Patents

Literature

51 results about "Diisobutylketone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

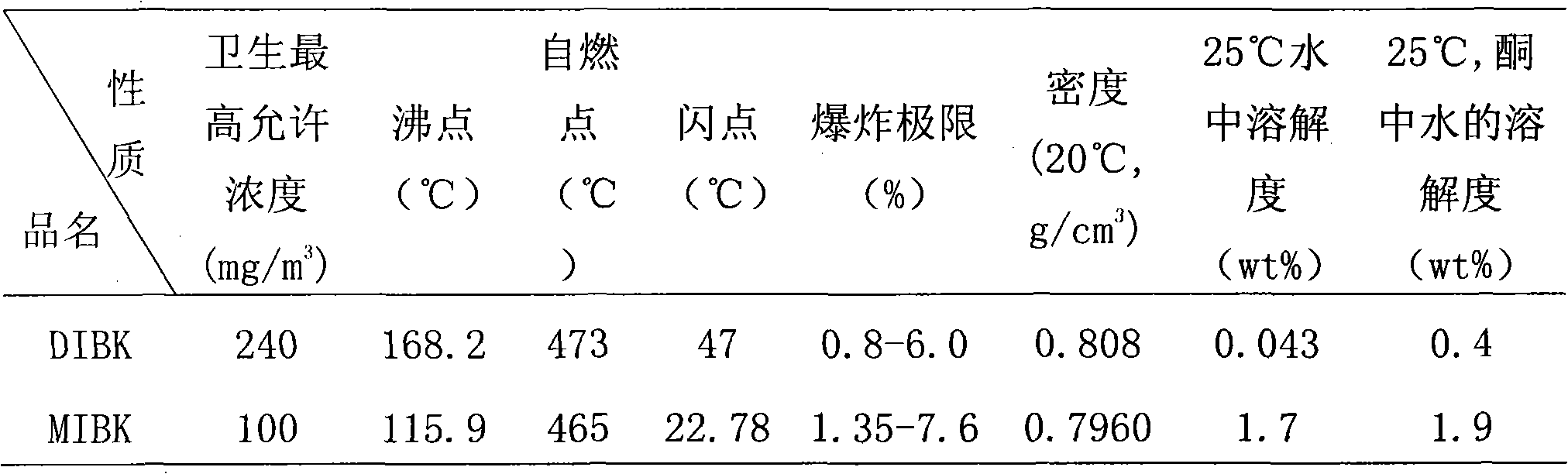

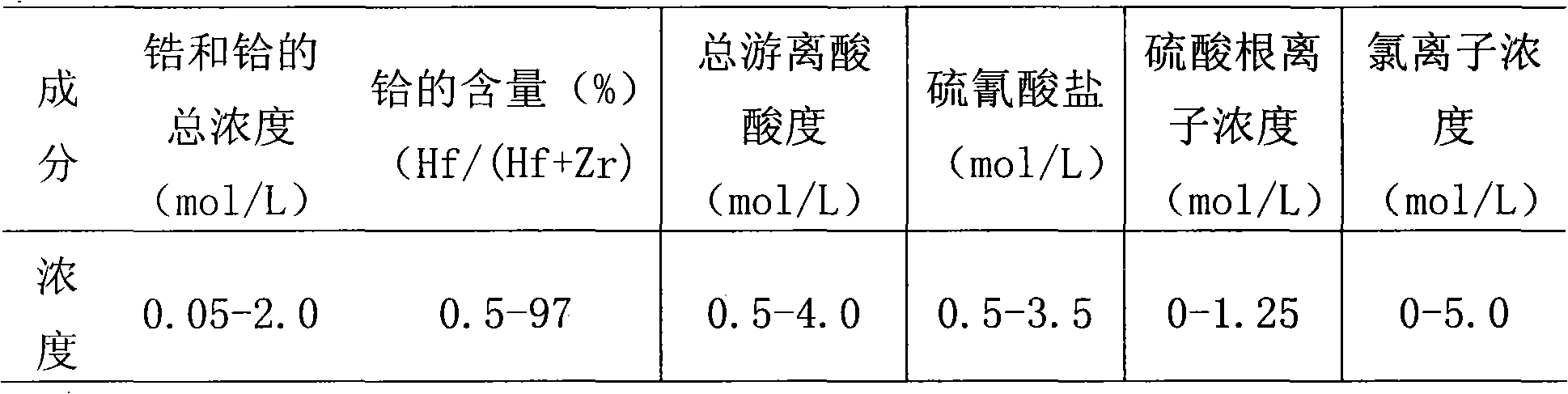

Method for separating zirconium and hafnium

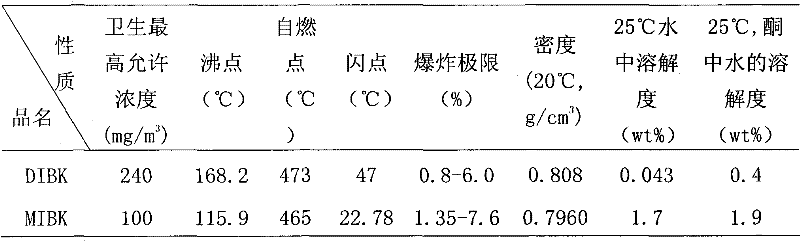

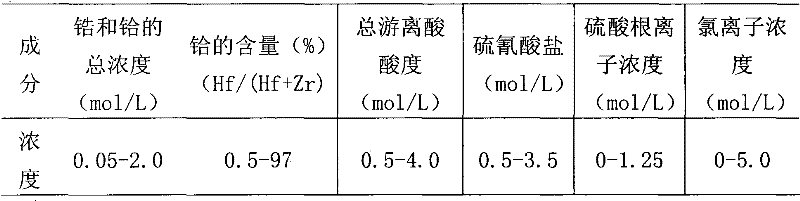

ActiveCN102453801ALess mass transferLarge extraction capacityProcess efficiency improvementSolubilityHafnium

The invention relates to a method for separating zirconium and hafnium, which specifically comprises the following steps of: using the acidic water solution of a zirconium compound as a raw material, extracting hafnium in the material liquid into an organic phase by using diisobutyl ketone (DIBK) or the synergism of DIBK with a neutral phosphorous extracting agent or the synergism of DIBK with anacidic phosphorus-containing extracting agent, and washing and stripping the oganic phase to produce a hafnium-rich liquid such that the separation of zirconium and hafnium is realized; respectively precipitating the hafnium-rich liquid and the remaining organic phase by using ammonia water, and washing and roasting the precipitates to obtain atomic energy level zirconium oxide and hafnium oxide.In the technical method provided by the invention, low content of hafnium in zirconium hafnium is preferably extracted, and the method has simple process and high extraction efficiency. The extraction system used in the method reaches the same zirconium and hafnium separation performance to MIBK (Methyl Isobutyl Ketone) but has smaller water solubility, high boiling point and flashing point and smaller toxicity compared with MIBK, and the problems of great solvent loss, easy outbreak of fire, environmental pollution and the like in the MIBK extraction separation method are solved.

Owner:有研资源环境技术研究院(北京)有限公司

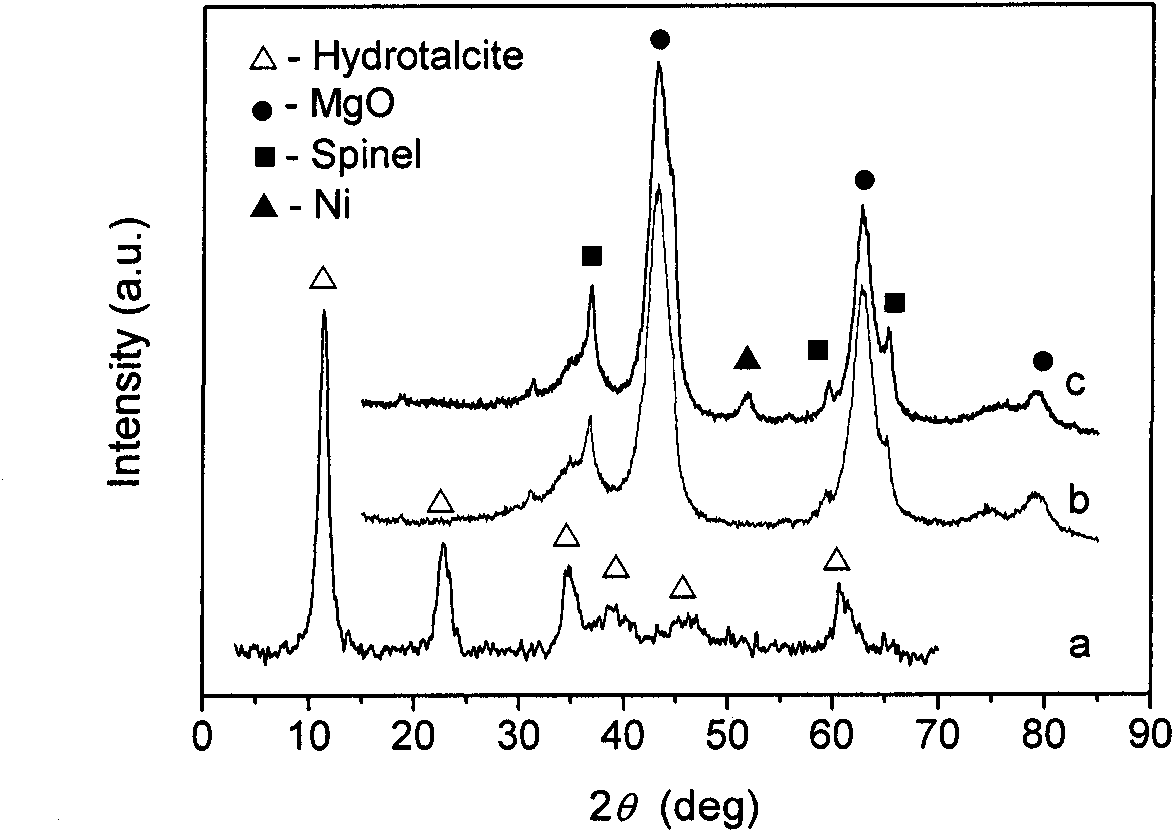

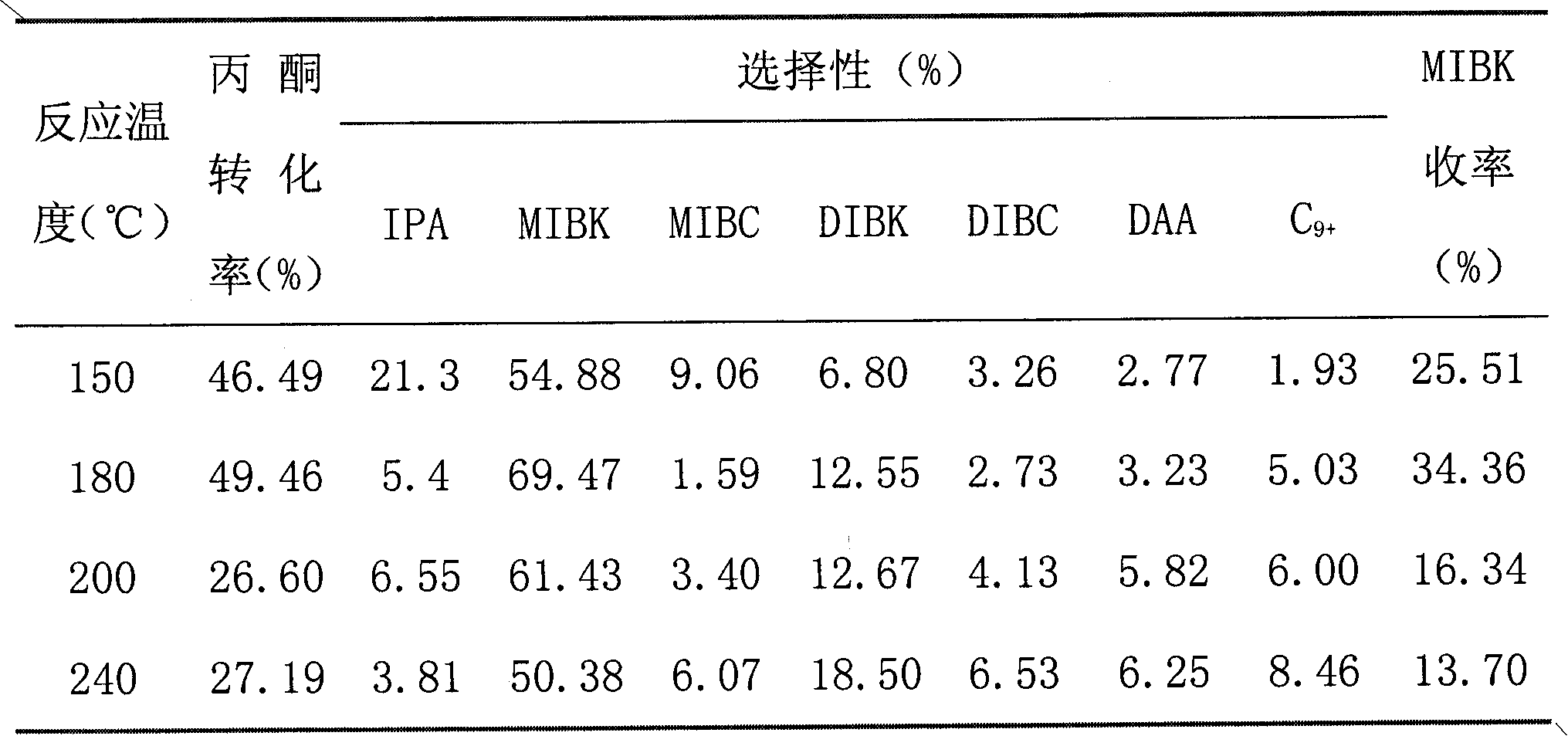

Method for preparing Ni/MgO-Al2O3 catalyst for coproduction of methylisobutylketone and diisobutylketone

InactiveCN101875012AImprove reducibilitySimple preparation processOrganic compound preparationCarbonyl compound preparationHydrogenMethyl isobutyl ketone

