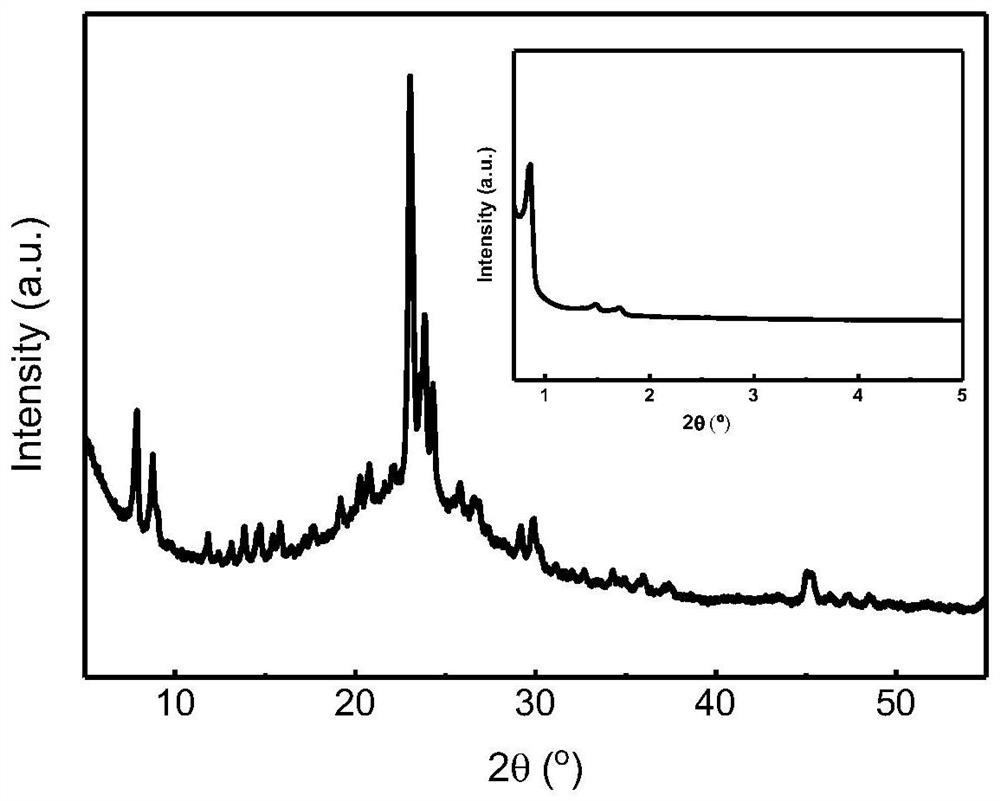

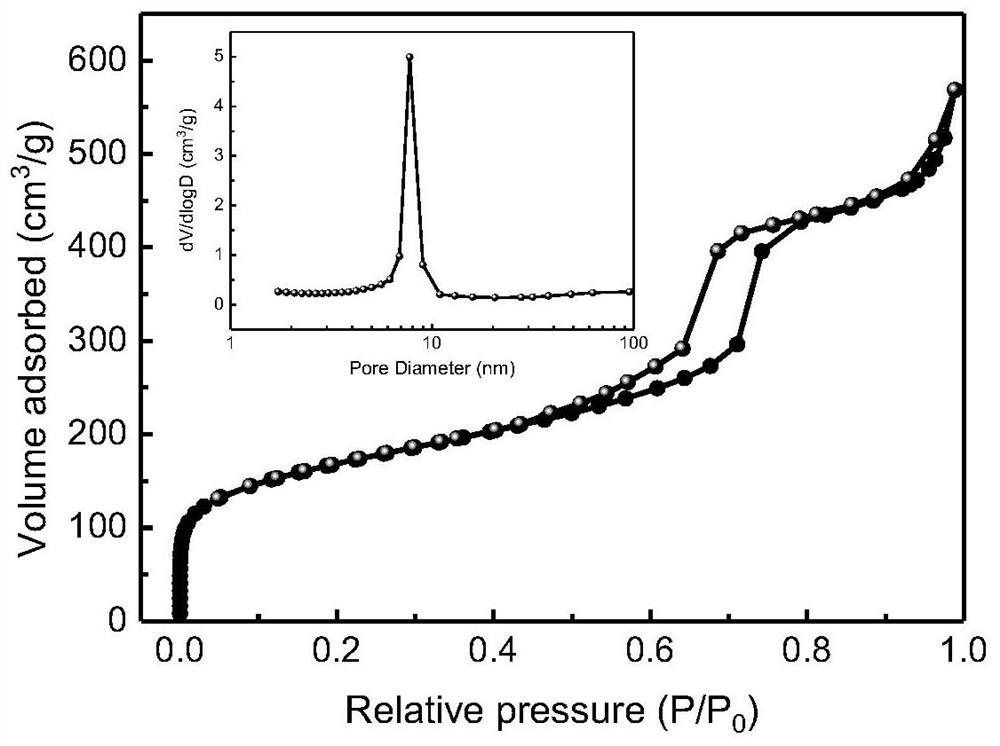

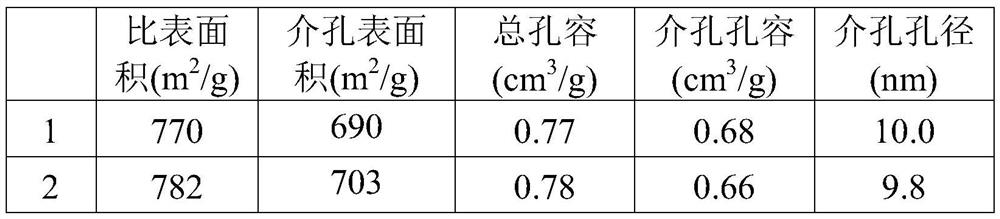

Preparation method of SBA-15/ZSM-5 composite molecular sieve, catalyst and application in double branched chain isomerization

A technology of ZSM-5 and composite molecular sieves, which is applied in molecular sieve catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of low selectivity of double-branched isoparaffins, low yield of isoparaffins, cracking, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] Activation of natural minerals: Weigh 40g of diatomite powder and roast at 800°C for 6h; weigh 80g of retort earth, 80g of sodium hydroxide, and 300g of water, stir mechanically at room temperature for 1h, then activate in an oven at 200°C for 10h, then Crush and set aside.

[0076] Preparation of ZSM-5 nanocrystal precursor solution: Weigh 10g of activated diatomite, 1.8g of activated rectorite, and 1.5g of NaOH, dissolve 0.2g of seed crystal in 60g of deionized water, and then age in a water bath at 80°C for 4h. The mixture was put into a stainless steel crystallization kettle lined with polytetrafluoroethylene, heated to 170°C for static crystallization for 24h. Cool to room temperature after crystallization, stir evenly and set aside.

[0077] Pre-hydrolysis of silicon-aluminum source of composite material: Add 5 g of the above-mentioned nanocrystalline precursor solution and 5 g of tetraethyl orthosilicate to 18 g of hydrochloric acid solution, then adjust the pH ...

Embodiment 2

[0082] This embodiment provides a SBA-15 / ZSM-5 composite molecular sieve carrier material, the preparation steps are the same as in Example 1, only some parameters are adjusted, as follows:

