Patents

Literature

31results about How to "Small cell constant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for modifying mesoporous-rich USY (Ultra-Stable Y) molecular sieve in combined manner

InactiveCN104229823ASmall cell constantIncreased secondary pore contentFaujasite aluminosilicate zeoliteInorganic saltsMolecular sieve

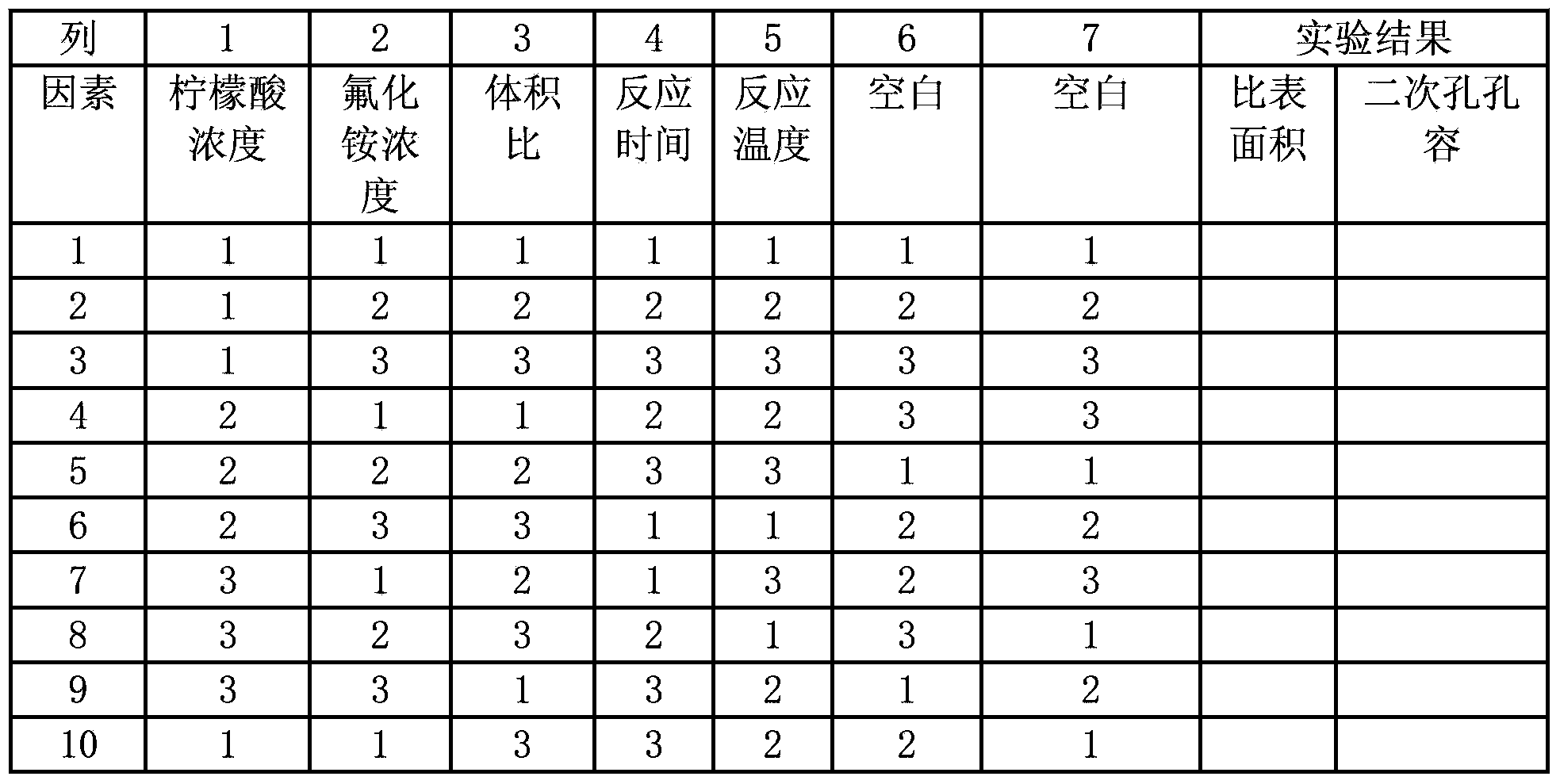

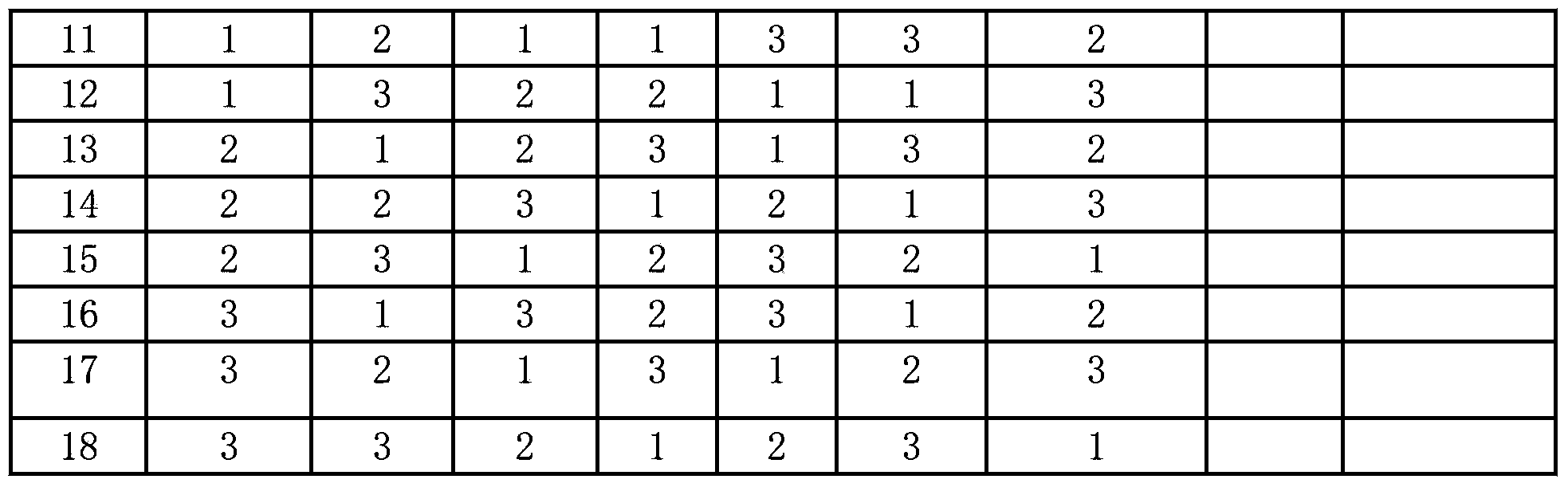

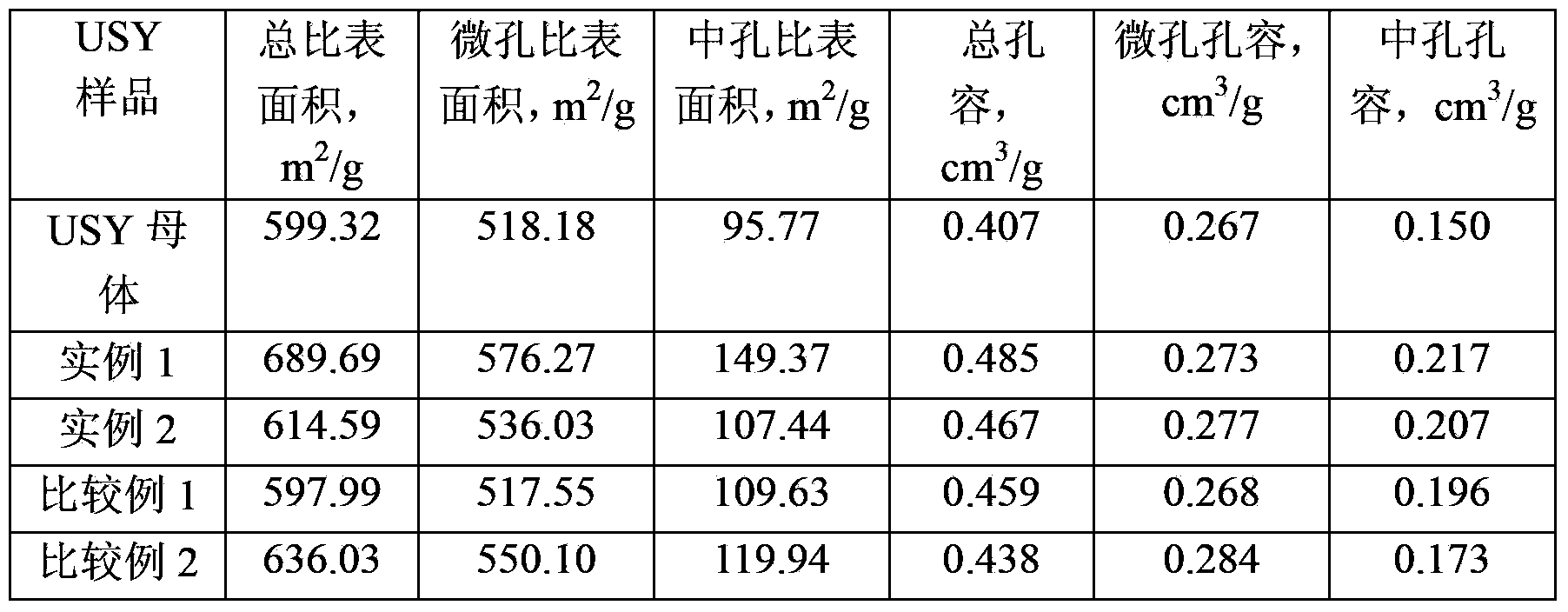

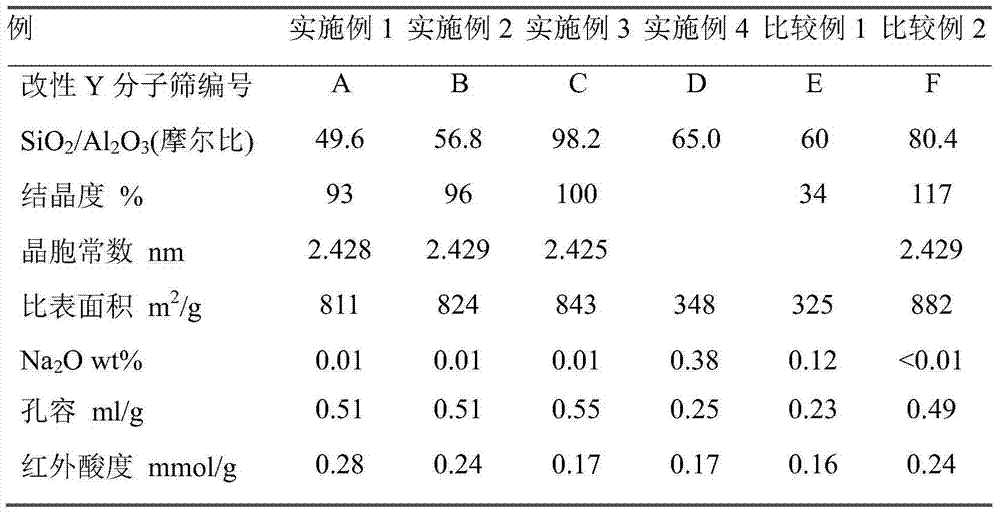

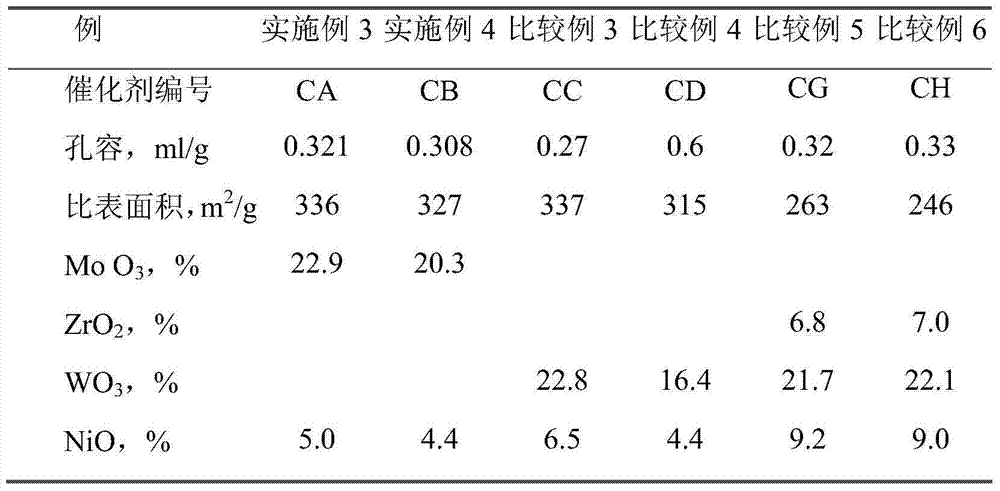

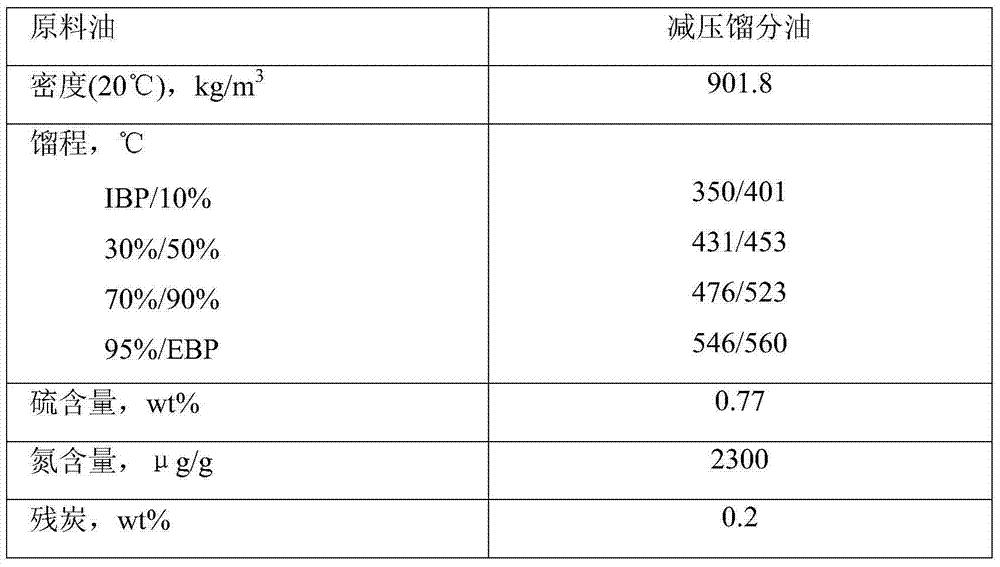

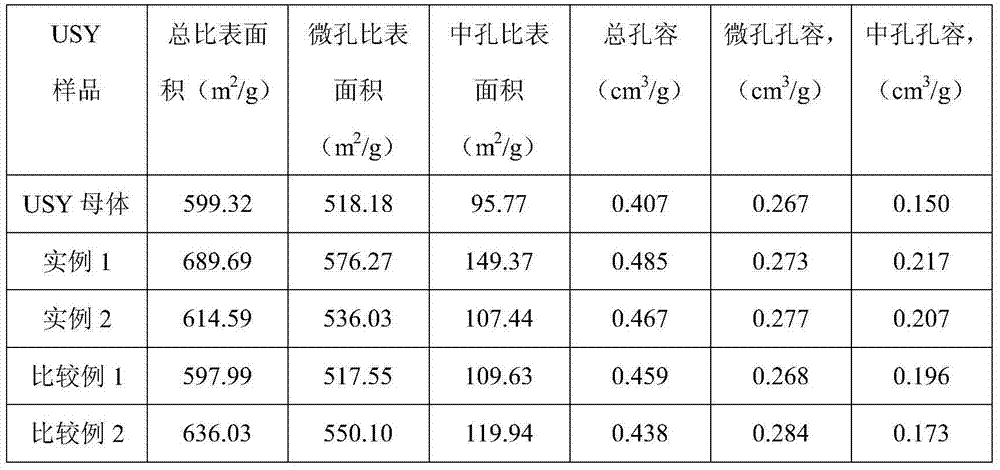

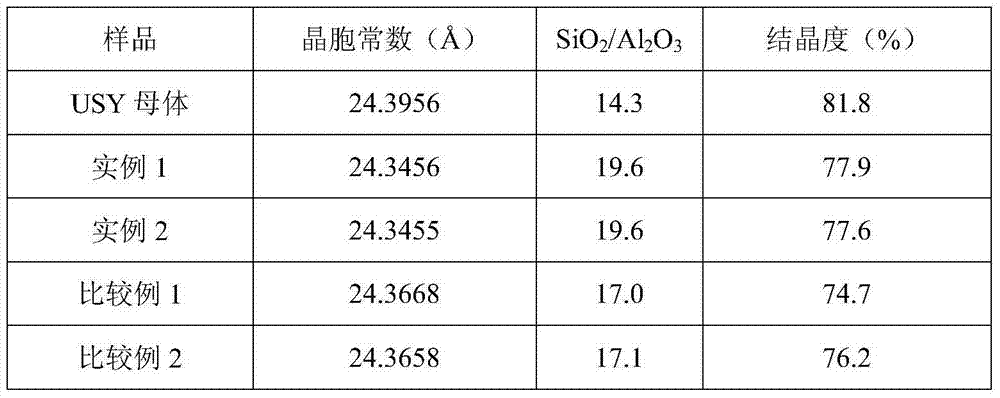

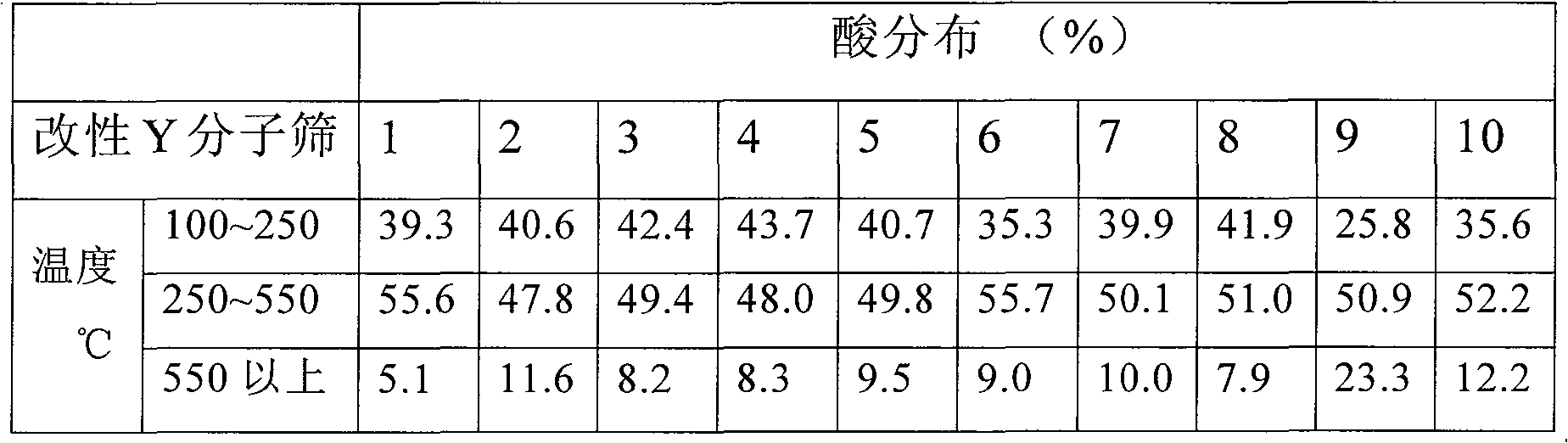

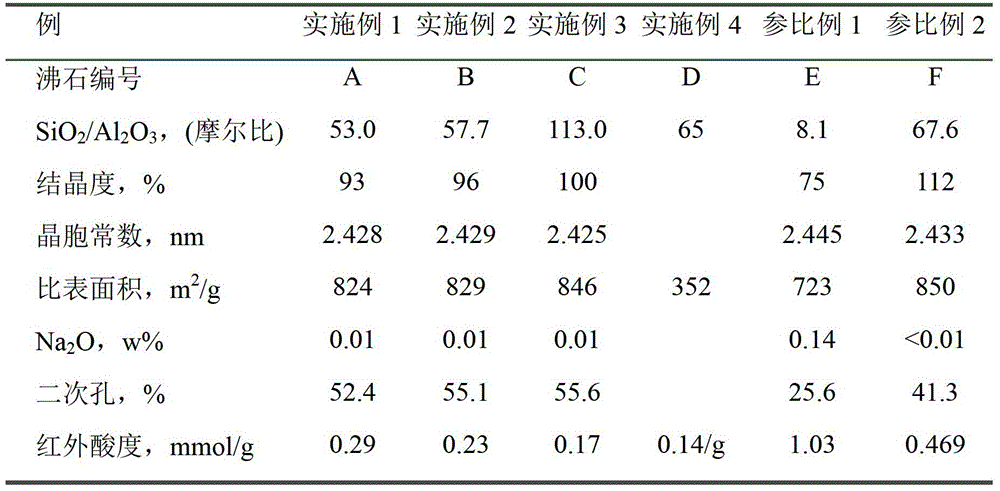

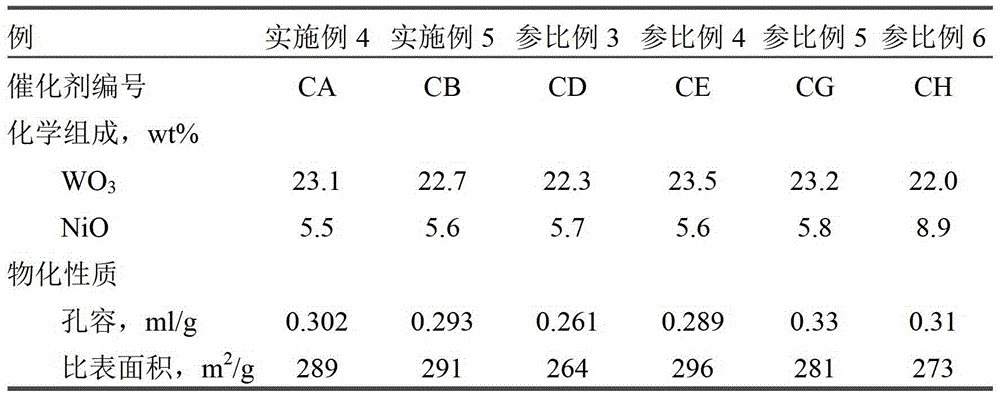

The invention relates to a method for modifying a USY (Ultra-Stable Y) molecular sieve. The method is characterized in that organic acid and an inorganic salt dealuminizing reagent are simultaneously added in a modifying process for organic acid-inorganic salt combined modification, and optimum process conditions, namely optimum concentration, volume ratio, reaction time, reaction temperature and the like, of an organic acid and an inorganic salt solution are determined by virtue of an orthogonal test. Compared with an industrial USY molecular sieve, the USY molecular sieve obtained by adopting the method disclosed by the invention is obviously increased in secondary pore content, can be kept at higher crystallinity and is enhanced in silica-alumina ratio, reduced in lattice constant and suitable for high-medium oil type hydrocracking catalyst carriers.

Owner:PETROCHINA CO LTD +1

Y molecular sieve modification method

ActiveCN1803612ASmall cell constantHigh crystal retentionCatalyst carriersMolecular sieve catalystsMolecular sieveDistilled oil

The invention relates to a modifying method for Y molecular sieve, which comprises: using industrial NaY molecular sieve as material for ammonium exchange, baking deeply; then, adding surfactant during dealumination with acid. This invention obtains HY molecular sieve with high SiO2 / Al2O3(9~15) and crystallinity, improves secondary pores and acid structure compared with the industrial NaY, and fits to be carrier for hydrotreating catalyst for heavy distilled oil.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

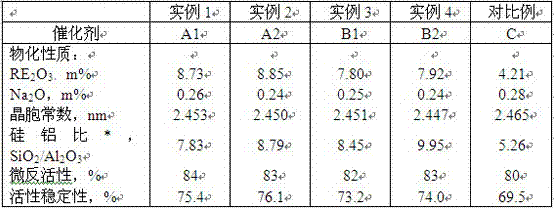

Composite molecular sieve-containing medium oil type hydrocracking catalyst, preparation method and application thereof

