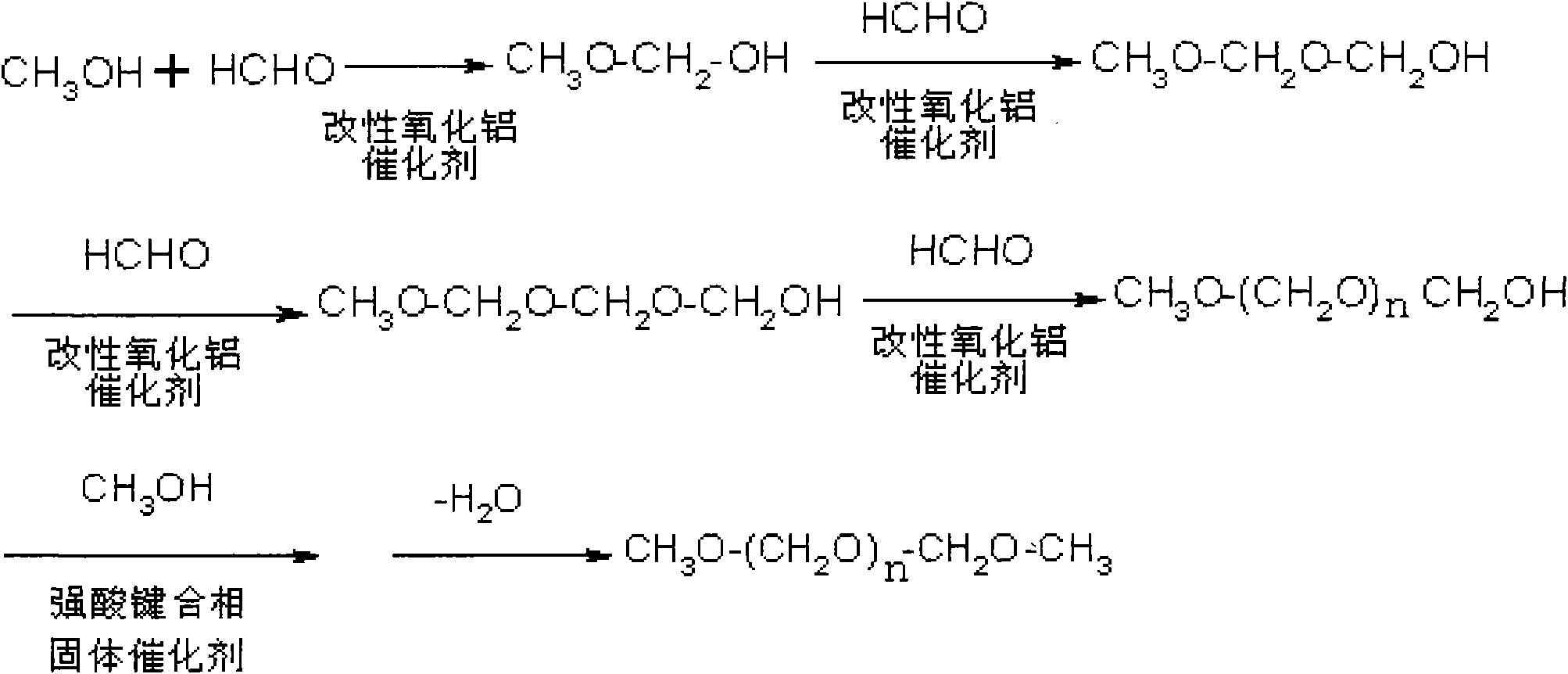

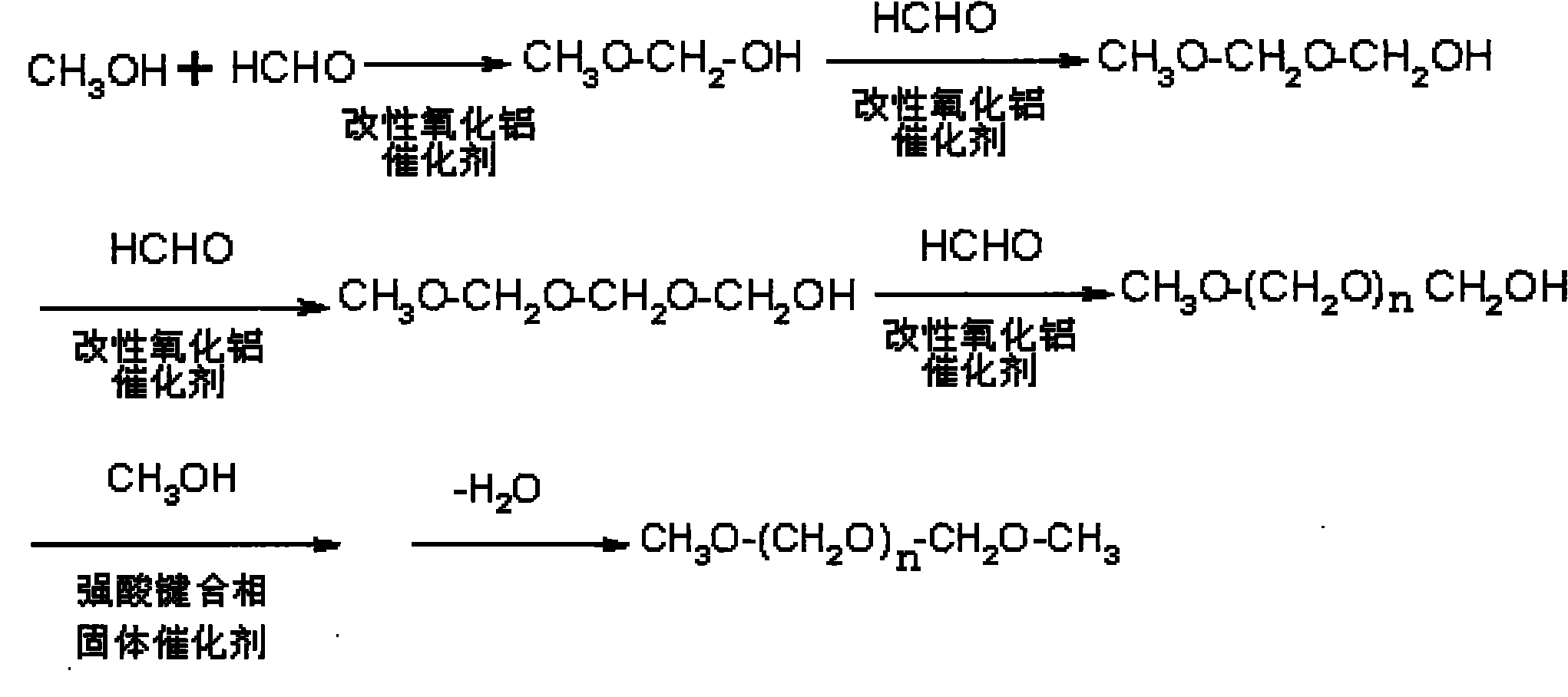

Method for synthesizing polyoxymethylene dimethyl ethers

A technology of dimethyl ether and polyoxymethylene, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as low yield of target products, difficult industrialization of processes, poor product selectivity, etc., and achieve good results Heat stability and solvent stability, ease of handling, effect of improving conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

