Ultra-stabilization treatment method of high-rare-earth-content in-situ crystallization catalyst

A technology with high rare earth content and in-situ crystallization, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

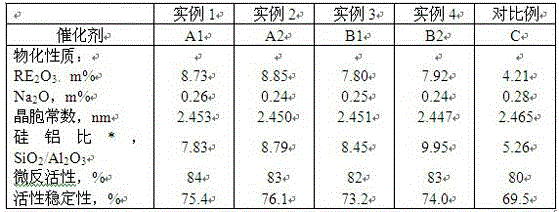

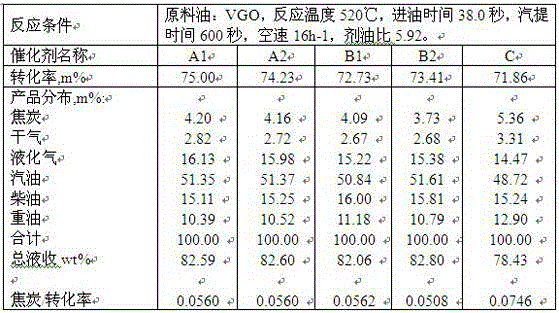

Examples

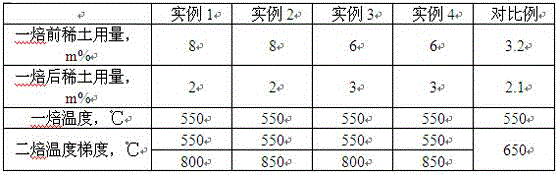

example 1

[0034] (1) Ammonium exchange

[0035]Add 1200g of deionized water to the stainless steel kettle, add 300g of in-situ crystallization NaY catalyst and 90g of ammonium chloride under stirring conditions, adjust the pH value to 3.0-4.0 with 4% dilute hydrochloric acid solution, and exchange at 80°C for 40 minutes , filtered, and the filter cake was rinsed with deionized water, and exchanged again in the same way to obtain Na 2 NH with O content below 4.0m% 4 Y-type catalyst.

[0036] (2) Rare earth exchange

[0037] Add 1200g of deionized water to the above product, add RECl 3 Rare earth (RE 2 o 3 8% of the weight of the catalyst) solution, at a pH of 3.0-4.0, exchanged for 40 minutes at 80°C to obtain REY and NH 4 Type Y catalyst mixture.

[0038] (3) Once roasted

[0039] The above mixture was hydrothermally calcined at 550° C. for 4 hours.

[0040] (4) Rare earth supplementation for materials after first roasting

[0041] Add 1200g of deionized water and 60g of ammon...

example 2

[0047] According to the method of Example 1, the in-situ crystallized NaY type product is subjected to ultra-stabilization modification treatment: wherein the step (5) roasting temperature gradient is: the filter cake is roasted at 550°C for 2 hours, and then heated to 850°C and then roasted for 2 hours. Other conditions are the same as example 1 to obtain catalyst A2.

example 3

[0049] (1) Ammonium exchange

[0050] Add 1200g of deionized water to the stainless steel kettle, add 300g of in-situ crystallization NaY catalyst and 90g of ammonium chloride under stirring conditions, adjust the pH value to 3.0-4.0 with 4% dilute hydrochloric acid solution, and exchange at 80°C for 40 minutes , filtered, and the filter cake was rinsed with deionized water, and exchanged again in the same way to obtain Na 2 NH with O content below 4.0m% 4 Y-type catalyst.

[0051] (2) Rare earth exchange

[0052] Add 1200g of deionized water to the above product, add RECl 3 Rare earth (RE 2 o 3 6% by weight of the catalyst) solution, exchanged for 40 minutes at pH 3.0-4.0, 80°C, to obtain REY type and NH 4 Type Y catalyst mixture.

[0053] (3) Once roasted

[0054] The above mixture was fired at 550°C for 4 hours.

[0055] (4) Rare earth supplementation for materials after first roasting

[0056] Add 1200g of deionized water and 60g of ammonium chloride to the above...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cell constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com