ActiveCN103551186BHigh crystallinityIncrease surface areaMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNaphtha

The invention relates to a composite molecular sieve-containing medium oil type hydrocracking catalyst, which comprises an active component and a binder, wherein the active component adopts amorphous SiO2-Al2O3 as a carrier, adopts a composite molecular sieve as an acid component, and adopts a group VIB metal and a group VIII metal as hydrogenation activity components, and the composite molecular sieve comprises a Y molecular sieve and a ZSM-23 molecular sieve. According to the present invention, the deep dealuminzation modified Y molecular sieve has characteristics of high crystallinity, large surface area, high silica-alumina ratio, low cell constant, rich secondary pore, low acid center density, high moderate-intensity acid center ratio, and the like; the modified ZSM-23 molecular sieve has characteristics of smooth pore channel, less acid center and outstanding isomerism performance, wherein a light naphtha component is isomerized so as to increase an octane number of naphtha; the composite molecular sieve compounded from the Y molecular sieve and the ZSM-23 molecular sieve is adopted as the acid cracking component so as to provide advantages of the Y molecular sieve and the ZSM-23 molecular sieve, and compounding is performed according to the ratio of the present invention, such that the best catalysis effect can be obtained, and the obtained catalyst is suitable for the medium oil type hydrocracking catalyst; and the catalyst prepared from the composite molecular sieve has characteristics of excellent medium oil selectivity, good activity and good stability.

Owner:CHINA NAT OFFSHORE OIL CORP +3

Method for preparing rare-earth ultrastable Y-type zeolite

ActiveCN1676463AImprove exchange efficiencyEfficient removalCatalytic crackingMolecular sieve catalystsActive componentGasoline

The present invention relates to a preparation method of rare earth overstable Y zeolite. It is characterized by that said method includes the following steps: using mixed solution formed from rare earth salt and citric acid or mixed solution formed from inorganic ammonium salt, rare earth salt and citric acid to treat zeolite. Said zeolite can be used as active component of cracking catalyst, and has the advantages of reducing olefin content of catalytic cracked gasoline and obviously raising catalytic cracked light oil yield.

