A kind of method for catalyzing synthesis of ethylene bis-stearamide by compound doped heteropoly acid salt

A technology of ethylene bisstearamide and heteropolyacid salt, which is applied in the field of catalyzed synthesis of ethylene bisstearamide by composite doping of heteropolyacid salt, which can solve the impact of product quality and application, product whiteness needs to be improved, product Yellowing and other problems, to achieve excellent catalytic performance, good affinity, light color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

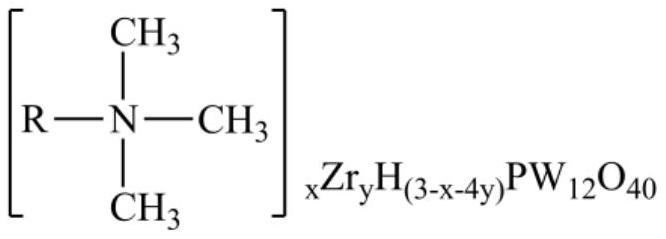

[0016] Preparation of catalyst: 0.5 mmol cetyltrimethylammonium chloride, 0.5 mmol zirconium nitrate and 1 mmol phosphotungstic acid were weighed and dissolved in 20 ml of deionized water, respectively; after complete dissolution, at room temperature and under continuous stirring conditions , first slowly add the cetyltrimethylammonium chloride solution dropwise to the phosphotungstic acid solution, and then continue to slowly add the zirconium nitrate solution dropwise to gradually form a white precipitate; after the dropwise addition, continue to stir for 0.5 h, Set to age for 1 h. After the white precipitate is separated by filtration and dried, the molecular formula is [(C 16 H 33 )N(CH 3 ) 3 ] 0.5 Zr 0.5 H 0.5 PW 12 O 40 of complex doped heteropolyacid salts.

Embodiment 2

[0018] The preparation of catalyst: the preparation process is the same as in Example 1, only the addition of cetyltrimethylammonium chloride is changed to 0.4 mmol, and the addition of zirconium nitrate is changed to 0.6 mmol, and the available molecular formula is [(C 16 H 33 )N(CH 3 ) 3 ] 0.4 Zr 0.6 H 0.2 PW 12 O 40 of complex doped heteropolyacid salts.

Embodiment 3

[0020] The preparation of catalyst: the preparation process is the same as in Example 1, only the addition of cetyltrimethylammonium chloride is changed to 0.6 mmol, and the addition of zirconium nitrate is changed to 0.4 mmol, and the available molecular formula is [(C 16 H 33 )N(CH 3 ) 3 ] 0.6 Zr 0.4 H 0.8 PW 12 O 40 of complex doped heteropolyacid salts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com