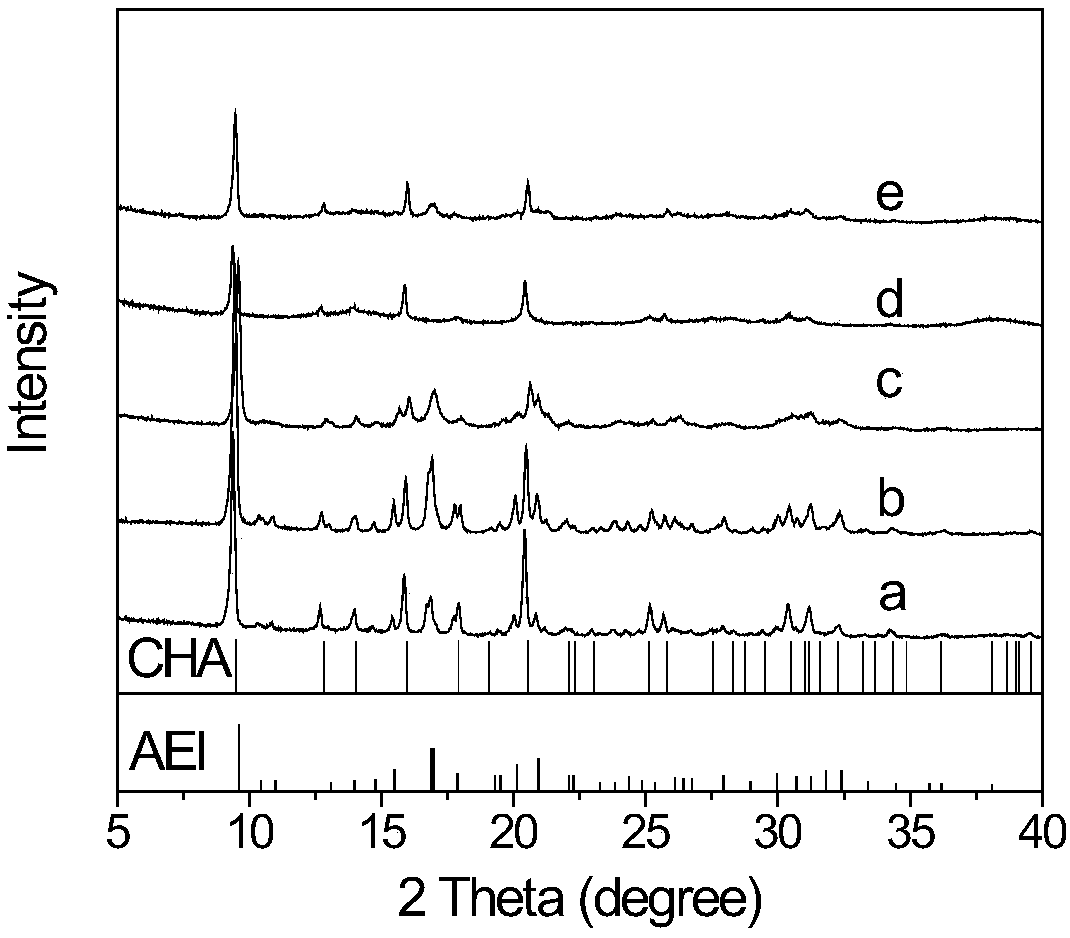

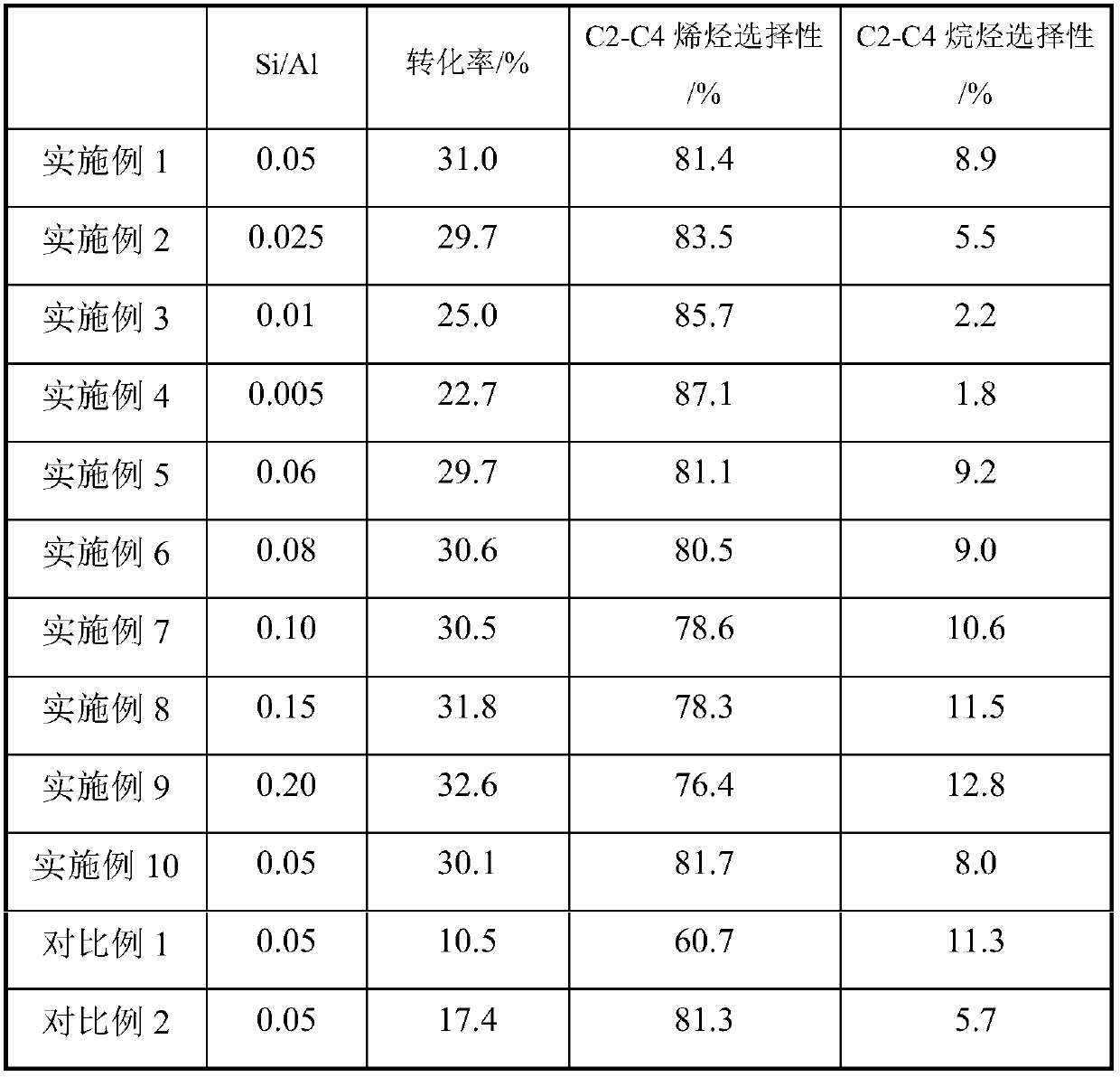

Eutectic nano molecular sieve, preparation method and applications thereof

A nano-molecular sieve and molecular sieve technology, applied in the field of molecular sieves, can solve the problems of low AEI content of synthetic molecular sieve, large amount of expensive template agent, complicated preparation process, etc., and achieve the effects of moderate acid strength, reduced preparation cost and high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Preparation of seed crystals:

[0035] Add 10.2g of aluminum isopropoxide solid powder to 59.9g of tetraethylammonium hydroxide (TEAOH, 25wt%) solution, stir at 25°C for 1h until dissolved and clear; add 11.6g of phosphoric acid (85%) and deionized water to In the above clear solution, continue stirring for 1 h; after the stirring is completed, the mixed solution is placed in a reaction kettle and crystallized at 170° C. for 3 days.

[0036] (2) Synthesis of SAPO-18 / SAPO-34 eutectic molecular sieves:

[0037] 23.1g phosphoric acid (85%), 12.0g pseudo-boehmite aluminum (Al 2 o 3 , 75.8%) was added to a certain amount of deionized water, and stirred until evenly mixed; 1.50g of silica sol (40%) and 20.2g of triethylamine, seed (Al 2 o 3 5.0% meter) etc. were added to the above mixed sol, and the stirring was continued for 1 h until the components were uniformly dispersed; the mixed gel was placed in a reaction kettle and hydrothermally crystallized at 150° C. Af...

Embodiment 2

[0039] (1) seed crystal is prepared by [embodiment 1]:

[0040] Add 10.2g of aluminum isopropoxide solid powder to 59.9g of tetraethylammonium hydroxide (TEAOH, 25wt%) solution, stir at 25°C for 1h until dissolved and clear; add 11.6g of phosphoric acid (85%) and deionized water to In the above clear solution, continue stirring for 1 h; after the stirring is completed, the mixed solution is placed in a reaction kettle and crystallized at 170° C. for 3 days.

[0041] (2) Synthesis of SAPO-18 / SAPO-34 eutectic molecular sieves:

[0042] 23.1g phosphoric acid (85%), 12.0g pseudo-boehmite aluminum (Al 2 o 3 ,75.8%) was added to a certain amount of deionized water, and stirred until uniformly mixed; 0.75g of silica sol (40%) and 20.2g of triethylamine, seed crystals (Al 2 o 3 5.0% meter) etc. were added to the above mixed sol, and the stirring was continued for 1 h until the components were uniformly dispersed; the mixed gel was placed in a reaction kettle and hydrothermally cr...

Embodiment 3

[0044] (1) seed crystal is prepared by [embodiment 1]:

[0045] Add 10.2g of aluminum isopropoxide solid powder to 59.9g of tetraethylammonium hydroxide (TEAOH, 25wt%) solution, stir at 25°C for 1h until dissolved and clear; add 11.6g of phosphoric acid (85%) and deionized water to In the above clear solution, continue stirring for 1 h; after the stirring is completed, the mixed solution is placed in a reaction kettle and crystallized at 170° C. for 3 days.

[0046] (2) Synthesis of SAPO-18 / SAPO-34 eutectic molecular sieves:

[0047] 23.1g phosphoric acid (85%), 12.0g pseudo-boehmite aluminum (Al 2 o 3 , 75.8%) was added to a certain amount of deionized water, stirred until uniformly mixed; 0.30g silica sol (40%) and 20.2g triethylamine, seed crystal (Al 2 o 3 5.0% meter) etc. were added to the above mixed sol, and the stirring was continued for 1 h until the components were uniformly dispersed; the mixed gel was placed in a reaction kettle and hydrothermally crystallized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com