Owner:CHINA PETROLEUM & CHEM CORP

Combined modification method for mesopore USY molecular sieve

InactiveCN103936024AHigh crystallinityHigh ratio of silicon to aluminumMolecular sieve catalystsFaujasite aluminosilicate zeoliteInorganic saltsMolecular sieve

The invention relates to a modification method for a USY molecular sieve and in particular relates to a combined modification method for a mesopore USY molecular sieve. The combined modification method for the mesopore USY molecular sieve comprises that raw materials such as a USY material, an organic acid solution and an inorganic salt solution are measured in ratio, stirring in a closed reactor is carried out, temperature is increased to 90 DEG C, an organic acid-inorganic salt combined dealumination reaction is carried out for 8 hours; reactants are washed at room temperature, and suction filtration is carried out until the surface of USY is neutral; and drying is carried out at constant temperature of 110 DEG C for 16 hours, so that the USY molecular sieve product is obtained. The combined modification method for the mesopore USY molecular sieve has the advantages that a mixed aqueous solution of organic acid and inorganic salt is adopted for treating the USY type molecular sieve, so that high crystallinity of the molecular sieve can be maintained, silica-alumina ratio of the molecular sieve is increased, lattice constant is reduced, specific surface of the molecular sieve is increased, and acidity and acid distribution of the molecular sieve are improved; and more secondary holes are formed through dealumination, so that components with larger molecular diameter can easily enter into pore passages of the molecular sieve or get close to the surface of the molecular sieve, and conversion efficiency of hydrogen cracking can be improved.

Owner:PETROCHINA CO LTD +1

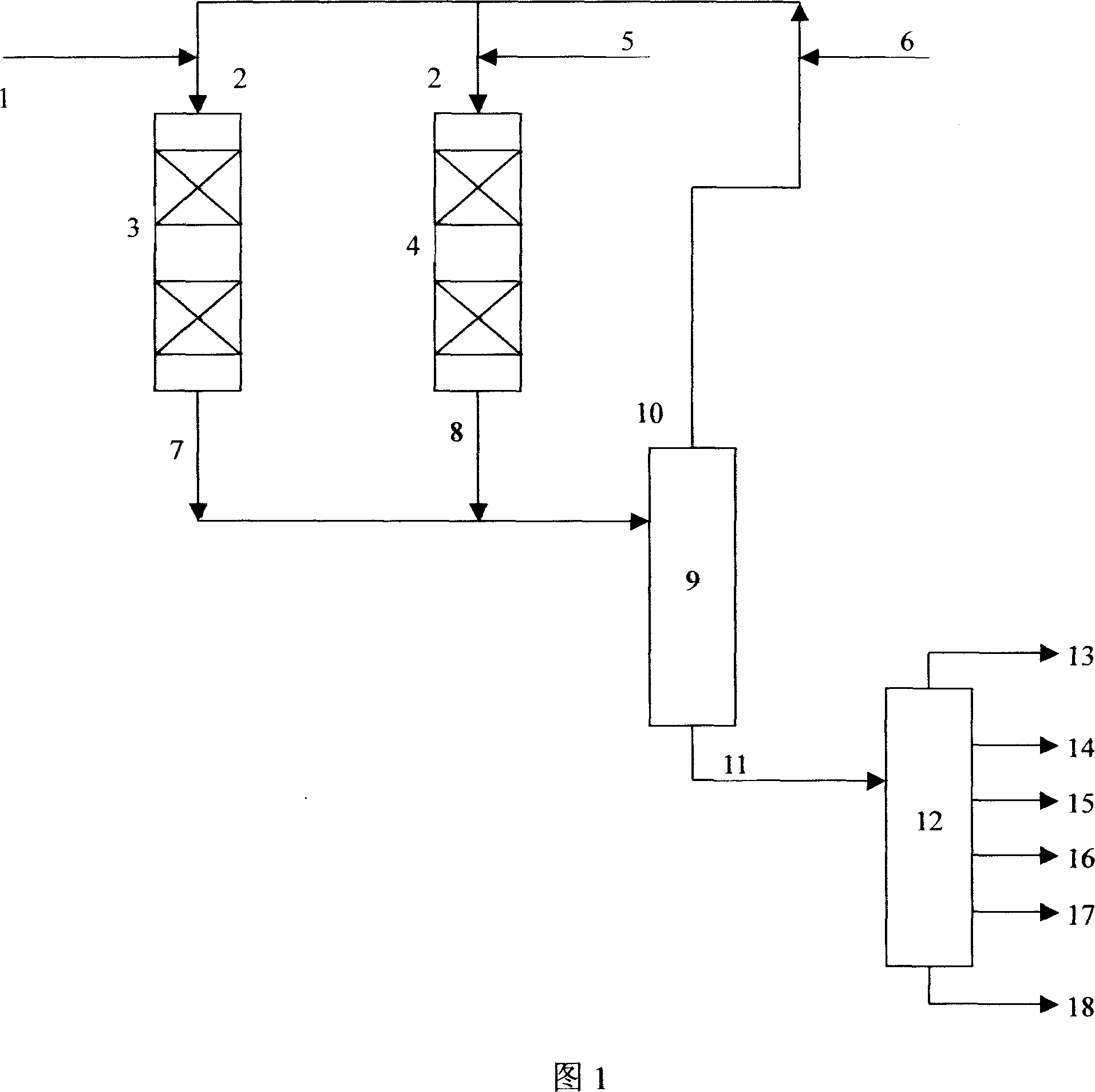

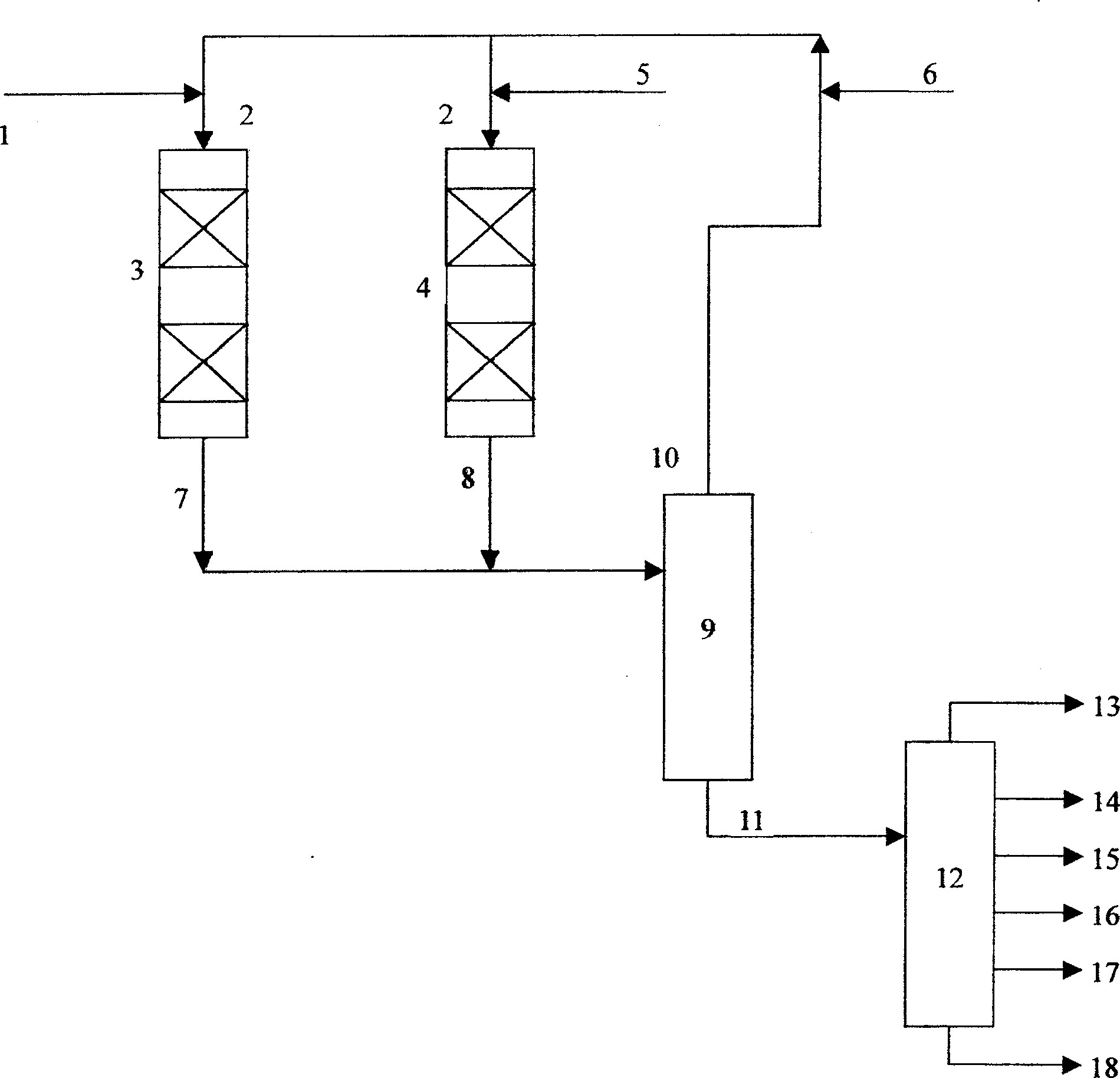

Parallel hydrocracking method

ActiveCN1955259ALow BMCIIncrease the molar ratio of silicon to aluminumTreatment with hydrotreatment processesHexadecaneCatalytic reforming

This invention discloses a hydrocracking method, and this invention is used for producing high aromatic hydrocarbon heavy naphtha and high quality end oil.It includes that heavy distillate oil and poor quality catalytic cracking diesel hydrocracks separately, and the mixture of the cracking products is conducted gas liquid separation. Light naphtha, heavy naphtha, aviation kerosene, diesel oil and end oil will be obtained by distillating the liquid phase. The density of the poor quality catalytic cracking diesel oil is above 0.9g / ml, and the aromatic hydrocarbon is over 60wt% and the value of hexadecane is under 30. It is a adequate utilization of catalytic cracking craft to produce high aromatic hydrocarbon heavy naphtha and high quality end oil with heavy distillate oil and poor quality catalytic cracking diesel, which can be separately used as catalytic reforming material and making ethylene material by steam cracking method. High aromatic hydrocarbon heavy naphtha in this invention will produce a large amount of reforming hydrogen after catalytic reforming treatment, which can be used in the process of hydrocracking to make this preparation more ecnomical and reasonable.

Owner:CHINA PETROLEUM & CHEM CORP +2

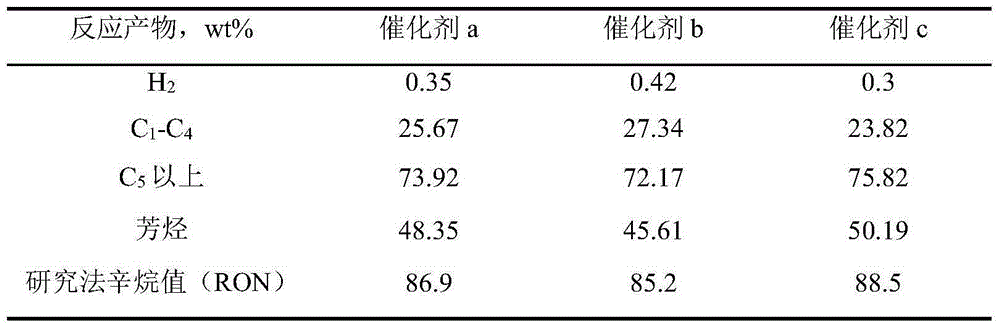

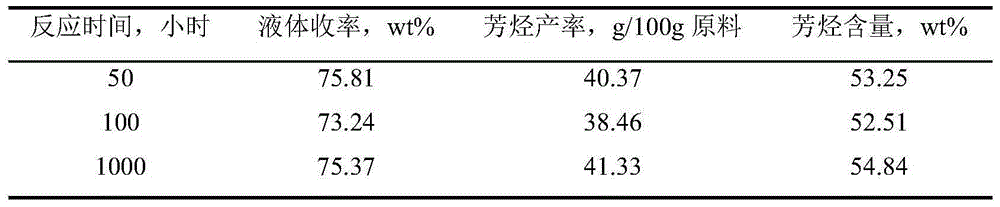

Catalyst for straight-run naphtha aromatization and preparation method thereof

InactiveCN106552663ARegular skeleton structureFast responseMolecular sieve catalystsHigher alkanesNaphtha

The invention discloses a catalyst for straight-run naphtha aromatization and a preparation method thereof. The catalyst for straight-run naphtha aromatization is prepared by modifying a nano ZSM-5 molecular sieve, preparing a carrier and preparing the catalyst. The catalyst is suitable for treating raw materials with high alkane content. And the catalyst has high catalytic activity and high arene selectivity. So the catalyst can be applied to more mild process conditions and can be applied to production of high-octane gasoline blending components and chemical raw materials like benzene, toluene, xylene, etc.