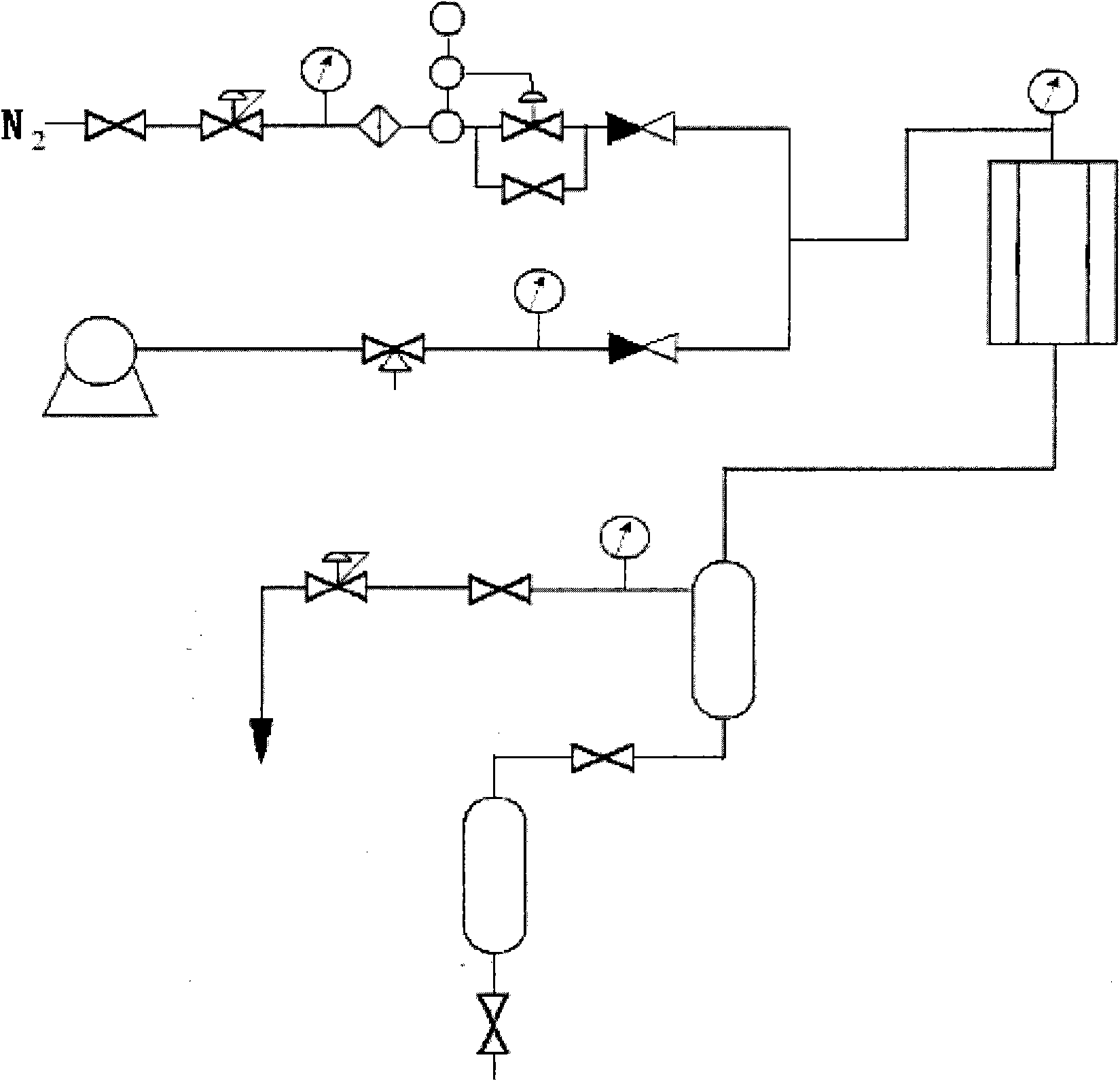

Method used

Image

Examples

Embodiment 1

[0048] Fill the reaction tube with 20-40 mesh H 3 PO 4 Modified γ-Al 2 o 3 -P catalyst, the reaction temperature of the first step is controlled at 60°C, the reaction pressure is 0.5MPa, and the molar ratio of materials is m 甲醛(低聚合度多聚甲醛) :m 甲醇 =10:1, liquid volume hourly space velocity (LHSV) 0.5h -1 ; second step m 多聚半缩醛 :m 甲醇 =10: 3, the catalyst adopts active carbon-based organic strong acid bonded phase solid catalyst, the catalyst accounts for 5wt% of the total material, and cyclohexane is used as a water separating agent, the reaction temperature is 80~90°C, the reaction time is 4h, and the methanol is analyzed by gas chromatography The conversion rate was 91.5%. The relative content (product distribution) of methylal with different n values in the product is: n=1, 19.6%; n=2, 7.6%; n=3-8, 60.9%; n>8, 11.9%.

Embodiment 2

[0050] Fill the reaction tube with 40-60 mesh H 3 BO 3 Modified γ-Al 2 o 3 -B catalyst, the reaction temperature of the first step is controlled at 90°C, the reaction pressure is 4.0MPa, and the molar ratio of the materials is m 甲醛(低聚合度多聚甲醇) :m 甲醇 =10:2, liquid volume hourly space velocity (LHSV) 0.5h -1 ; second step m 多聚半缩醛 :m 甲醇 =10: 2, the catalyzer adopts the solid catalyst of silica gel-based organic strong acid bonded phase, the catalyzer accounts for 0.5wt% of the total material, toluene is used as the water separating agent, the reaction temperature is 90~110°C, the reaction time is 4h, and the methanol is analyzed by gas chromatography The conversion rate is 92.7%; the relative content of methylal in the product (product distribution) n=1, 17.8%; n=2, 12.3%; n=3~8 60.1%; n>8, 9.8%.

Embodiment 3

[0052] Fill the reaction tube with 40-60 mesh HF-modified γ-Al 2 o 3 -F catalyst, the reaction temperature of the first stage is controlled at 90°C, the reaction pressure is 4.0MPa, and the molar ratio of materials is m 甲醛(低聚合度多聚甲醛) :m 甲醇 =10:2, liquid volume hourly space velocity (LHSV) 0.5h -1 ; the second paragraph m 多聚半缩醛 :m 甲醇 =10:2, the catalyst adopts silica gel-based organic strong acid bonded phase solid catalyst, the catalyst accounts for 5wt% of the total material, toluene is used as a water separating agent, the reaction temperature is 90~110°C, the reaction time is 4h, and the conversion of methanol is analyzed by gas chromatography The rate is 92.7%; the relative content of methylal in the product (product distribution) n=1, 14.3%; n=2, 9.2%; n=3~8, 67.1%; n>8, 9.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com