Catalyst for preparing styrene by phenylethanol dehydration as well as preparation and application methods of catalyst

An application method and catalyst technology, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of catalyst activity decline, etc., and achieve easy operation and reduce the occurrence of side reactions of carbon deposition in styrene Probability, effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0024] (1) Weigh aluminum nitrate (Al(NO 3 ) 3 "9H 2 O) 20g and zirconium oxychloride (ZrOCl 2 "8H 2 (0) 6.3g, dissolved in 200mL deionized water;

[0025] (2) Add 1-butyl-3-methylimidazolium bromide (2.0g) and 1-butanesulfonate-3-methylimidazolium bisulfate (8.0g) to the solution obtained in step (1);

[0026] (3) Add 5 g of urea to the mixture obtained in step (2), and react at 60° C. for 3 hours;

[0027] (4) centrifuging the mixture obtained in step (3), and washing the obtained gel with deionized water until the pH value of the washing solution is <8;

[0028] (5) Put the gel obtained in step (4) into an oven, dry at 100° C. for 12 hours, and then bake at 500° C. for 5 hours to obtain a Zr—Al catalyst.

preparation Embodiment 2~4

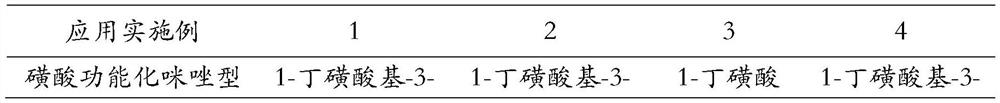

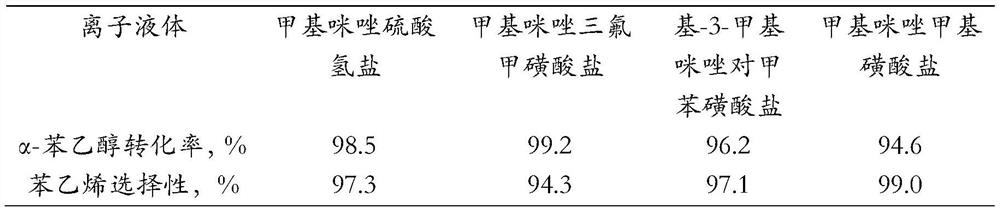

[0033] The same as the preparation method of Preparation Example 1, just change the sulfonic acid functionalized imidazole type ionic liquid in step (2) to be 1-butanesulfonic acid group-3-methylimidazole trifluoromethanesulfonate, 1-butanesulfonic acid Base-3-methylimidazole p-toluenesulfonate and 1-butanesulfonate-3-methylimidazole methanesulfonate to prepare the respective required Zr-Al catalysts of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com