Owner:PETROCHINA CO LTD

Deep sealumination modified Y zeolite preparation method

ActiveCN1951816AStable structureHigh crystallinityMolecular sieve catalystsFaujasite aluminosilicate zeoliteHigh densityCrystallinity

The invention discloses a preparing method of deep aluminium-stripping Y-zeolite, which comprises the following steps: adopting NH4NaY with the content of Na2O not more than 2.5w%; proceeding first water heat disposal; utilizing high-density H+ ammonium salt solution to exchange to strip aluminium; proceeding second water heat disposal; removing non-frame aluminium through acid solution; setting the disposing temperature of second water heat disposal higher than the first one; improving crystallinity and silicon-aluminium rate with abundant secondary hole.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite molecular sieve-containing medium oil type hydrocracking catalyst, preparation method and application thereof

ActiveCN103551186AHigh crystallinityIncrease surface areaMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNaphtha

The invention relates to a composite molecular sieve-containing medium oil type hydrocracking catalyst, which comprises an active component and a binder, wherein the active component adopts amorphous SiO2-Al2O3 as a carrier, adopts a composite molecular sieve as an acid component, and adopts a group VIB metal and a group VIII metal as hydrogenation activity components, and the composite molecular sieve comprises a Y molecular sieve and a ZSM-23 molecular sieve. According to the present invention, the deep dealuminzation modified Y molecular sieve has characteristics of high crystallinity, large surface area, high silica-alumina ratio, low cell constant, rich secondary pore, low acid center density, high moderate-intensity acid center ratio, and the like; the modified ZSM-23 molecular sieve has characteristics of smooth pore channel, less acid center and outstanding isomerism performance, wherein a light naphtha component is isomerized so as to increase an octane number of naphtha; the composite molecular sieve compounded from the Y molecular sieve and the ZSM-23 molecular sieve is adopted as the acid cracking component so as to provide advantages of the Y molecular sieve and the ZSM-23 molecular sieve, and compounding is performed according to the ratio of the present invention, such that the best catalysis effect can be obtained, and the obtained catalyst is suitable for the medium oil type hydrocracking catalyst; and the catalyst prepared from the composite molecular sieve has characteristics of excellent medium oil selectivity, good activity and good stability.