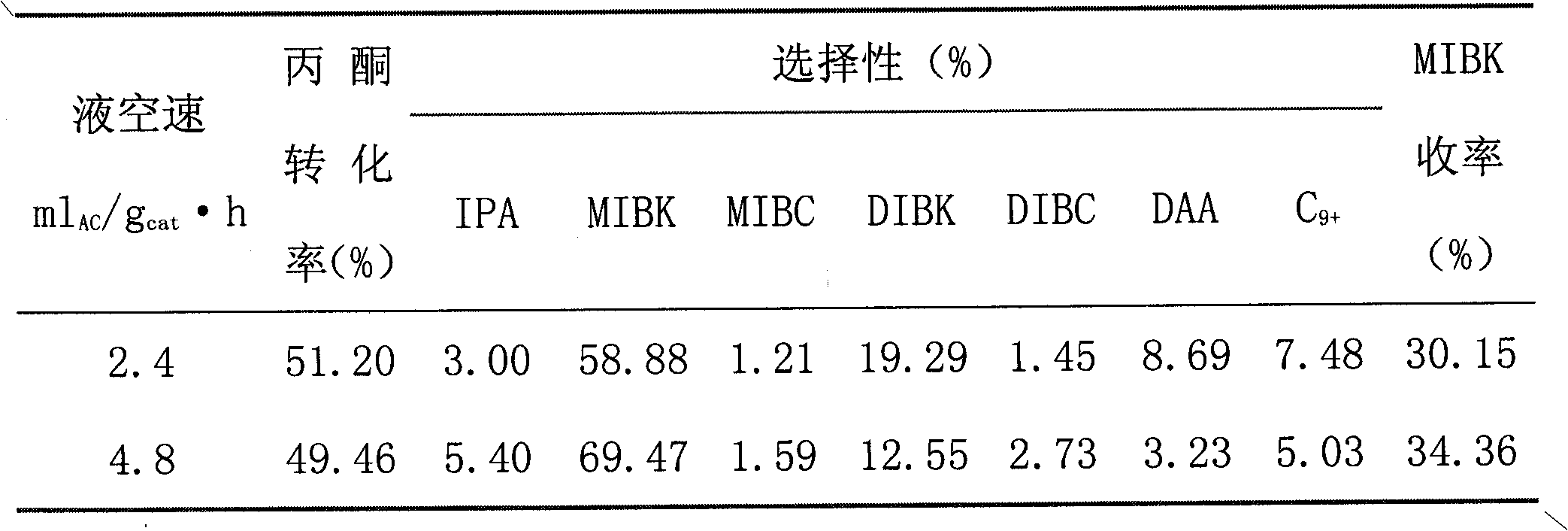

The invention discloses a method for preparing a Ni / MgO-Al2O3 catalyst for coproduction of methylisobutylketone and diisobutylketone, and relates to a chemical solvent. In the method, a Pd / MgO-Al2O3-ZrO2 catalyst is used, the catalyst consists of 4 weight percent of Ni, 53 weight percent of MgO and 43 weight percent of Al2O3, and the catalyst is prepared from a reconfigured NiMgAl hydrotalcite-like compound at the reaction temperature of between 150 and 240 DEG C at the liquid space velocity of 2.4 to 4.8 ml / gcat.h in a molar ratio of hydrogen to ketone of 0.5-2; and in a fixed bed reactor, the conversion rate of acetone is 30 to 56 percent, and the selectivity of the methylisobutylketone reaches 57 to 69 percent. Ni<2+> of the Ni / MgO-Al2O3 catalyst prepared by a reconfigured hydrotalcite-like method is mainly distributed on the surface of the catalyst, is easy to reduce, is used in the reaction of synthesizing MIBK by an acetone gas phase one-step method, and has high catalytic performance.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

