Patents

Literature

32results about How to "Moderate acid strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

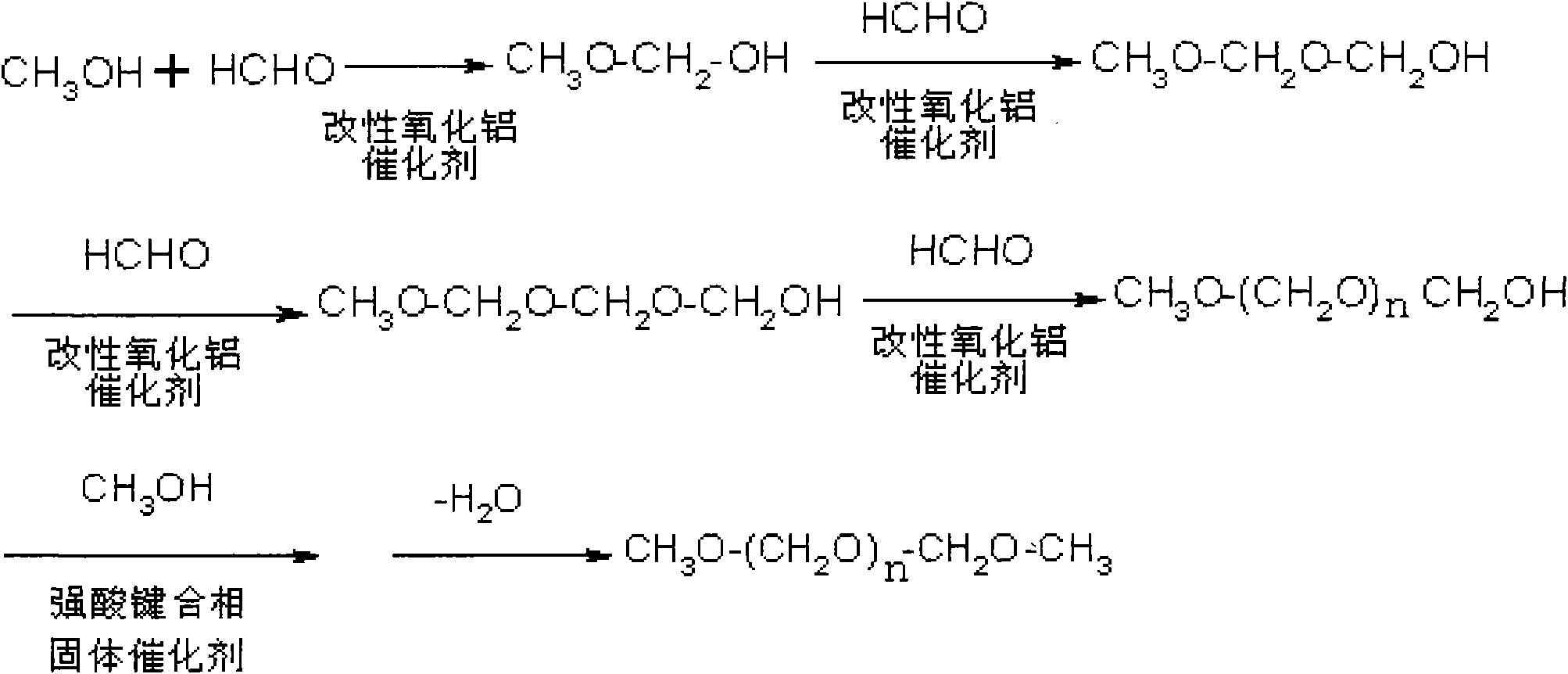

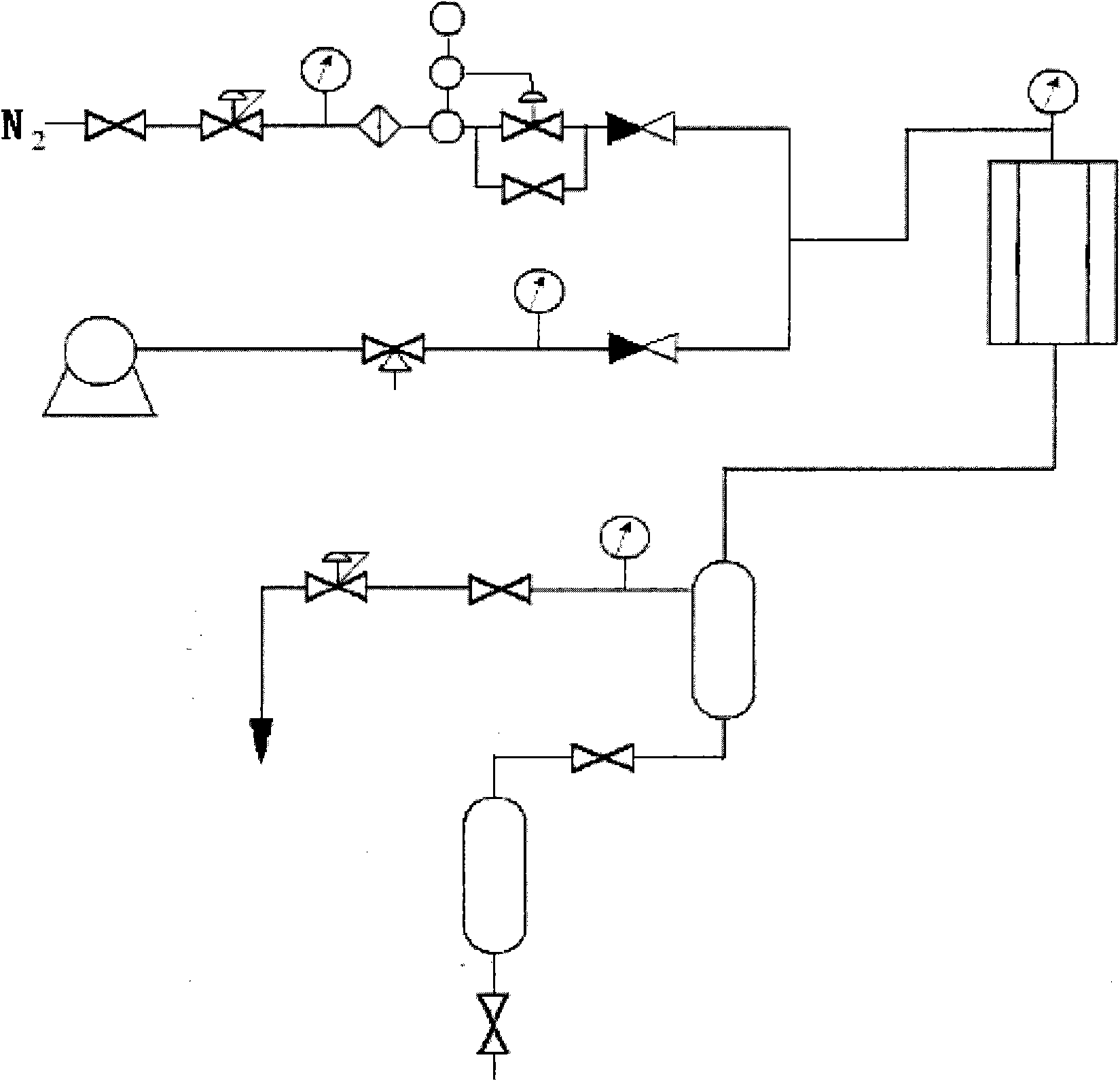

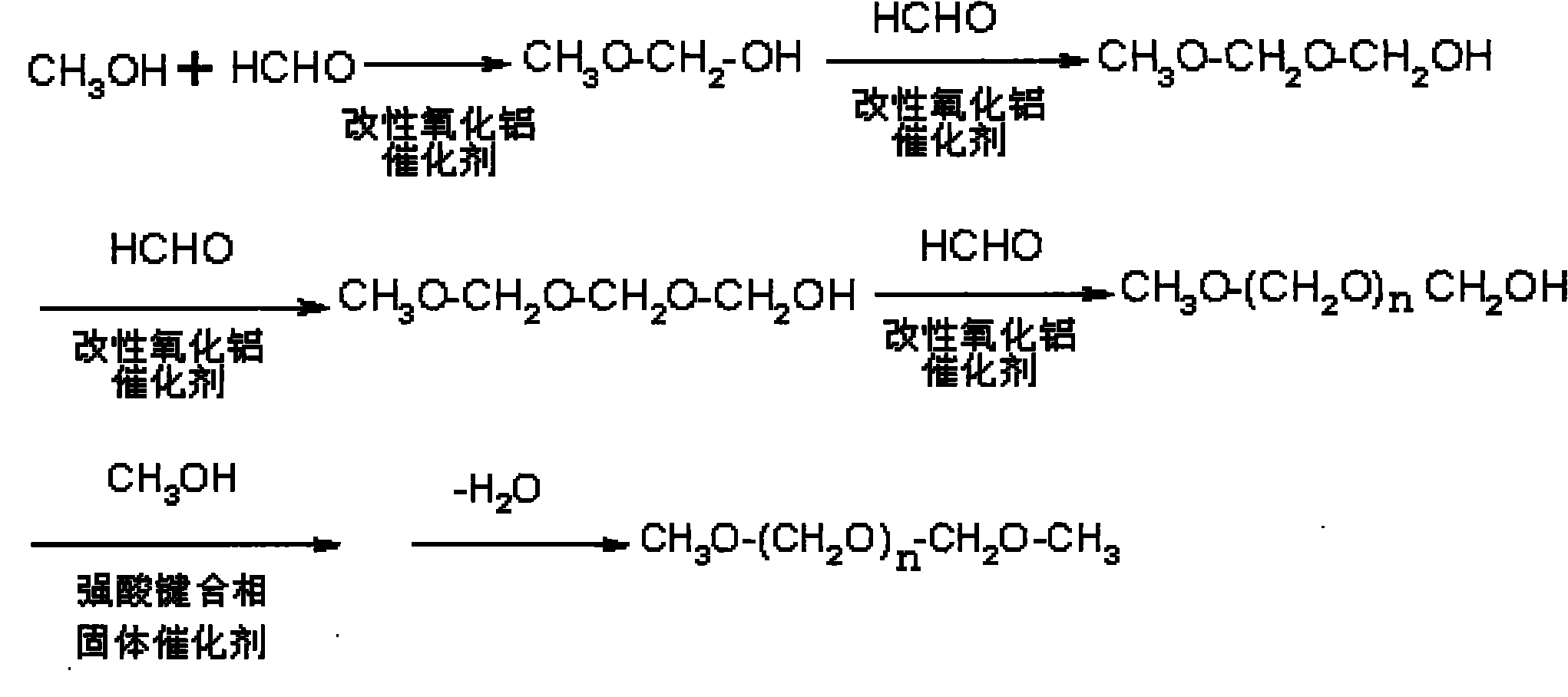

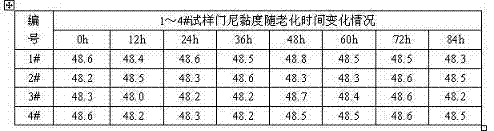

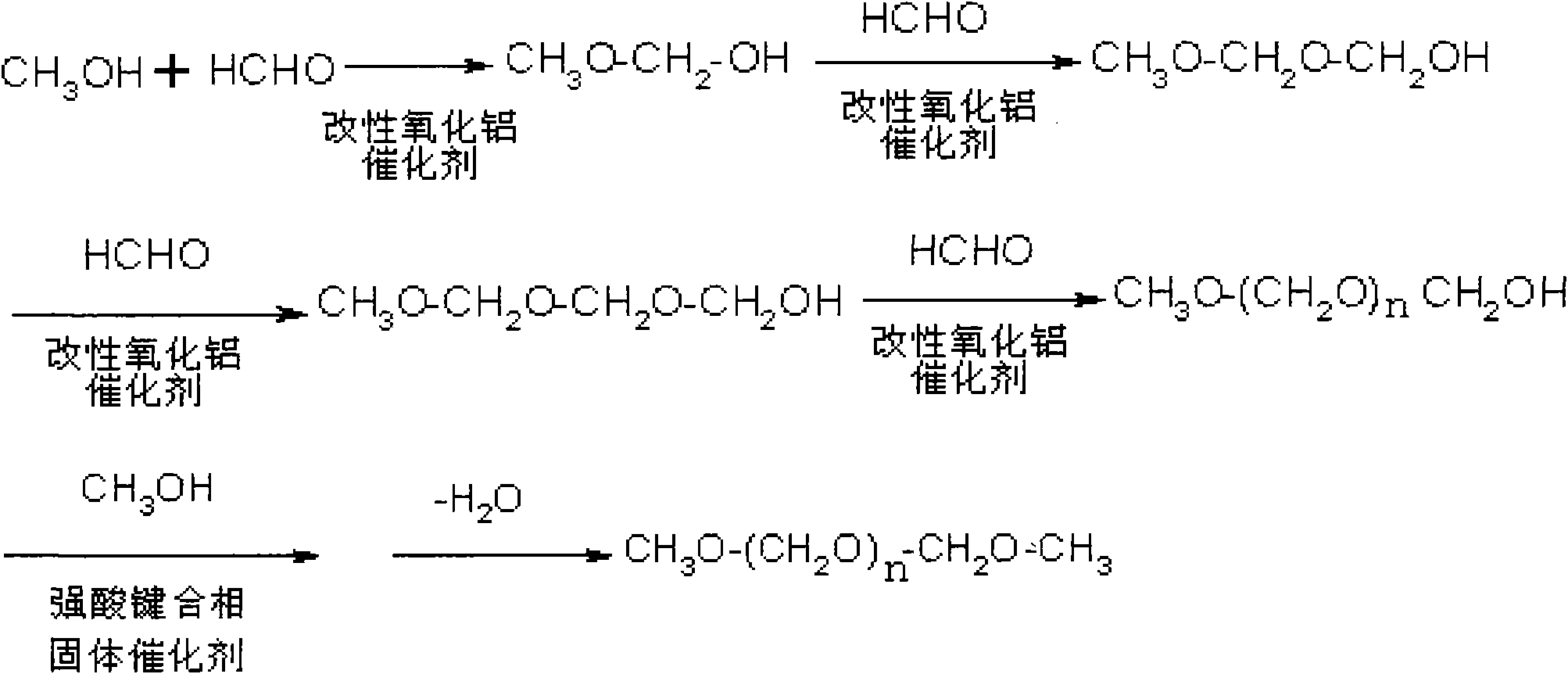

Method for synthesizing polyoxymethylene dimethyl ethers

ActiveCN101898943AImprove conversion rateHigh selectivityOrganic chemistryOrganic compound preparationSynthesis methodsStrong acids