Owner:CHINA NAT OFFSHORE OIL CORP +3

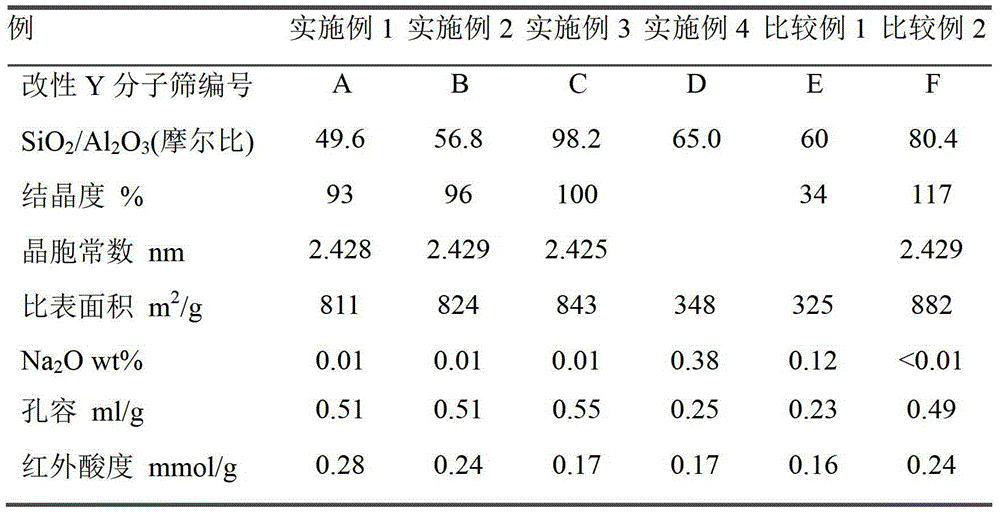

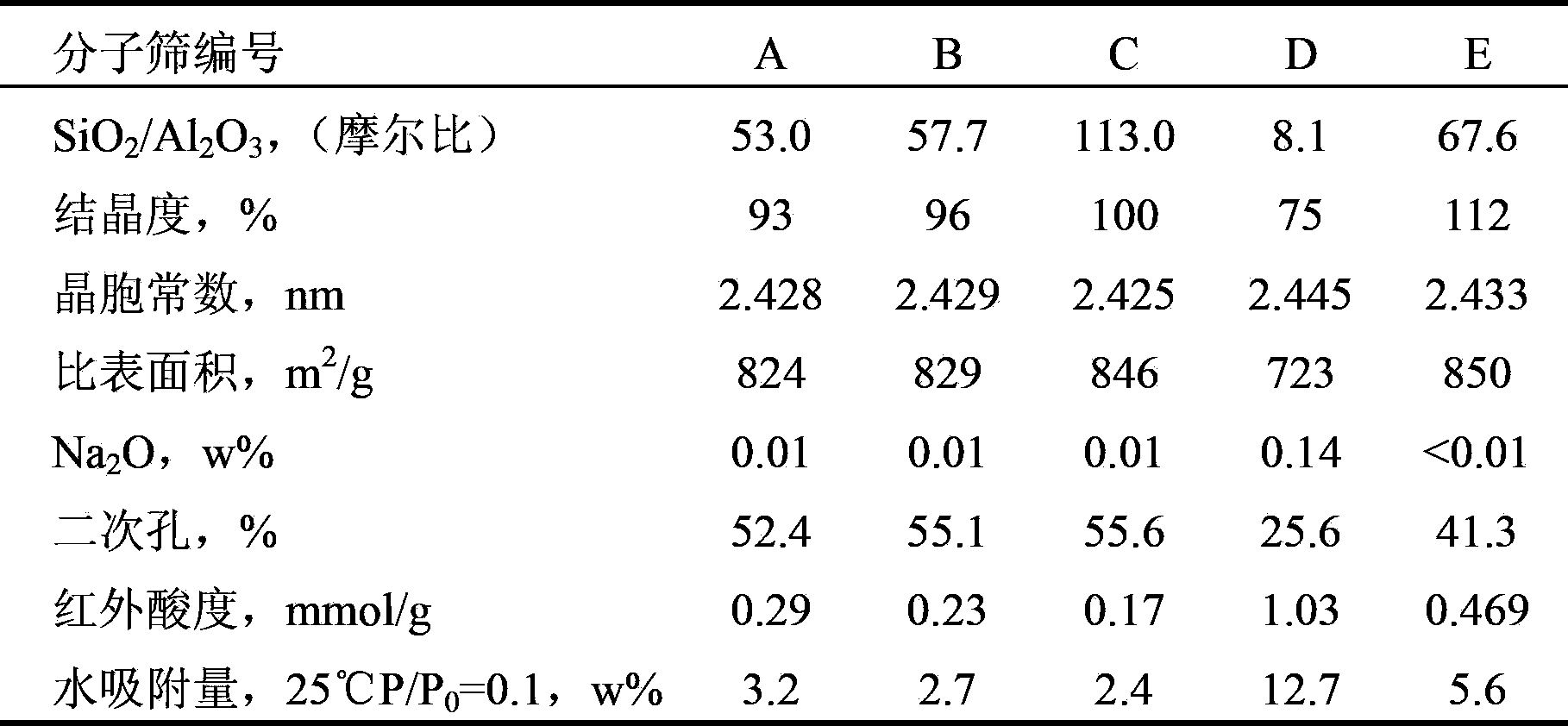

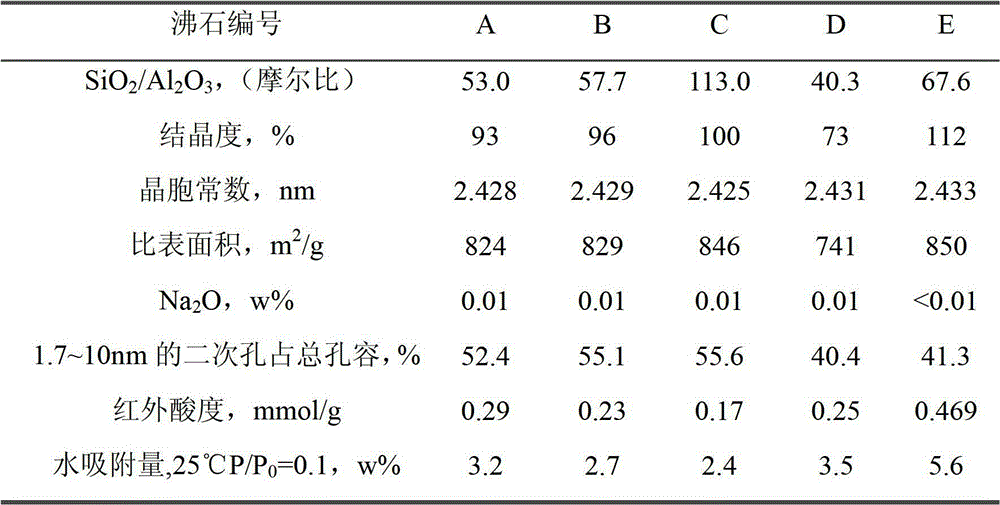

Hydrocracking catalyst carrier and preparation method thereof

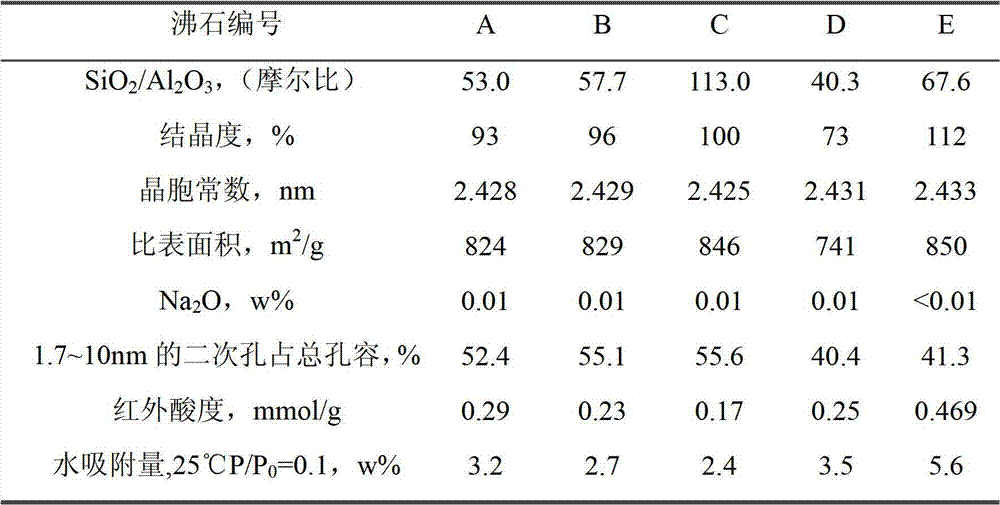

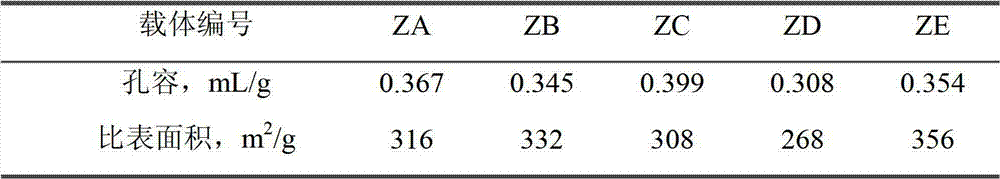

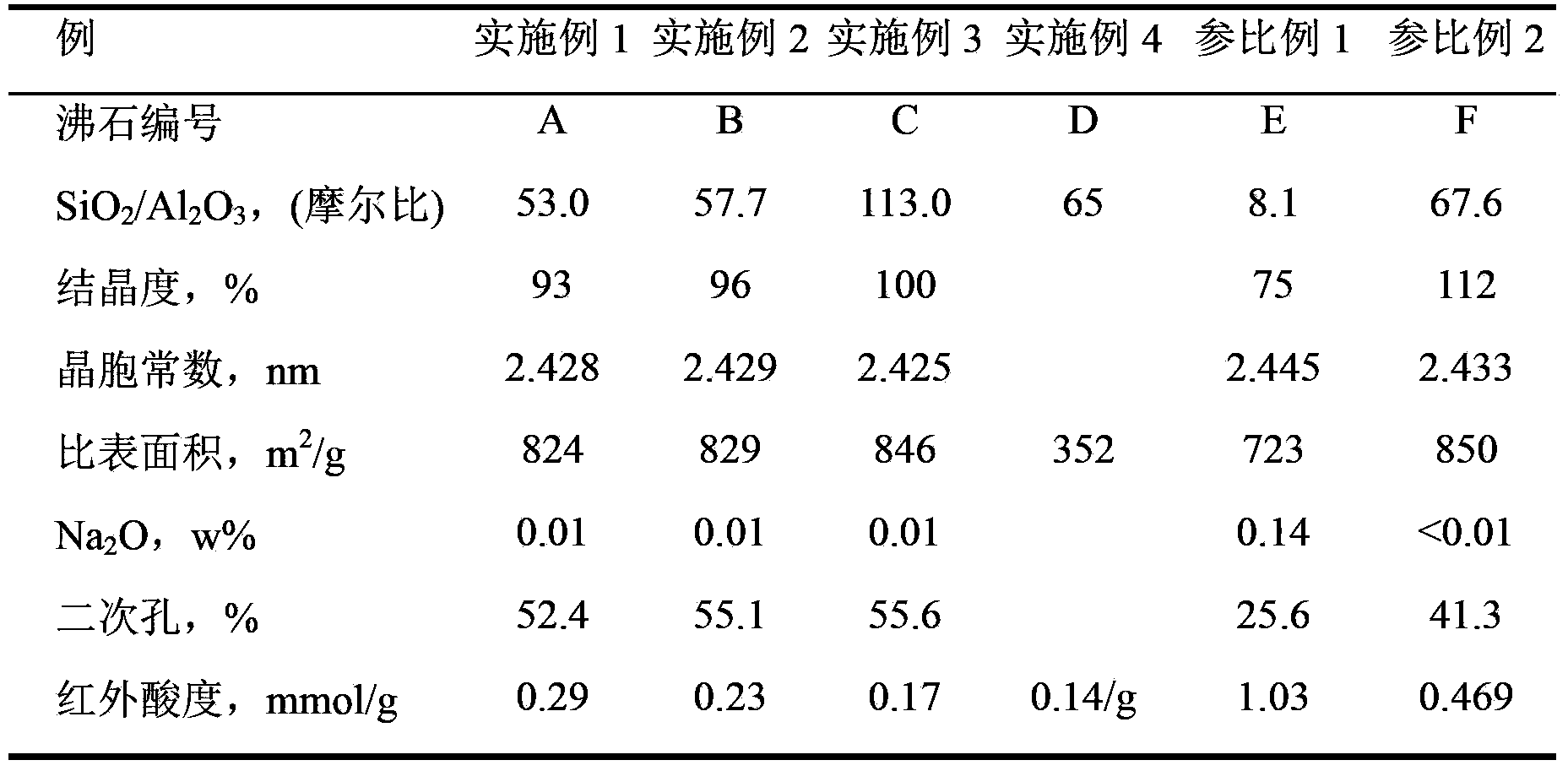

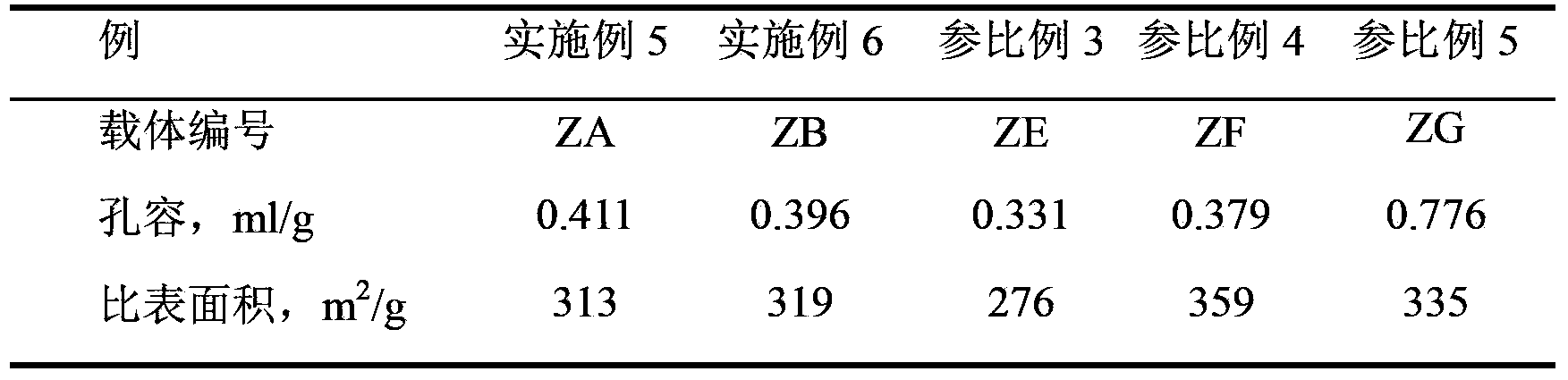

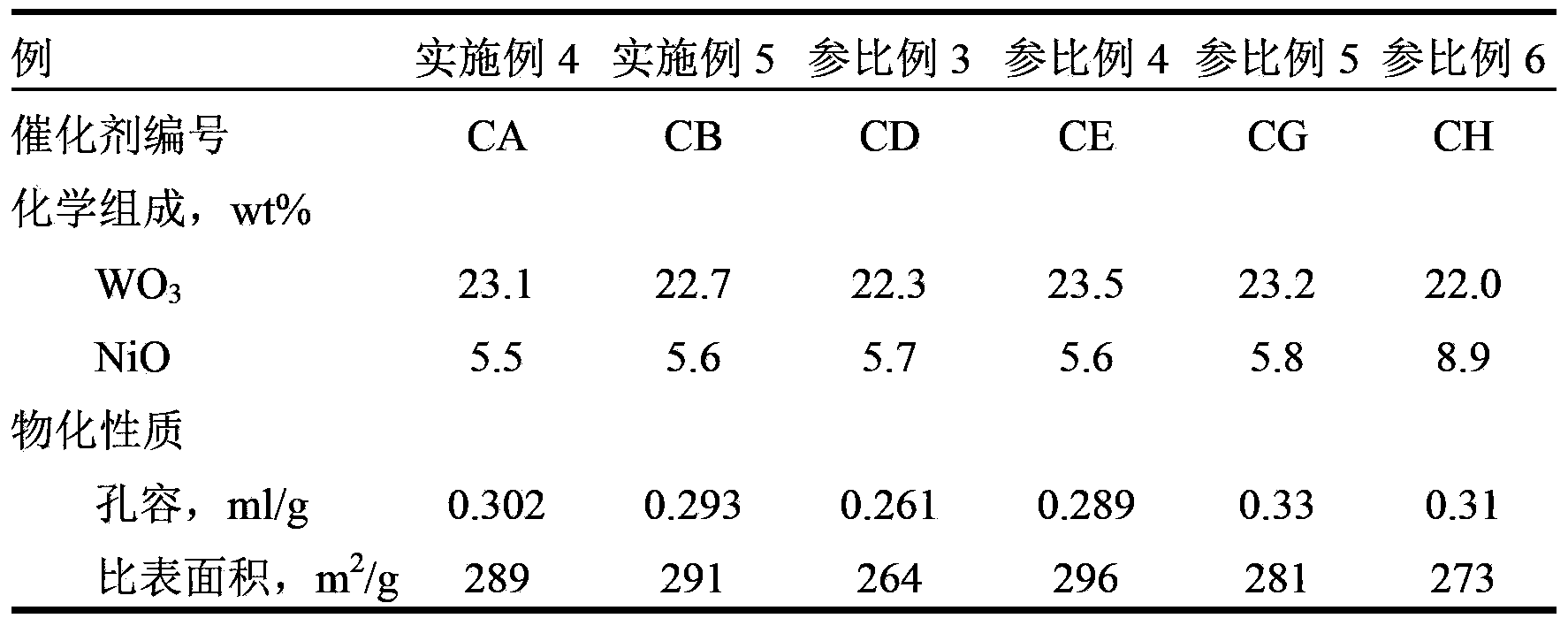

ActiveCN102786064AHigh activityImprove heat resistanceCatalyst carriersMolecular sieve catalystsIon exchangeExtrusion moulding

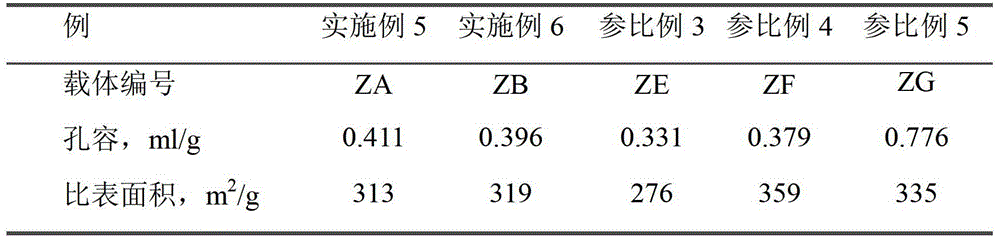

The invention discloses a hydrocracking catalyst carrier and a preparation method of the hydrocracking catalyst carrier. The hydrocracking catalyst carrier is prepared by using modified Y zeolite, aluminum oxide and amorphous silicon-aluminum. The modified Y zeolite has the following physiochemical properties: the mole ratio of SiO2 to Al2O3 is 30-120; the lattice constant is 2.420-2.435nm; the relative crystallinity is more than or equal to 90%; the specific surface area is 750-850m<2> / g; the secondary pore with 1.7-10nm accounts for more than 50% of the total pore volume; the infrared acidity is 0.10-0.50mmol / g; the ion exchange capacity is less than or equal to 0.10%; and the water adsorption quantity is less than 5.0% in percentage by weight at 25 DEG C and P / P0 of 1.0. The preparation method of the catalyst carrier provided by the invention comprises the following steps: mechanically mixing the modified Y zeolite, aluminum oxide, amorphous silicon-aluminum and adhesive, grinding, extrusion-moulding, drying and calcining to obtain the catalyst carrier. The catalyst carrier prepared by using the modified (deeply dealuminated) Y zeolite as the acidic cracking component is suitable to be used as the hydrocracking catalyst for middle distillates oil.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Method for preparing rare-earth ultrastable Y-type zeolite

ActiveCN1307098CImprove exchange efficiencyEfficient removalCatalytic crackingMolecular sieve catalystsActive componentGasoline

Owner:CHINA PETROLEUM & CHEM CORP

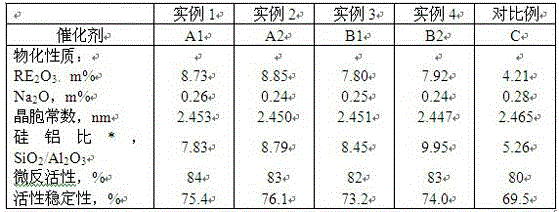

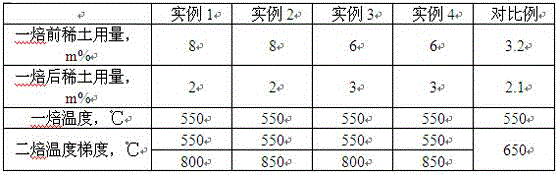

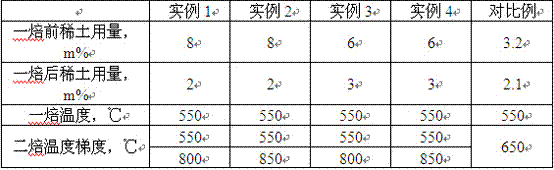

Ultra-stabilization treatment method of high-rare-earth-content in-situ crystallization catalyst

ActiveCN104923282AHigh rare earth contentSmall cell constantMolecular sieve catalystsPtru catalystRare earth ions

The invention discloses an ultra-stabilization treatment method of a high-rare-earth-content in-situ crystallization catalyst. The ultra-stabilization treatment method includes that the ultra-stabilization catalyst high in rare earth content and lower than 2.455nm in lattice constant is prepared by high-temperature hydrothermal calcining of NaY-type catalyst for in-situ crystallization under different temperature gradient conditions after multiple times of exchange of ammonium ions and rare earth ions. The high-rare-earth-content in-situ crystallization catalyst has the advantages of high rare earth content, high silicon-aluminum ratio, high activity, high stability and excellent coke selectivity.

Owner:湖北赛因斯科技开发有限公司

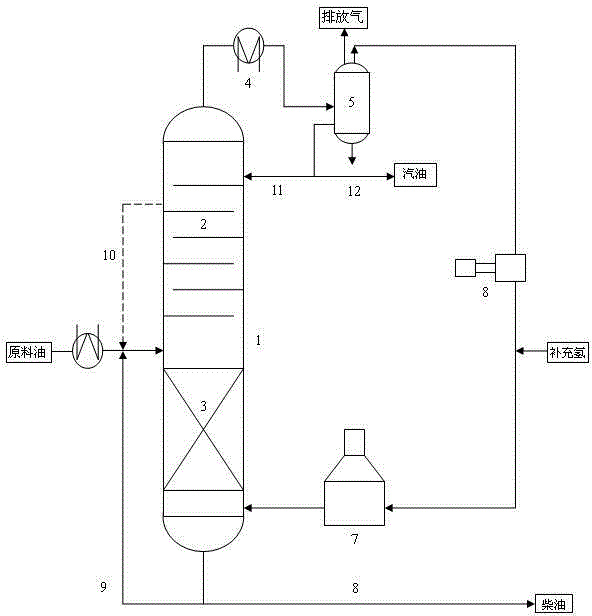

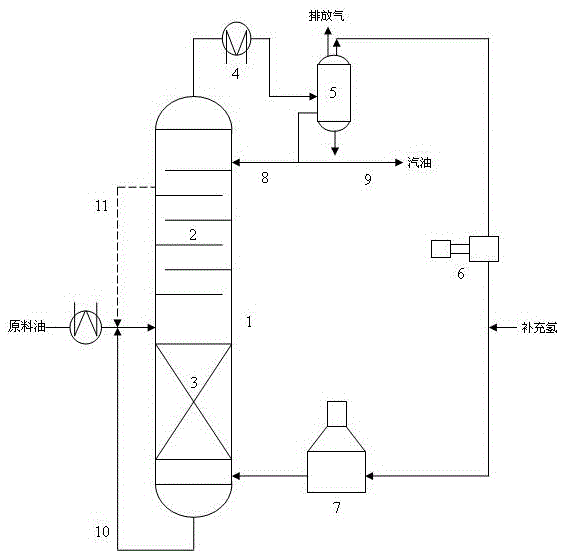

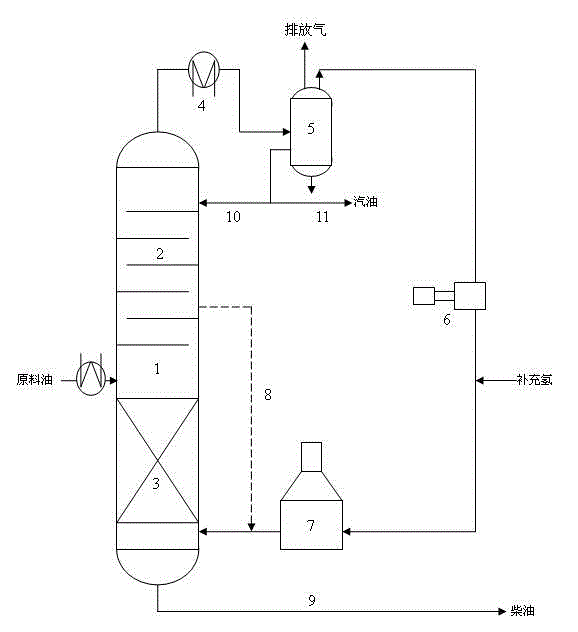

Catalytic diesel fuel reaction distillation method

ActiveCN104611049ABoost octaneIncrease cetane numberTreatment with hydrotreatment processesIsomerizationPoor quality

