Method for preparing propylene glycol ether

A technology of propylene glycol ether and aliphatic alcohol, applied in the field of preparation of propylene glycol ether, can solve the problems of product yield, isomer ratio not reaching an ideal state, low catalyst stability, etc., achieving high selectivity, excellent reaction performance, stable good effect

Active Publication Date: 2010-12-01

CHINA PETROLEUM & CHEM CORP +1

View PDF6 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The technical problem to be solved by the present invention is the low stability of the catalyst in the prior art, the defect that the product yield and the ratio of isomers cannot reach the ideal state, and a new preparation method of propylene glycol ether is provided, which has the advantages of high catalyst activity, stable Good performance, but also has the advantages of propylene glycol ether selectivity and high isomer ratio

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

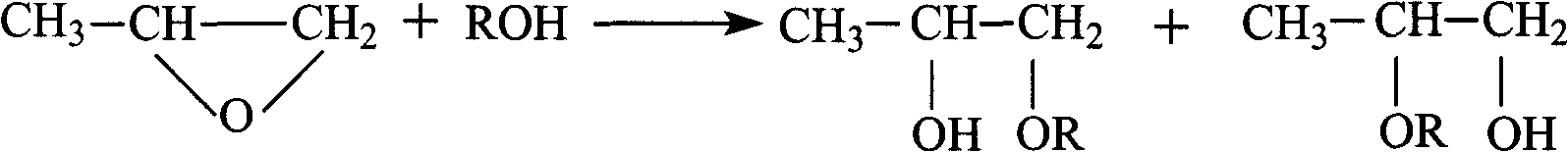

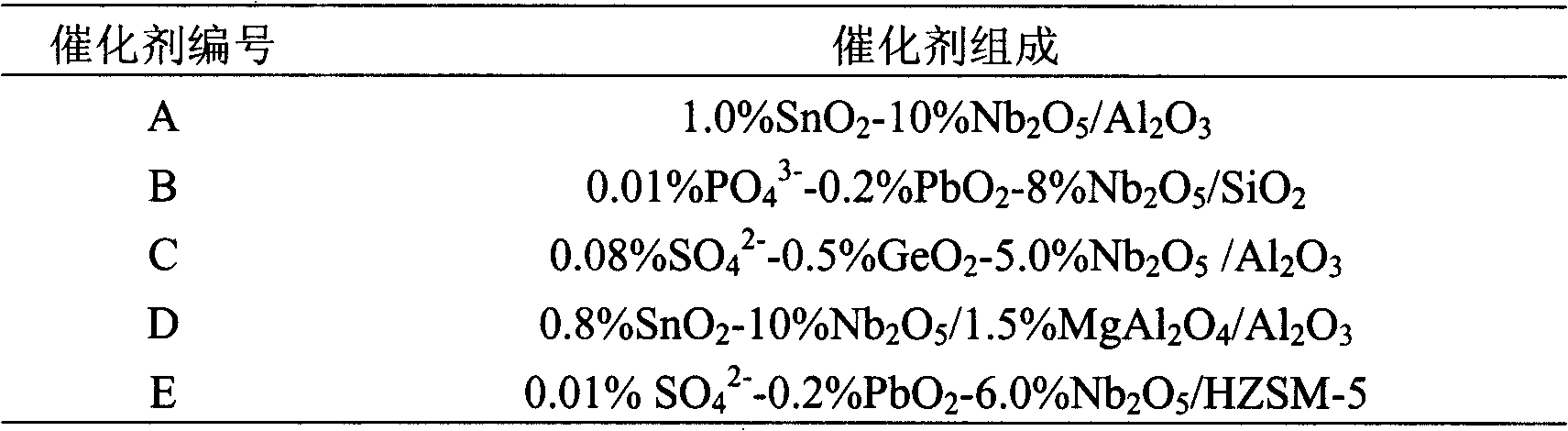

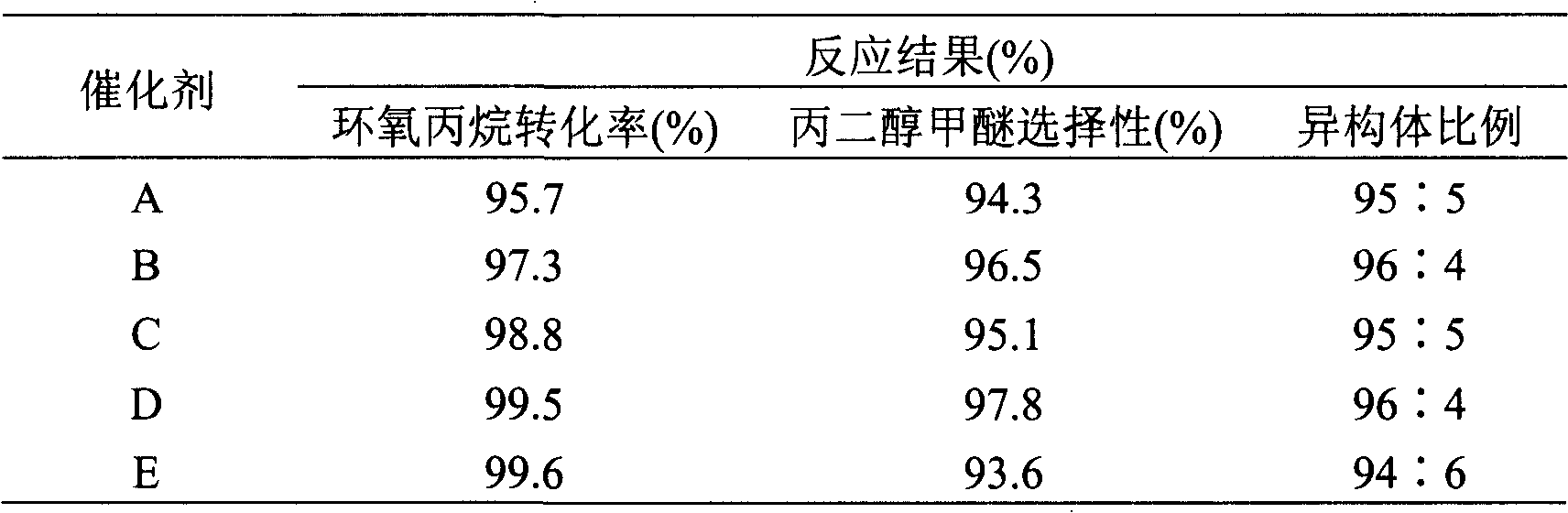

The invention relates to a propylene glycol ether preparation method, mainly solving the shortcomings that catalyst of the prior art has low stability and imperfect products yield and isomers proportion. The invention adopts epoxy propane and higher fatty alcohol as materials, adopts niobium oxide as a main activated component, and chooses at least one of elements or oxides of Ge, Sn, Pb, P or S as auxiliary agent to form the catalyst, to prepare propylene glycol ether under the temperature of 100 to 300 DEG C, reaction pressure 1.0 to 3.0MPa, lower fatty alcohol / epoxy propane ratio 1-10: 1,liquid space