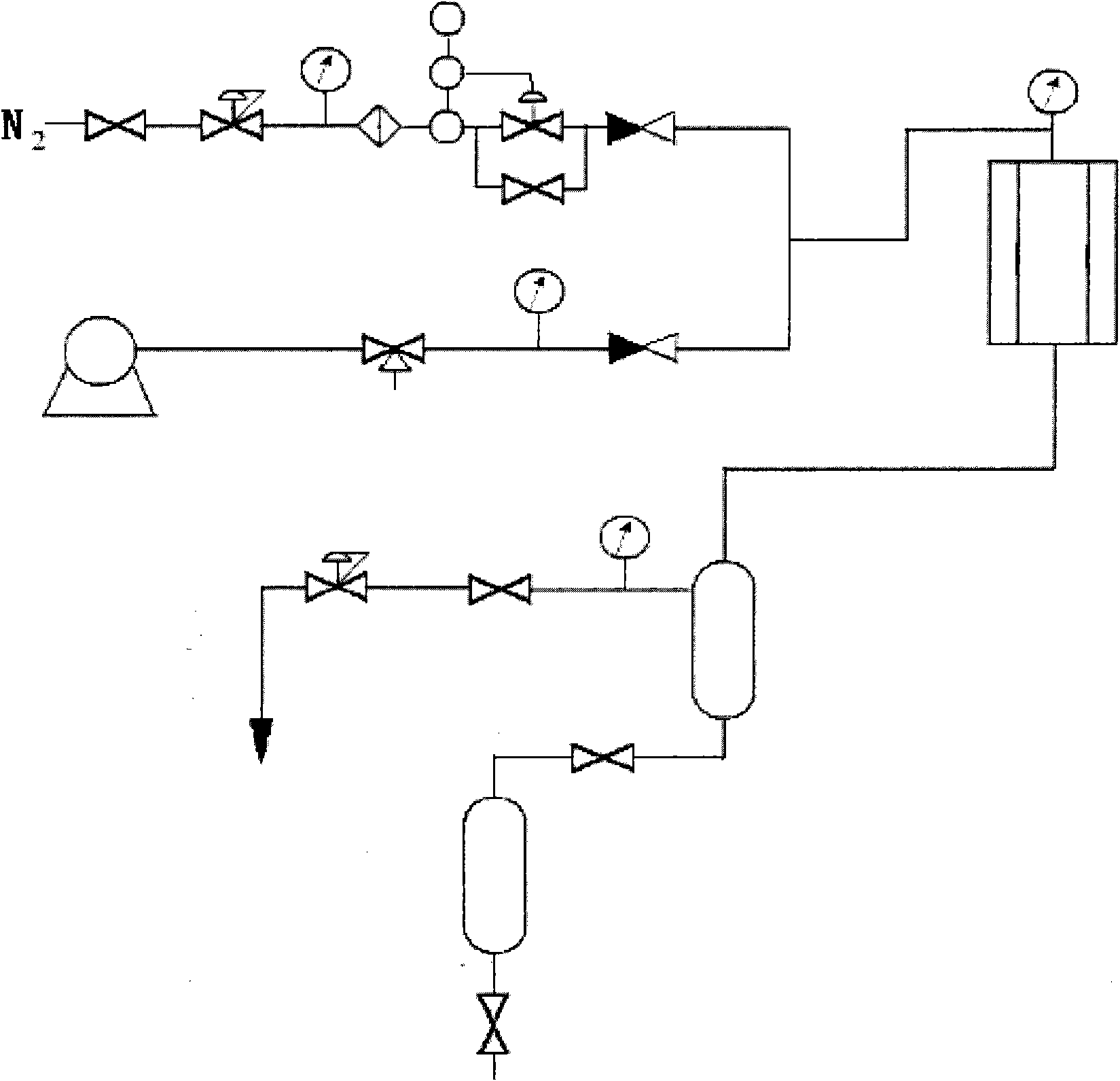

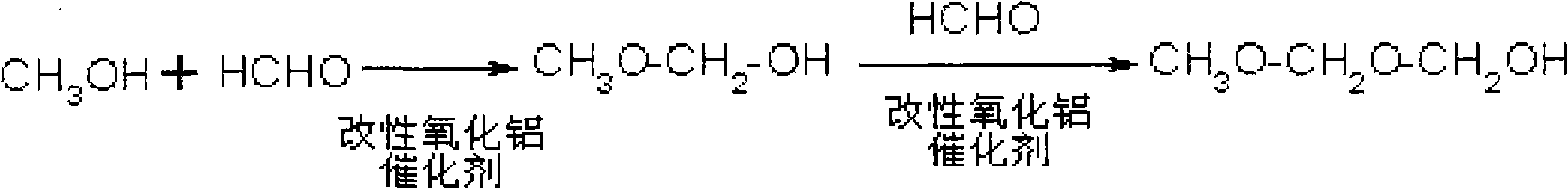

The invention relates to a method for synthesizing polyoxymethylene dimethyl ethers, comprising the following steps: step one, generating hemiacetal by methanol and excessive methanal or paraformaldehyde with low polymerization degree under the existence of a modified alumina catalyst, reacting the hemiacetal with methanal to generate hemiacetal with one more carbon, and successively continuing the above steps to generate poly-hemiacetal with more carbon atoms; and step two, generating the polyoxymethylene dimethyl ethers by the poly-hemiacetal mixture under the existence of methanol and an organic strong acid bonded phase solid catalyst. The invention can achieve the technical targets of improving raw material conversion rate, product selectivity, target product yield and economical efficiency by the two steps of reaction process, adjusts the space velocity by a fixed bed continuous reactor and combines with a catalyst to control the polymerization degree. The synthesis method in the invention has mild reaction conditions and easy control.

Owner:DONGFANG HONGSHENG NEW ENERGY APPL TECH RES INST +1

Preparation method of styrenated hindered phenol or styrenated phenol antioxidant product

ActiveCN102267876AImprove antioxidant capacityAvoid pollutionOrganic chemistryOrganic compound preparationTert butyl phenolButadiene-styrene rubber

The invention discloses a preparation method of a styrenated hindered phenol or styrenated phenol antioxidant product, belonging to the field of preparation process methods of polymer antioxidant products. The preparation method is characterized in that: o-tert-butyl phenol or phenol, p-cresol, o-cresol and m-cresol are used as raw materials, styrene is used as an alkylation reagent, an organic acid compound is used as a catalyst, a small amount of polymerization inhibitor is added, and the styrenated hindered phenol product or styrenated phenol product is prepared through catalytic alkylation reaction; a neutralizing and decolorizing agent is added to the styrenated product to deactivate the acidic catalyst and remove the coloring source material, thus obtaining a white-like or light yellow viscous liquid namely the styrenated phenol antioxidant product which has clear and transparent appearance, pH value of 6.5-7.5, storage stability and high use efficiency; and the styrenated phenol antioxidant product is free of water-soluble pollutants such as free phenol or methyl phenol, thereby solving the problem of environmental pollution caused by the use of the product in styrene butadiene rubber latex.

Owner:CHANGZHOU UNIV

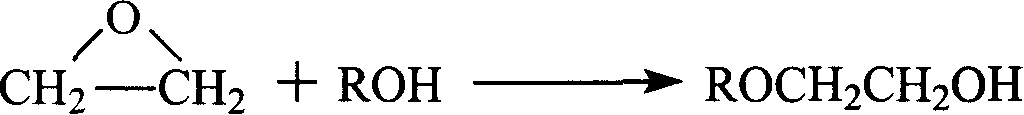

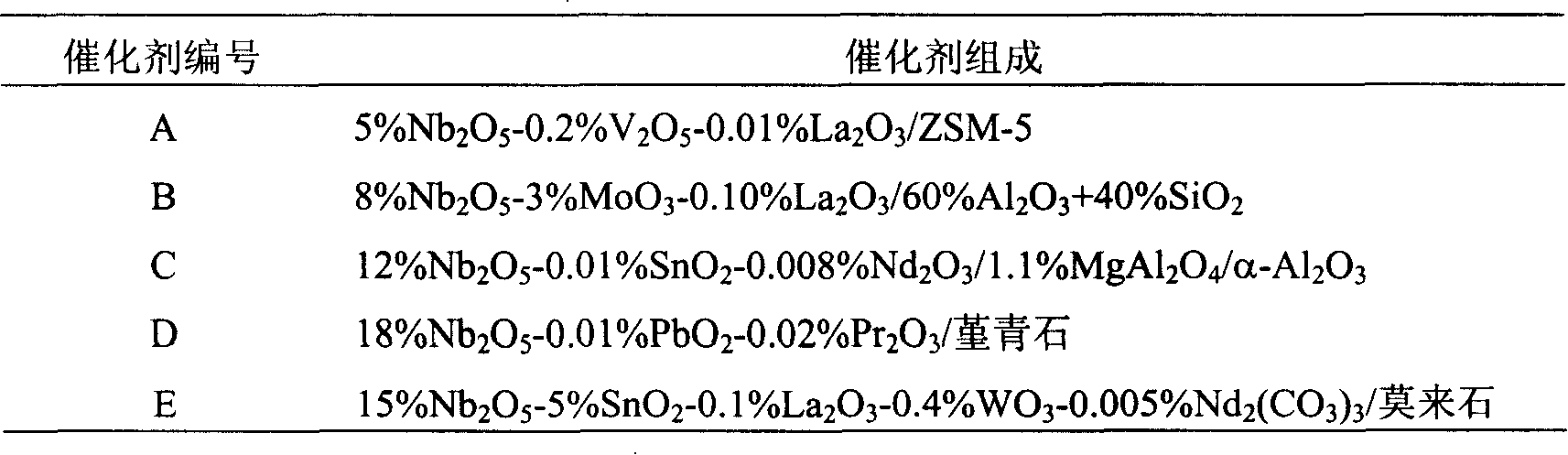

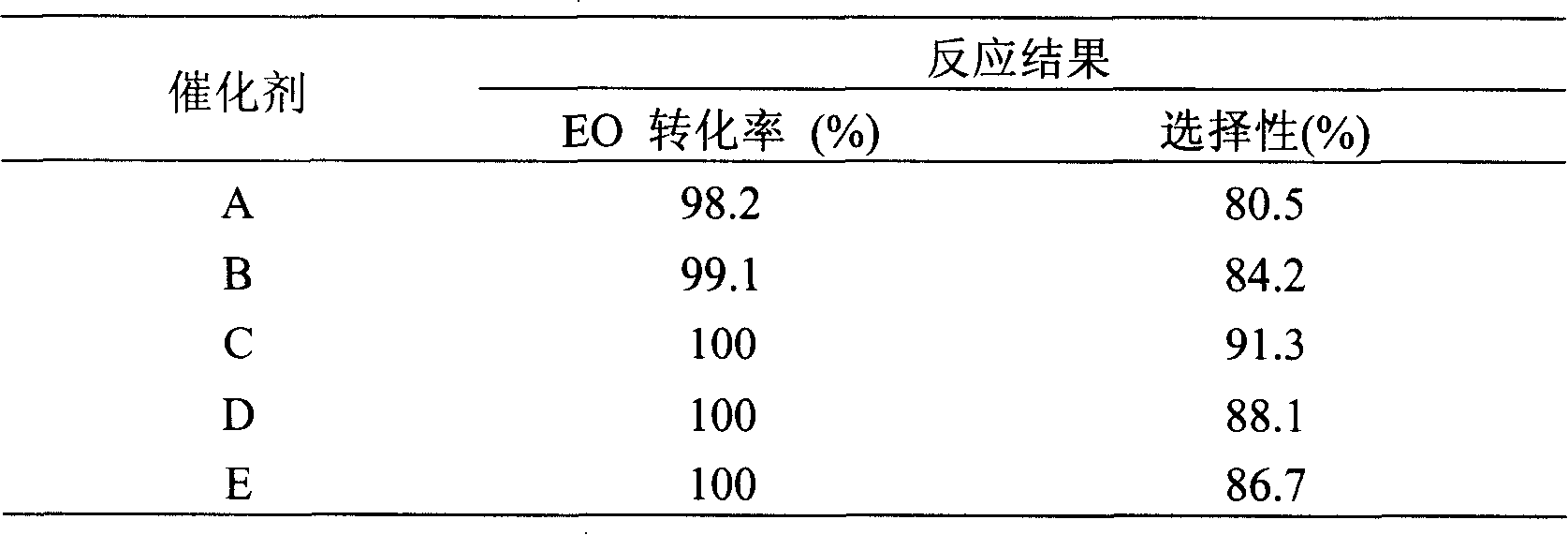

Method for preparing ethylene glycol ether

ActiveCN101190876AHigh activityReduced activityMolecular sieve catalystsEther preparation from oxiranesEpoxyEthylene oxide

The invention relates to a glycol ether preparation method, mainly solving the problems of the original technique that the target product, glycol ether, has low selectivity, high alcohol / epoxy ethane ratio (alcohol / alkyl ratio) and no concern on catalyst stability. The invention uses epoxy ethane and lower fatty alcohol as raw materials, adopts niobium oxide as a main activated component, and chooses at least one of elements or compounds of V, Mo, Sn, Pb, La, Pr, Nd as auxiliary agent to form catalyst, so as to prepare glycol ether under the reaction temperature of 100 to 300 DEG C, reaction pressure of 0.1 to 3.0MPa, alcohol / alkyl ratio of 1-5: 1, and reaction time of 30 minutes to 8.0 hours. The technical proposal can well solve the problem and can be used for the industrial production of the glycol ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

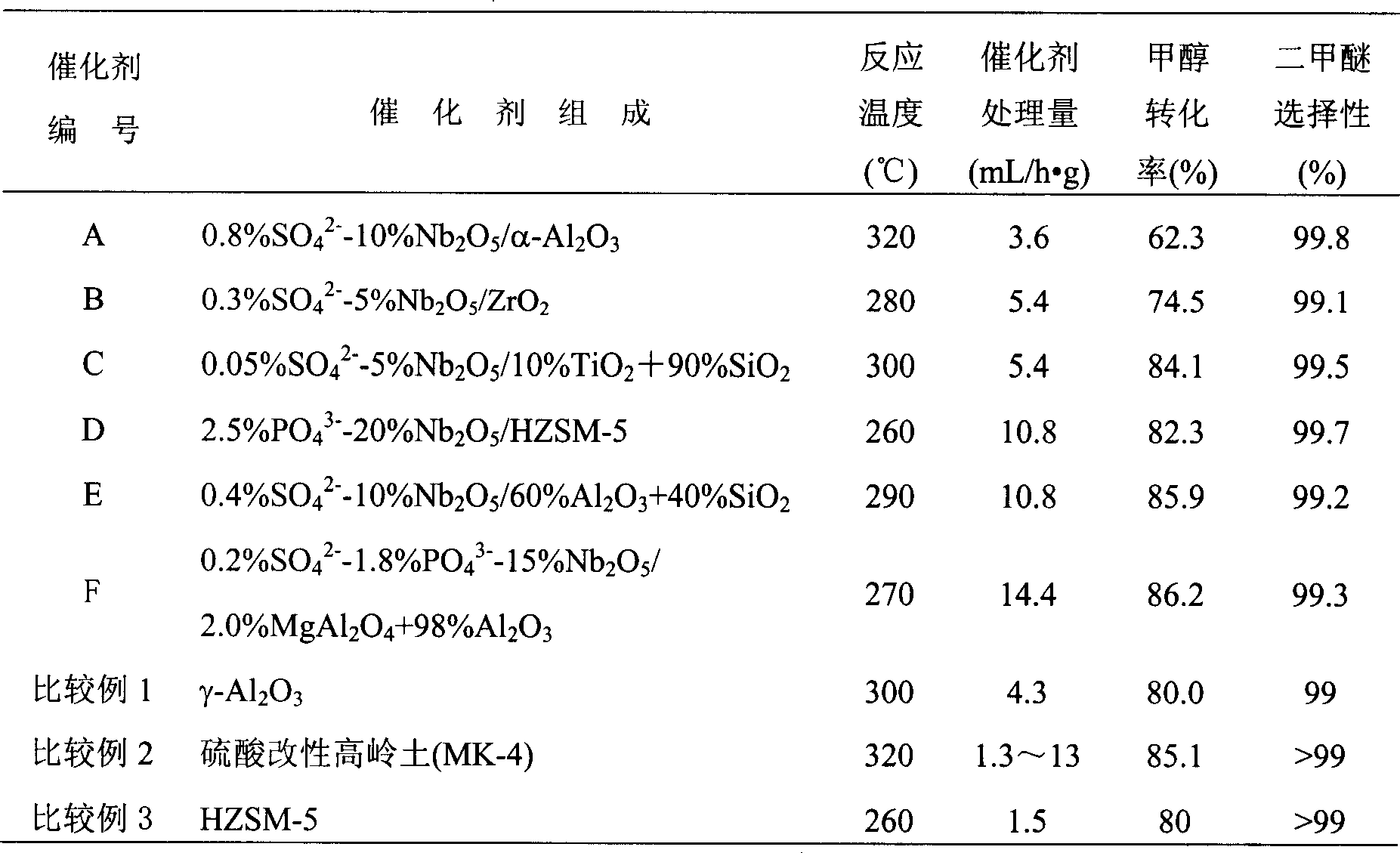

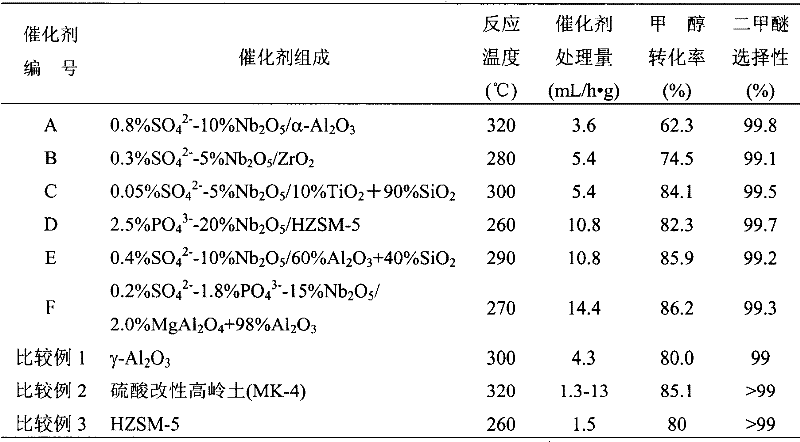

Catalyst for preparing dimethyl ether from methanol

ActiveCN101147860AHigh activityActivity unchangedCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsAlcoholActive component

