Method for preparing ethylene glycol by ethylene one-step method

A technology of ethylene glycol and ethylene, which is applied in the field of one-step preparation of ethylene glycol from ethylene, which can solve the problems of easy loss of aluminum elements, high energy consumption for separation, and low effective utilization rate of hydrogen peroxide.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0033] In order to develop a new process for the one-step production of ethylene glycol from ethylene with low energy consumption, less carbon emissions, and high product concentration of ethylene glycol, the invention provides a method for preparing ethylene glycol in one step from ethylene, which includes preparing ethylene glycol The steps: specifically, under acidic reaction conditions, ethylene, hydrogen peroxide and titanium-silicon molecular sieves are contacted in water to carry out oxidation and hydration reaction to obtain ethylene glycol.

[0034] In the above-mentioned step of preparing ethylene glycol, the acidic reaction conditions are provided by non-zeolite molecular sieves; preferably, the acidic reaction conditions are provided by non-zeolite molecular sieves and water, which can be understood as that the acidic reaction conditions are provided by non-zeolite molecular sieves. The acidic environment provided by zeolite molecular sieve and water, further, the a...

Embodiment 1

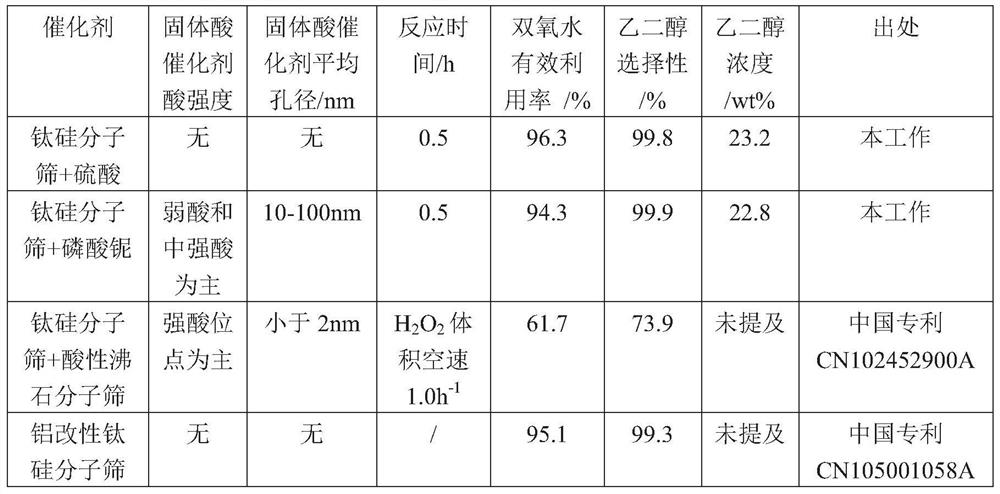

[0068] The reaction is carried out in a reactor, and the catalyst is a hollow titanium-silicon molecular sieve, which is a commercially available industrial product of the molecular sieve described in CN1301599A. The specific reaction conditions are: 0.1g hollow titanium silicon molecular sieve (HTS) catalyst, 8g 30wt% hydrogen peroxide, 8g water, 0.2g sulfuric acid, 50°C, 1.5MPa ethylene, 0.5h. The effective utilization rate of hydrogen peroxide is 96.3%, the selectivity of ethylene glycol is 99.8%, and the mass fraction of ethylene glycol is 23.2%.