velocity 1.0 to 4.0 hour<-1>. The technical proposal can well solve the problem, and has epoxy propane conversion rate higher than 98 percent, propylene glycol ether selectivity higher than 95 percent, and isomers proportions higher than 95: 5. The method of the invention can achieve comparatively high product yield and isomers proportion, and has the advantages of small energy consumption, low production cost, environmental protection and free of device corrosion, and can be used for industrial production of the propylene glycol ether.

Description

The preparation method of propylene glycol ether technical field The invention relates to a method for preparing propylene glycol ether, in particular to a method for preparing propylene glycol ether by reacting propylene oxide and low-carbon fatty alcohol. Background technique Propylene glycol ether has become one of the advanced solvents in fine chemicals due to its unique chemical structure and dual functions of lipophilicity and hydrophilicity. It is called a universal solvent and is widely used due to its low toxicity. The main varieties are propylene glycol methyl ether (PM), propylene glycol ethyl ether (PE), and propylene glycol butyl ether (PB) series. The synthesis of propylene glycol ether mainly includes the Williamson method, the acetal method, the ethoxypropylene oxide method and the propylene oxide method, among which the propylene oxide method is the most widely and deeply studied, and industrialized production has been realized. There are two main types o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C07C43/10C07C41/03B01J23/22B01J27/195B01J27/053B01J32/00

Inventor 李应成何文军何立王嘉华

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com