The present invention relates to a catalyst for preparing dimethyl ether by using methyl alcohol dehydration. Said catalyst is made up by using niobium oxide as main active component and selecting at least one kind of phosphorus or sulfur as adjuvant through a certain preparation process. Said catalyst not only has good activity, but also possesses good stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

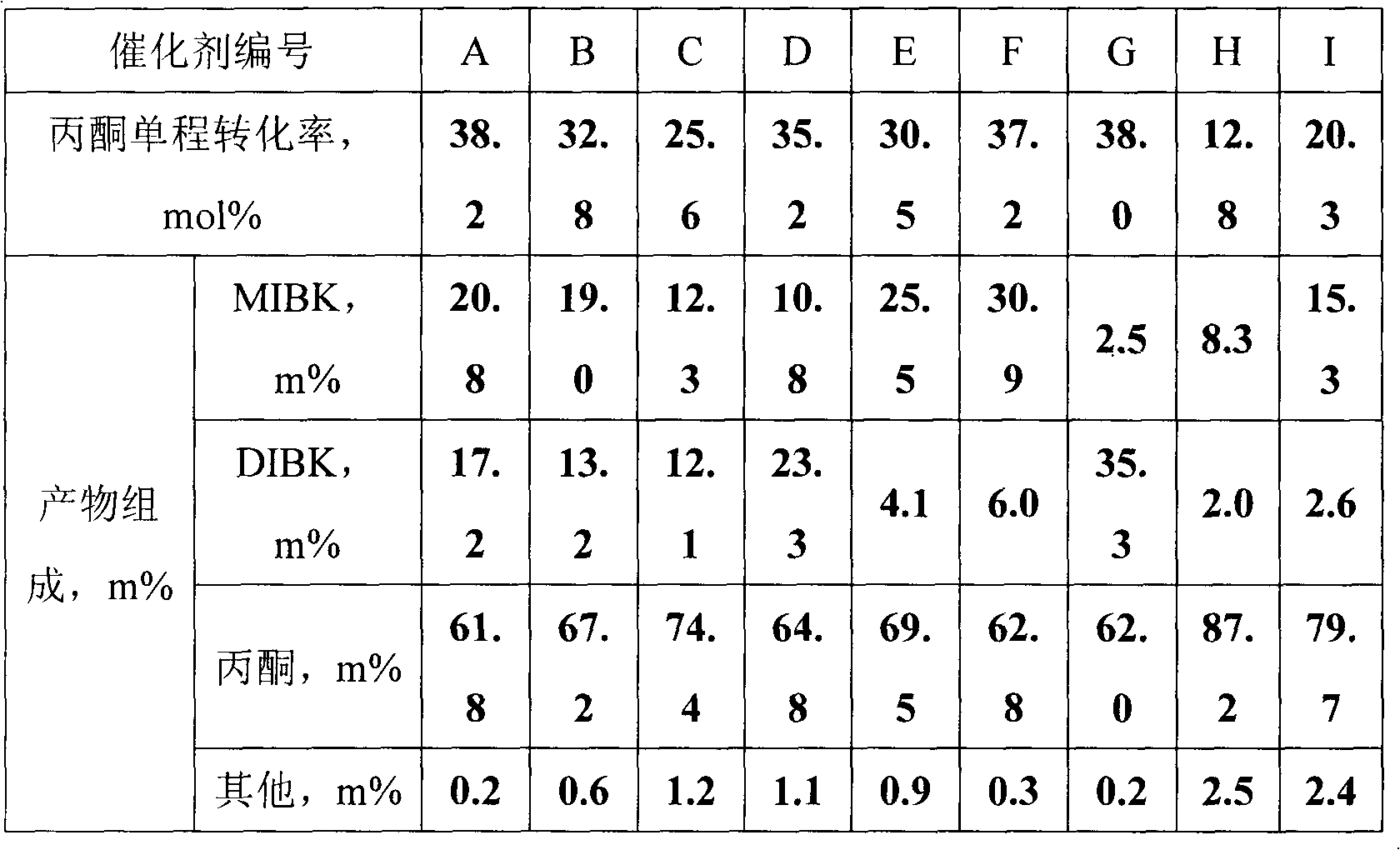

Preparation method of isobutyl ketone synthesis catalyst

ActiveCN102416325ALow priceStable activityOrganic compound preparationCarbonyl compound preparationSol-gelOxide

The invention relates to a preparation method of an isobutyl ketone synthesis catalyst. The catalyst is prepared by loading bimetallic nickel and copper on alkaline-earth metallic oxide / aluminum oxide composite carrier. The preparation method of the catalyst comprises the three steps of: firstly adopting a sol-gel method to prepare the alkaline-earth metallic oxide / aluminum oxide composite carrier; then introducing active metal nickel and copper by an immersion method; and finally carrying out water hydrothermal treatment to prepare the catalyst. The preparation method has the advantages of simplicity, high activity and selectivity, integration of three catalysis functions such as condensation, dehydration and hydrogenation of acetone, and simple reaction process flow.