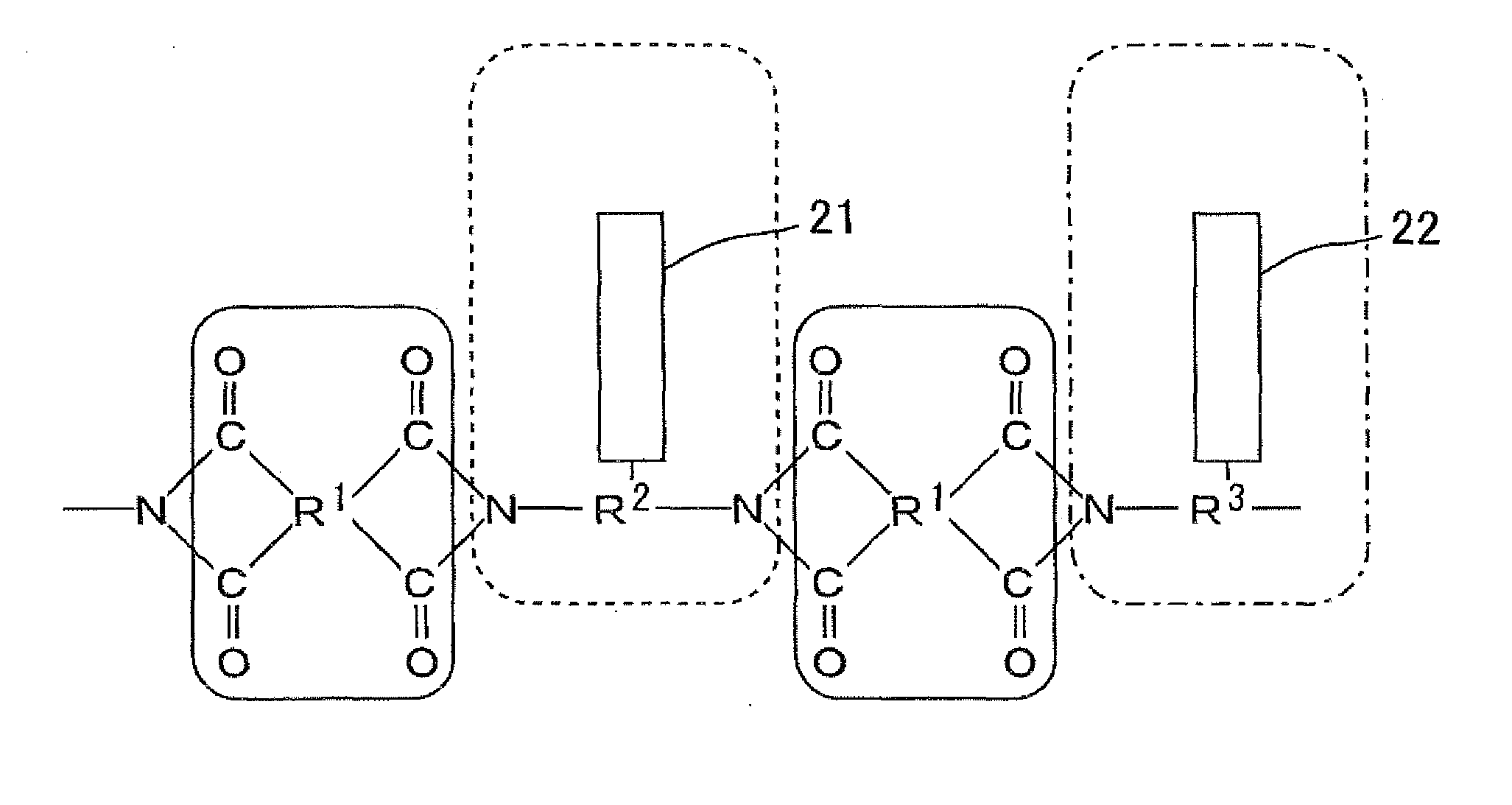

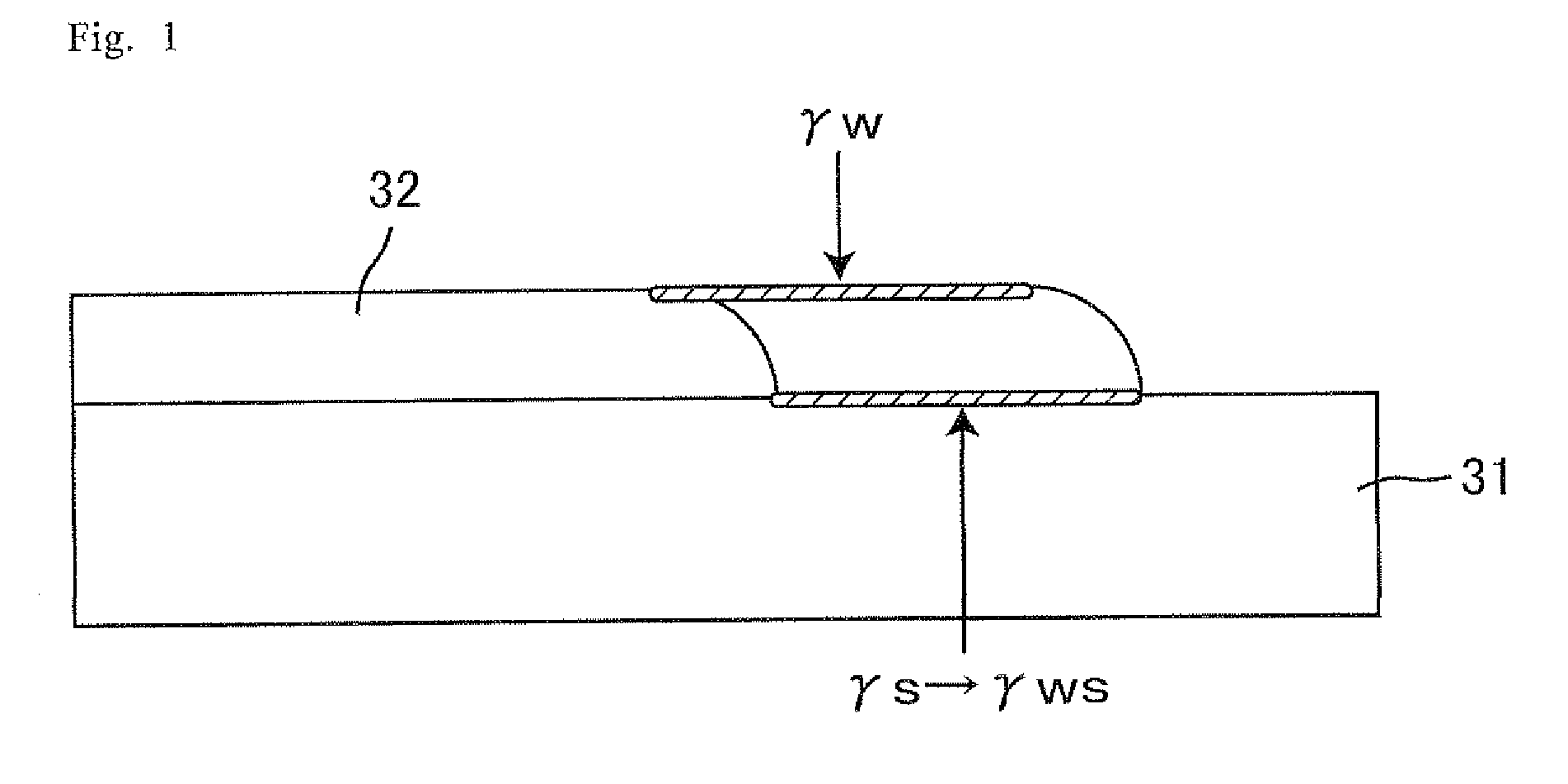

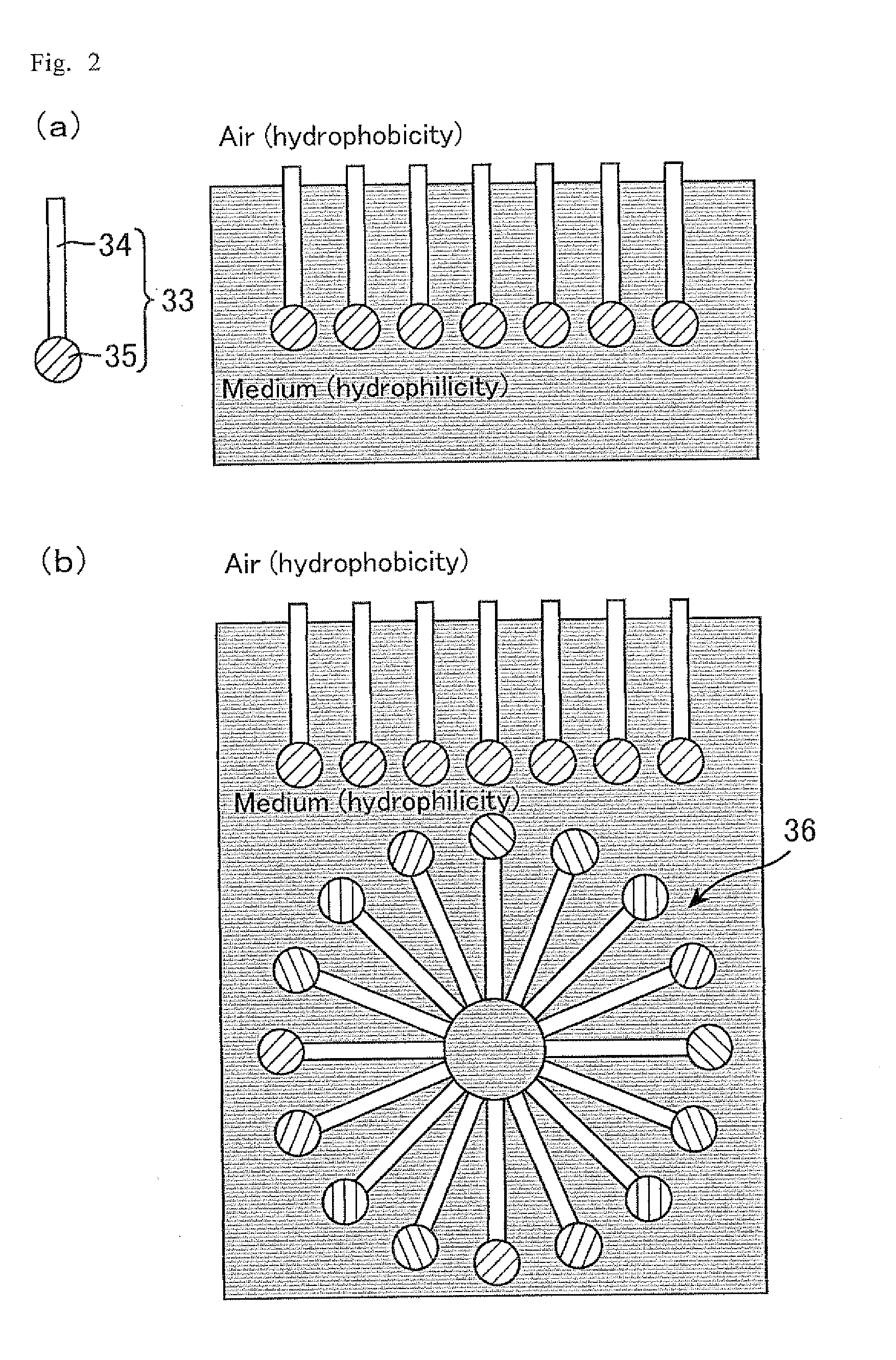

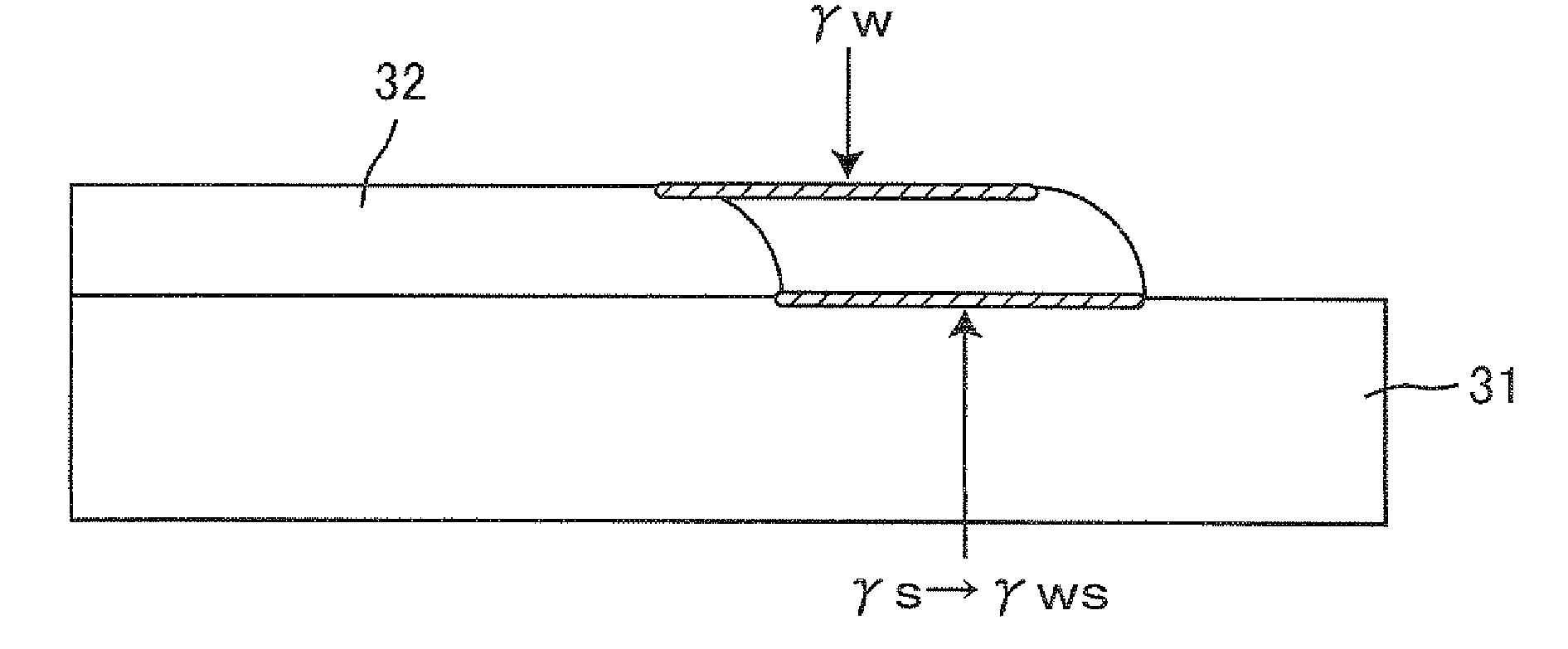

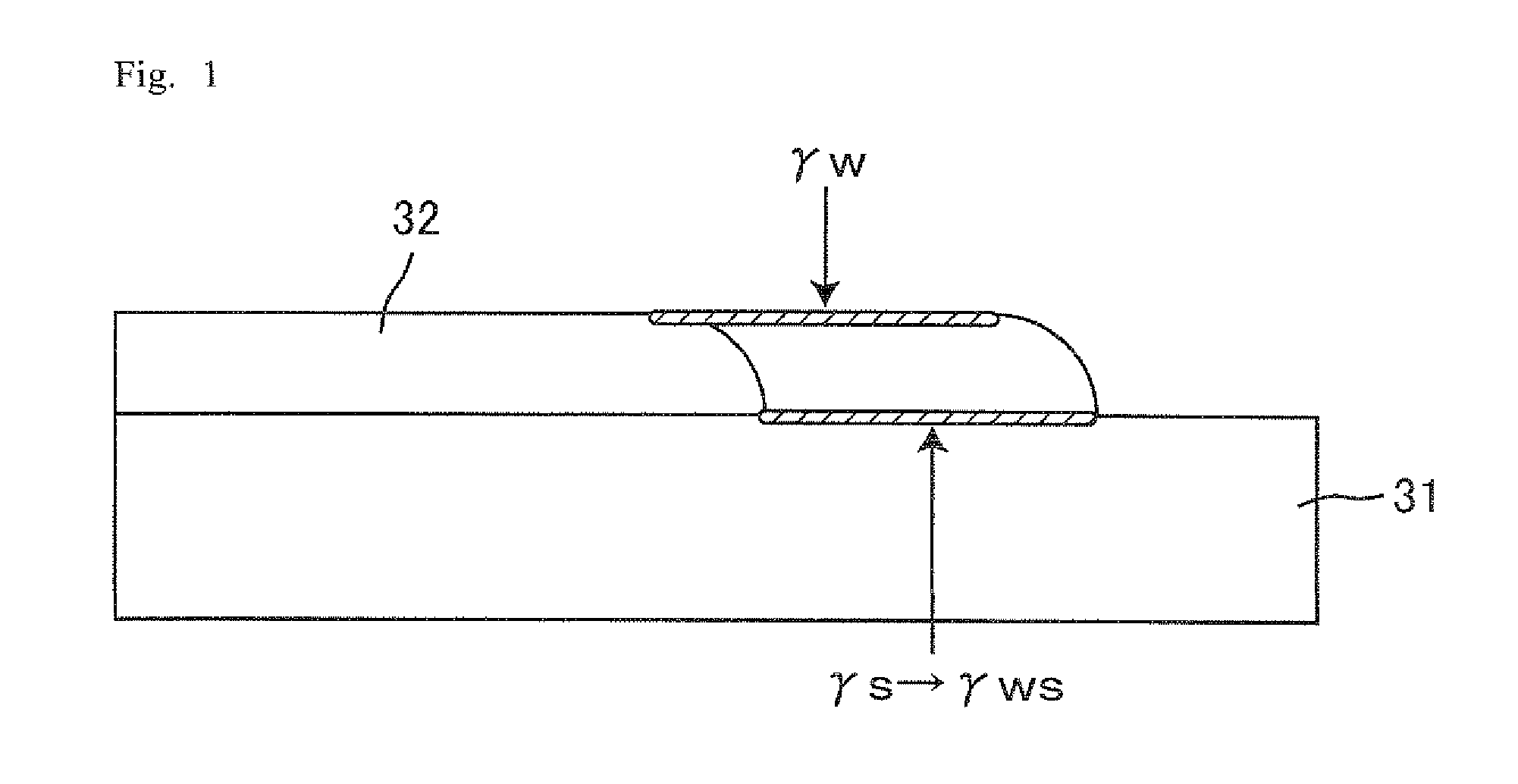

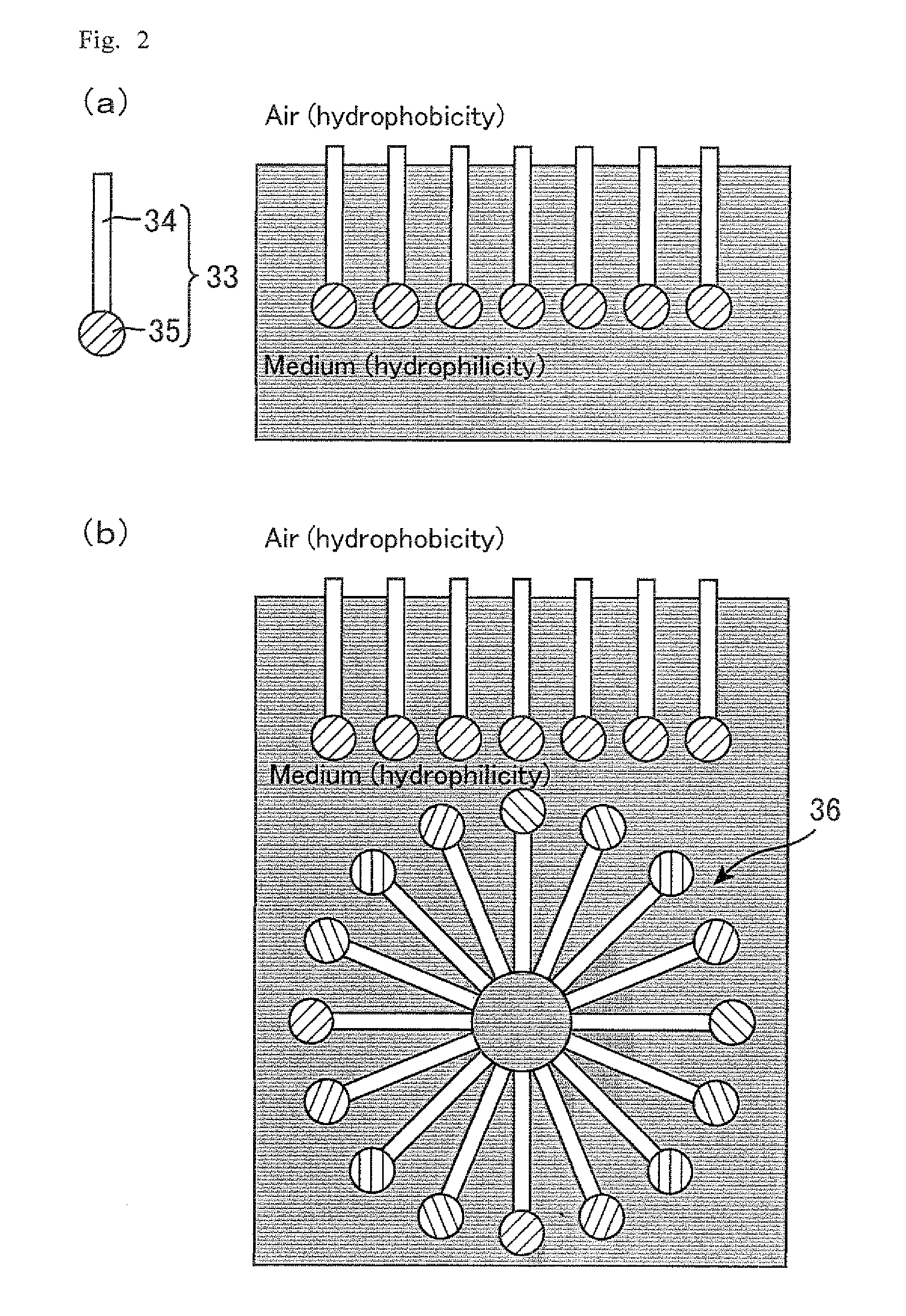

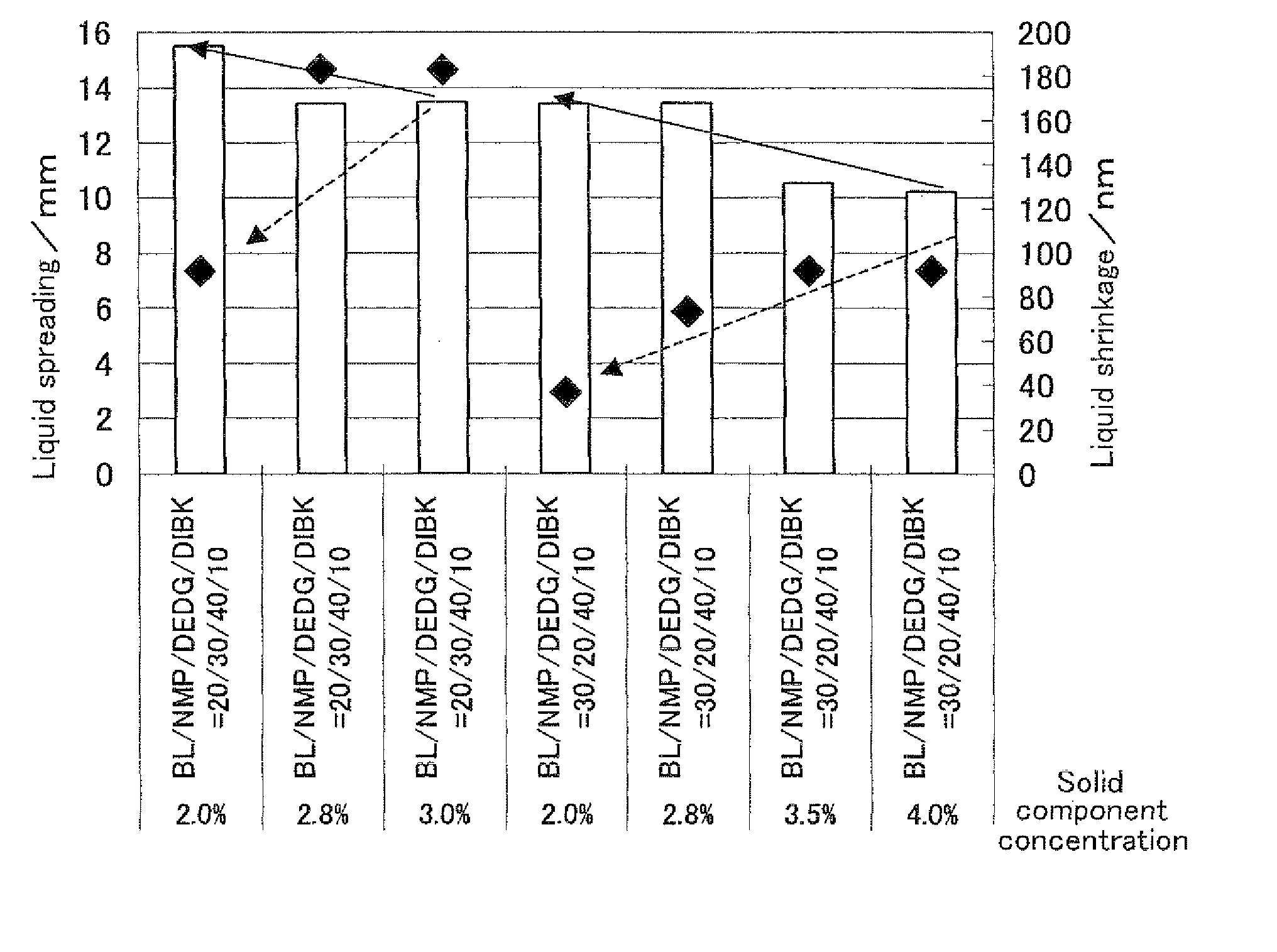

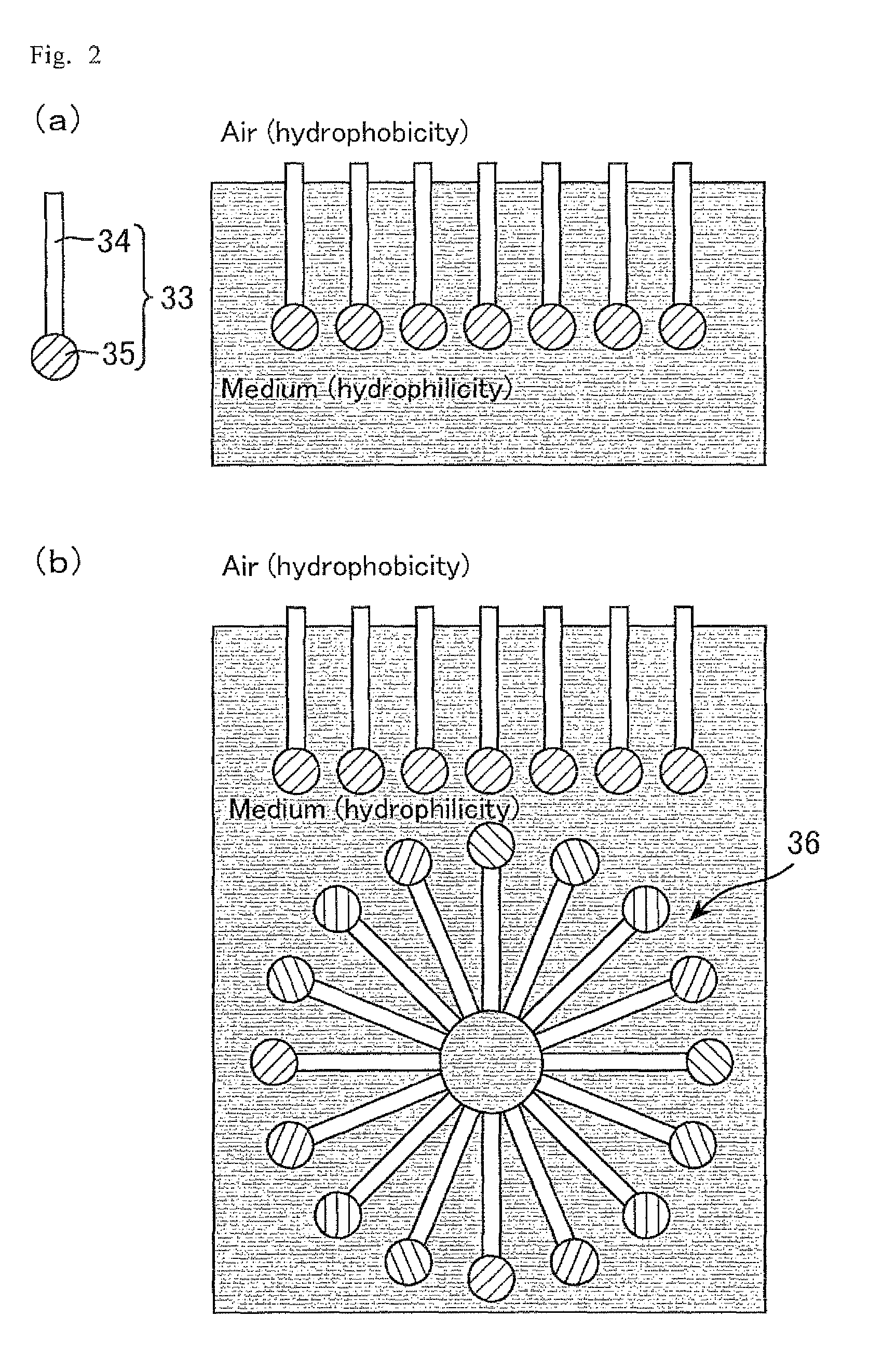

Composition for forming a liquid crystal alignment film, and liquid crystal display device

ActiveUS20110007254A1Good coating performanceSuppress display unevennessLiquid crystal compositionsPlastic/resin/waxes insulatorsDiethylene glycol diethyl etherLiquid-crystal display

The present invention provides: a composition for forming a liquid crystal alignment film capable of forming a liquid crystal alignment film excellent in evenness; and a liquid crystal display device. The present invention provides a composition for forming a liquid crystal alignment film, wherein the composition comprises: a material for forming a liquid crystal alignment film; diethylene glycol diethyl ether; diisobutyl ketone; and at least one of γ-butyrolactone and N-methyl-2-pyrrolidone as solvents.

Owner:SHARP KK +1

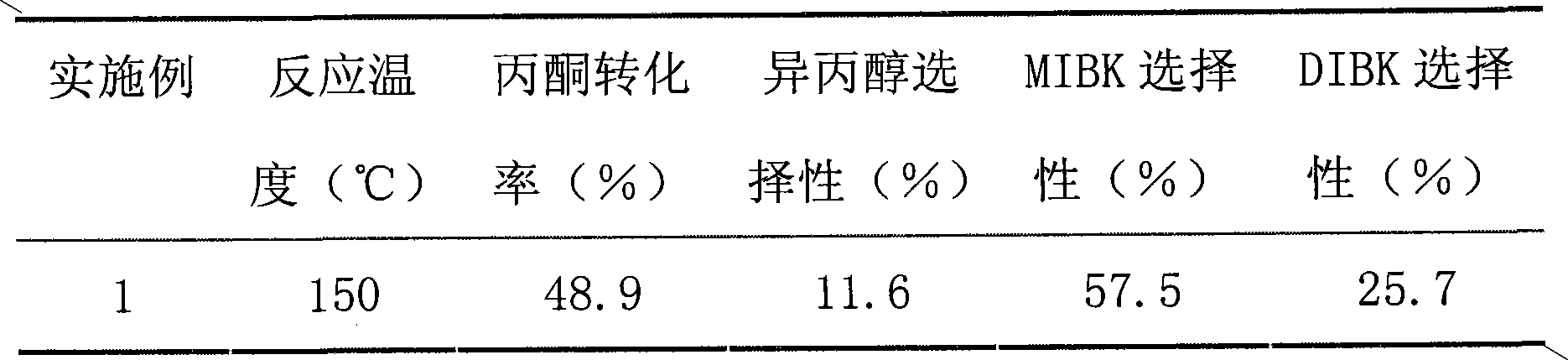

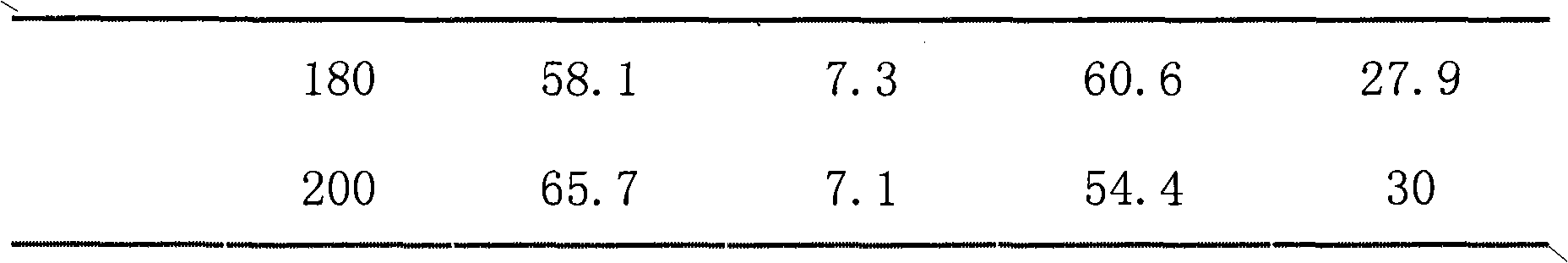

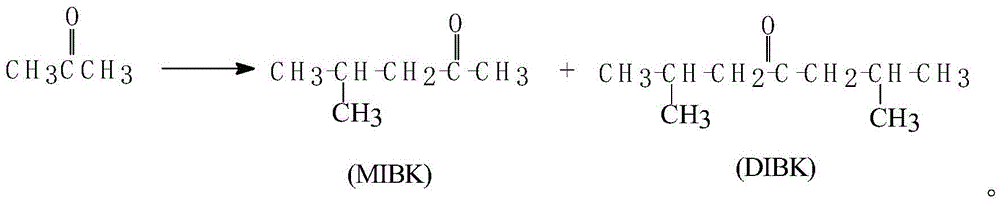

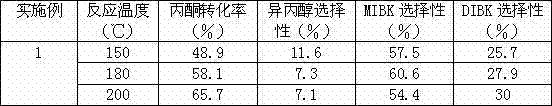