The present invention discloses a catalytic diesel fuel reaction distillation method. According to the method, equipment mainly comprises a reaction distillation tower and a hydrogen circulation system, the stripping section of the reaction distillation tower adopts a hydrocracking catalyst as a filler, the rectification section is provided with the rectification tower plate, the tower plate can be provided with an isomerization catalyst, one part of the tower bottom oil is circulated to the material inlet of the tower, the remaining part is discharged out from the equipment and is adopted as the product, a hydrogen circulation heating furnace is arranged, the heated hydrogen gas enters the bottom of the tower, and the gasoline distillate is obtained from the top of the tower. With the method, the characteristics of the hydrocracking and the reaction distillation process are completely utilized so as to reduce the secondary reaction of the light distillates and improve the hydrogenation reaction speed of the gasoline distillate. According to the present invention, the poor-quality cracking diesel fuel is adopted as the raw material to produce the high octane number naphtha and the high-quality diesel fuel, such that the obtained products can respectively be adopted as the blending component of the high octane number naphtha and the blending component of the high-quality diesel fuel; and compared with the conventional hydrogenation process, the method of the present invention has characteristics of simple process and energy saving.

Owner:CHINA PETROLEUM & CHEM CORP +1

Y molecular sieve modification method

ActiveCN100572275CSmall cell constantHigh crystal retentionCatalyst carriersMolecular sieve catalystsMolecular sieveCrystallinity

The invention relates to a modification method of Y molecular sieve. The method is characterized in that surfactants are added in the acid dealumination process, that is, industrial NaY molecular sieves are used as raw materials through ammonium exchange, and after deep roasting, acid dealumination is carried out under the protection of surfactants, and a higher SiO2 / Al2O3 ( 9-15) HY molecular sieves while maintaining high crystallinity. Compared with industrial NaY molecular sieves, the secondary pores of the molecular sieve prepared by this method are greatly improved, and the acid structure is also further improved. Support for hydrotreating catalysts for heavy distillate oils.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Silicon-aluminum carrier containing two modified molecular sieves, preparation method and application thereof

ActiveCN104250010ASmall cell constantImprove stabilityMolecular sieve catalystsFaujasite aluminosilicate zeoliteMolecular sieveAmorphous silicon

The invention relates to a silicon-aluminum carrier containing two modified molecular sieves. The silicon-aluminum carrier includes a modified Y molecular sieve, a modified ZSM-23 molecular sieve, and amorphous silicon-aluminum. The modified Y molecular sieve adopted by the carrier is a deep dealuminated Y molecular sieve, which has the characteristics of integral crystal form, high silicon-aluminum ratio, low acid center density, high medium-strong acid proportion and abundant secondary pores, and is suitable to serve as the acidic cracking component of a medium oil type hydrocracking catalyst. The high specific surface and developed secondary pores not only promote exertion of the hydrogenation activity, but are also conducive to spread of the reaction product, the secondary pores are numerous, and the acid center density is low, so that the probability of excessive cracking and secondary cracking can be reduced. Therefore, the catalyst can have excellent medium oil selectivity, high silicon-aluminum ratio, small lattice constant and stable structure, and has very good stability.

Owner:CHINA NAT OFFSHORE OIL CORP +3

A kind of molecular sieve desulfurizer and preparation method thereof

ActiveCN103252211BModerate acid strengthSmall cell constantOther chemical processesHydrocarbon oils refiningWater bathsHazardous substance

The invention relates to a molecular sieve desulfurizer and a preparation method thereof. The method comprises heating a NaY molecular sieve and an ammonium salt solution in a water bath of 80-100 DEG C for ammonium exchanging, treating the ammonium-exchanged molecular sieve with inorganic acid or / and organic acid aqueous solutions, preparing an aqueous solution containing lanthanum and cerium with a concentration of 0.05-0.08 mol / L to exchange and modify the obtained molecular sieve ions until an exchange degree of the exchanged and modified lanthanum or cerium is 71-73 %, molding, drying and roasting the modified molecular sieve, and using an isopyknic immersion method to load transition metal elements so that a mass percent of loaded metals (on basis of oxide) is 10.0-20.0 %. Therefore, adsorptivity, selectivity and stability of the desulfurizer is well distributed, the experiment is simple to operate, raw materials are cheap and easy to purchase, a preparation process is simple, and no poisonous and harmful substances are generated.

Owner:PETROCHINA CO LTD

A kind of high-octane gasoline production method

ActiveCN104611062BBoost octaneQuick responseTreatment with hydrotreatment processesIsomerizationHydrogenation process

The present invention discloses a high octane number gasoline production method, which is used for processing catalytic diesel fuel so as to produce the high octane number gasoline distillate, wherein the process mainly adopts a reaction distillation tower and a hydrogen circulation system, the stripping section of the reaction distillation tower adopts a hydrocracking catalyst as a filler, the rectification section is provided with the rectification tower plate, the tower plate is provided with an isomerization catalyst, the tower bottom oil is circulated to the material inlet of the tower, a hydrogen circulation heating furnace is arranged, the heated hydrogen gas enters the bottom portion of the tower, the gasoline distillate is obtained from the top of the tower, and a small amount (less than 2%) of the diesel fuel distillate is periodically discharged from the bottom of the tower. According to the method of the present invention, the characteristics of the hydrocracking and the reaction distillation process are completely utilized, such that the secondary cracking reaction of the light distillate is reduced, the liquid yield is increased, and the gasoline distillate yield is more than 90%. With the method of the present invention, the catalytic diesel fuel is completely catalyzed, the octane number of the produced is high, and compared with the conventional hydrogenation process, the method of the present invention has characteristics of simple process and energy saving.

Owner:CHINA PETROLEUM & CHEM CORP +1

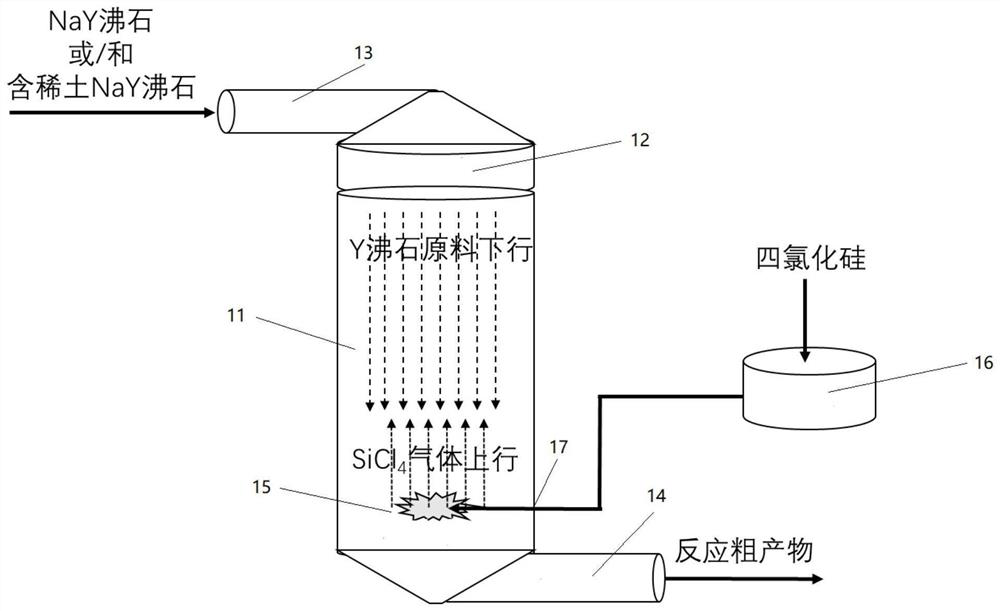

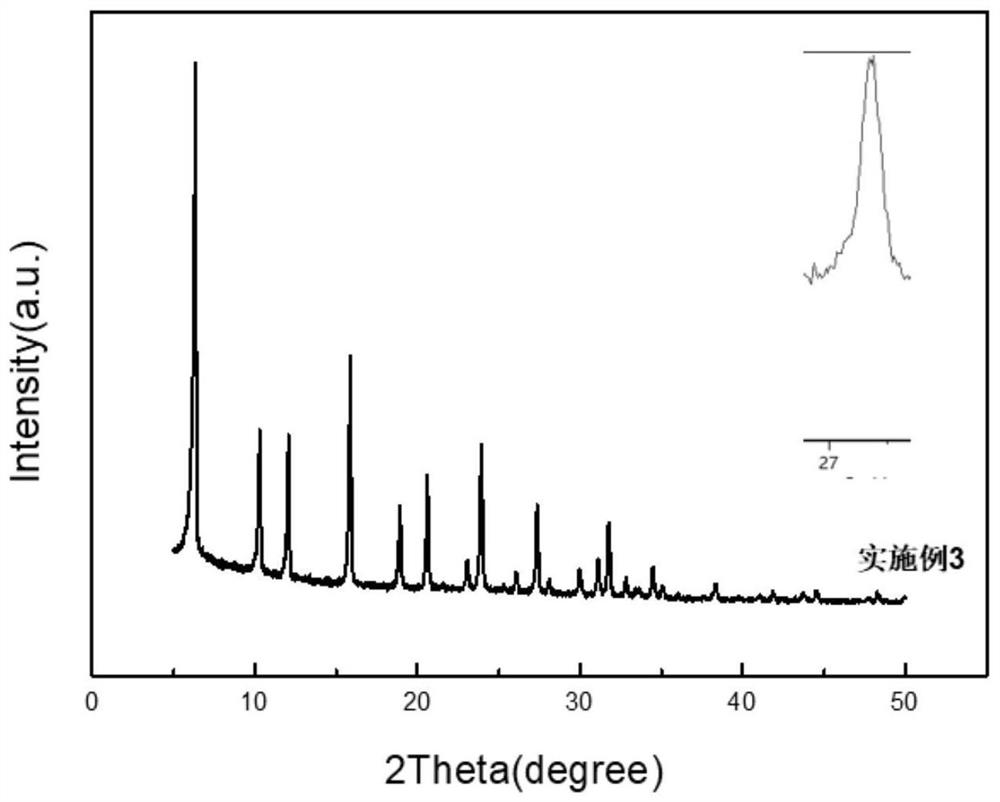

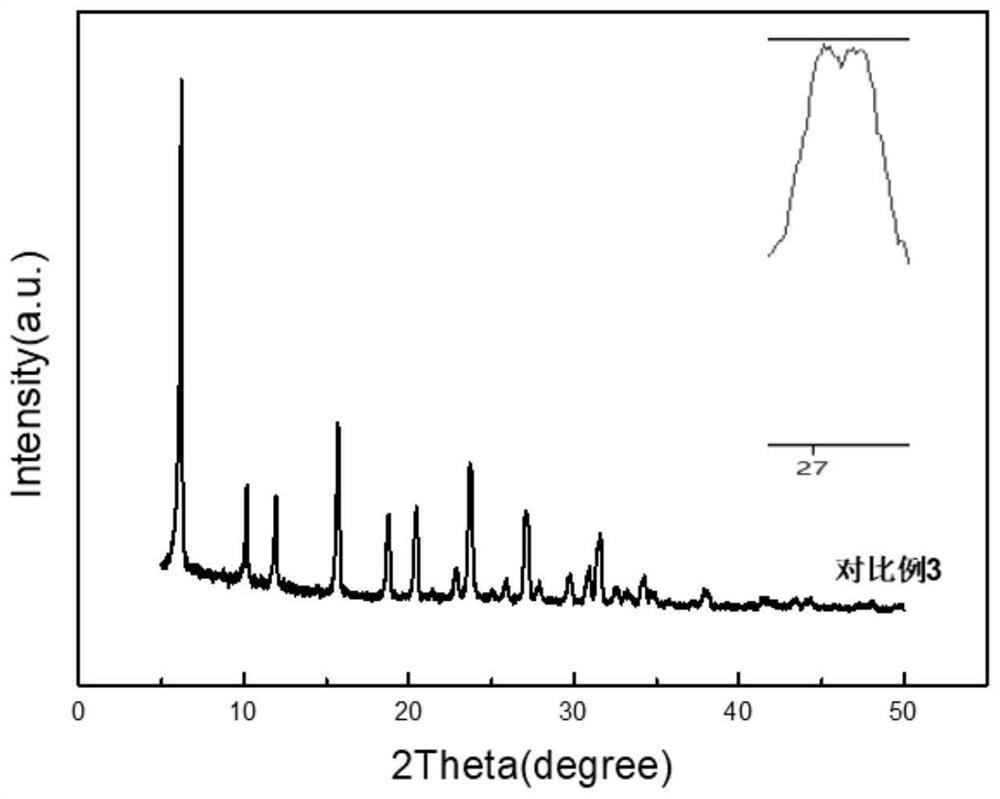

Modification method of faujasite molecular sieve, obtained modified faujasite molecular sieve and application

PendingCN114100672ALower requirementSignificant improvementCatalytic crackingMolecular sieve catalystsMolecular sievePtru catalyst

The invention provides a modification method of a faujasite molecular sieve, the obtained modified faujasite molecular sieve and application, the method comprises the following steps: the faujasite molecular sieve and gaseous silicon tetrachloride are subjected to a contact reaction, the contact reaction time is not more than 5 seconds, and the modified faujasite molecular sieve is obtained. The space of the contact reaction is more than two times of the bulk volume of the faujasite molecular sieve in the reaction area, and the temperature of the contact reaction is 250-600 DEG C. The relative crystallization retention degree of the obtained modified zeolite molecular sieve is not less than 85%, the unit cell constant is lower than 24.55 angstroms, and a catalytic cracking catalyst prepared from the modified faujasite molecular sieve has high gasoline yield and total light oil yield when used for catalytic cracking of heavy oil.