Owner:CHINA NAT OFFSHORE OIL CORP +1

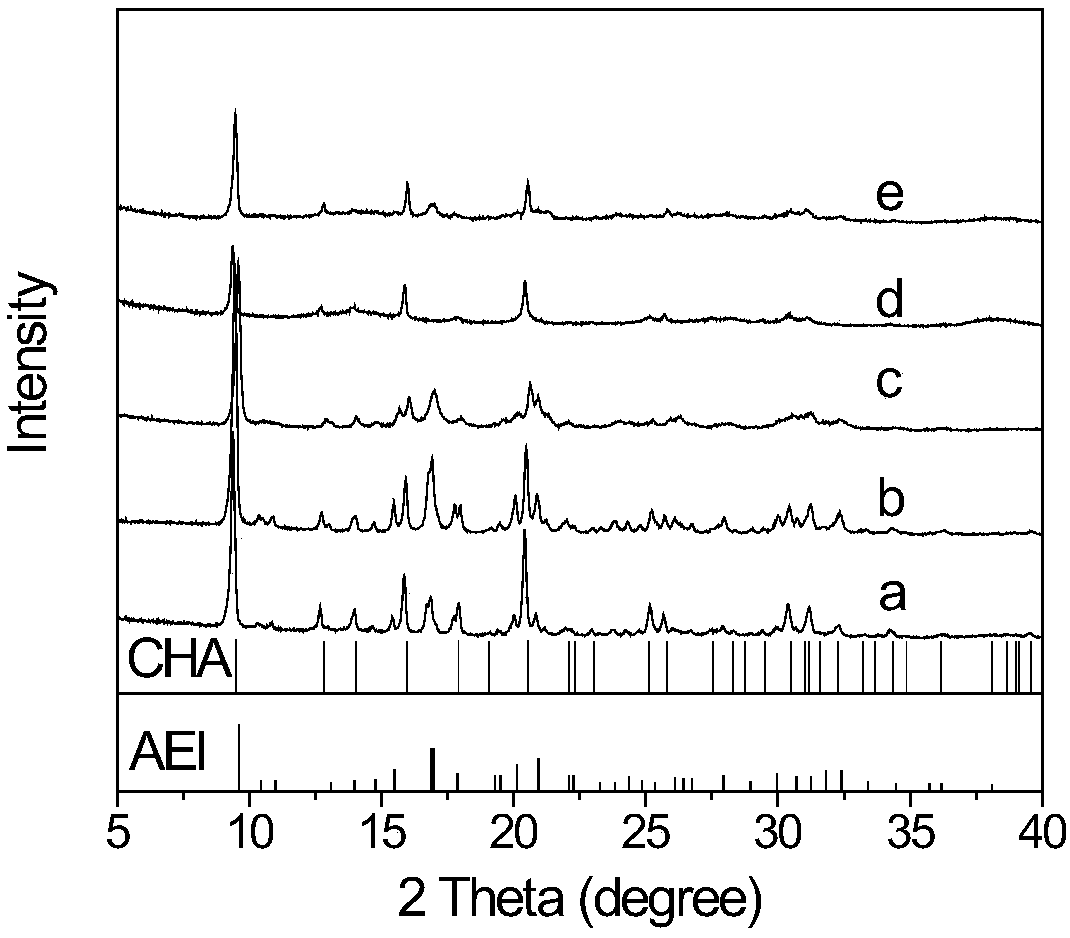

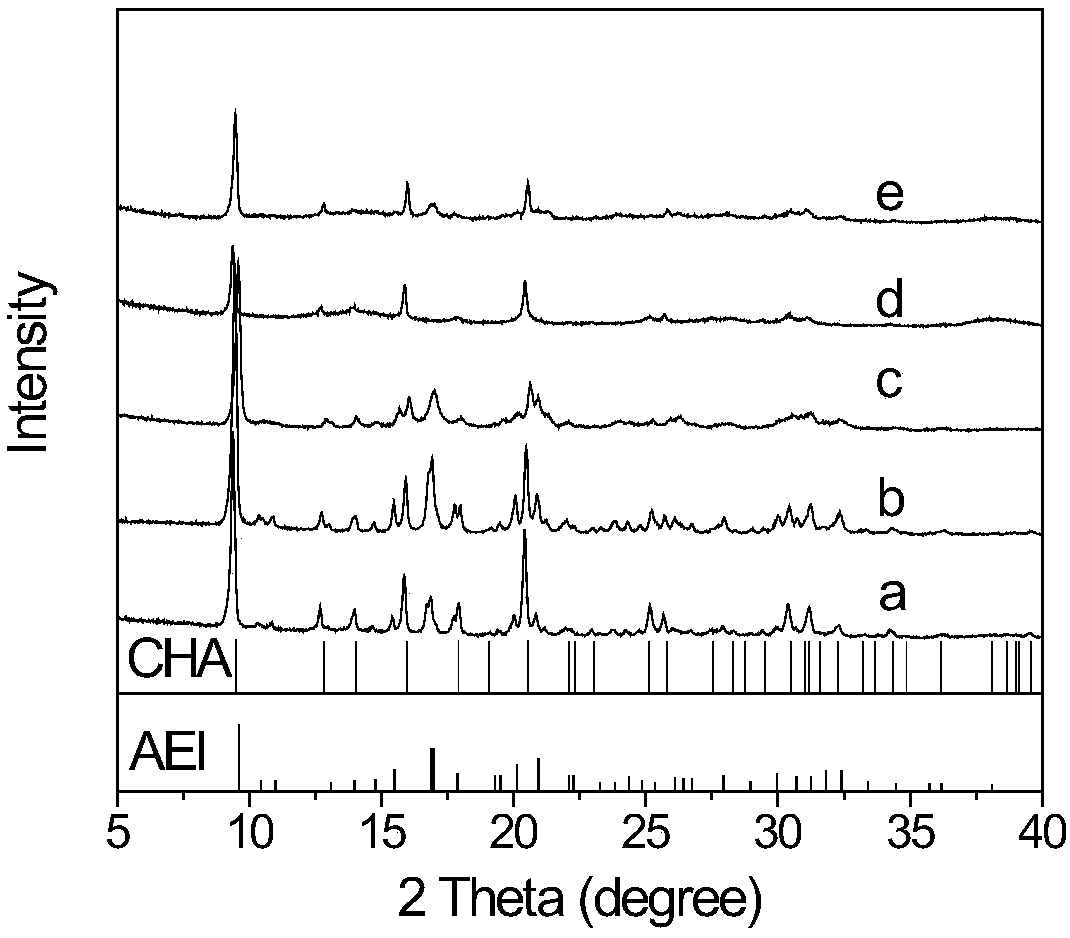

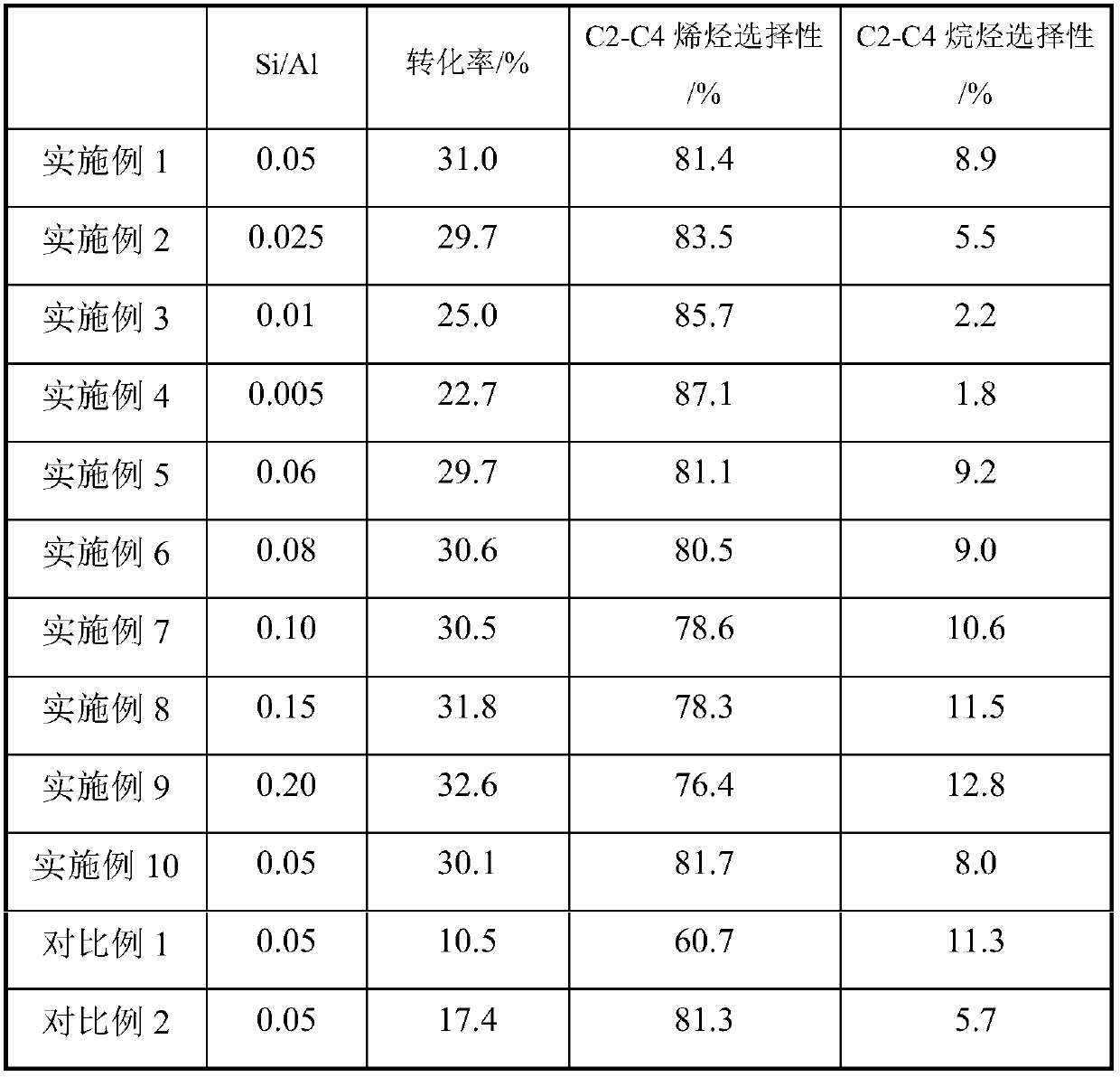

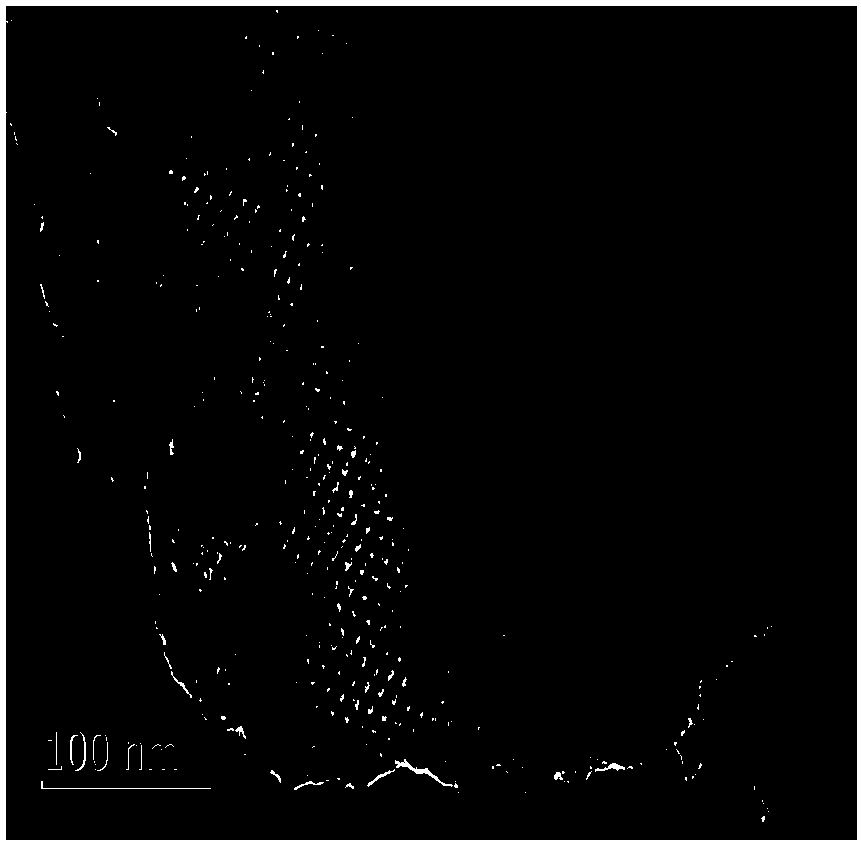

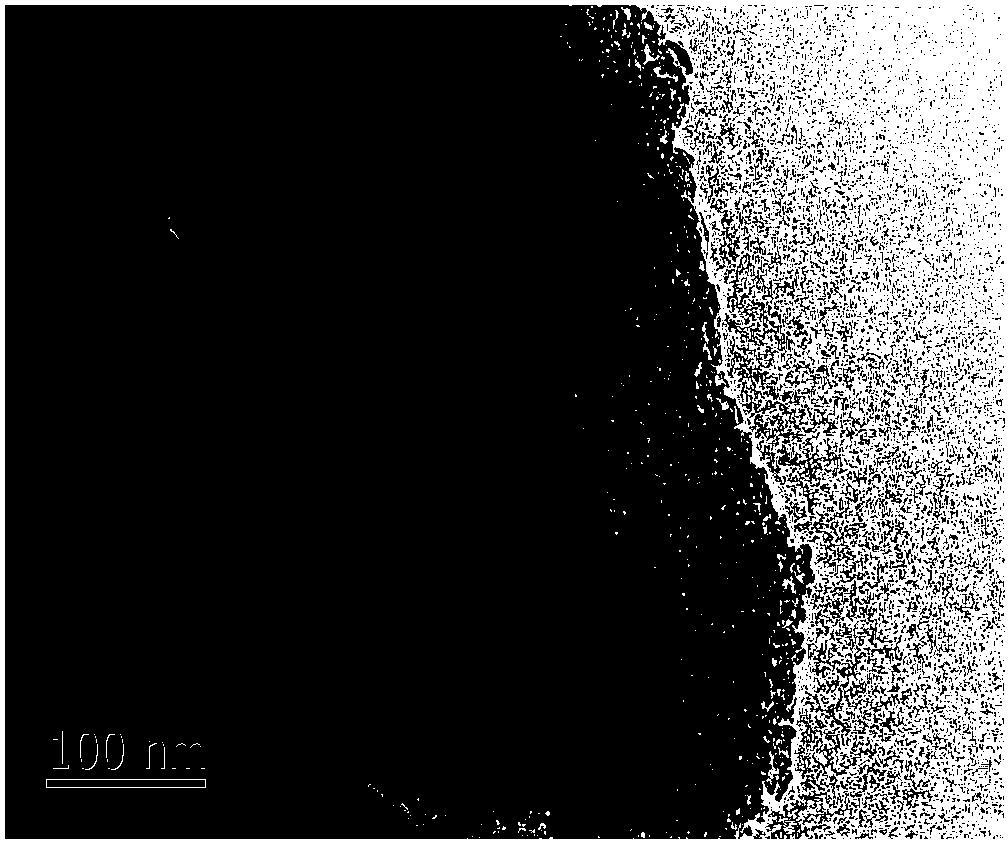

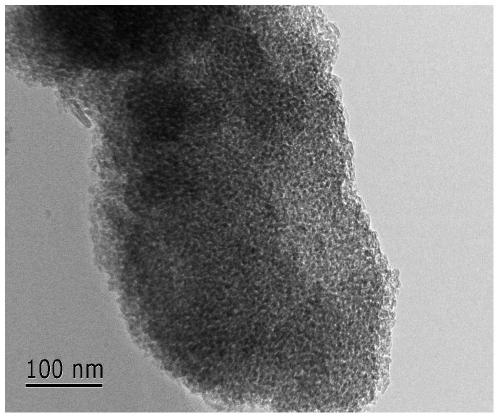

Eutectic nano molecular sieve, preparation method and applications thereof

ActiveCN111115655AReduce dosageReduce manufacturing costMaterial nanotechnologyHydrocarbon from carbon oxidesMolecular sieveDistilled water

The invention belongs to the field of molecular sieves, particularly relates to a low-silicon AEI / CHA eutectic nano molecular sieve, a preparation method and applications thereof. A purpose of the invention is mainly to solve the problems of low AEI content, complex preparation process, high template agent price, high template agent dosage, high production cost and the like in the AEI / CHA eutecticmolecular sieve prepared by the conventional synthesis method. The preparation method of the molecular sieve specifically comprises the following steps: adding an aluminum source, a phosphorus source, a template agent and the like into distilled water, uniformly stirring and dispersing, and then adding a seed crystal to obtain a mixed solution; and crystallizing, separating, washing, drying and roasting the obtained mixed solution to obtain the eutectic nano molecular sieve formed by AEI and CHA symbiosis. The molecular sieve obtained in the invention has the advantages of high proportion ofAEI structural units and uniform dispersion of silicon species, and further has high CO conversion rate and low carbon olefin selectivity in a reaction for preparing low carbon olefins through directconversion of catalytic synthesis gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

New method for hydrogenation saturation of aromatic hydrocarbons

ActiveCN107629814AExtended service lifeRegular mesoporous structureMetal/metal-oxides/metal-hydroxide catalystsRefining by aromatic hydrocarbon hydrogenationHydrogenReaction temperature

The present invention relates to a new method for hydrogenation saturation of aromatic hydrocarbons. The main steps comprise: under mild operation conditions (the pressure is less than 3 MPa, and thetemperature is less than 80 DEG C), mixing an oil product containing an aromatic hydrocarbon and M / Al2O3, introducing hydrogen to achieve a certain pressure, carrying out a reaction at a certain temperature, reducing to a room temperature from the reaction temperature after the aromatic hydrocarbon is subjected to complete hydrogenation saturation, and recovering the separated catalyst, wherein Min the catalyst M / Al2O3 is one selected from Ru, Rh, Pd, Pt, Ir and other noble metals or a combination comprising two materials selected from Ru, Rh, Pd, Pt, Ir and other noble metals, and Al2O3 hasan ordered mesoporous structure. According to the present invention, the reaction conditions are mild, and the catalyst shows high aromatic hydrocarbon hydrogenation activity and high stability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing dimethyl ether

ActiveCN101148397AHigh activityNo decrease in activityCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsSulfurActive component

The present invention relates to process of preparing dimethyl ether, and aims at providing technological scheme of preparing dimethyl ether in lowered reaction temperature, high catalyst efficiency, long service life of catalyst and other merits. The process of preparing dimethyl ether adopts methanol as main material and catalyst with niobium oxide as the main active component and P and / or S as the co-catalyst, and has reaction temperature of 100-350 deg.c and catalyst efficiency of 1-20 ml methanol / hr.g. The present invention may be applied in industrial production of dimethyl ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

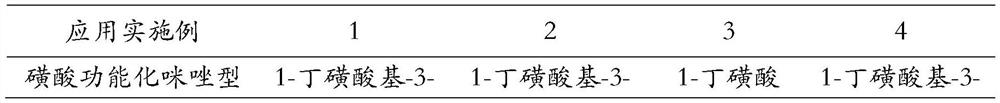

Catalyst for preparing styrene by phenylethanol dehydration as well as preparation and application methods of catalyst

ActiveCN112221480ALarge specific surface areaLarge apertureCatalyst activation/preparationHydrocarbon from oxygen organic compoundsPtru catalystCarbon deposit

The invention discloses a ZrAl catalyst. The catalyst is composed of ZrO2-Al2O3, and the weight percentage of the catalyst is 20-50%. The catalyst is prepared by a following method: reacting a mixed solution of aluminum and zirconium precursors with urea to form gel; and drying the gel and roasting the gel to obtain the catalyst. The preparation method is simple, easy to operate and high in repeatability. The invention also discloses a use method of the catalyst for catalyzing alpha-phenylethanol dehydration to prepare styrene. The catalyst has high activity, produces less carbon deposit and has good catalytic stability.

Owner:HEBEI UNIV OF TECH

Preparation method of 2,6-DiMethylnaphthalene (DMN) by using SAPO-11 molecular sieve

InactiveCN102746102BEasy to separateEasy to operateMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationAlkyl transferMolecular sieve

The invention relates to a preparation method of the 2,6-DMN, in particular to a preparation method of the 2,6-DMN by using a SAPO-11 molecular sieve. The preparation method mainly solves the problems that catalysts cannot be provided with high activity and 2,6-DMN selectivity simultaneously, and the catalysts are easy to inactivate. The method includes activating the SAPO-11 molecular sieve synthesized by microwave radiation and heating, mixing naphthalene and alkylation reagents with a solvent according to a molar ratio of 1:(2-4):(6-12), and performing alkylation reaction to obtain the 2,6-DMN at a temperature of 350 DEG C to 450 DEG C, at a pressure of 2 MPa to 5 MPa, at a quality airspeed of 0.5-2h-1 and at a carrier gas flow rate of 20-60 mL / min. According to the preparation method, the synthesized SAPO-11 molecular sieve can shorten the crystallization time greatly, and has high catalytic activity to the alkylation reaction of the naphthalene and high selectivity and good anti-carbon deposition competence to the 2,6-DMN.

Owner:HEILONGJIANG UNIV

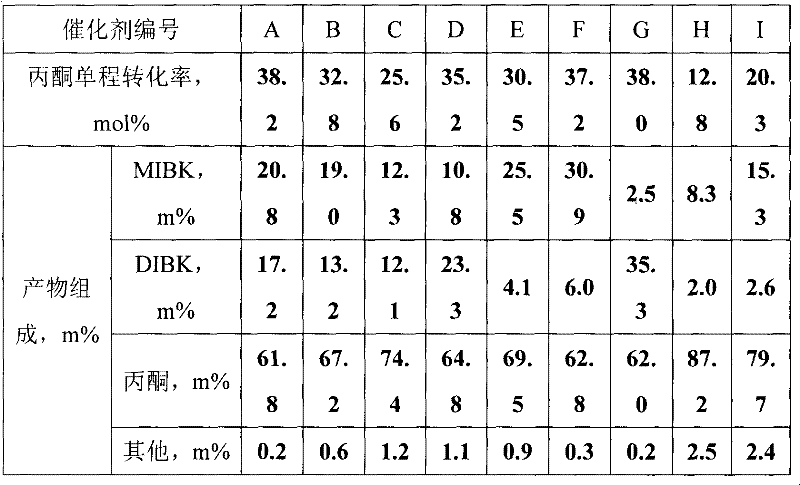

Preparation method of catalyst for coproducing isopropanol and methyl isobutyl ketone by acetone hydrogenation

ActiveCN102806086BLow content of active metal componentsExtended service lifeOxygen-containing compound preparationOrganic compound preparationMethyl isobutyl ketoneNitrate

The invention relates to a preparation method of a catalyst for coproducing isopropanol and methyl isobutyl ketone by acetone hydrogenation. The catalyst comprises an alumina carrier and Ni and Mg loaded on the gamma-Al2O3 carrier, and particularly comprises, by total weight, 10-18% of the Ni, 3-8% of the Mg and the balance alumina; and the BET specific surface area of the catalyst ranges from 100m<2> / g to 180m<2> / g, and the pore volume of the catalyst ranges from 0.35mL / g to 0.55mL / g. The preparation method includes steps of (1), preparing the carrier by details of weighing pseudo-boehmite powder, adding binders and extrusion assistants into the pseudo-boehmite powder, forming by strip extrusion or granulating by rotation, drying and calcining, cooling to reduce temperature so as to obtain the stripped or spherical carrier; (2), impregnating the carrier into magnesium nitrate by details of loading a magnesium additive onto the carrier by means of saturated impregnation, drying and then calcining for 2-6 hours at the temperature ranging from 400 DEG C to 500 DEG C; (3), loading the actively metallic nickel by details of impregnating for 10-24 hours and calcining for 2-6 hours at the temperature ranging from 350 DEG C to 480 DEG C; and (4), loading the actively metallic nickel again by details of drying a semi-finished product, impregnating the dried semi-finished product into impregnation liquid of nickel nitrate again, repeating the step (3) once, and calcining the semi-finished product for 2-4 hours at the temperature ranging from 400 DEG C to 450 DEG C so as to obtain the finished catalyst.

