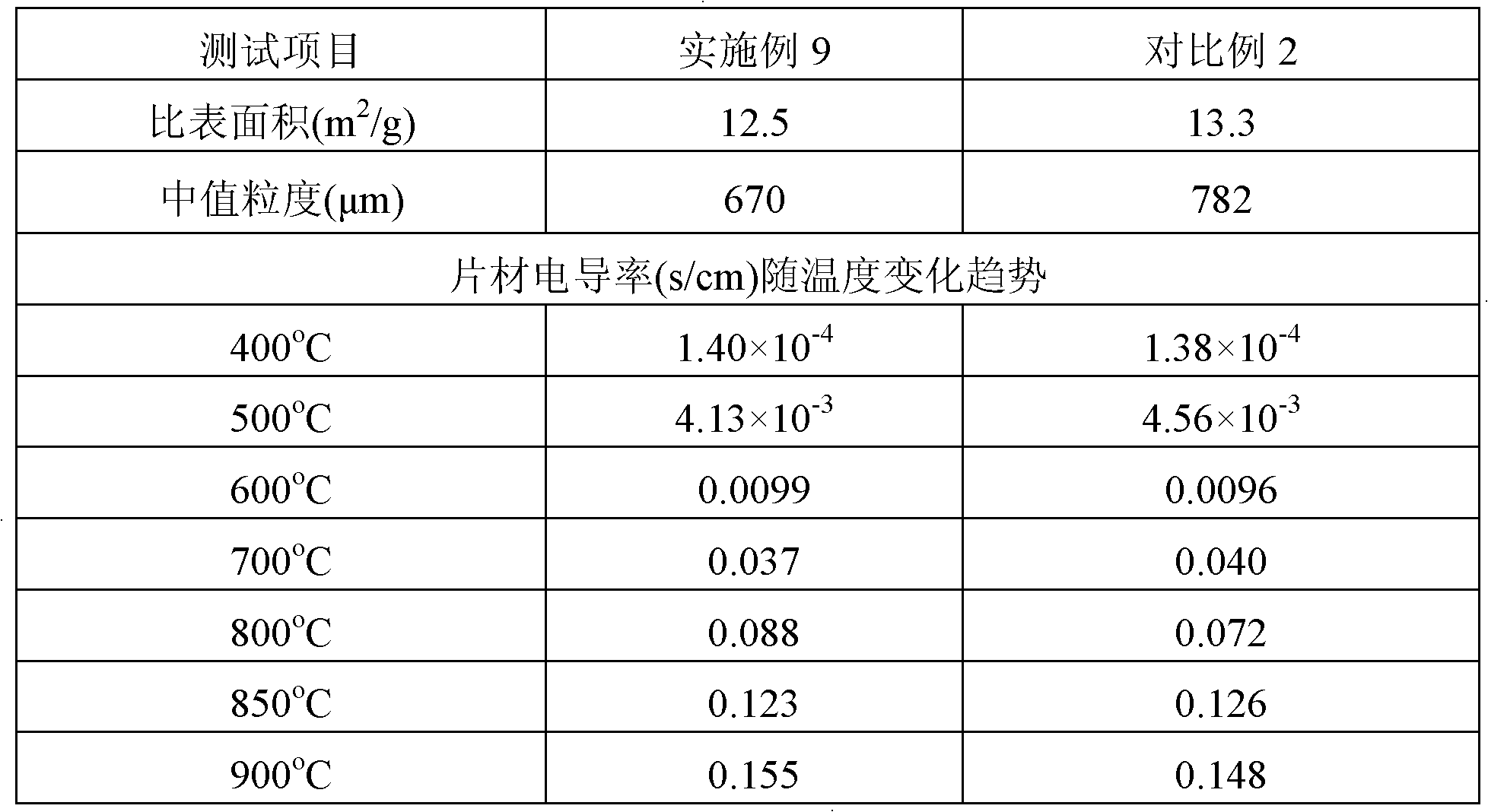

Embodiment 1

[0056] Weigh cerium chloride and zirconium oxychloride crystals according to the molar ratio of rare earth and zirconium being 9:1, prepare chloride solutions respectively, the molar concentrations of the two are 0.9M and 0.1M respectively, and the volumes are 10L each, and the prepared 50L sulfuric acid Ammonium solution and 1wt% hexamethylenetetramine are used as the base liquid, the amount of ammonium sulfate is 1.02 times the theoretical amount required for double salt precipitation, heated to 60 °C, and under stirring, 2L of the rare earth salt solution is first mixed with 0.5 L / min was added to the ammonium sulfate bottom solution, and then the remaining rare earth salt solution and zirconium salt solution were mixed to form a mixed solution, and the flow rate was controlled to 1.0L / min, and aged to form a core-shell structure of double salt precipitation.

[0057] After clarification, washing and filtration, the double salt precipitate was obtained, and 1.05 times the am...

Embodiment 2

[0060] Weigh rare earth chloride (70mol% Ce+25mol%La+5%molY) and zirconium oxychloride crystals according to the molar ratio of rare earth and zirconium being 1:9, and prepare chloride solutions respectively, and the molar concentrations of the two are respectively 0.1M and 0.9M, each volume 10L, the prepared 50L ammonium sulfate and hydrazine hydrate accounting for 0.1wt% of rare earth zirconium-based oxides are used as the bottom liquid, the amount of ammonium sulfate is 3 times the theoretical amount required for double salt precipitation, and heated to 60 ℃, under stirring, first add 2 L of rare earth salt solution into the ammonium sulfate base solution at 0.5 L / min, then make the remaining rare earth salt solution and zirconium salt solution into a mixed solution, add it at a controlled flow rate of 1.0 L / min, and age Formation of double salt precipitation with a core-shell structure.

[0061] After clarification, washing and filtering, the double salt precipitate was ob...

Embodiment 3

[0064] Weigh rare earth chloride (85mol% Ce+5mol%La+5mol%Nd+5mol%Pr) and zirconium oxychloride crystals according to the molar ratio of rare earth and zirconium being 2.5:7.5, prepare chloride solutions respectively, and the molar concentrations of the two are respectively 0.25M and 0.75M, each 10L in volume, the prepared 50L sodium sulfate solution and polyvinyl alcohol accounting for 0.2wt% of rare earth zirconium-based oxides are used as the bottom liquid, and the amount of sodium sulfate is the theoretical amount required for double salt precipitation. 1.2 times, heated to 90°C, under stirring, first add 2L of rare earth salt solution into the ammonium sulfate base solution at 0.5L / min, then make the remaining rare earth salt solution and zirconium salt solution into a mixed solution, control the flow rate of 1.0 Add L / min, age, and form a double salt precipitation with a core-shell structure.

[0065]After clarification, washing and filtering, the double salt precipitate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com