Method for synthesizing methyl isobutyl ketone and diisobutyl ketone by acetone gas-phase one-step method

InactiveCN101830787ASimple preparation processSuitable for mass productionOxygen-containing compound preparationOrganic compound preparationHydrogenMethyl isobutyl ketone

The invention relates to a method for synthesizing methyl isobutyl ketone and diisobutyl ketone by an acetone gas-phase one-step method, which relates to a chemical solvent. A Pd / MgO-Al2O3-ZrO2 catalyst is used in the method, comprises the components of 1wt% of Pd, 55wt% of MgO, 10wt% of Al2O3 and 34wt% of ZrO2 and is prepared from a PdMgAlZr four-element houghite compound. under the condition that the reaction temperature is 150-200 DEG C,the liquid air speed is 4.8ml / gcat.h, and the hydrogen-ketone mol ratio is 1, in a fixed bed reactor, the acetone conversion rate is 30-73 percent, and theselectivity of the methyl isobutyl ketone and the diisobutyl ketone respectively reaches 50-60 percent and 23-30 percent. The catalyst has simple preparation process and is suitable for large-scale production. After the ZrO2 is added, the catalyst has proper acid-base property and higher activity. The catalyst can be simultaneously used for preparing the two products of the methyl isobutyl ketoneand the diisobutyl ketone.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