Owner:CHINA NAT OFFSHORE OIL CORP +1

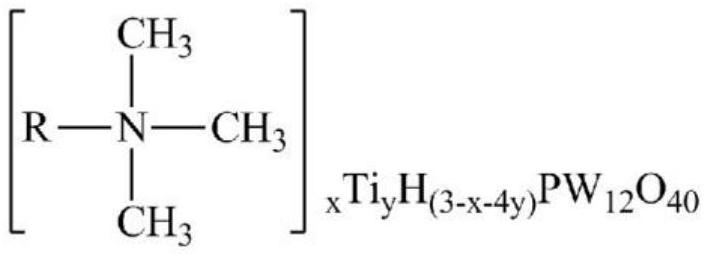

Method for catalytic synthesis of cyclohexanone ethylene ketal from titanium phosphotungstate and ammonium phosphotungstate composite salt

ActiveCN108191814AIncrease the areaHigh densityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsCyclohexanoneTitanium

The invention relates to a method for catalytic synthesis of cyclohexanone ethylene ketal from titanium phosphotungstate and ammonium phosphotungstate composite salt. The titanium phosphotungstate andammonium phosphotungstate composite salt is taken as a catalyst, cyclohexanone ethylene ketal is generated from cyclohexanone and ethylene glycol through a condensation reaction, and the condensed structural formula of the titanium phosphotungstate and ammonium phosphotungstate composite salt is (NH4)xTiyH(3-x-4y)PW12O40, wherein x=0.4-0.6, and y=0.4-0.6. The titanium phosphotungstate and ammonium phosphotungstate composite salt as the catalyst has larger specific surface area, higher surface acid density and proper acid strength, so that the catalyst has excellent catalytic performance, andproduct yield is high. Besides, raw materials of the catalyst are easily available, the preparation process is simple, the catalyst and the product are easy to separate, and the catalyst is recyclable.

Owner:SHAOYANG UNIV

A kind of molecular sieve desulfurizer and preparation method thereof

ActiveCN103252211BModerate acid strengthSmall cell constantOther chemical processesHydrocarbon oils refiningWater bathsHazardous substance

The invention relates to a molecular sieve desulfurizer and a preparation method thereof. The method comprises heating a NaY molecular sieve and an ammonium salt solution in a water bath of 80-100 DEG C for ammonium exchanging, treating the ammonium-exchanged molecular sieve with inorganic acid or / and organic acid aqueous solutions, preparing an aqueous solution containing lanthanum and cerium with a concentration of 0.05-0.08 mol / L to exchange and modify the obtained molecular sieve ions until an exchange degree of the exchanged and modified lanthanum or cerium is 71-73 %, molding, drying and roasting the modified molecular sieve, and using an isopyknic immersion method to load transition metal elements so that a mass percent of loaded metals (on basis of oxide) is 10.0-20.0 %. Therefore, adsorptivity, selectivity and stability of the desulfurizer is well distributed, the experiment is simple to operate, raw materials are cheap and easy to purchase, a preparation process is simple, and no poisonous and harmful substances are generated.

Owner:PETROCHINA CO LTD

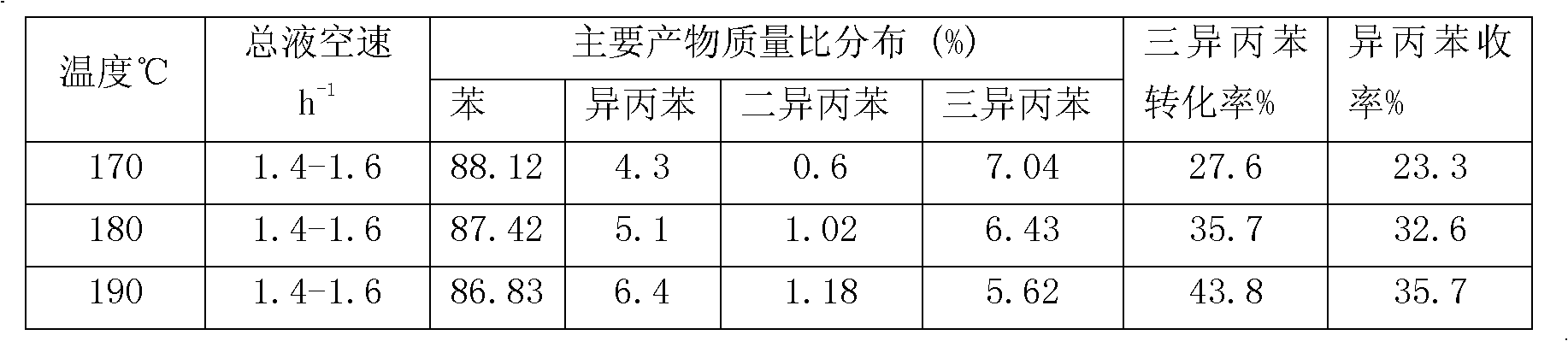

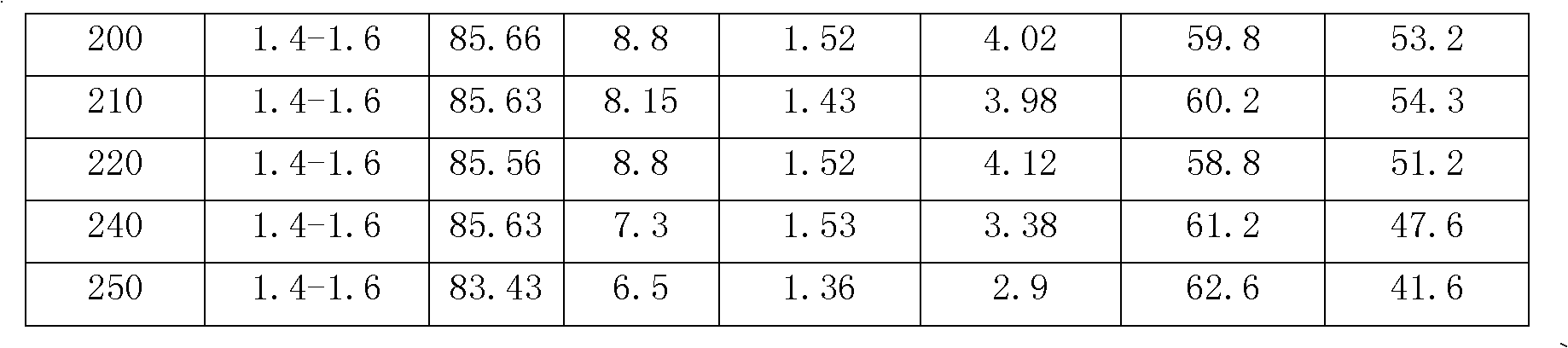

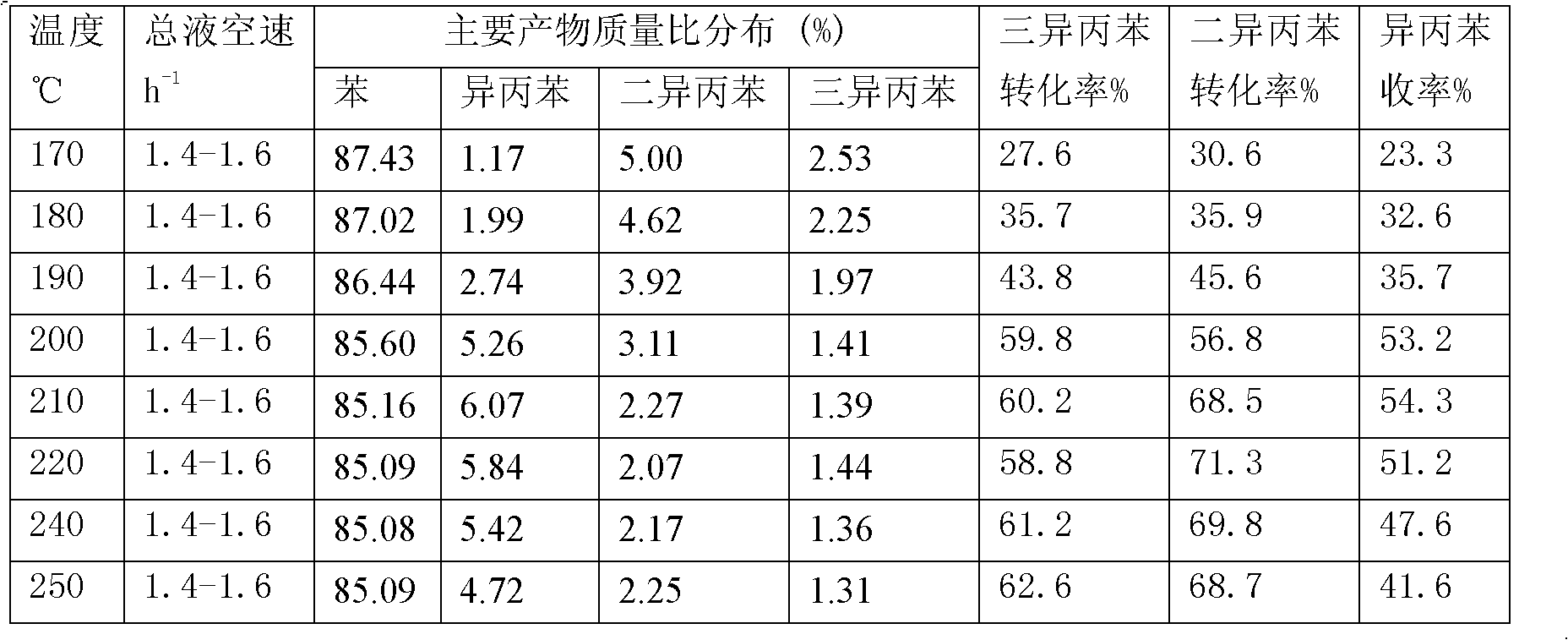

Method for producing isopropylbenzene through transalkylation

InactiveCN102863311AMany through holesLow reaction temperatureMolecular sieve catalystsHydrocarbonsMolecular sievePhosphoric acid

The invention relates to a method for producing isopropylbenzene through transalkylation. Transalkylation catalyst is obtained by mixing Hbeta / HMCM-49 composite molecular sieve powder, assistant, binding agent, pore-forming agent and lubricant evenly in proportion. The transalkylation catalyst is grinded, granulated, squeezed in strip mode, dried, roasted and cooled to obtain the assistant styrene (SB) powder or one of the SB powder, phosphoric acid, ammonium phosphate and boric acid. The binding agent is sesbania powder, the pore-forming agent is one of methylcellulose, citric acid and oxalic acid, the lubricant is one or two of nitric acid with the concentration of 0.5-15% and phosphoric acid with the concentration of 0.5-15%, and a raw material is diisopropylbenzene or / and triisopropylbenzene and benzene. The transalkylation catalyst is good in activity, high in selectivity and long in service life, and yield of the isopropylbenzene can reach 72.1%-94.1%.

Owner:PETROCHINA CO LTD

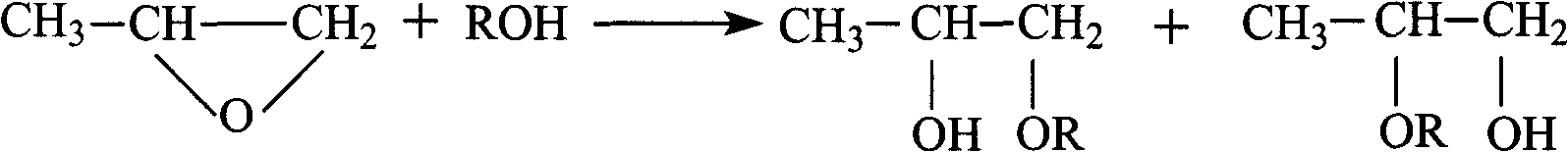

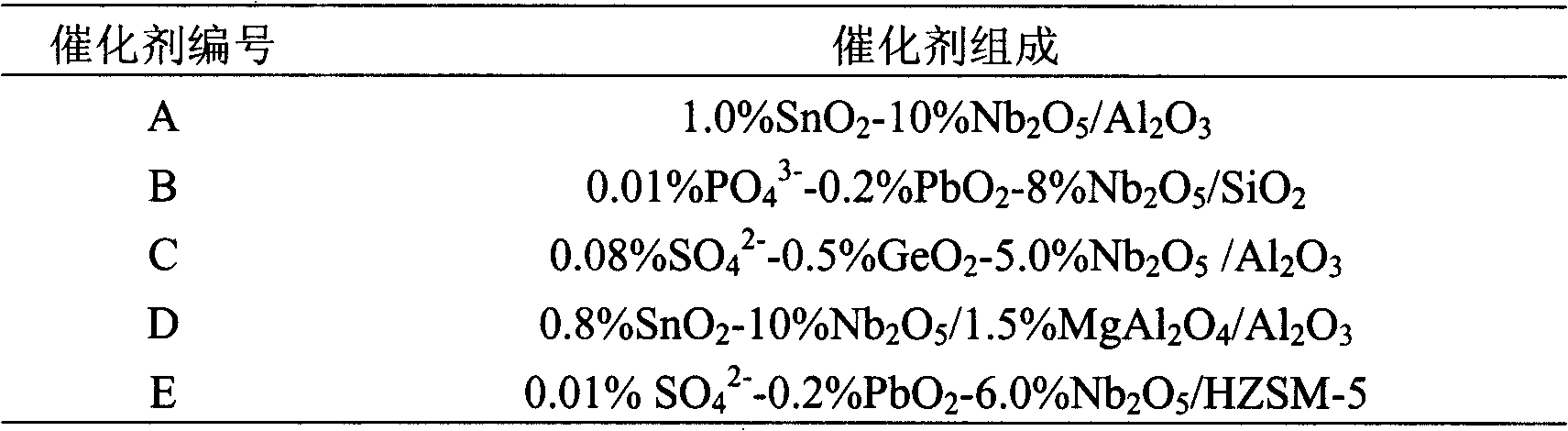

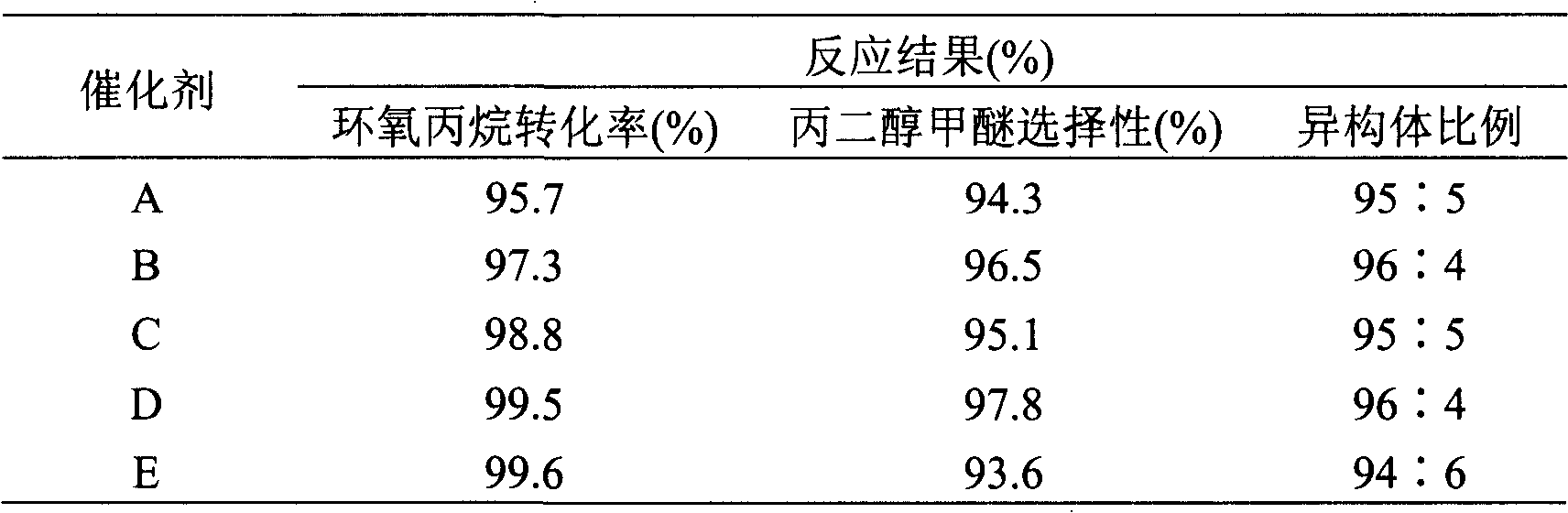

Method for preparing propylene glycol ether

ActiveCN101190878BHigh activityEnhanced Surface AcidityCatalyst carriersEther preparation from oxiranesEpoxyFatty alcohol

