Method for producing isopropylbenzene through transalkylation

A technology of transalkylation and cumene, applied in the production of bulk chemicals, chemical instruments and methods, hydrocarbons, etc., can solve the problems of unsatisfactory catalytic effect and achieve the effect of low reaction temperature and high space velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

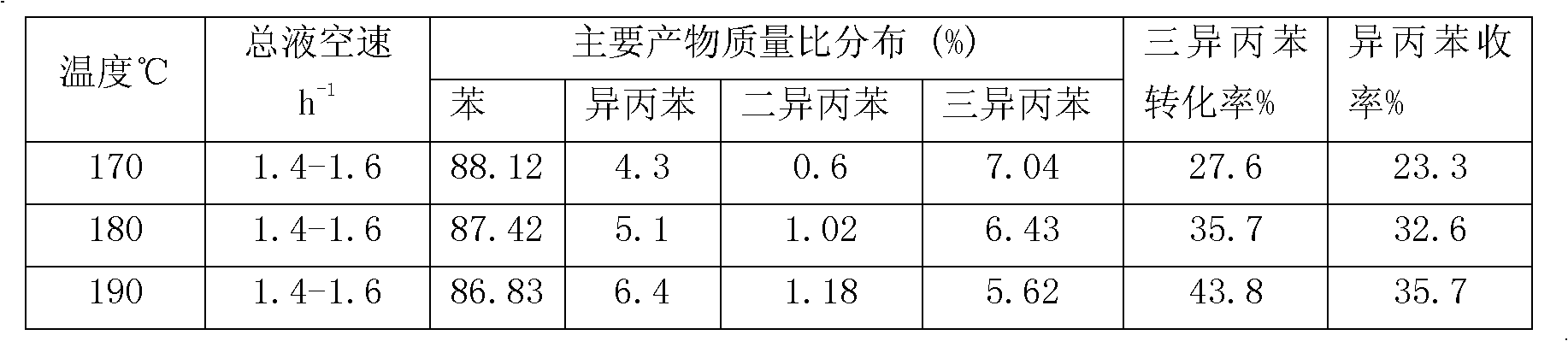

Embodiment 1

[0025] Preparation of the catalyst: weighing HMCM-49 / Hβ mass ratio is 45% Hβ / HMCM-49 composite molecular sieve former powder 75g (developed by the research institute of Jilin Petrochemical Company), SB powder 25g, safflower powder 2.0g, formazan Base cellulose 3.5g, mix evenly with 120ml of 15% nitric acid, roll for 20 minutes; carry out granulation; carry out extruding in extruder, wet strip material is placed on the enamel plate, put into oven, heat up to 130 ℃, dry After drying for 5.5 hours, roast in a muffle furnace: from room temperature to 120°C for 30 minutes; at 120°C for 20 minutes; from 120°C to 400°C for 40 minutes; at 400°C for 30 minutes; from 400°C to 580°C ℃ for 30 minutes, then keep the temperature for 300 minutes; cool down to room temperature naturally to prepare the catalyst. Catalyst activity evaluation: put the catalyst into a tubular reactor with a diameter of Φ25*2*900mm, and carry out the reaction of triisopropylbenzene and benzene, the mass percentage...

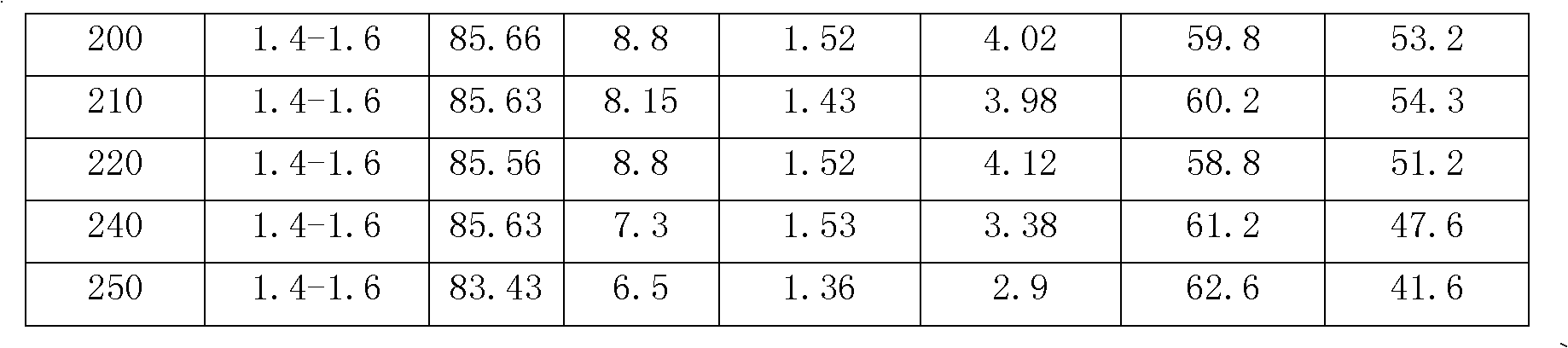

Embodiment 2

[0030] Catalyst preparation: weighing HMCM-49 / H β mass ratio is 58% H β / HMCM-49 composite molecular sieve former powder 75g (developed by the research institute of Jilin Petrochemical Company), SB powder 12g, ammonium phosphate 8g, Sesame powder 1.5g, citric acid 2g. Mix evenly with 125ml of 15% nitric acid aqueous solution, roll on a roller compactor for 30 minutes, granulate with a granulator, extrude in a extruder, place the wet strip on an enamel plate, and dry at 120°C for 5 hours ; After drying, move to the roasting tray and roast in the muffle furnace, from room temperature to 120 ° C for 30 minutes; at 120 ° C for 20 minutes; from 120 ° C to 400 ° C for 40 minutes; at 400 ° C for 30 minutes; from 400 The temperature was raised to 560°C for 30 minutes, and then kept at a constant temperature for 300 minutes; the temperature was naturally cooled to room temperature to prepare the catalyst.

[0031] Catalyst activity evaluation: put the catalyst into a tubular reactor, t...

Embodiment 3

[0035] Preparation of the catalyst: Weigh 75g of HMCM-49 / Hβ mass ratio of 72% Hβ-HMCM-49 composite molecular sieve powder (developed by Jilin Petrochemical Company Research Institute), 18g of SB powder, 2g of boric acid, 2.5g of Sesame powder g, oxalic acid 1.5g, stir evenly with 130ml of 15% phosphoric acid aqueous solution, rolled on roller compactor for 30 minutes, carried out granulation with granulator, extruded strip at extruder, wet strip material is placed on the enamel dish, in Dry at 120°C for 6 hours; after drying, move to a baking tray and roast in a muffle furnace from room temperature to 120°C for 30 minutes; at 120°C for 20 minutes; from 120°C to 400°C for 40 minutes; at 400°C The temperature was kept constant for 30 minutes; the temperature was raised from 400°C to 545°C for 30 minutes, and then the temperature was kept constant for 300 minutes; the temperature was naturally lowered to room temperature to prepare the catalyst.

[0036] Catalyst activity evaluat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com