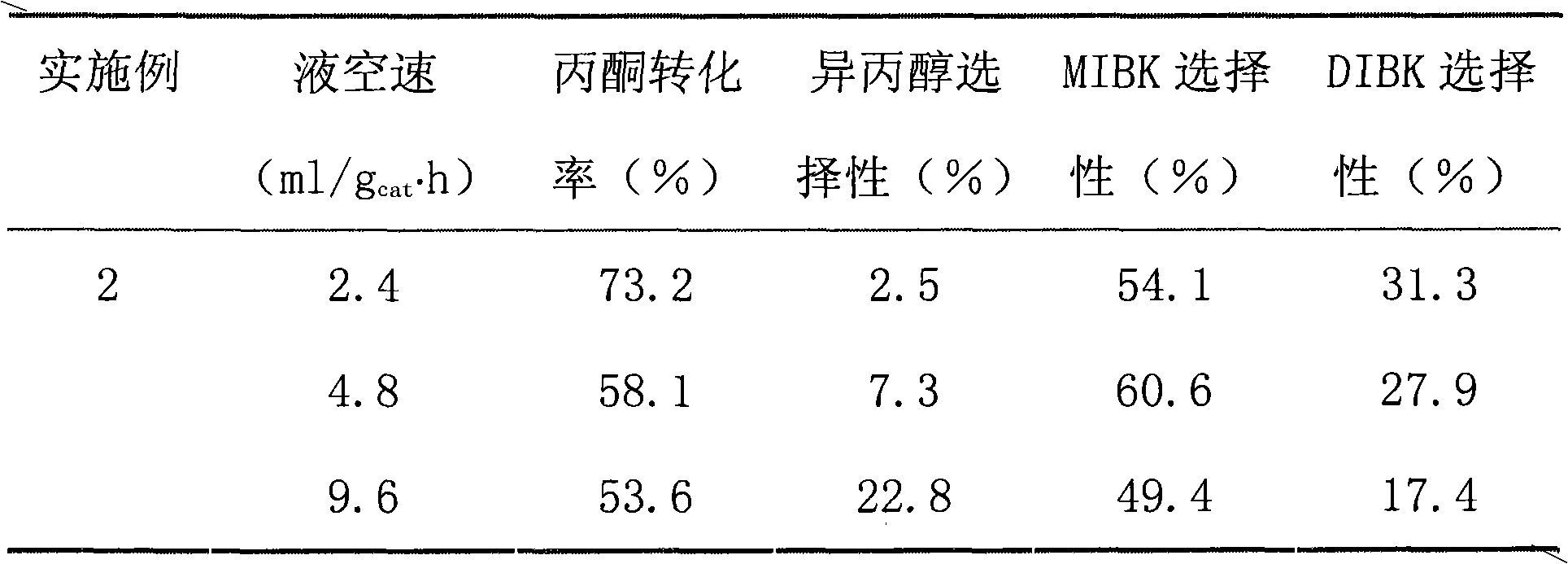

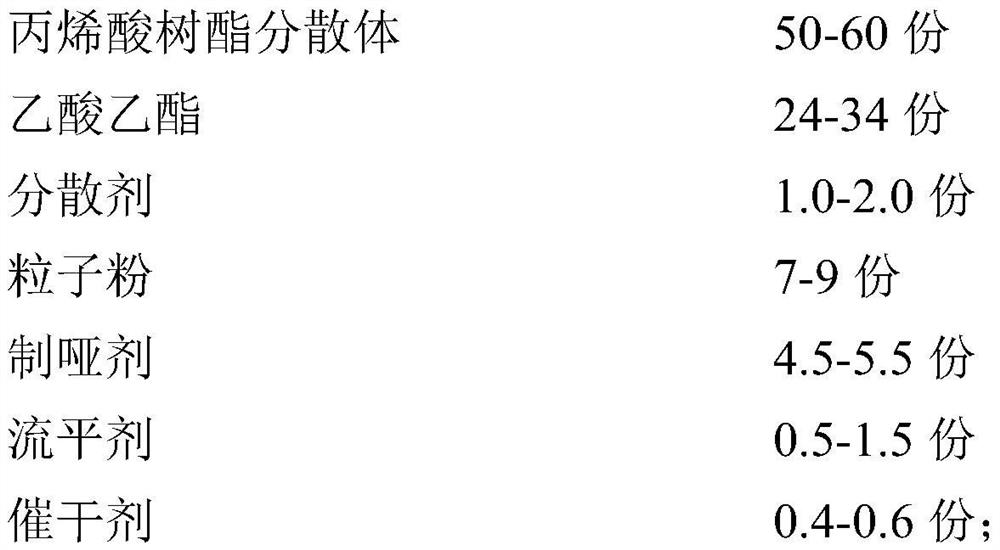

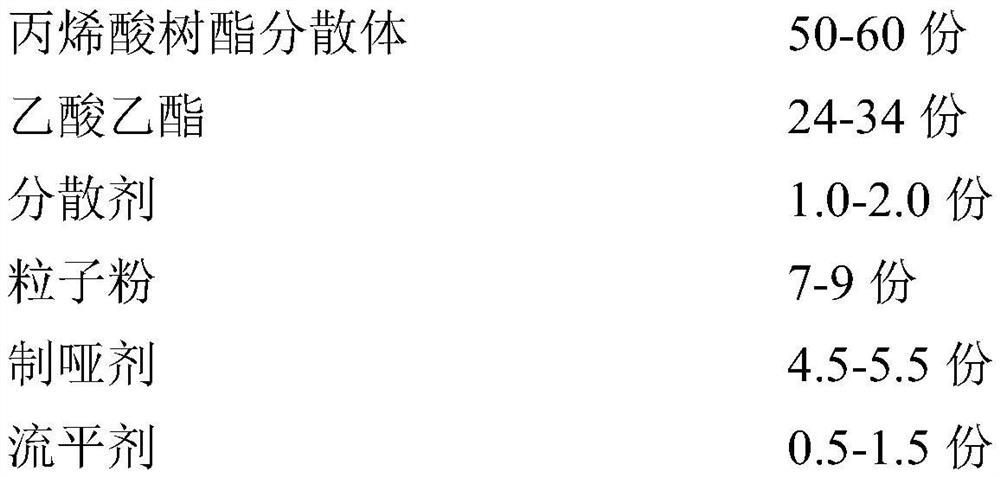

Plated film paint system, plastic part with metal effect coating, and preparation method of plated film paint system

ActiveCN108276898AImprove adhesionHigh hardnessPretreated surfacesAnti-corrosive paintsAcrylic resinLacquer

The invention discloses a plated film paint system. The plated film paint system comprises a transparent UV priming paint, a transparent UV intermediate coat used for coating a clad layer, a colored paint, and a transparent UV finishing coat; the transparent UV intermediate coat comprises, by weight, 20 to 50% of polyurethane acrylate, 5 to 10% of hydroxy acrylic resin, 10 to 20% of acetic ester,10 to 20% of butyl acetate, 10 to 20% of 2,6-Dimethyl-4-heptanone, and 0.5 to 3% of an auxiliary agent, wherein the molecular weight of the hydroxy acrylic resin is larger than 50000. The plated filmpaint system is adopted in preparation of the plastic part with metal effect coating, laser carving is carried out after coating of all the coats, the transparent UV finishing coat and the colored paint layer are removed via calcinations, clad layer metal effect is achieved. Compared with the prior art, the technology possesses following advantages: technology process is simple, production efficiency is increased, paint layer clunging force is high, and color change is not caused after laser carving.

Owner:长沙松润新材料有限公司

Process for producing methylisobutylketone and diisobutyl ketone by using acetone

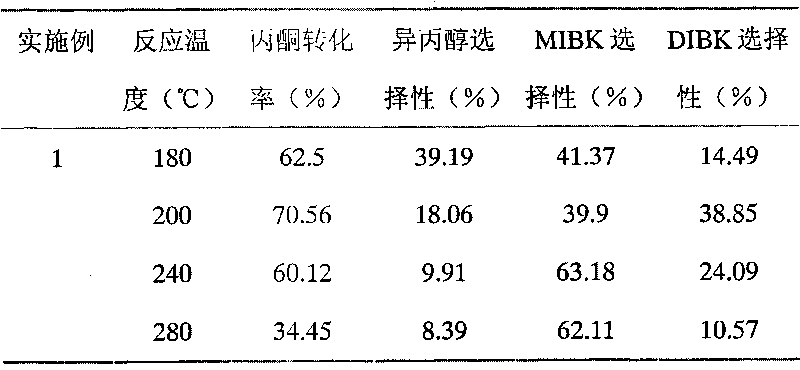

InactiveCN101712606ASimple preparation processSuitable for mass productionOrganic compound preparationCarbonyl compound preparationMethyl isobutyl ketoneHydrogen

The invention discloses a process for producing methylisobutylketone and diisobutyl ketone by using acetone, relating to a process for preparing chemical solvents. An Ni / MgO-Al2O3-ZrO2 catalytic agent containing 6wt percent of Ni, 60wt percent of MgO, 21wt percent of Al2O3 and 13wt percent of ZrO2 is used in the invention; the catalytic agent is prepared from an NiMgAlZr quadri hydrotalcite compound. Under the conditions that the reaction temperature is 180-280 DEG C, the liquid airspeed is 4.8ml / gcat.h and the mole ratio of hydrogen to ketone is 1, in a fixed bed reactor, the acetone percent conversion is 60 percent, and the selectivity of methylisobutylketone and diisobutyl ketone respectively reaches 63 percent and 24 percent. Methylisobutylketone and diisobutyl ketone can widely serve as solvents for producing high-grade coatings.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

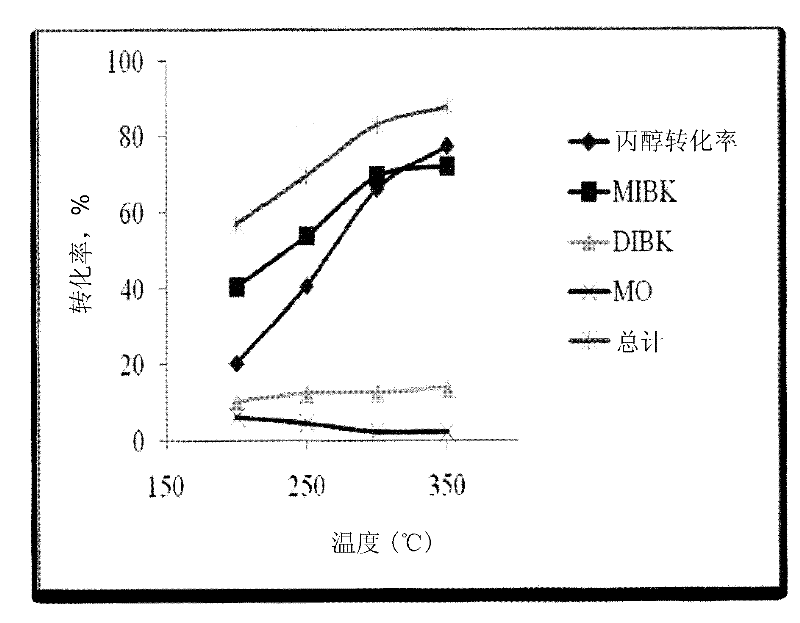

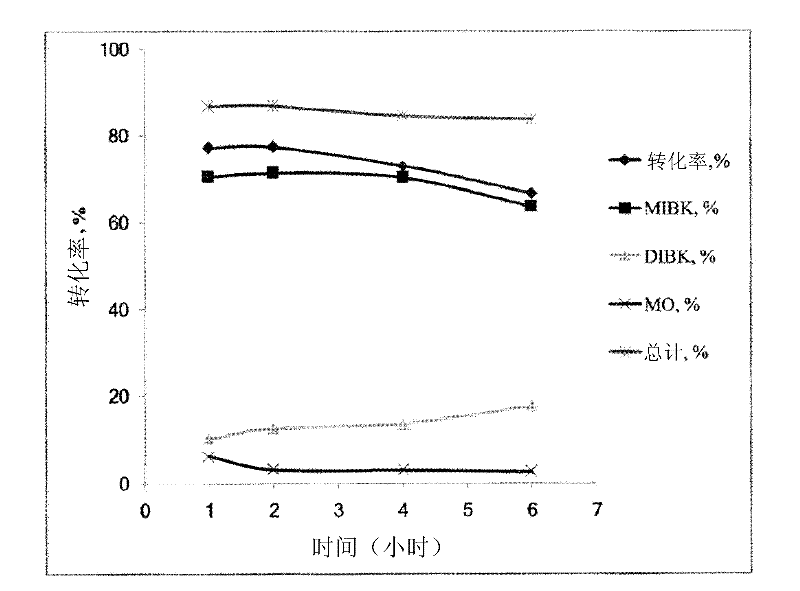

Synthesizing and utilizing novel nano-crystalline zinc chromite-supported nano-palladium catalyst

InactiveCN102371153AOrganic compound preparationCatalyst regeneration/reactivationGas phaseDesorption

Several metal-supported catalyst compositions based on nano-crystalline zinc oxide were synthesized and characterized by X-ray powder diffraction (XRD), Carbon dioxide temperature programmed desorption (CO2 TPD), and nitrogen adsorption at -196 DEG C. The Pd-supported nano-ZnO mixed with different oxides such as Cr2O3, CrO3, MgO, and [gamma]-Al2O3 showed high catalytic activity in acetone condensation in gas-phase process under hydrogen flow. This reaction involves the base-acid coupling of acetone to form mesityl oxide, followed by its hydrogenation to methyl isobutyl ketone (MIBK). The novel catalyst 1% wt. n-Pd / n-ZnCr2O4 was utilized during gas-phase reaction during production of MIBK. MIBK selectivity was 70-72% at 66-77% acetone conversion at 300-350 DEG C. Diisobutyl ketone (DIBK) was the main by-product, with a total MIBK+DIBK selectivity up to 88%. The prepared catalysts showed stable activity and may be used repeatedly and for a longer period of time.

Owner:KING ABDULAZIZ CITY FOR SCINCE & TECH (KACST)

Composition for forming liquid crystal alignment film and liquid crystal display device

InactiveUS20120013837A1Efficient driveEasy to provideLiquid crystal compositionsNon-fibrous pulp additionLiquid-crystal displayDiisobutylketone

Owner:SHARP KK +1

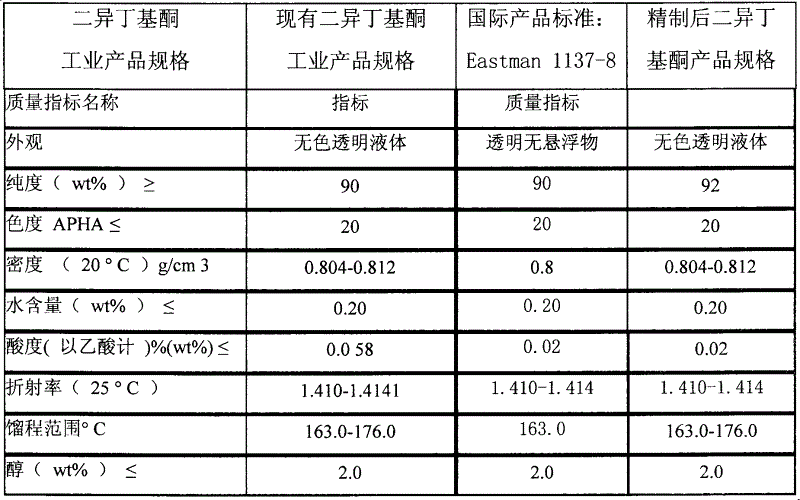

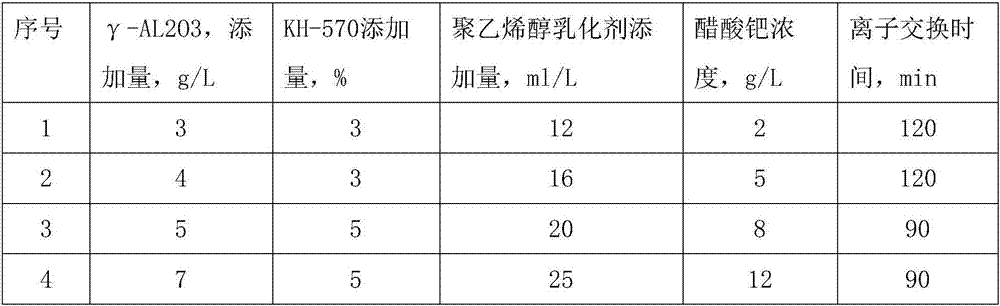

Application of inorganic alkaline and fixed-bed adsorption technique to deacidification and purification of diisobutyl ketone

InactiveCN102617314ALow in free acidsCost-effective wayOther chemical processesCarbonyl compound separation/purificationSorbentAdhesive

The invention relates to an inorganic alkaline adsorbing agent for deacidification and purification of diisobutyl ketone, a preparation method and a fixed-bed adsorption technique, which belong to the field of fine chemical engineering. The adsorbing agent comprises organic alkaline substances accounting for 70-90% of the overall weight of the adsorbing agent. The preparation method is characterized in that the organic alkaline substances are used as carriers, adhesives, pore-enlarging additives and an appropriate amount of deionized water are added and proportionally mixed, and then the adsorbing agent is obtained by means of forming, drying and sintering. A fixed-bed adsorption column is added to a product outlet of a diisobutyl ketone production device and operated at the normal temperature and under the normal pressure, and the inorganic alkaline adsorbing agent can be regenerated by means of high-temperature sintering and reused for 8-10 times. The content of free acid in the diisobutyl ketone is reduced from 0.05% to less than or equal to 0.02%. The technique effectively meets the requirements which cannot be met by a traditional method, and has the advantages that equipment investment is low, raw materials are easy to obtain, the technique is simple, material loss is low and the like. Waste water is avoided in inorganic alkaline adsorbing agent preparation, deacidification and purification and adsorbing agent regeneration techniques.