The invention relates to a propylene glycol ether preparation method, mainly solving the shortcomings that catalyst of the prior art has low stability and imperfect products yield and isomers proportion. The invention adopts epoxy propane and higher fatty alcohol as materials, adopts niobium oxide as a main activated component, and chooses at least one of elements or oxides of Ge, Sn, Pb, P or S as auxiliary agent to form the catalyst, to prepare propylene glycol ether under the temperature of 100 to 300 DEG C, reaction pressure 1.0 to 3.0MPa, lower fatty alcohol / epoxy propane ratio 1-10: 1,liquid space velocity 1.0 to 4.0 hour<-1>. The technical proposal can well solve the problem, and has epoxy propane conversion rate higher than 98 percent, propylene glycol ether selectivity higher than 95 percent, and isomers proportions higher than 95: 5. The method of the invention can achieve comparatively high product yield and isomers proportion, and has the advantages of small energy consumption, low production cost, environmental protection and free of device corrosion, and can be used for industrial production of the propylene glycol ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

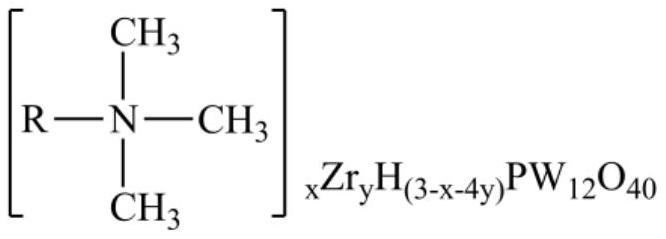

A kind of method for catalyzing synthesis of ethylene bis-stearamide by compound doped heteropoly acid salt

ActiveCN110655475BHigh affinityHigh yieldOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsEthylene diaminePtru catalyst

The invention relates to a method for catalyzing and synthesizing ethylene bisstearamide by compound doped heteropoly acid salt, which is characterized in that the compound doped heteropoly acid salt is used as a catalyst to catalyze stearic acid and ethylene diamine to synthesize ethylene bis-stearamide. Stearamide, the structural formula of described compound doped heteropoly acid salt is: wherein, R=-C 16 H 33 , x=0.4~0.6, y=0.4~0.6. The advantages of the present invention lie in that the molecular structure of the compound-doped heteropolyacid salt catalyst involved contains lipophilic groups, has good affinity for the raw material stearic acid, has a relatively high specific surface area, suitable acid strength and comparatively low acidity. The high surface acid content has excellent catalytic performance for the reaction of synthesizing ethylene bis-stearamide, and the product has high yield, light color and high purity.

Owner:湖南雄创新材料科技有限公司

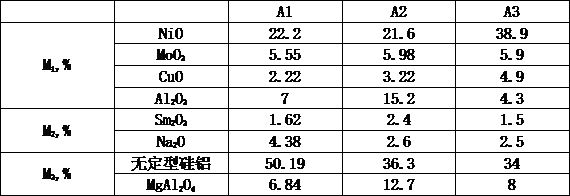

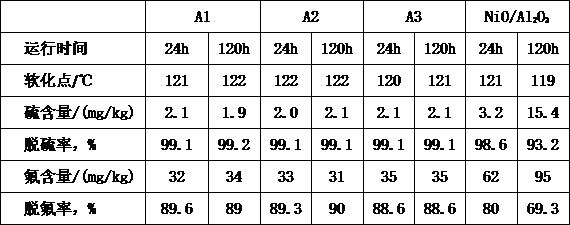

High-fluorine-containing C9 resin hydrogenation catalyst and preparation method and application thereof

ActiveCN112604692AHigh activityIncrease profitMetal/metal-oxides/metal-hydroxide catalystsPtru catalystFluorine containing

The invention relates to a high-fluorine-containing C9 resin hydrogenation catalyst, which is composed of an active component M1, an auxiliary agent component M2 and a carrier component M3. Based on 100% of the total weight of the catalyst, the content of the M1 component is 37%-54%, the content of the M2 component is 4%-6%, and the balance is the M3 component. The component M1 contains Ni, Mo, Cu and Al, the component M2 contains Sm and Na, and the component M3 is amorphous silicon-aluminum MgAl2O4 composite oxide. The invention also discloses a preparation method and application of the catalyst. The catalyst provided by the invention is used for hydrogenation removal of fluorine and sulfur in C9 resin, and can effectively delay fluorine and sulfur poisoning of a rear-stage hydrogenation catalyst.

Owner:WUHAN KELIN FINE CHEM

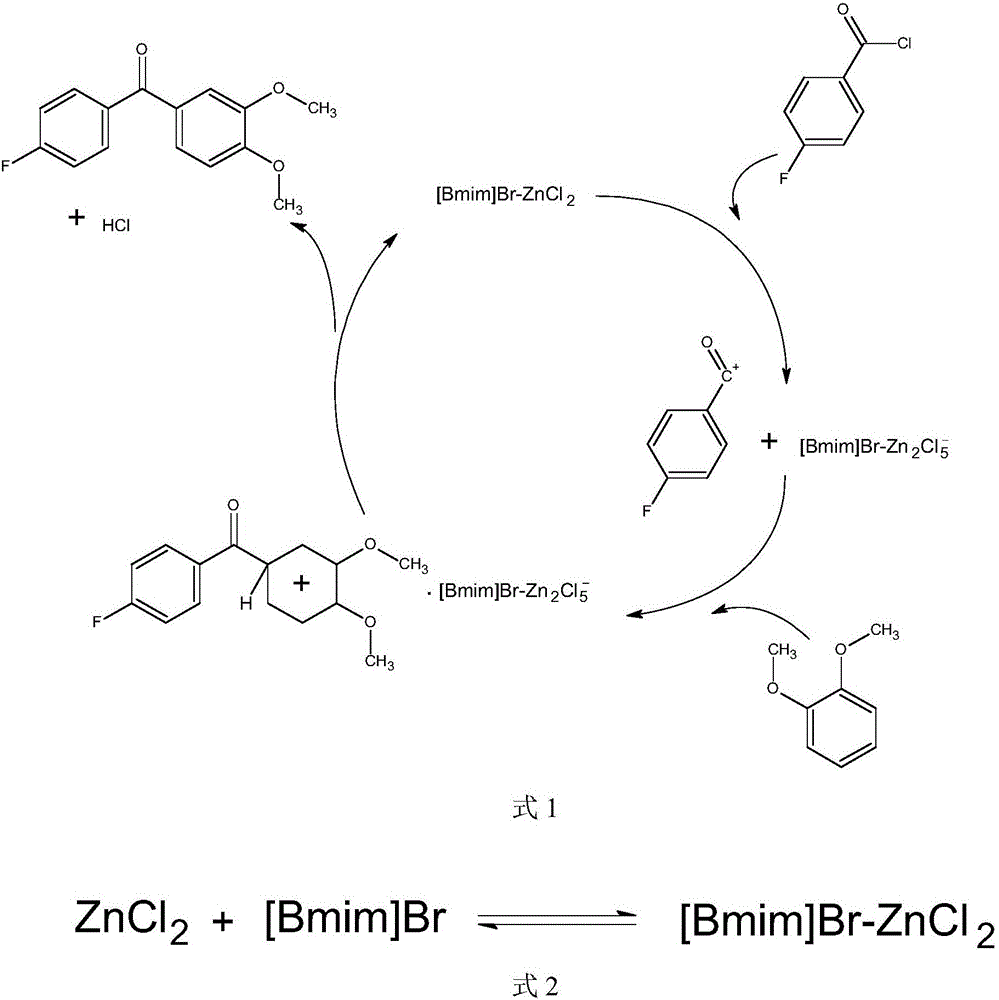

Synthesis method of (3,4-dimethoxyphenyl)(4-p henyl fluoride) ketone

InactiveCN106699529AEmission reductionReduce pollutionCarbonyl compound preparation by condensationSynthesis methodsSlag

The invention relates to a synthesis method of (3,4-dimethoxyphenyl)(4-p henyl fluoride) ketone, and solves the problem that in the prior art, the synthesis method brings large amout of pollution and the cost is high. According to the method, acidic ionic liquid is applied as the catalyst which is polymerized by an ionic liquid precursor containing positive electricity and metal halides with negative electricity, wherein, the ionic liquid precursor is [Bmim] C1 or [Bmim] Br, the metal halide is AlCl3, FeC13, ZnCl2 or CuCl2. The synthesis method of (3,4-dimethoxyphenyl)(4-p henyl fluoride) ketone has the advantages of largely reducing the use amout of catalysts, lowering the emission of the waste water, saving the neutralization process of sulfuric acid, eliminating the waste water generated in the step, avoiding the corrosion caused by strong acid. Compared with the original reaction, the emission of slag is omitted. The reaction product is easy to be separated. The post-treatment is simpler. The reaction temperature is low. The energy cost is low. The product yield rate can reach as high as 97% or higher.

