Preparation method of 2,6-DiMethylnaphthalene (DMN) by using SAPO-11 molecular sieve

A technology of SAPO-11 and dimethylnaphthalene, applied in molecular sieve catalysts, chemical instruments and methods, condensation between hydrocarbons and non-hydrocarbons, etc., can solve the problems that catalysts cannot have high activity at the same time, catalysts are easy to deactivate, etc. , to facilitate large-scale production, good catalytic stability, and reduce synthesis costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0022] Specific embodiment one: the method for preparing 2,6-dimethylnaphthalene by a kind of SAPO-11 molecular sieve of the present embodiment is to carry out according to the following steps: one, SAPO-11 molecular sieve is put into the catalyst bed layer of fixed bed reactor , activate at 500°C~600°C for 2h; 2. Mix naphthalene, alkylating agent and solvent evenly to obtain the raw material liquid, and use a metering pump to continuously inject the raw material liquid into the catalyst bed of the fixed-bed reactor in step 1 , and at a temperature of 350°C~450°C, a pressure of 2~5MPa, and a mass space velocity of 0.5~2h -1 , under the condition that the carrier gas flow rate is 20~60mL / min, carry out the alkylation reaction for 1~24h to obtain 2,6-dimethylnaphthalene; wherein, the molar ratio of naphthalene to alkylation reagent is 1:2~ 4. The molar ratio of naphthalene to solvent is 1:6~12.

[0023] This embodiment includes the following beneficial effects:

[0024] 1. The...