Owner:PETROCHINA CO LTD +1

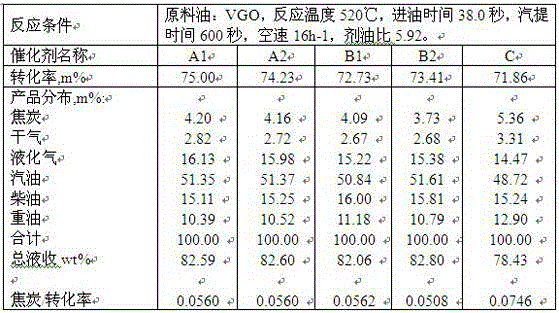

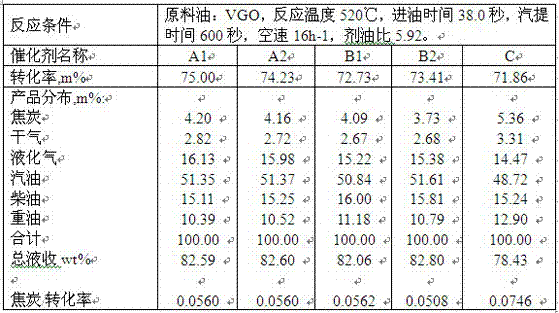

Catalytic cracking catalyst and preparation and application thereof

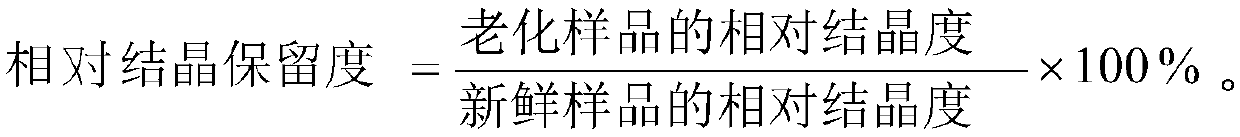

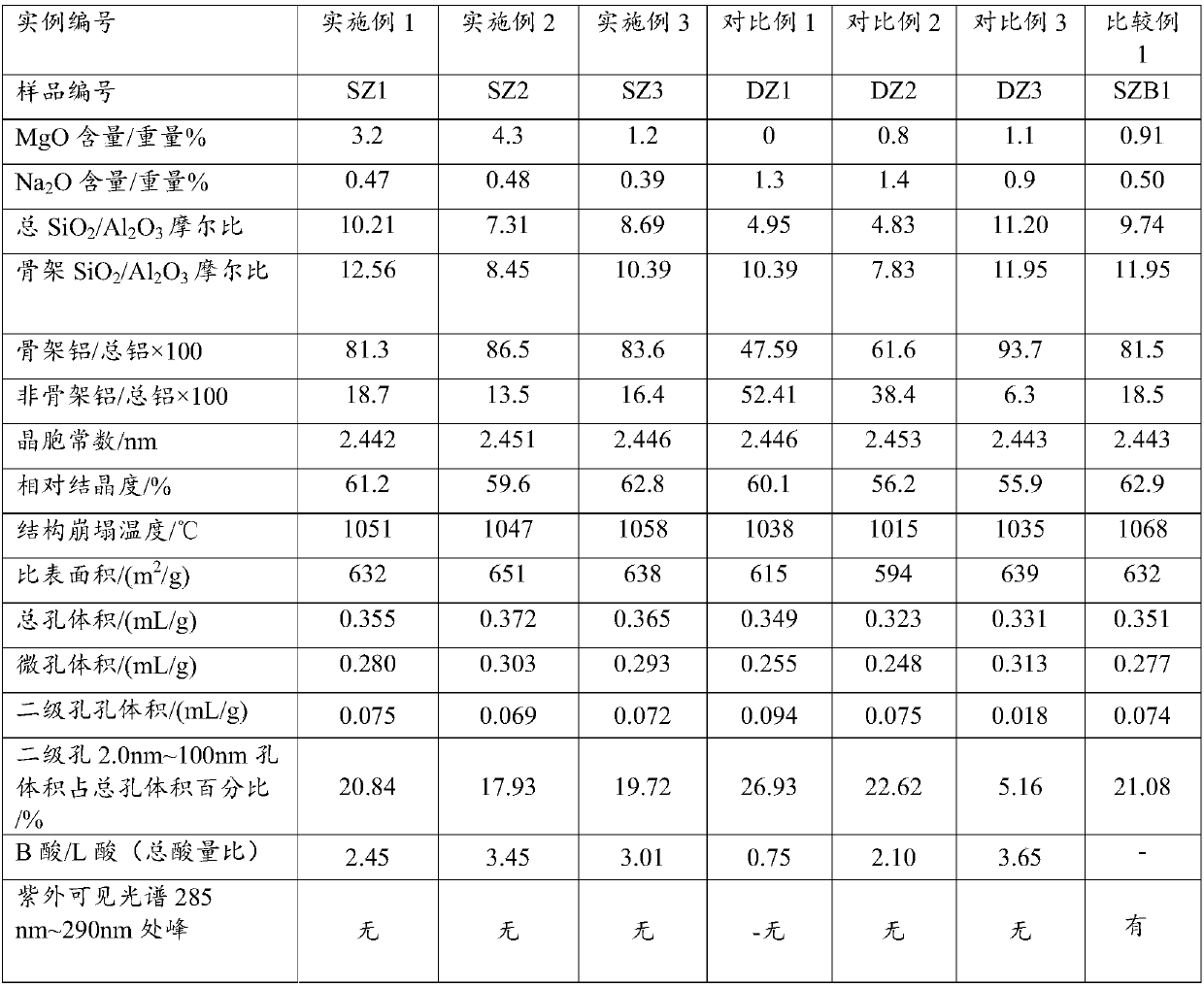

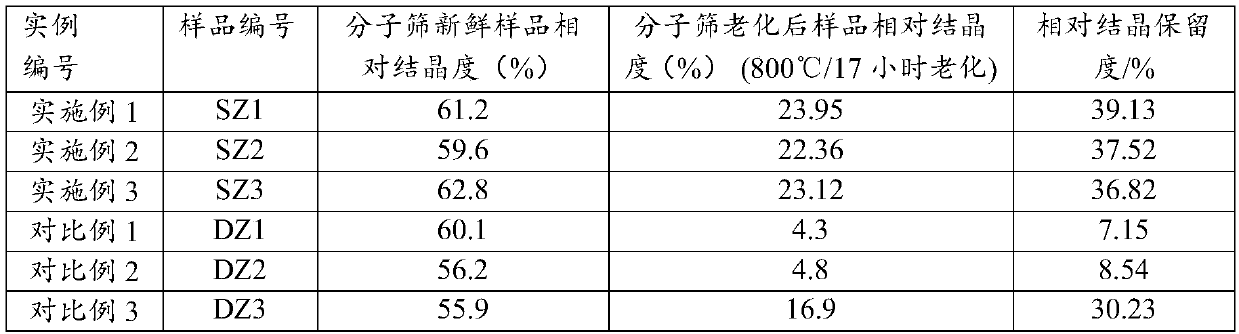

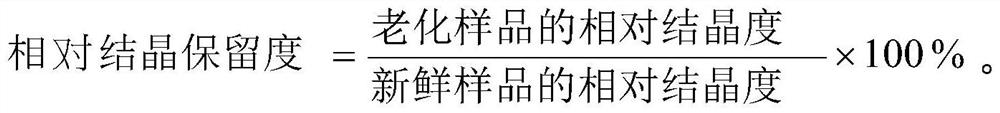

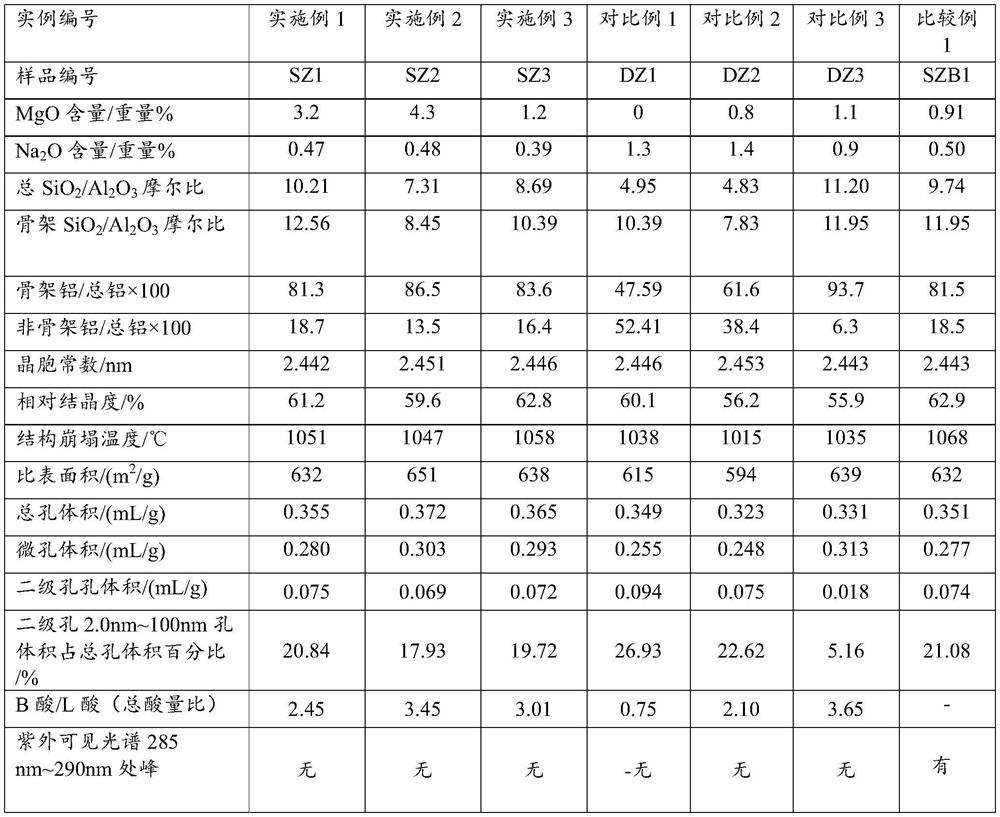

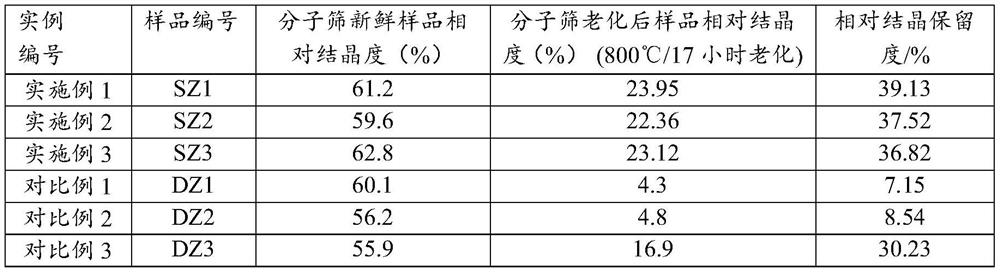

ActiveCN110653000AReduce sodium oxide contentLow non-framework aluminum contentCatalytic crackingMolecular sieve catalystsMolecular sievePtru catalyst

