New method for hydrogenation saturation of aromatic hydrocarbons

A technology for hydrogenation of aromatics and aromatics, applied in the field of hydrogenation and saturation of aromatics, can solve problems such as irregular pore size distribution, and achieve the effects of easy separation and recovery, high service life, and reduced operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Catalyst preparation:

[0023] a. Weigh 2.0g of P123 and dissolve it in 40ml of absolute ethanol, add dropwise 3ml of concentrated nitric acid with a mass concentration of 65%, add 4.08g of aluminum isopropoxide under vigorous stirring, and continue stirring for 5 Hour. Then, the resulting solution was evaporated to dryness of ethanol at 60°C and aged for 48 hours to obtain a pale yellow solid. The pale yellow solid was raised from room temperature to 400° C. at a heating rate of 1° C. / min in a muffle furnace, and calcined for 4 hours to obtain supported alumina.

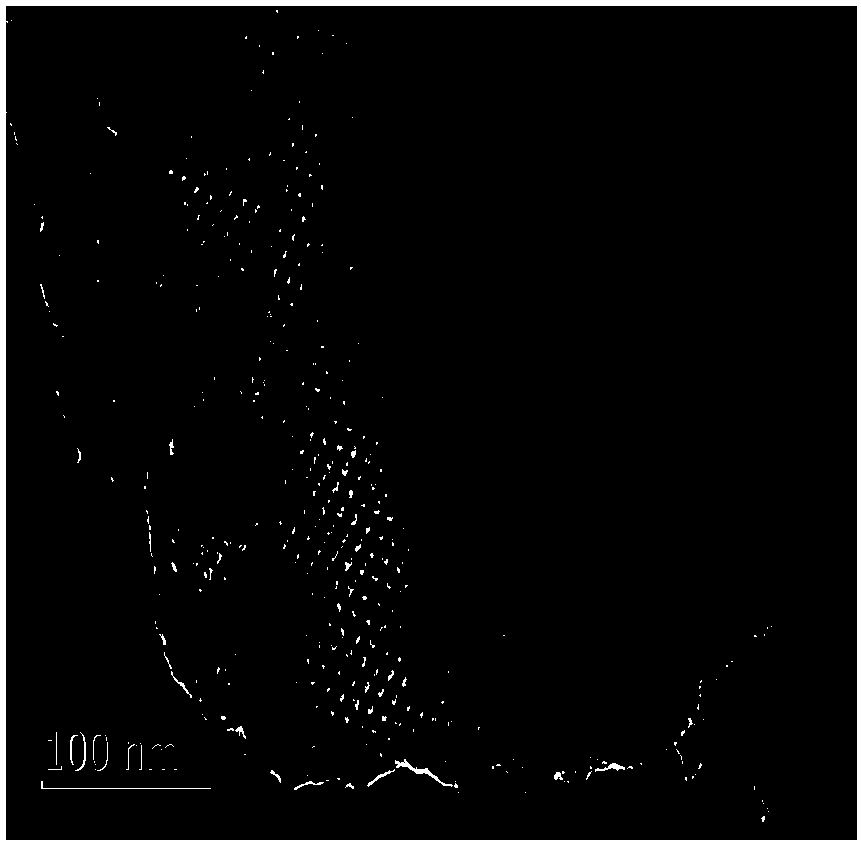

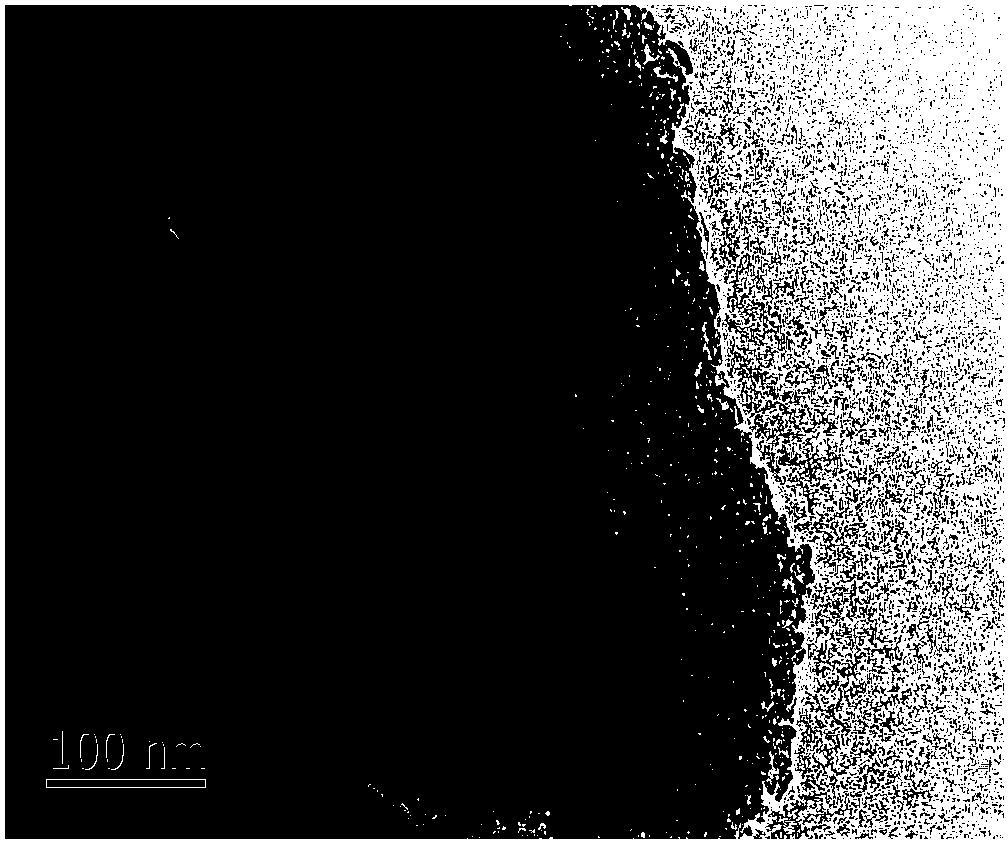

[0024] b. Prepare the Ru precursor solution at 1% by mass, and load Ru on the above-mentioned alumina carrier by the equal volume impregnation method. With a heating rate of 5°C / min and a hydrogen flow rate of 60ml / g, the Ru / Al 2 o 3 Reduction, the reduced state metal catalyst A is obtained. The catalyst has an ordered mesoporous structure, and its pore shape is hexagonal, HR-TEM sees figure 1 .

Embodiment 2

[0028] Except for using the Rh precursor in step b, it was prepared by the same method as described in Example 1 to obtain a reduced metal catalyst B.

Embodiment 3

[0030] Except for using the Pd precursor in step b, it was prepared by the same method as described in Example 1 to obtain a reduced metal catalyst C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com