[0083] Preparation of ZSM-5 nanocrystalline precursor solution: Weigh 8.5g of activated diatomite, 2.7g of 600°C activated bauxite, and 1.3g of NaOH, dissolve 0.14g of seed crystals in 60g of deionized water, and then °C for aging in a water bath for 4 hours, put the mixture into a stainless steel crystallization kettle lined with polytetrafluoroethylene, and raise the temperature to 170°C for static crystallization for 24 hours. Cool to room temperature after crystallization, stir evenly and set aside.

[0084] Pre-hydrolysis of silicon-aluminum source of composite materials: Add 5 g of the above-mentioned nanocrystalline precursor solution and 4.2 g of methyl orthosilicate to 18 g of hydrochloric acid solution, then adjust the pH value of the solution to 4, perform pre-hydrolysis at 60 ...

Embodiment 3

[0089] This embodiment provides a SBA-15 / ZSM-5 composite molecular sieve carrier material, the preparation steps are the same as in Example 1, only some parameters are adjusted, as follows:

[0090] Preparation of ZSM-5 nanocrystalline precursor solution: Weigh 6.9g of activated diatomite, 1g of bauxite activated at 600°C, 1.5g of rectorite, and 0.8g of NaOH, and dissolve 0.17g of seed crystals in 60g of deionized water, and then aged in a water bath at 80°C for 4h, the mixture was put into a stainless steel crystallization kettle with a polytetrafluoroethylene liner, and the temperature was raised to 170°C for static crystallization for 24h. Cool to room temperature after crystallization, stir evenly and set aside.

[0091] Pre-hydrolysis of the silicon-aluminum source of the composite material: add 5 g of the above-mentioned nanocrystalline precursor solution and 4 g of methyl orthosilicate to 20 g of hydrochloric acid solution, then adjust the pH value of the solution to 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com