The invention discloses a catalytic cracking catalyst as well as preparation and application thereof. The catalyst contains a modified Y-type molecular sieve, an aluminum oxide binder and clay; according to the modified Y-type molecular sieve, the content of magnesium oxide in the modified Y-type molecular sieve is 0.5-4.5 wt%; the content of sodium oxide is 0.1 wt%-0.5 wt%; the total pore volumeis 0.33 mL / g to 0.39 mL / g; the pore volume of secondary pores with the pore diameter of 2nm-100nm of the modified Y-type molecular sieve accounts for 10%-25% of the total pore volume, the lattice constant is 2.440 to 2.455nm, the content of non-skeleton aluminum in the modified Y-type molecular sieve is not higher than 20% of the total aluminum content, the lattice collapse temperature is not lower than 1040 DEG C, and the ratio of the amount of acid B to the amount of acid L in the total acid amount of the modified Y-type molecular sieve, which is measured by pyridine adsorption infrared method at 200 DEG C, is not lower than 2.30; when the molecular sieve is used for ultraviolet and visible light analysis, the ultraviolet and visible absorption spectrum is not absorbed at the wavelengthof 285-295 nm. The catalytic cracking catalyst is used for catalytic cracking of heavy oil, and has the advantages of low coke selectivity, high gasoline yield, high liquefied gas yield and high isohydrocarbon content in gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method of manufacturing an electrode with a small cell constant

ActiveCN104280583BHigh responseImprove parallelismManufacture of electrical instrumentsFluid resistance measurementsCapacitancePolytetrafluoroethylene

Owner:PETROCHINA CO LTD +1

A silica-alumina carrier containing two modified molecular sieves and its preparation method and application

ActiveCN104250010BSmall cell constantImprove stabilityMolecular sieve catalystsFaujasite aluminosilicate zeoliteMolecular sieveHydrogen

A silica-alumina carrier containing two kinds of modified molecular sieves, including modified Y molecular sieve, modified ZSM-23 molecular sieve and amorphous silica-alumina, the modified Y molecular sieve used in the inventive carrier is deeply dealuminated Y molecular sieve with complete crystal form, High silicon-aluminum ratio, low acid center density, high proportion of medium-strong acid, abundant secondary pores, suitable for use as acidic cracking component of medium oil hydrocracking catalyst, high specific surface area and developed secondary pores of molecular sieves not only facilitate the process of hydrocracking The hydrogen activity is exerted, and it is beneficial to the diffusion of reaction products. The secondary pores are many, and the acid center density is low, which reduces the probability of excessive cracking and secondary cracking, so that the catalyst has excellent medium oil selectivity and high silicon-aluminum ratio. , the unit cell constant is small and the structure is stable, so the catalyst has good stability.

Owner:CHINA NAT OFFSHORE OIL CORP +3

Method for manufacturing electrodes with small electrode constants

ActiveCN104280583AHigh responseImprove parallelismFluid resistance measurementsManufacture of electrical instrumentsCapacitanceEngineering

The invention belongs to the technical field of supporting facilities of electrical measurement devices, and provides a method for manufacturing electrodes with small electrode constants. Teflon is adopted by an electrode fixing material capacitance pool pole plate support and a sample pool in a capacitance pool body; a teflon base of the capacitance pool pole plate support enables the length of an inner electrode pole plate to be smaller than that of an outer electrode pole plate, and therefore the base and the cylindrical outer electrode pole plate also form a part of electrodes, in the measuring process, the inner electrode pole plate can be completely soaked in solution, and when the solution is affected by temperature changing to expand or contract in the measuring process, the corresponding area between the inner electrode pole plate and the outer electrode pole plate is not changed; three small round holes with the diameters being about 1 mm are formed in the upper edge of the cylindrical outer electrode pole plate, so that gas between the two pole plates conveniently flows out when the electrodes are soaked in the solution, and experiment errors caused by gas are reduced. The electrodes manufactured through the method are small in electrode constant, convenient to operate and use, small in error and suitable for measuring the conductivity, capacitance and dielectric constants of a heavy oil system.

Owner:PETROCHINA CO LTD +1

Parallel hydrocracking method

ActiveCN100497545CLow BMCIIncrease the molar ratio of silicon to aluminumTreatment with hydrotreatment processesCatalytic reformingHexadecane

This invention discloses a hydrocracking method, and this invention is used for producing high aromatic hydrocarbon heavy naphtha and high quality end oil.It includes that heavy distillate oil and poor quality catalytic cracking diesel hydrocracks separately, and the mixture of the cracking products is conducted gas liquid separation. Light naphtha, heavy naphtha, aviation kerosene, diesel oil and end oil will be obtained by distillating the liquid phase. The density of the poor quality catalytic cracking diesel oil is above 0.9g / ml, and the aromatic hydrocarbon is over 60wt% and the value of hexadecane is under 30. It is a adequate utilization of catalytic cracking craft to produce high aromatic hydrocarbon heavy naphtha and high quality end oil with heavy distillate oil and poor quality catalytic cracking diesel, which can be separately used as catalytic reforming material and making ethylene material by steam cracking method. High aromatic hydrocarbon heavy naphtha in this invention will produce a large amount of reforming hydrogen after catalytic reforming treatment, which can be used in the process of hydrocracking to make this preparation more ecnomical and reasonable.

Owner:CHINA PETROLEUM & CHEM CORP +2

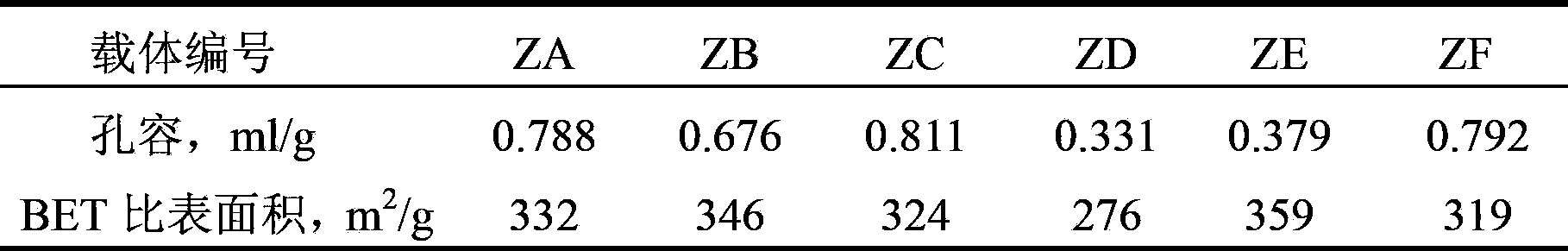

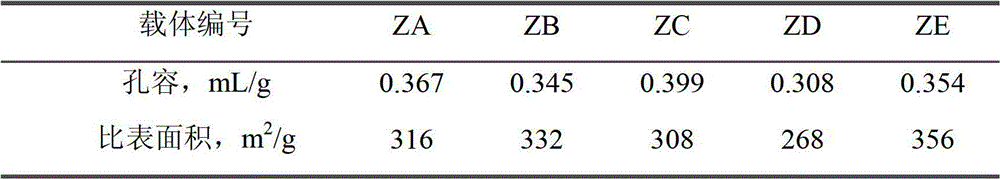

A kind of silica-alumina carrier containing molecular sieve and preparation method thereof

ActiveCN103011192BPrevent sinteringHigh catalytic efficiencyMolecular sieve catalystsFaujasite aluminosilicate zeoliteMolecular sievePhysical chemistry

The invention discloses a silicon-aluminium carrier comprising a molecular sieve and a preparation method thereof. The silicon-aluminium carrier is prepared from 5 weight percent to 50 weight percent of a modified Y molecular sieve and 50 weight percent to 95 weight percent of amorphous silicon-aluminium; and the silicon-aluminium carrier has a BET specific surface area of 260 to 400m<2> / g and a pore volume of 0.50 to 0.95ml / g. The preparation method of the silicon-aluminium carrier comprises the following steps of: (1) mixing a silicon source and an aluminium source which are used for preparing the amorphous silicon-aluminium, and then adding a precipitating agent under the stirring condition to obtain a gelatinous mixture; (2) adding the modified Y molecular sieve into the gelatinous mixture to carry out aging; (3) filtering aged slurry to obtain a filter cake and carrying out drying, lamination and extrusion forming on the filter cake; and (4) sequentially carrying out washing, steam processing, drying and roasting on the product obtained after extrusion forming so as to obtain the silicon-aluminium carrier.

Owner:CHINA NAT OFFSHORE OIL CORP +2

A super-stabilization treatment method for in-situ crystallization catalyst with high rare earth content

ActiveCN104923282BHigh rare earth contentSmall cell constantMolecular sieve catalystsIn situ crystallizationRare earth ions

The invention discloses an ultra-stabilization treatment method for an in-situ crystallization catalyst with high rare earth content. The method is to exchange the in-situ crystallized NaY type catalyst with ammonium ions and rare earth ions for many times, and then exchange the in-situ crystallization catalyst under different temperature gradient conditions. Under high-temperature hydrothermal roasting, an ultra-stable catalyst product with high rare earth content and a unit cell constant lower than 2.455nm is prepared. The catalyst obtained by the present invention has high rare earth content, high silicon-aluminum ratio, good activity, stability and Excellent coke selectivity and other characteristics.

Owner:湖北赛因斯科技开发有限公司

Hydrocracking catalyst carrier and preparation method thereof

ActiveCN102786064BHigh activityImprove heat resistanceCatalyst carriersMolecular sieve catalystsPtru catalystIon exchange

The invention discloses a hydrocracking catalyst carrier and a preparation method of the hydrocracking catalyst carrier. The hydrocracking catalyst carrier is prepared by using modified Y zeolite, aluminum oxide and amorphous silicon-aluminum. The modified Y zeolite has the following physiochemical properties: the mole ratio of SiO2 to Al2O3 is 30-120; the lattice constant is 2.420-2.435nm; the relative crystallinity is more than or equal to 90%; the specific surface area is 750-850m<2> / g; the secondary pore with 1.7-10nm accounts for more than 50% of the total pore volume; the infrared acidity is 0.10-0.50mmol / g; the ion exchange capacity is less than or equal to 0.10%; and the water adsorption quantity is less than 5.0% in percentage by weight at 25 DEG C and P / P0 of 1.0. The preparation method of the catalyst carrier provided by the invention comprises the following steps: mechanically mixing the modified Y zeolite, aluminum oxide, amorphous silicon-aluminum and adhesive, grinding, extrusion-moulding, drying and calcining to obtain the catalyst carrier. The catalyst carrier prepared by using the modified (deeply dealuminated) Y zeolite as the acidic cracking component is suitable to be used as the hydrocracking catalyst for middle distillates oil.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Y zeolite preparation

InactiveCN1406869AImprove catalytic performanceHigh activityFaujasite aluminosilicate zeoliteHydrogen fluorideAmmonia

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of catalytic cracking catalyst and its preparation and application

ActiveCN110653000BReduce sodium oxide contentLow non-framework aluminum contentCatalytic crackingMolecular sieve catalystsMolecular sievePtru catalyst

A catalytic cracking catalyst and its preparation and application. The catalyst contains modified Y-type molecular sieve, alumina binder and clay; the magnesium oxide content of the modified Y-type molecular sieve is 0.5% by weight to 4.5% by weight. The sodium content is 0.1% to 0.5% by weight, the total pore volume is 0.33mL / g to 0.39mL / g, and the pore volume of the secondary pores with a pore diameter of 2nm to 100nm of the modified Y-type molecular sieve accounts for the percentage of the total pore volume. is 10% to 25%, the unit cell constant is 2.440nm to 2.455nm, the non-framework aluminum content in the modified Y-type molecular sieve accounts for no more than 20% of the total aluminum content, and the lattice collapse temperature is no less than 1040°C. Moreover, the ratio of the B acid amount to the L acid amount in the total acid amount of the modified Y-type molecular sieve measured at 200°C using the pyridine adsorption infrared method is not less than 2.30; when the molecular sieve is subjected to ultraviolet-visible light analysis, the ultraviolet-visible absorption spectrum There is no absorption at 285nm~295nm. The catalytic cracking catalyst is used for catalytic cracking of heavy oil, has lower coke selectivity, higher gasoline yield, liquefied gas yield, and higher isomeric hydrocarbon content in the gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

Y zeolite preparation

InactiveCN1168658CImprove thermal stabilityThe unit cell constant does not decrease significantlyFaujasite aluminosilicate zeoliteHydrogen fluorideAmmonia

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of catalytic diesel reaction distillation method

ActiveCN103805256BHigh octane gasoline fractionBoost octaneTreatment with hydrotreatment processesNaphthaHydrogenation reaction

The invention discloses a reaction distillation method of catalytic diesel oil. The method is used for processing catalytic diesel oil to produce naphtha with a high octane number and high-quality diesel oil; the equipment comprises a reaction distillation column and a hydrogen circulation system; a stripping section of the reaction distillation column is a packed column and packed with a hydrocracking catalyst, and a rectifying section is equipped with a rectifying column plate. The naphtha fraction is obtained at the column top, and the diesel oil fraction is obtained at the column bottom. The method of the invention makes full use of the characteristics of hydrocracking and reaction distillation technology, reduces the secondary reaction of light fractions, and improves the hydrogenation reaction depth of the inferior diesel oil fraction. The method of the invention adopts inferior catalytically-cracked diesel oil as a raw material to produce naphtha with a high octane number and high-quality diesel oil which can be used respectively as a blending component of gasoline with a high octane number and a blending component of high-quality diesel oil; when compared with traditional hydrogenation technology, the method of the invention omits the product fractionating tower, is simpler and more energy-saving in process flow.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com