Embodiment 2

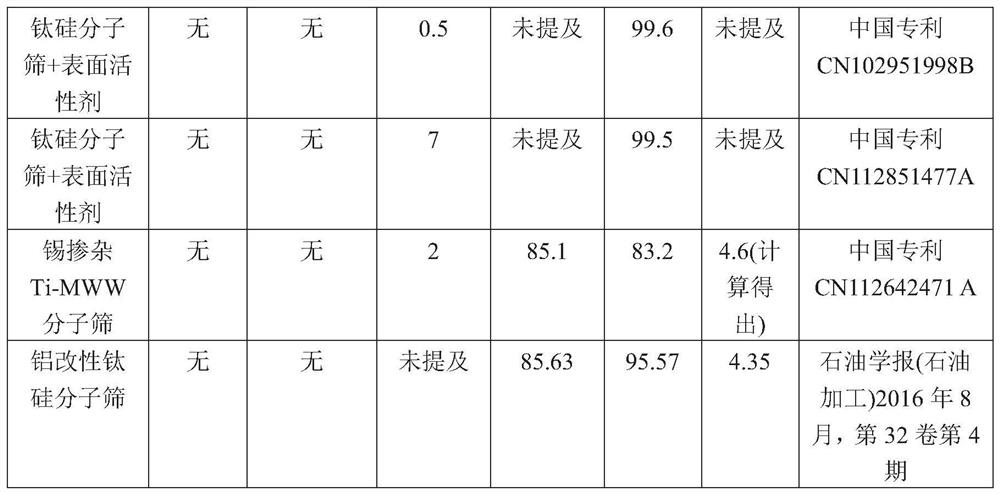

[0070] The reaction is carried out in a reactor, and the catalyst is a hollow titanium-silicon molecular sieve, which is a commercially available industrial product of the molecular sieve described in CN1301599A. The specific reaction conditions are: 0.1g hollow titanium silicon molecular sieve (HTS) catalyst, 8g 30wt% hydrogen peroxide, 8.2g water, 1g niobium phosphate, 50°C, 1.5MPa ethylene, 0.5h. The effective utilization rate of hydrogen peroxide is 94.3%, the selectivity of ethylene glycol is 99.9%, and the mass fraction of ethylene glycol is 22.8%. Compared with the existing patent literature, the reaction time and ethylene glycol concentration are greatly improved, and compared with the ethylene oxide hydration process, it is also improved.

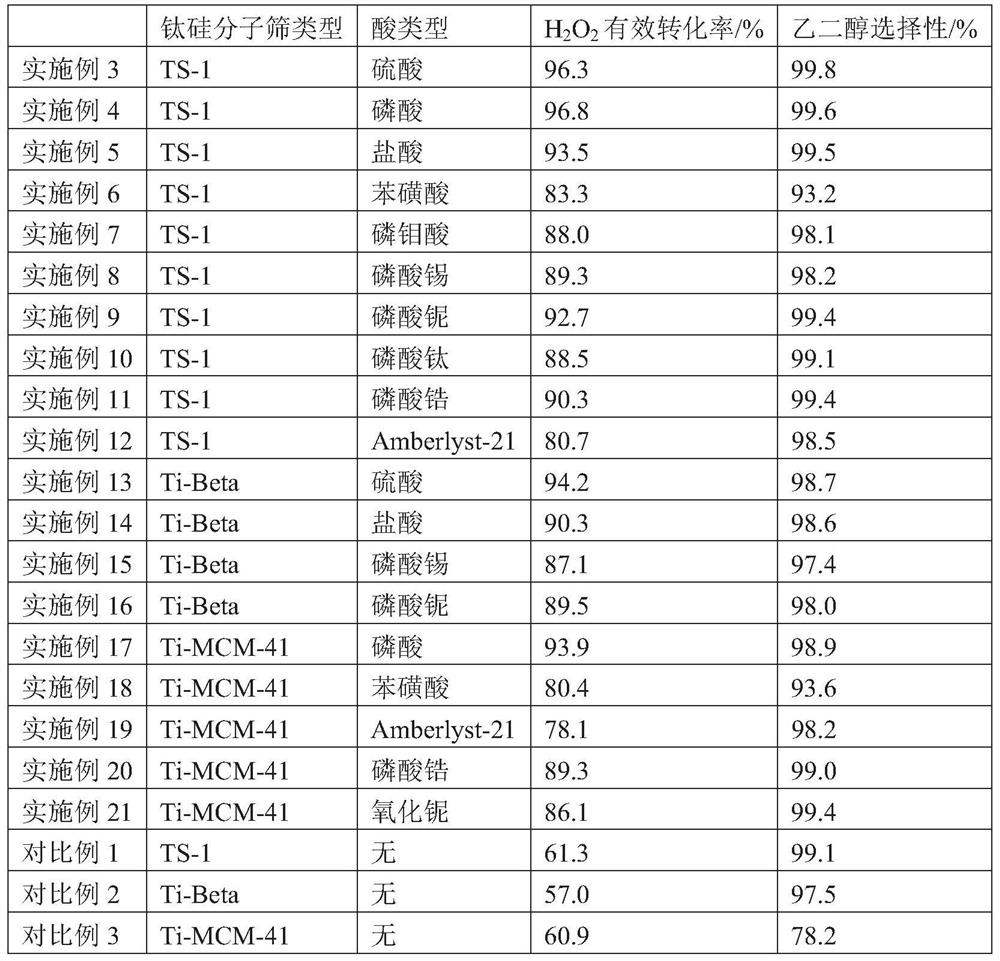

[0071] The following examples are intended to illustrate that the addition of homogeneous or heterogeneous acids has a universal effect on the one-step preparation of ethylene glycol catalyzed by different types of titanium-silicon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com