Owner:JILIN INST OF CHEM TECH

Cleaning agent for cleaning 3D-type sand printing head and preparation method of cleaning agent

InactiveCN105039025AOvercoming toxicityOvercome the disadvantages of strong pungent smellOrganic non-surface-active detergent compositionsEngineeringCleansing Agents

The invention relates to a cleaning agent for cleaning a 3D type sand printing head and a preparation method of the cleaning agent. The cleaning agent for cleaning the 3D type sand printing head comprises the following components in percentage by weight: 30-40% of sec-amyl alcohol, 18-26% of tetramethylurea, 18-22% of dipropyl ether, 6-14% of pinacolone, 9-15% of valerone and 0.6-1.4% of a stabilizing agent, wherein the stabilizer is propylene glycol methyl ether. The cleaning agent has the beneficial effects that raw materials relatively mild to human bodies and production environments are selected to reduce harms to the bodies and the environments to the utmost extent; the cleaning agent is small in surface tension and viscosity and strong in osmotic force, and can quickly dissolve resin crystals in the 3D-type sand printing head to ensure that the patency rate of an ore canal in the printing head is not less than 98.5%; the cleaning agent is stable in chemical property and cannot cause swelling and corroding actions on other parts of the printing head; the cleaning agent can reduce the production cost and prolong the service life of the 3D type sand printing head.

Owner:GANSU KOCEL CHEM

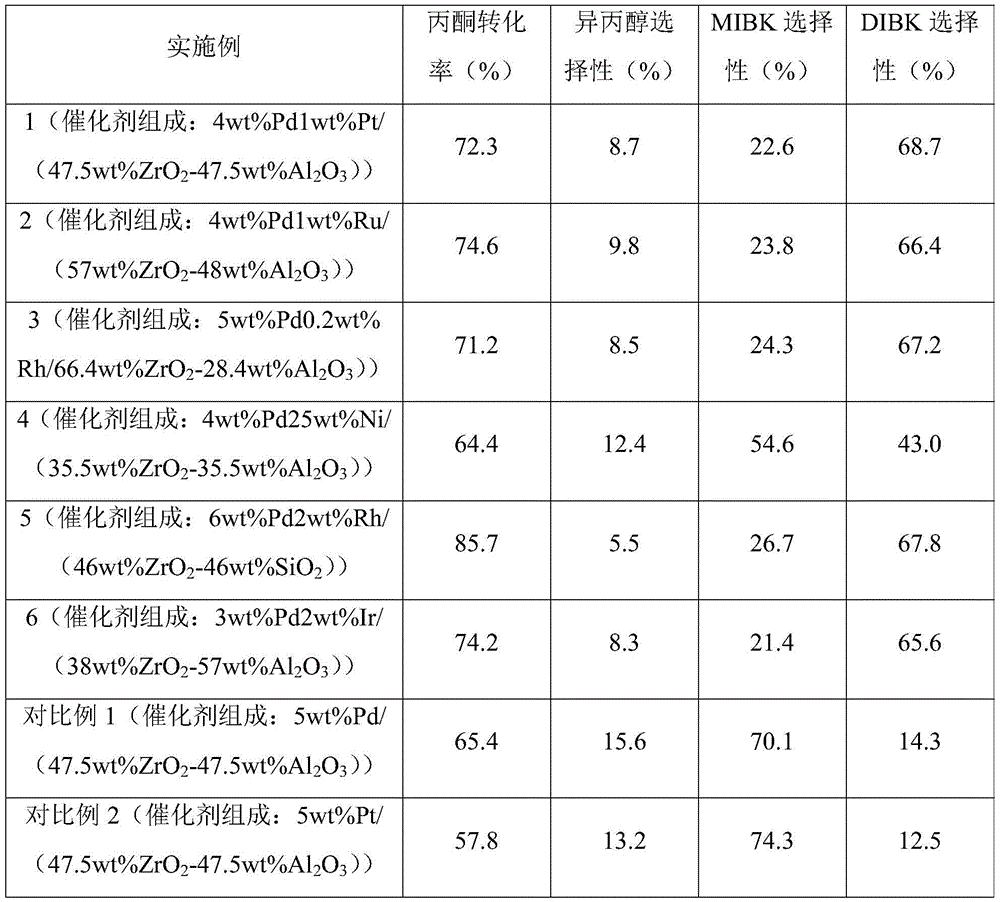

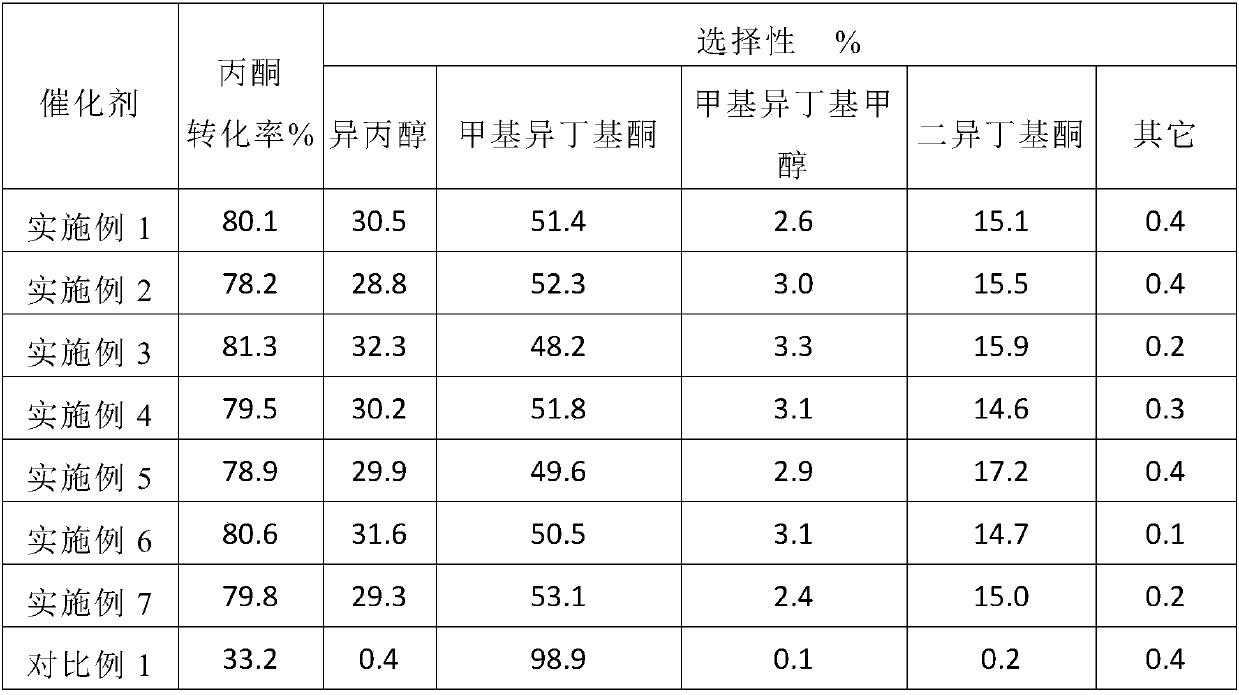

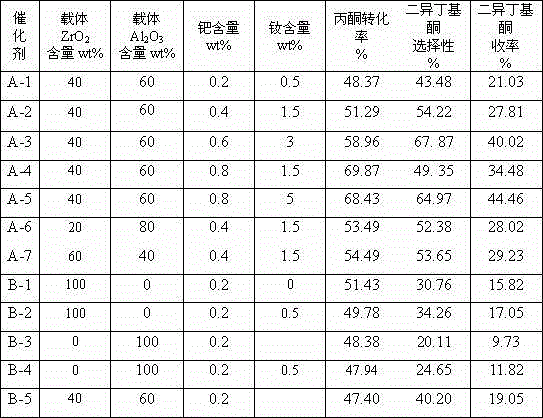

A polycondensation catalyst, a preparing method thereof, applications of the catalyst, a diisobutyl ketone preparing method and a diisobutyl carbinol preparing method

ActiveCN106622215AHigh polycondensation activityHigh selectivityOrganic compound preparationHeterogenous catalyst chemical elementsComponent LoadDiisobutylketone

The invention relates to the field of catalytic materials, and particularly provides a polycondensation catalyst, a preparing method thereof and applications of the catalyst. The catalyst includes a carrier and metal components loaded by the carrier. The carrier comprises a carrier A and a carrier B, the carrier A is zirconia, and the carrier B is a silicon-containing and / or aluminum-containing oxide. The metal components include a metal component A and a metal component B. The metal component A is palladium. The metal component B is a non-palladium VIII-group metal component and / or an IB-group metal component. A diisobutyl ketone preparing method and a diisobutyl carbinol preparing method are provided. The catalyst is high in polycondensation activity, and selectivity of a target product is high. The catalyst is particularly used for acetone polycondensation and can be used for synthesizing diisobutyl ketone with high selectivity and the acetone conversion ratio is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