specific Embodiment approach 2

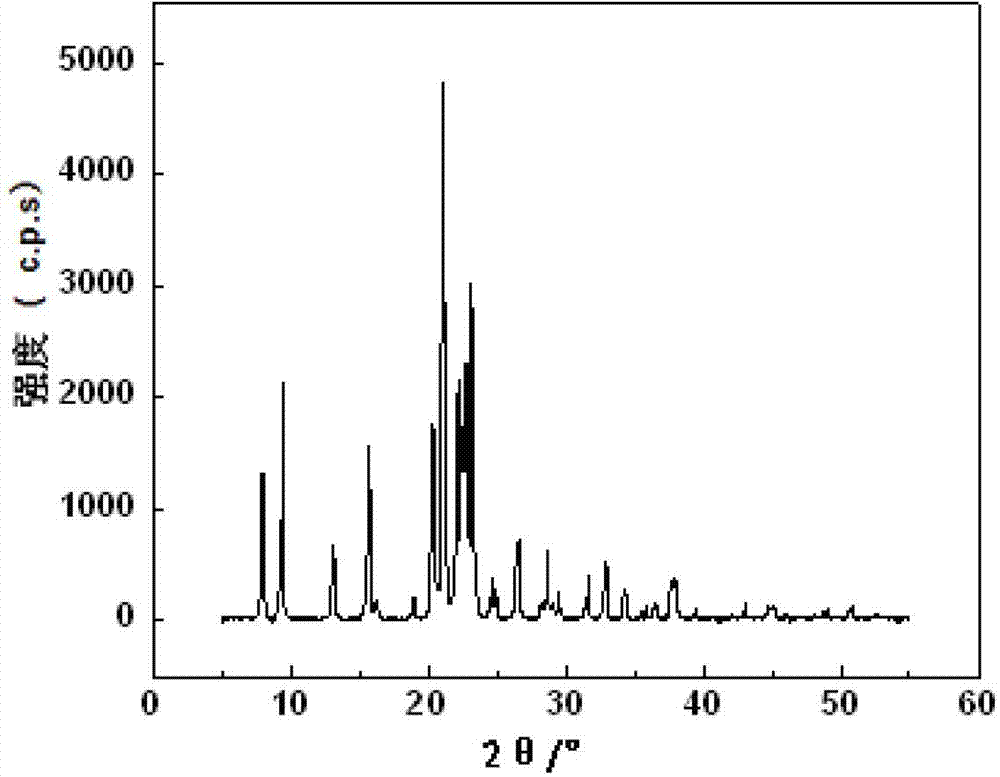

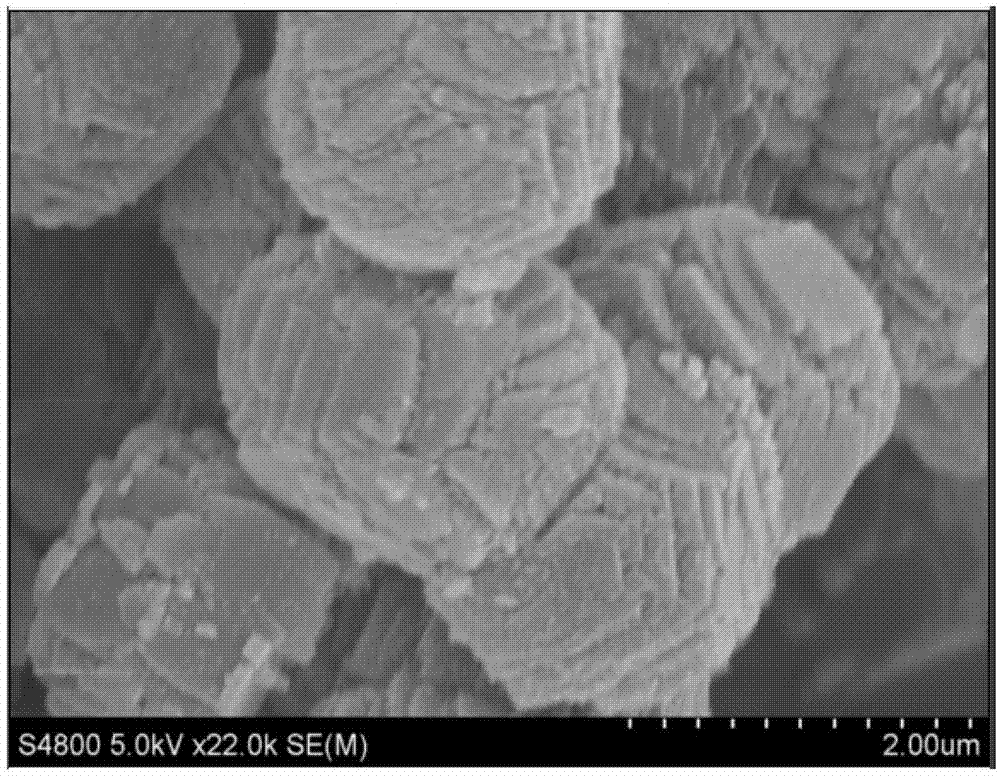

[0029] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the prepared SAPO-11 molecular sieve described in step 1 is synthesized in the water system by means of microwave heating, and the specific steps are as follows: 2 o 3 :SiO2 2 :P 2 o 5 :DPA:H 2 The O molar ratio is 1:0.2~1.2:1:1:40 and the ratio is evenly stirred to obtain a gel. Put the polytetrafluoroethylene lining with the gel into the ceramic outer lining, and then put it into a microwave oven. With a power of 600W and a temperature of 160°C~180°C, crystallize for 0.5~4h to obtain a solid-liquid mixture; then wash the solid phase obtained by filtration and dry it at a temperature of 110°C for 12h. Then calcined at 650°C for 7 hours to obtain SAPO-11 molecular sieve. Others are the same as in the first embodiment.

specific Embodiment approach 3

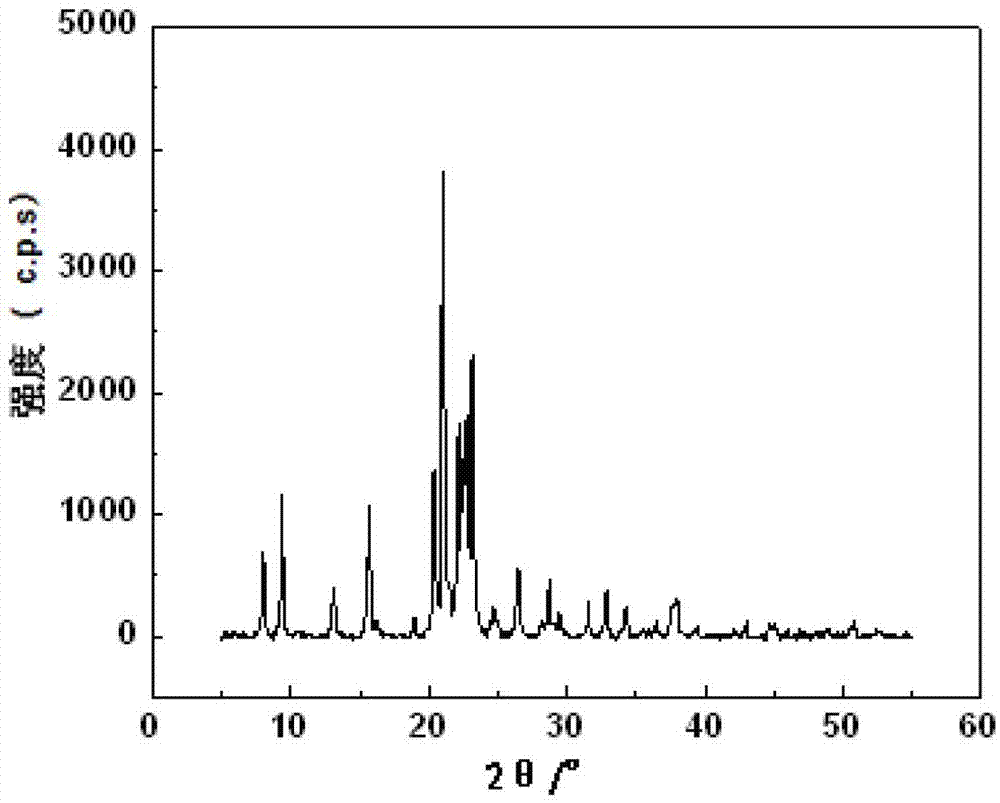

[0030] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the SAPO-11 molecular sieve described in step 1 is synthesized in alcohol-water system by traditional electric heating method, and the specific steps are as follows: press Al 2 o 3 :SiO2 2 :P 2 o 5 :DPA:C 2 h 5 OH:H 2 O molar ratio is 1:0.2~1.2::1:1:10:(10~100) Stir evenly to get gel, put the polytetrafluoroethylene lining with gel into the stainless steel outer lining, Then put it into an oven, and crystallize for 12-48 hours at a temperature of 160°C~180°C to obtain a solid-liquid mixture; then wash the solid phase obtained by filtration, and dry it at a temperature of 110°C 12h, and then calcined at 650°C for 7h to obtain SAPO-11 molecular sieve. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com