Owner:BEIJING UNIV OF CHEM TECH

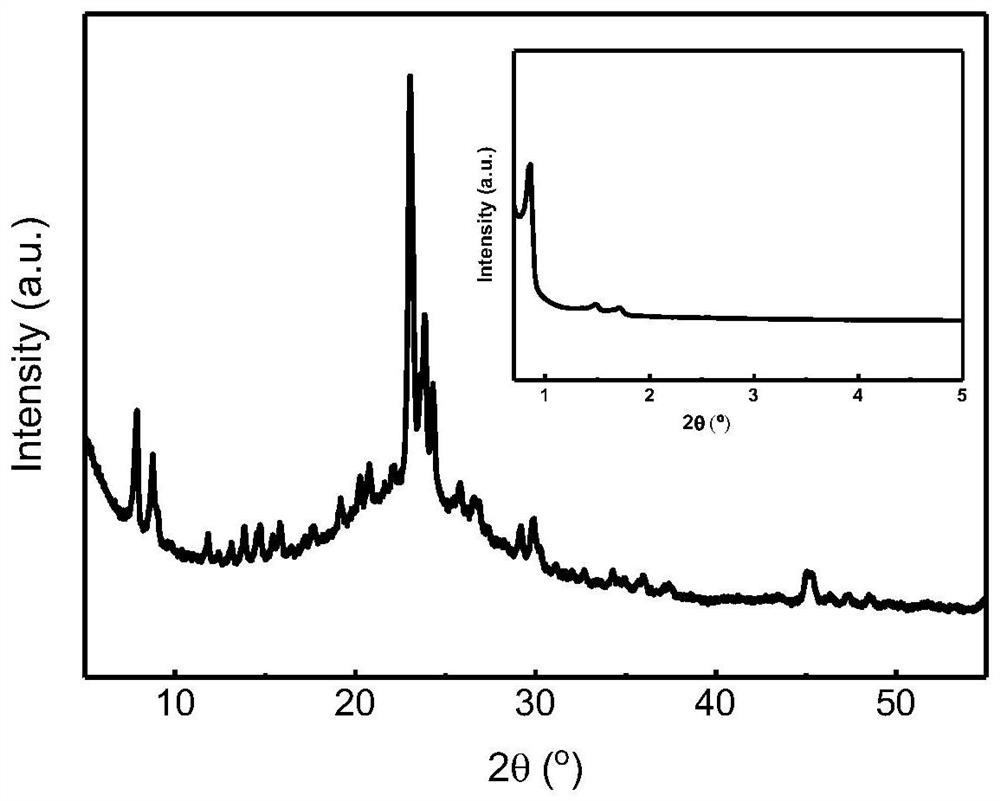

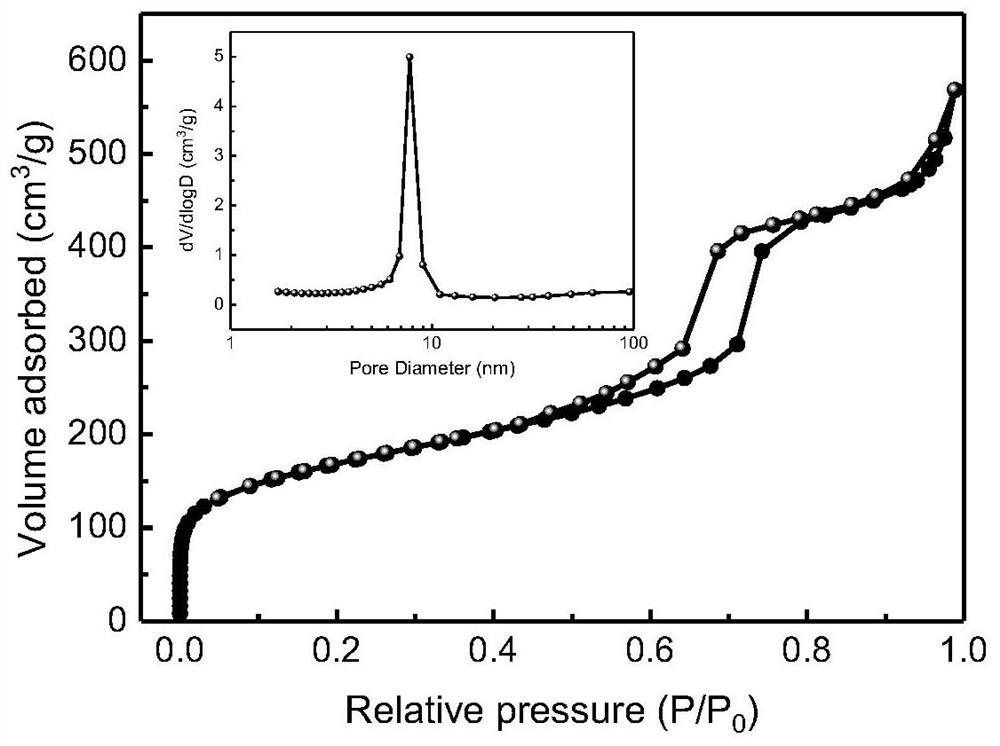

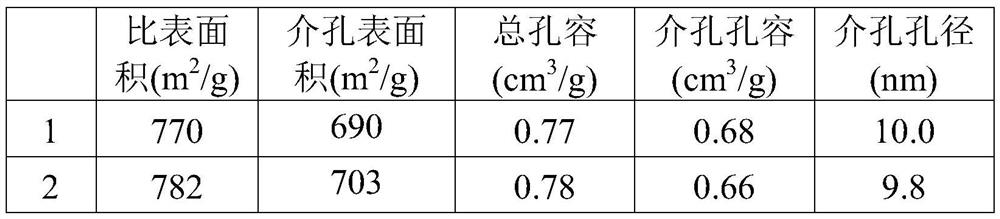

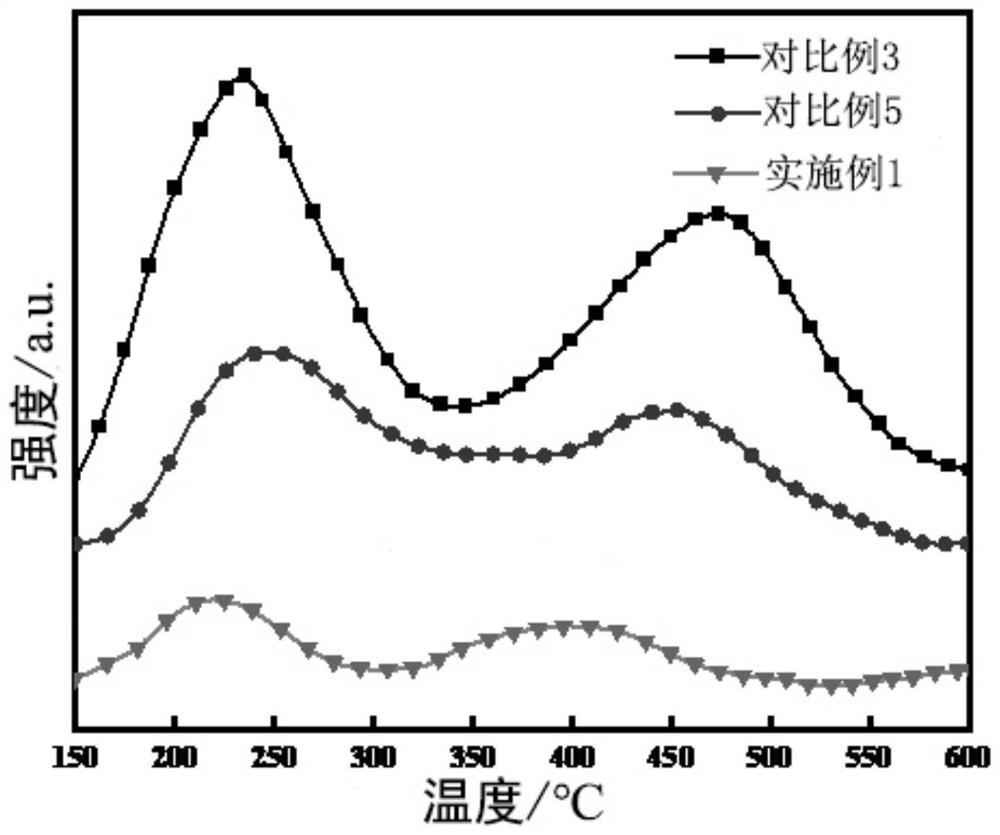

Preparation method of SBA-15/ZSM-5 composite molecular sieve, catalyst and application in double branched chain isomerization

PendingCN112642473ALow costReduce pollutionMolecular sieve catalystsHydrocarbon oils refiningPtru catalystIsomerization

The invention relates to the field of petroleum processing, discloses a preparation method of an SBA-15 / ZSM-5 composite molecular sieve material and application in double branched chain isomerization, and in particular relates to a low-cost green preparation method of an SBA-15 / ZSM-5 composite molecular sieve material with proper acidity and a stepped pore channel structure and a sulfur-tolerant double-branched-chain isomerization catalyst prepared by loading non-noble metals on the SBA-15 / ZSM-5 composite molecular sieve material. The catalyst is applied to a catalytic cracking (FCC) gasoline hydroisomerization reaction. According to the invention, a ZSM-5 molecular sieve nanocrystalline precursor solution is greenly synthesized by taking natural minerals as raw materials without a template agent, and then the SBA-15 / ZSM-5 composite molecular sieve carrier is prepared through in-situ assembly by adopting a low-acidity prehydrolysis method, so that the production cost is greatly reduced, the equipment corrosion is relieved, and the pollutant emission is reduced. Therefore, the method provided by the invention has good economic and environmental benefits, and provides technical support for promoting the industrialization process.

Owner:PETROCHINA CO LTD +1

Catalyst for preparing dimethyl ether from methanol

ActiveCN101147860BHigh activityActivity unchangedCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsPtru catalystAlcohol

The present invention relates to a catalyst for preparing dimethyl ether by using methyl alcohol dehydration. Said catalyst is made up by using niobium oxide as main active component and selecting at least one kind of phosphorus or sulfur as adjuvant through a certain preparation process. Said catalyst not only has good activity, but also possesses good stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing ethylene glycol by ethylene one-step method

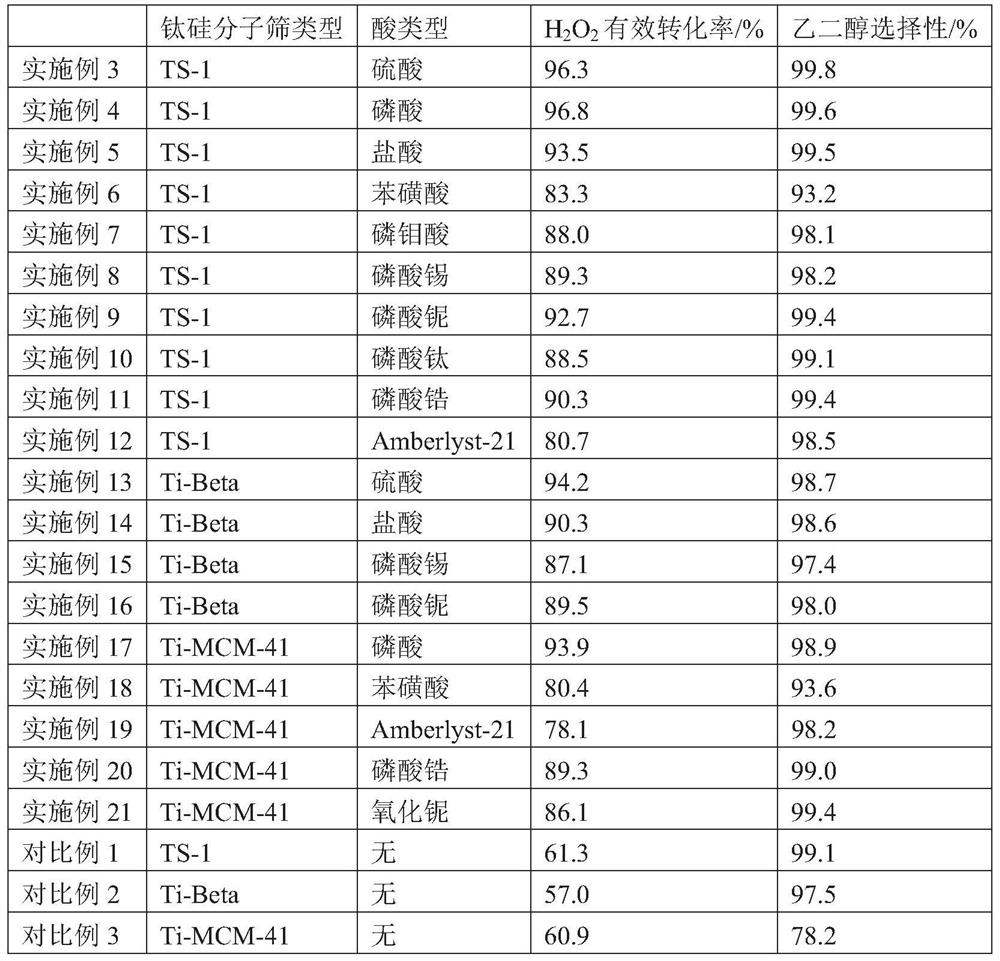

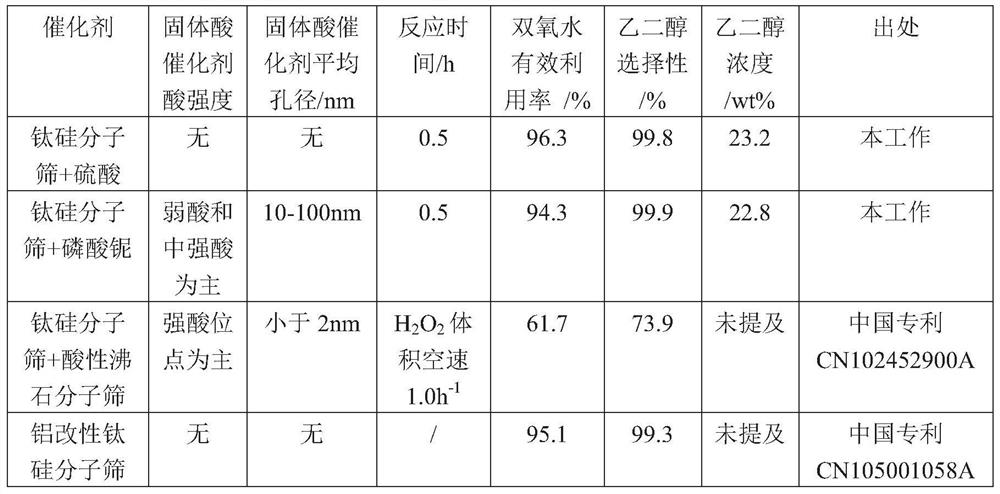

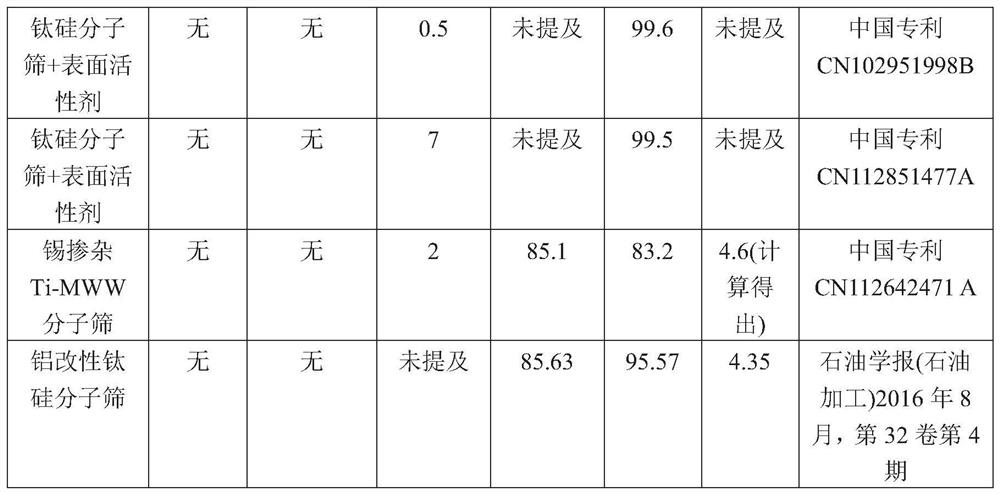

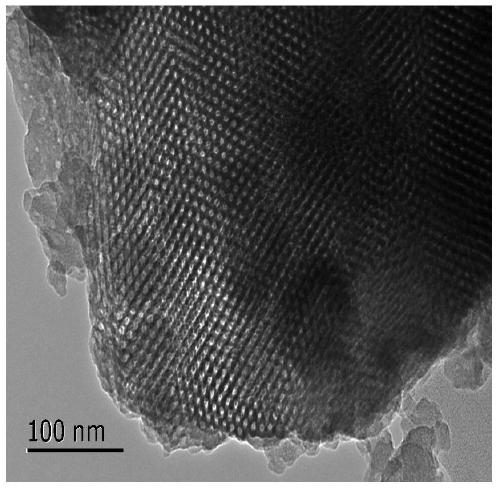

PendingCN114394882AImprove effective utilizationHigh selectivityPreparation by hydroxy group additionBulk chemical productionHydration reactionMolecular sieve

The invention relates to a method for preparing ethylene glycol by an ethylene one-step method. The method comprises the following steps: preparing ethylene glycol: under an acidic reaction condition, contacting ethylene, hydrogen peroxide and a titanium silicalite molecular sieve in water, and carrying out an oxidation hydration reaction to obtain the ethylene glycol. The acidic reaction condition is provided by a non-zeolite molecular sieve; the non-zeolite molecular sieve includes a homogeneous liquid acid and / or a heterogeneous solid acid. The method is high in effective utilization rate of hydrogen peroxide, and the target product ethylene glycol is high in selectivity and high in concentration.

Owner:BEIJING UNIV OF CHEM TECH

A kind of hydrogenation saturation method of aromatics

ActiveCN107629814BExtended service lifeRegular mesoporous structureMetal/metal-oxides/metal-hydroxide catalystsRefining by aromatic hydrocarbon hydrogenationHydrogenReaction temperature

The invention relates to a new method for hydrogenation saturation of aromatic hydrocarbons. The main steps are: under mild operating conditions (pressure lower than 3MPa, temperature lower than 80°C), oil containing aromatics and M / Al 2 o 3 Mix, pass hydrogen to a certain pressure, and react at a certain temperature. After the aromatics are completely hydrogenated and saturated, the reaction temperature will be room temperature, and the separated catalyst will be recovered. Catalyst M / Al 2 o 3 M in refers to one or any combination of noble metals such as Ru, Rh, Pd, Pt, Ir, and Al 2 o 3 It is an ordered mesoporous structure. The reaction condition of the invention is mild, and the catalyst exhibits high aromatic hydrogenation activity and stability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A kind of method for catalyzed synthesis of cyclohexanone ethylene glycol ketal by titanium ammonium phosphotungstate compound salt

ActiveCN108191814BIncrease the areaHigh densityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsCyclohexanonePtru catalyst

The invention relates to a method for catalytic synthesis of cyclohexanone ethylene ketal from titanium phosphotungstate and ammonium phosphotungstate composite salt. The titanium phosphotungstate andammonium phosphotungstate composite salt is taken as a catalyst, cyclohexanone ethylene ketal is generated from cyclohexanone and ethylene glycol through a condensation reaction, and the condensed structural formula of the titanium phosphotungstate and ammonium phosphotungstate composite salt is (NH4)xTiyH(3-x-4y)PW12O40, wherein x=0.4-0.6, and y=0.4-0.6. The titanium phosphotungstate and ammonium phosphotungstate composite salt as the catalyst has larger specific surface area, higher surface acid density and proper acid strength, so that the catalyst has excellent catalytic performance, andproduct yield is high. Besides, raw materials of the catalyst are easily available, the preparation process is simple, the catalyst and the product are easy to separate, and the catalyst is recyclable.