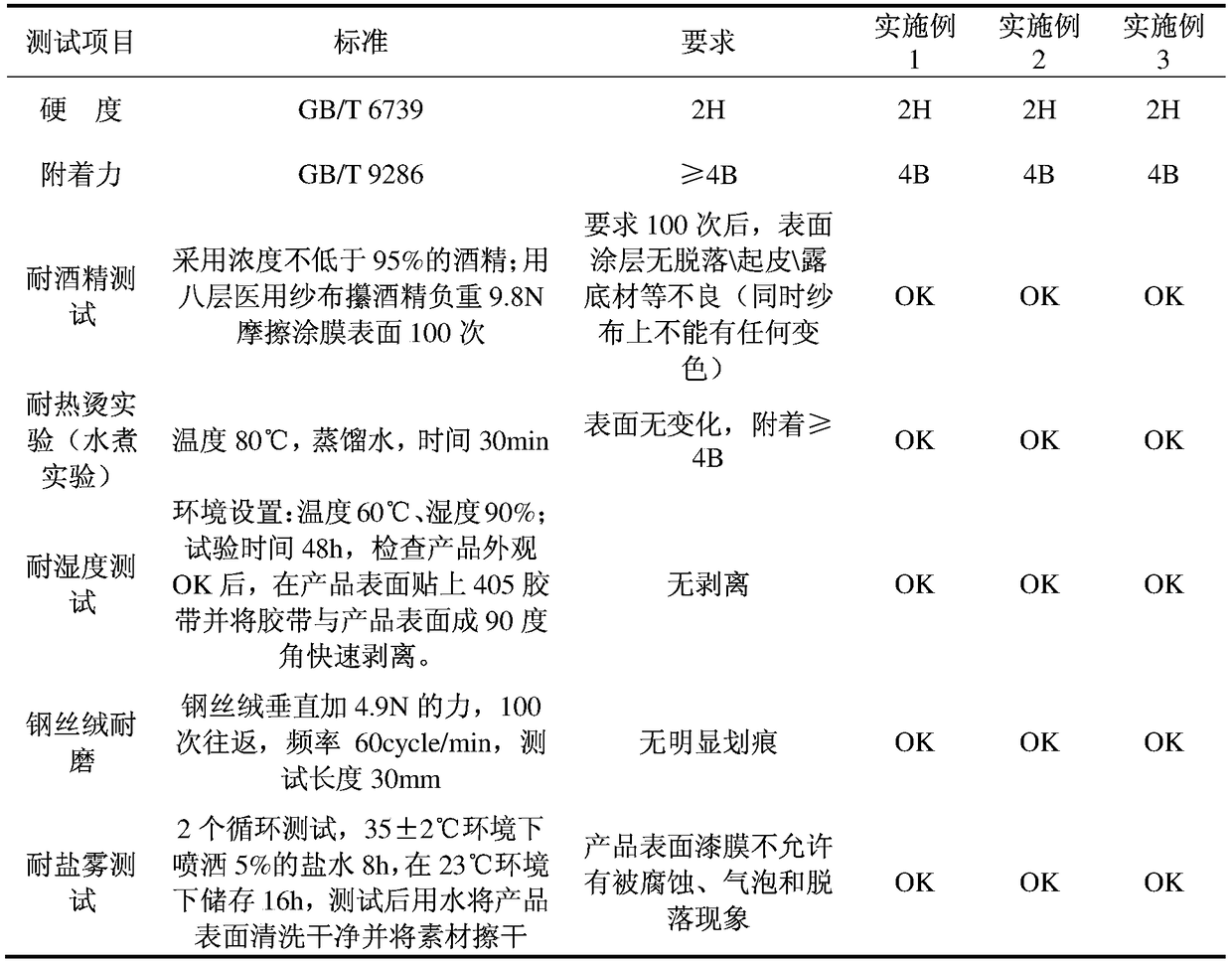

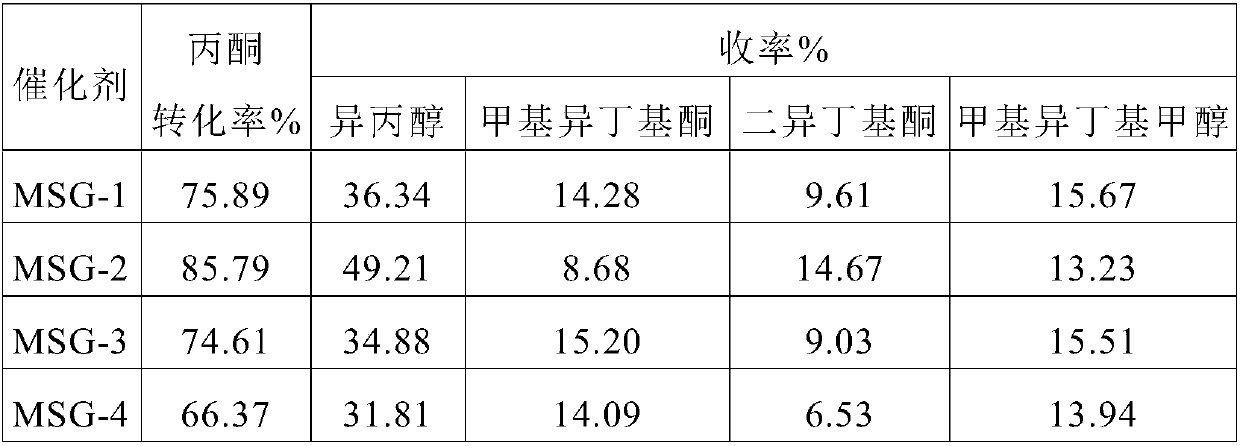

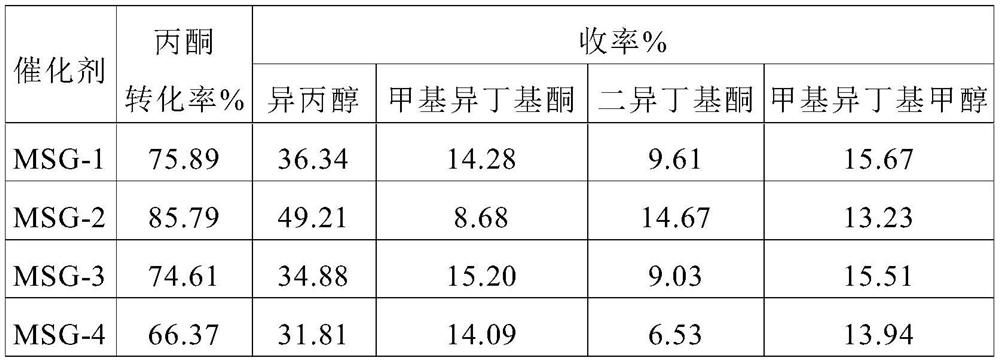

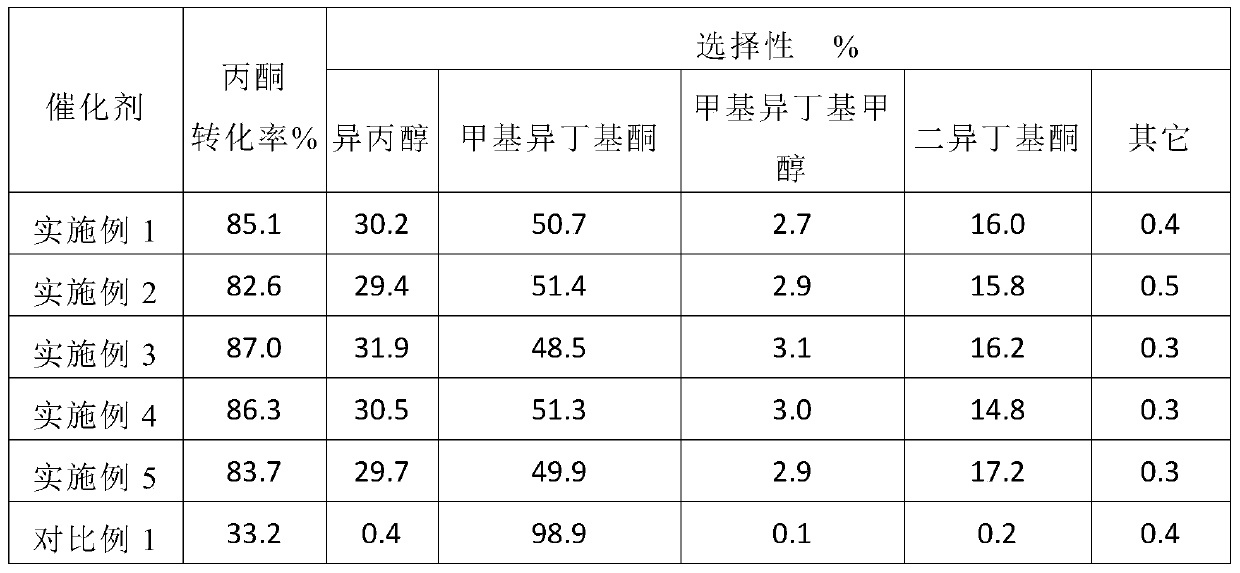

Preparation method of catalyst for co-generating of isopropanol and diisobutyl ketone through acetone hydrogenation and application

ActiveCN102806085AHigh activityImprove stabilityOrganic compound preparationHydroxy compound preparationNitrateAdhesive

The invention provides a preparation method of a catalyst for co-generating of isopropanol and diisobutyl ketone through acetone hydrogenation and an application. The preparation method is characterized in that the catalyst comprises an alumina carrier as well as Ni and Mg loaded on the gamma-Al2O3 carrier; in terms of total weight of the catalyst, the catalyst comprises 20-25% of Ni and 8-12% of Mg; the preparation method comprises the following procedures of 1) carrier preparation: taking a pseudo-boehmite powder body; adding a certain quantity of adhesives and extrusion assisting agents to the pseudo-boehmite powder body; extruding a mixture into strips or rotationally granulating the mixture; and drying and roasting the mixture so as to obtain the carrier; 2) impregnation of magnesium nitrate and nickel nitrate: impregnating the carrier in the magnesium nitrate and the nickel nitrate for 10-24 hours at room temperature; taking out the carrier after filtering the carrier; drying and roasting the carrier; and then naturally cooling the carrier; and 3) repeating of the step 2): using a magnesium nitrate and nickel nitrate impregnation liquor obtained in the step 2); impregnating a semi-finished product obtained in the step 2) in the impregnation liquor; and repeating the impregnating, drying and roasting process for at least three times according to the step 2) so as to obtain a catalyst finished product. The invention further relates to a catalytic application of the catalyst, which is prepared by the preparation method, used for co-generating the isopropanol and the diisobutyl ketone through acetone hydrogenation.

Owner:CHINA NAT OFFSHORE OIL CORP +1

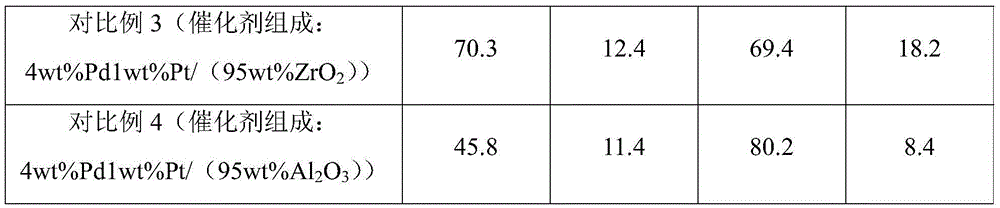

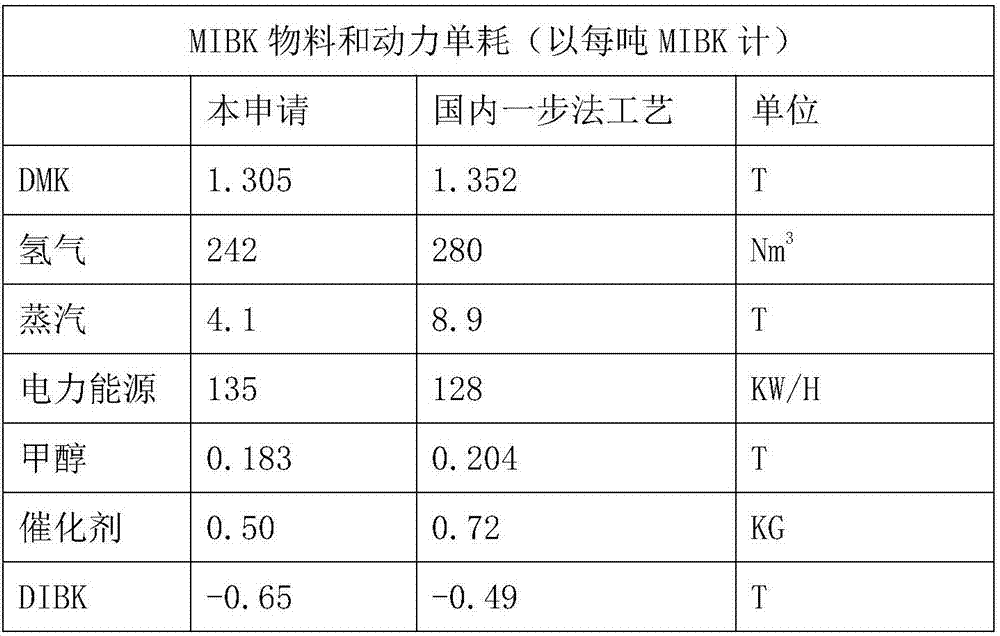

Technique for preparing MIBK (methyl isobutyl ketone) from acetone with liquid-phase one-step process

ActiveCN107400046AProcess method is shortReduce energy consumptionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystMethyl isobutyl ketone

The invention provides a technique for preparing MIBK (methyl isobutyl ketone) from acetone with a liquid-phase one-step process. The technique comprises the following steps: hydrogen and acetone are fed into a reactor and subjected to a reaction under catalysis of gamma-Al2O3 doped hydrogen-type polystyrene cation exchange resin, and a product is delivered to an acetone recovery tower for separation; organic light components in the recovery tower are delivered to a wastewater tower, acetone is delivered back to the reactor, and heavy components at the tower bottom are delivered to a water removal tower; light components at the top of the water removal tower are delivered to an extraction tower, and a reaction product at the tower bottom is delivered to a finished product tower; purified water is adopted as an extracting agent in the extraction tower, and heavy components are delivered to the wastewater tower; MIBK is produced from a side line of the finished product tower, 2,6-dimethyl-4-heptanone and high-class ketone are produced from a tower bottom liquid. The technique is short in flow and low in energy consumption, 2,6-dimethyl-4-heptanone is co-produced, few noble metal palladium active components in a palladium supported resin catalyst are lost, stable service life as long as 7,000 h is realized, and the production cost is reduced.

Owner:湖北三里枫香科技有限公司

Composition for forming a liquid crystal alignment film, and liquid crystal display device

ActiveUS8057868B2Good coating performanceSuppress display unevennessLiquid crystal compositionsPlastic/resin/waxes insulatorsDiethylene glycol diethyl etherLiquid-crystal display

The present invention provides: a composition for forming a liquid crystal alignment film capable of forming a liquid crystal alignment film excellent in evenness; and a liquid crystal display device. The present invention provides a composition for forming a liquid crystal alignment film, wherein the composition comprises: a material for forming a liquid crystal alignment film; diethylene glycol diethyl ether; diisobutyl ketone; and at least one of γ-butyrolactone and N-methyl-2-pyrrolidone as solvents.

Owner:SHARP KK +1

Cogeneration method of methyl isobutyl ketone and diiso butyl ketone

ActiveCN103755537ALow costImprove stabilityOrganic compound preparationCarbonyl compound separation/purificationCogenerationReaction temperature

The invention relates to a preparation method of a medical intermediate, and particularly relates to a cogeneration method of methyl isobutyl ketone and diiso butyl ketone. The method comprises the following steps: mixing and preheating acetone and isopropanol, entering a reactor containing copper-palladium-zirconium-zinc / molybdenum oxide catalysts; generating a reaction mixed solution of taking methyl isobutyl ketone and diiso butyl ketone as main ingredients from the acetone in a manner of reaction under the conditions that the reaction temperature is 130-210 DEG C, the reaction pressure is 0.1-4.0MPa, the liquid phase airspeed of isopropanol is 0.1-2.5h<-1> and the ketone alcohol mole ratio is 1-7; separating and refining, so as to obtain the methyl isobutyl ketone product and the diiso butyl ketone product. The cogeneration method has the advantages that the use cost of the catalyst is greatly reduced, and the method is low in energy consumption, simple in equipment, free of special requirements, fewer in heavy constituents, high in acetone utilization rate and high in product yield.