Owner:SHAOYANG UNIV

Preparation method of catalyst for co-generating of isopropanol and diisobutyl ketone through acetone hydrogenation and application

ActiveCN102806085BHigh activityImprove stabilityOrganic compound preparationHydroxy compound preparationPtru catalystDiisobutylketone

Owner:CHINA NAT OFFSHORE OIL CORP +1

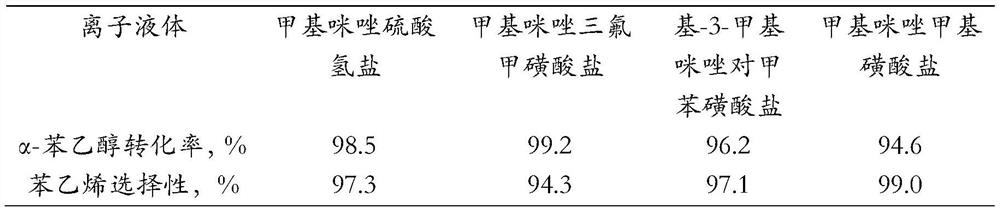

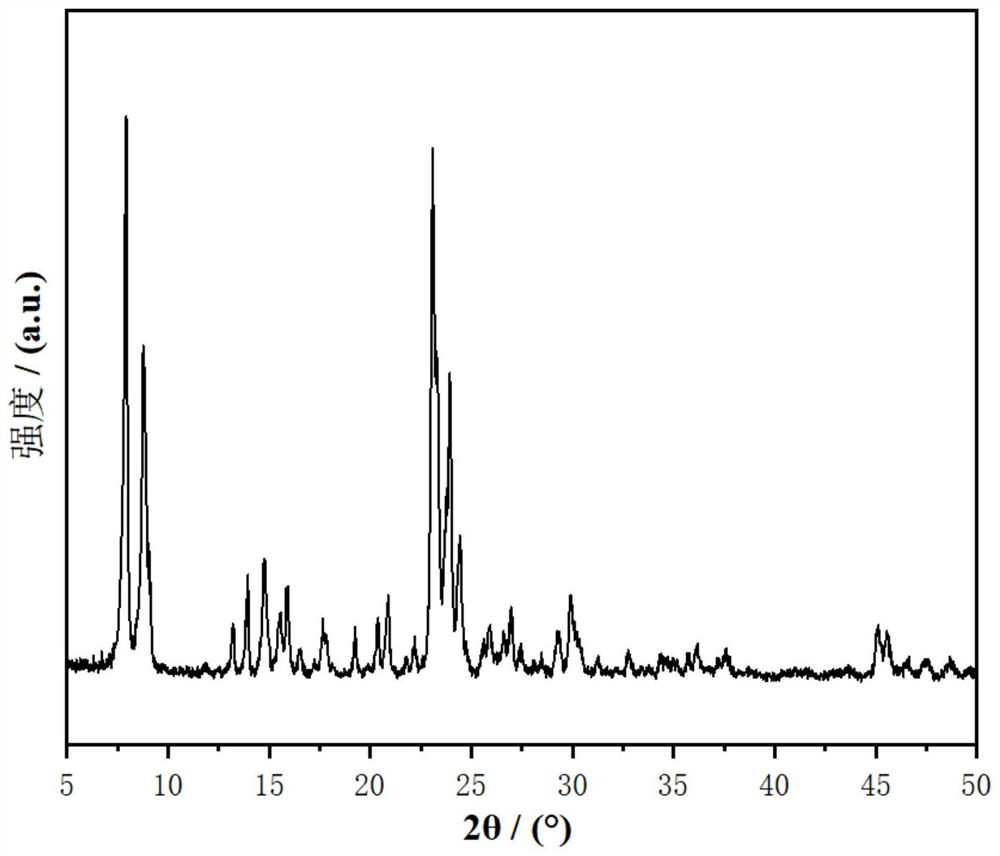

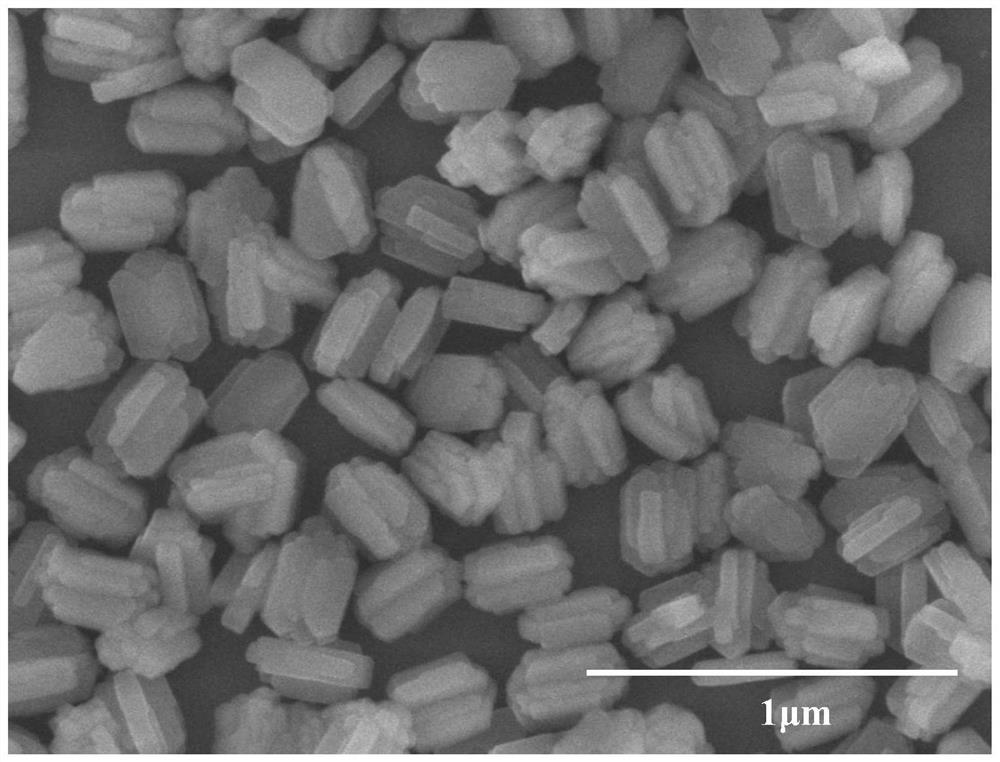

Ga-ZSM-5 catalyst as well as preparation method and application thereof

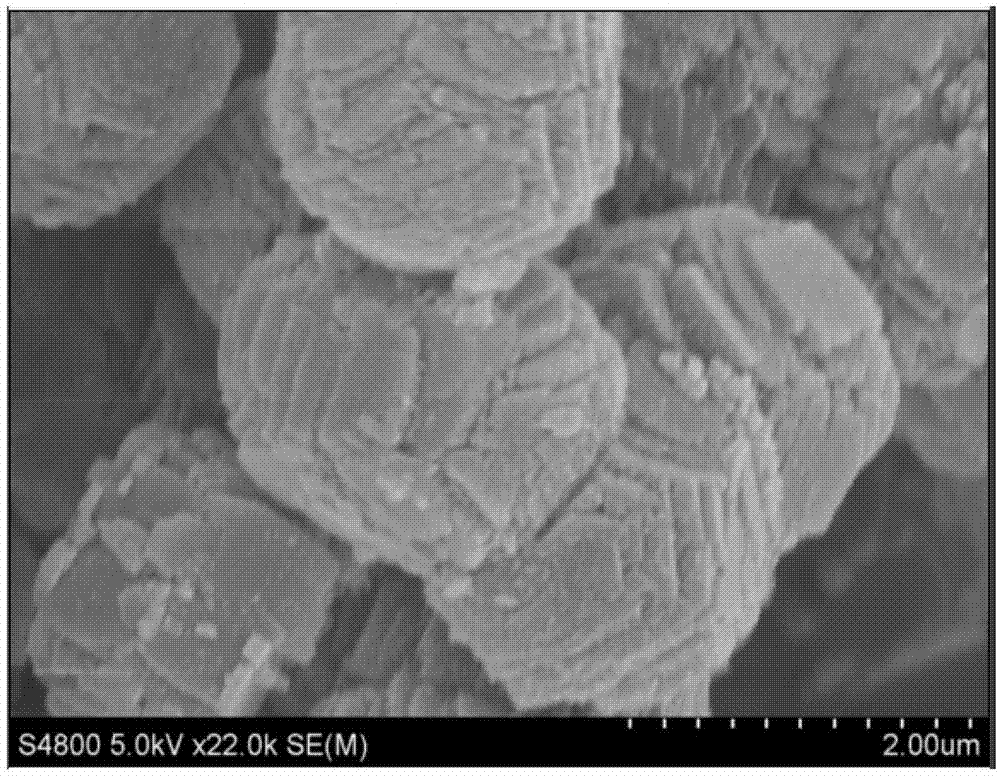

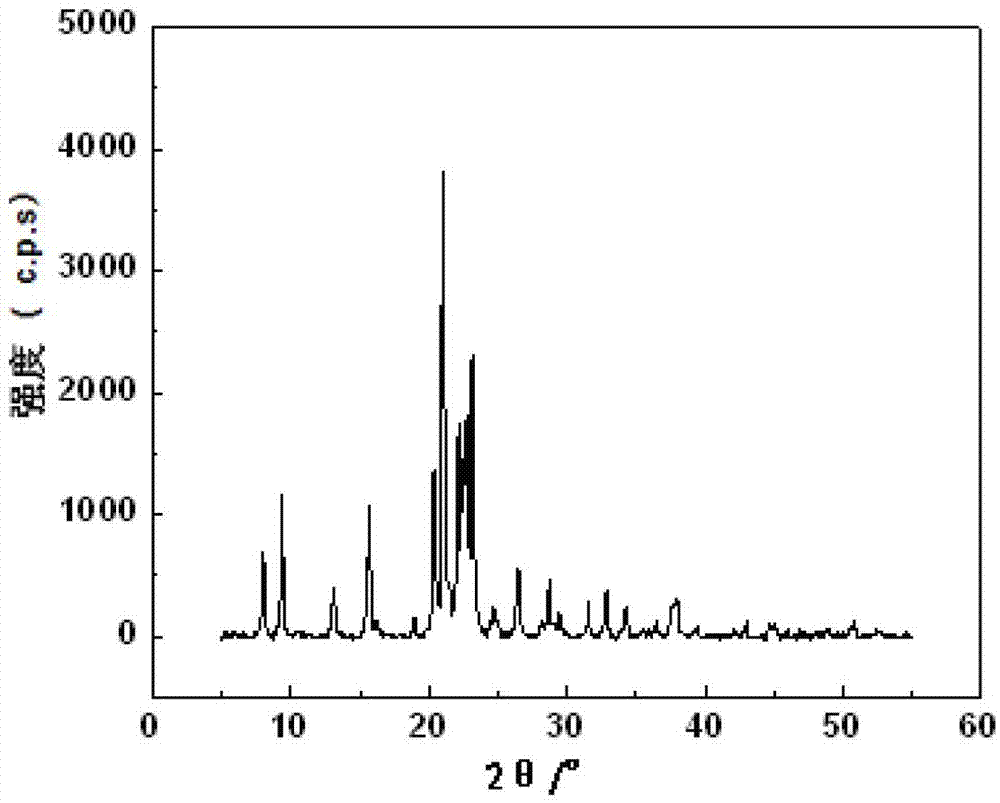

PendingCN113441170AReduce acid strengthModerate acid strengthMolecular sieve catalystsMolecular sieve catalystMolecular sievePtru catalyst

The invention provides a Ga-ZSM-5 catalyst as well as a preparation method and application thereof. The catalyst is of a crisscross sheet structure; and the thickness of the b axis of the Ga-ZSM-5 catalyst is 50 to 500 nm. According to the invention, the structure of the Ga-ZSM-5 molecular sieve is controlled by controlling conditions in the preparation process of the Ga-ZSM-5 catalyst, so the diffusion rate of reactants and products is increased, and the performance of the catalyst is further improved. Moreover, the Ga-ZSM-5 synthesized by the method is of the crisscross sheet structure, and has stable conversion rate, selectivity and longer service life when being used for preparing ethylbenzene through benzene alkylation; and the preparation method provided by the invention also has the advantages of simple process and low cost, and has good industrial prospects.

Owner:CHINA NAT OFFSHORE OIL CORP +4

Method for preparing dimethyl ether

ActiveCN101148397BHigh activityNo decrease in activityCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsActive componentReaction temperature

The present invention relates to process of preparing dimethyl ether, and aims at providing technological scheme of preparing dimethyl ether in lowered reaction temperature, high catalyst efficiency, long service life of catalyst and other merits. The process of preparing dimethyl ether adopts methanol as main material and catalyst with niobium oxide as the main active component and P and / or S as the co-catalyst, and has reaction temperature of 100-350 DEG C and catalyst efficiency of 1-20 ml methanol / hr.g. The present invention may be applied in industrial production of dimethyl ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of method for catalyzing synthesis of furfural ethylene glycol acetal by aluminum ammonium phosphotungstate composite salt

ActiveCN108187744BIncrease the areaHigh densityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystAcid strength

The invention relates to a method for catalyzing the synthesis of furfural glycol acetal by an aluminum ammonium phosphotungstate composite salt. The aluminum ammonium phosphotungstate composite salt is used as a catalyst to generate furfural glycol acetal through a condensation reaction between furfural and ethylene glycol. , the structural simplified formula of the aluminum ammonium phosphotungstate composite salt is: (NH 4 ) x Al y H (3‑x‑3y) PW 12 O 40 , among which, x=0.4~0.6, y=0.6~0.8. The aluminum ammonium phosphotungstate composite salt catalyst involved in the present invention has a high specific surface area and surface acid density, and has appropriate acid strength, resulting in excellent catalytic performance and high product yield. In addition, the raw materials required for the catalyst are easy to obtain, the preparation process is simple, and the catalyst and product are easy to separate and can be reused.

Owner:SHAOYANG UNIV

A kind of method for catalyzing synthesis of ethylene bis-stearamide by quaternary ammonium titanium salt of phosphotungstate

ActiveCN110668966BHigh affinityHigh yieldOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystAcid strength

The invention relates to a method for catalyzing the synthesis of ethylene bisstearamide by quaternary ammonium titanium phosphotungstate, which is characterized in that ethylene bisstearamide is synthesized from stearic acid and ethylenediamine by using quaternary ammonium titanium phosphotungstate as a catalyst. Stearamide, the structural formula of the quaternary ammonium titanium phosphotungstic acid is: wherein, R=-C 16 h 33 , x=0.4~0.6, y=0.4~0.6. The present invention has the advantages that the molecular structure of the involved quaternary ammonium titanium phosphotungstic acid catalyst contains lipophilic groups, has good affinity to raw material stearic acid, has higher specific surface area, suitable acid strength and comparative High surface acid content has excellent catalytic performance for the reaction of synthesizing ethylene bisstearamide, the yield of the product is high, the color is light, and the purity is high.

Owner:湖南雄创新材料科技有限公司

Preparation method of isobutyl ketone synthesis catalyst

ActiveCN102416325BDoes not significantly impact performanceHigh activityOrganic compound preparationCarbonyl compound preparationKetone synthesisHigh activity

Owner:CHINA NAT OFFSHORE OIL CORP +1

Method for synthesizing polyoxymethylene dimethyl ethers

ActiveCN101898943BImprove conversion rateHigh selectivityOrganic chemistryOrganic compound preparationSynthesis methodsStrong acids

Owner:DONGFANG HONGSHENG NEW ENERGY APPL TECH RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com