Owner:ZHEJIANG XINHUA CHEM

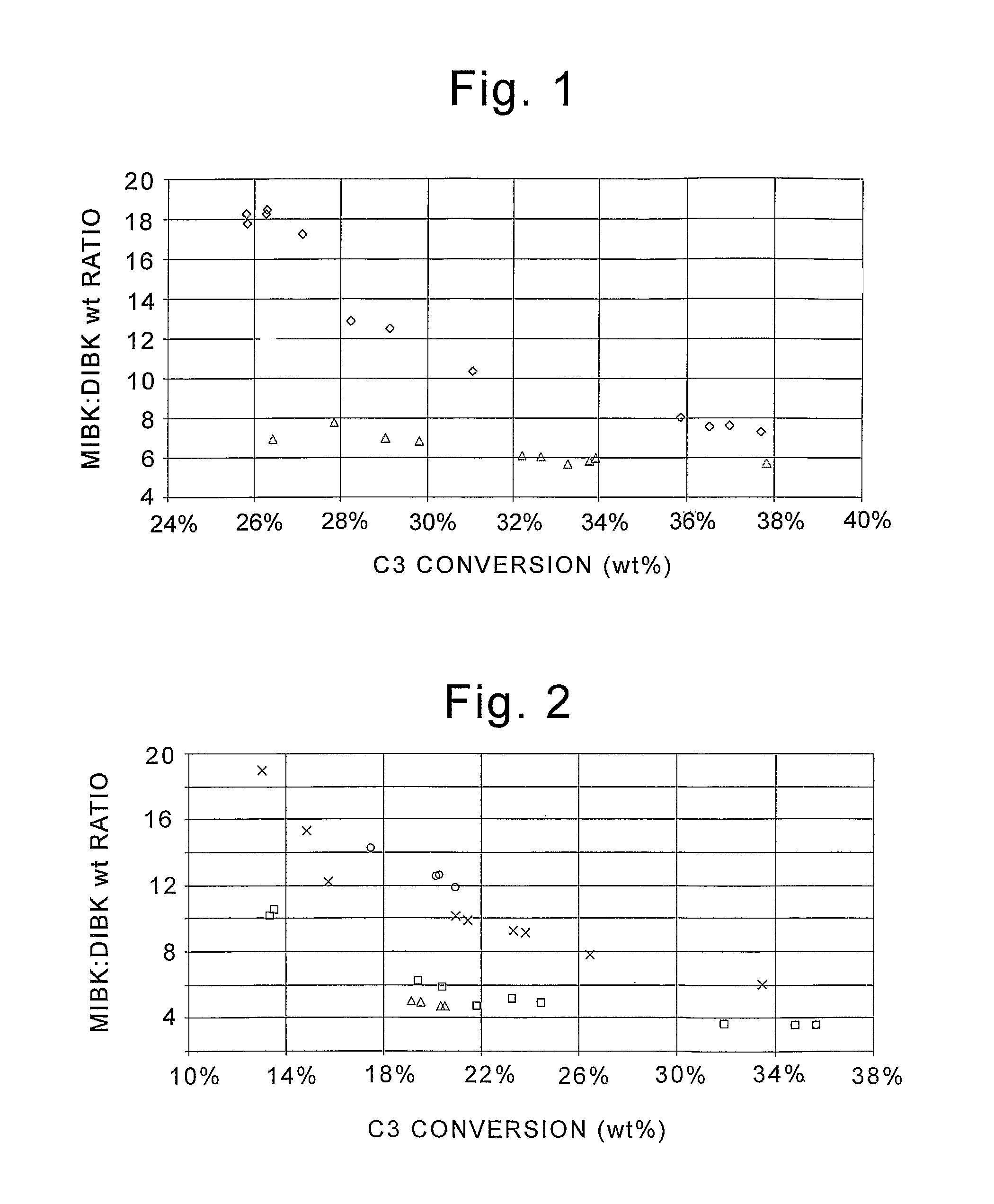

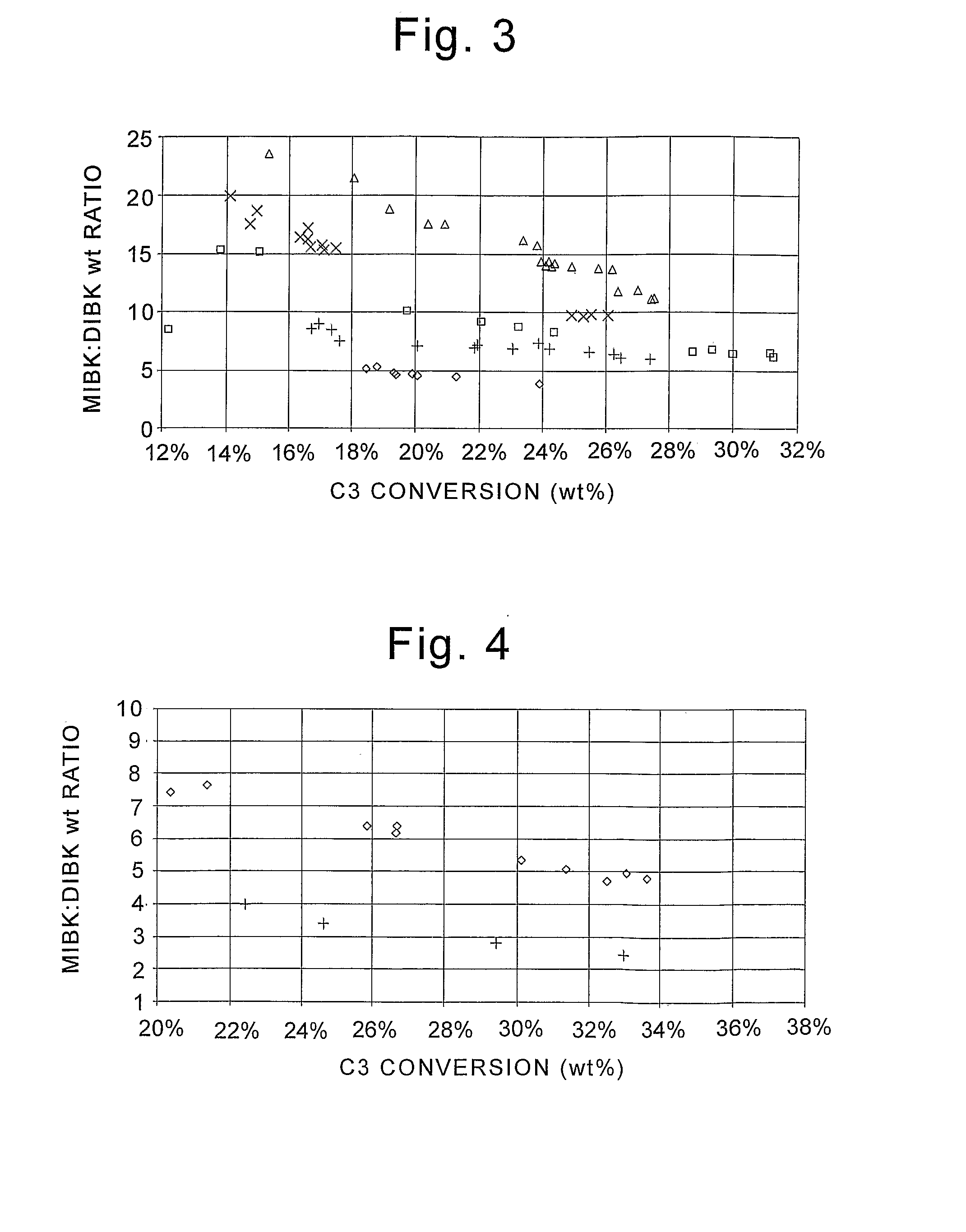

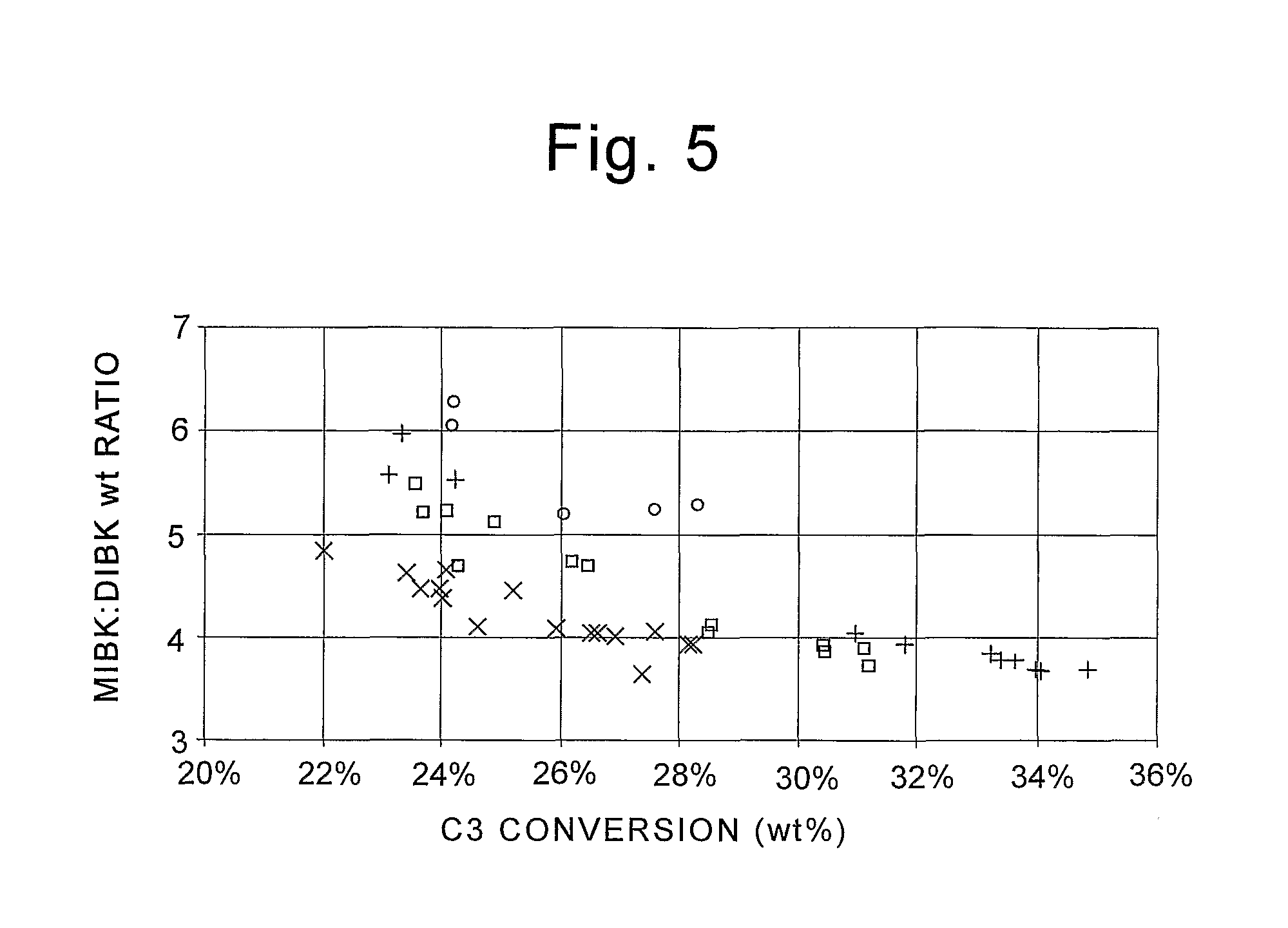

Method to make methyl isobutyl ketone and diisobutyl ketone

InactiveUS7767863B2Minimize deactivationRaise the ratioOrganic compound preparationCarbonyl compound preparationHydrogenMethyl isobutyl ketone

An improved method for the manufacture of MIBK and DIBK from DMK and / or IPA, by reacting, in the presence of an aldol condensation catalyst, a gaseous mixture comprising hydrogen and DMK and / or IPA. The improvement is the use of a reaction pressure greater than 207 kPa (30 psig) to increase the ratio of MIBK to DIBK. In addition a method for the manufacture of MIBK and DIBK by reacting, in the presence of an aldol condensation catalyst, a gaseous mixture consisting essentially of DMK and / or IPA and optionally water.

Owner:DOW TECH INVESTMENTS +1

Catalyst for co-producing methyl isobutyl ketone and diisobutyl ketone

ActiveCN107930635ALow costImprove stabilityOrganic compound preparationHeterogenous catalyst chemical elementsCeriumPalladium catalyst

The invention relates to a catalyst, and belongs to the technical field of applications and development of acetone downstream products, wherein cobalt and zinc are used as main active components, lanthanum and / or cerium are used as auxiliary agent components, aluminum oxide, silicon oxide or an aluminum oxide-silicon oxide composite carrier with rich pH value is selected to promote a reaction, thecatalyst is used under a mild reaction condition, an acetone one-step production process is used, and the yield of methyl isobutyl ketone in the application of the catalyst of the present invention is higher than the yield of methyl isobutyl ketone in the application of the palladium / resin catalyst used in the current industrial apparatus, and isopropanol and high added value diisobutyl ketone are co-produced. According to the present invention, the obtained catalyst has the ideal stability, has the cost significantly lower than the cost of the existing palladium catalyst, and has good economic benefits.

Owner:CHINA PETROLEUM & CHEM CORP +1

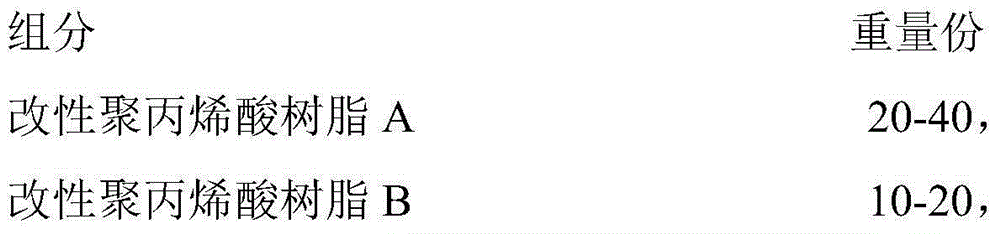

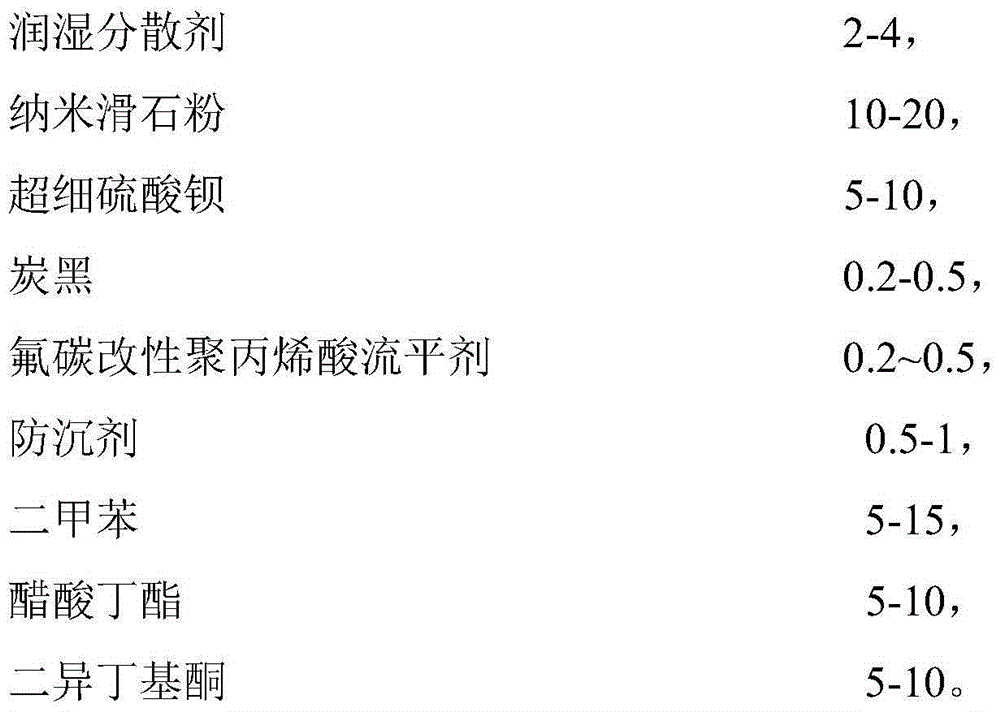

High-fillibility high-rubbing property primer and preparation method thereof

The invention relates to a high-fillibility high-rubbing property primer and a preparation method thereof. The method comprises the following steps: according to parts by weight, adding 20-40 parts of modified acrylic resin A, 10-20 parts of modified acrylic resin B, 2-4 parts of wetting dispersant, 10-15 parts of nano talcum powder, 5-10 parts of superfine barium sulfate, 0.2-0.5 parts of carbon black, 0.5-1 part of anti-settling agent, 5-15 parts of xylene, 5-10 parts of n-butyl acetate and 5-10 parts of dimethyl-4-heptanone respectively in a vat in sequence, and stirring for 30min at 600-800r / min, then putting into a grinder to grind to a fineness below 10 micrometers and discharging, and finally adding 0.2-0.5 parts of fluorocarbon-modified polyacrylic acid flatting agent and stirring for 30min at 600-800r / min. Compared with the prior art, the primer has the advantages of excellent adhesive force on various PP+GF (propene polymer and glass fiber), great easiness in polishing, excellent recoatability, suitability for various finishing coats and the like.

Owner:DONGLAI COATING TECH SHANGHAI

Process for producing dibk

InactiveUS20130245326A1Promote conversionGood choiceOrganic compound preparationCarbonyl compound preparationDiisobutylketoneHydrogenation reaction

A process for producing diisobutyl ketone (DIBK) which includes bringing together triacetone dialcohol (TDA) and a bifunctional catalyst that can perform a dehydration and hydrogenation reaction is described.

Owner:RHODIA POLIAMIDA E ESPECIALIDADES LTDA

Catalyst for synthesizing 2,6-dimethyl-4-heptanoneand preparation method for catalyst

ActiveCN104549252AHigh selectivityExtended service lifeOrganic compound preparationCarbonyl compound preparationDiisobutylketoneActive component

Owner:CHINA PETROLEUM & CHEM CORP +1

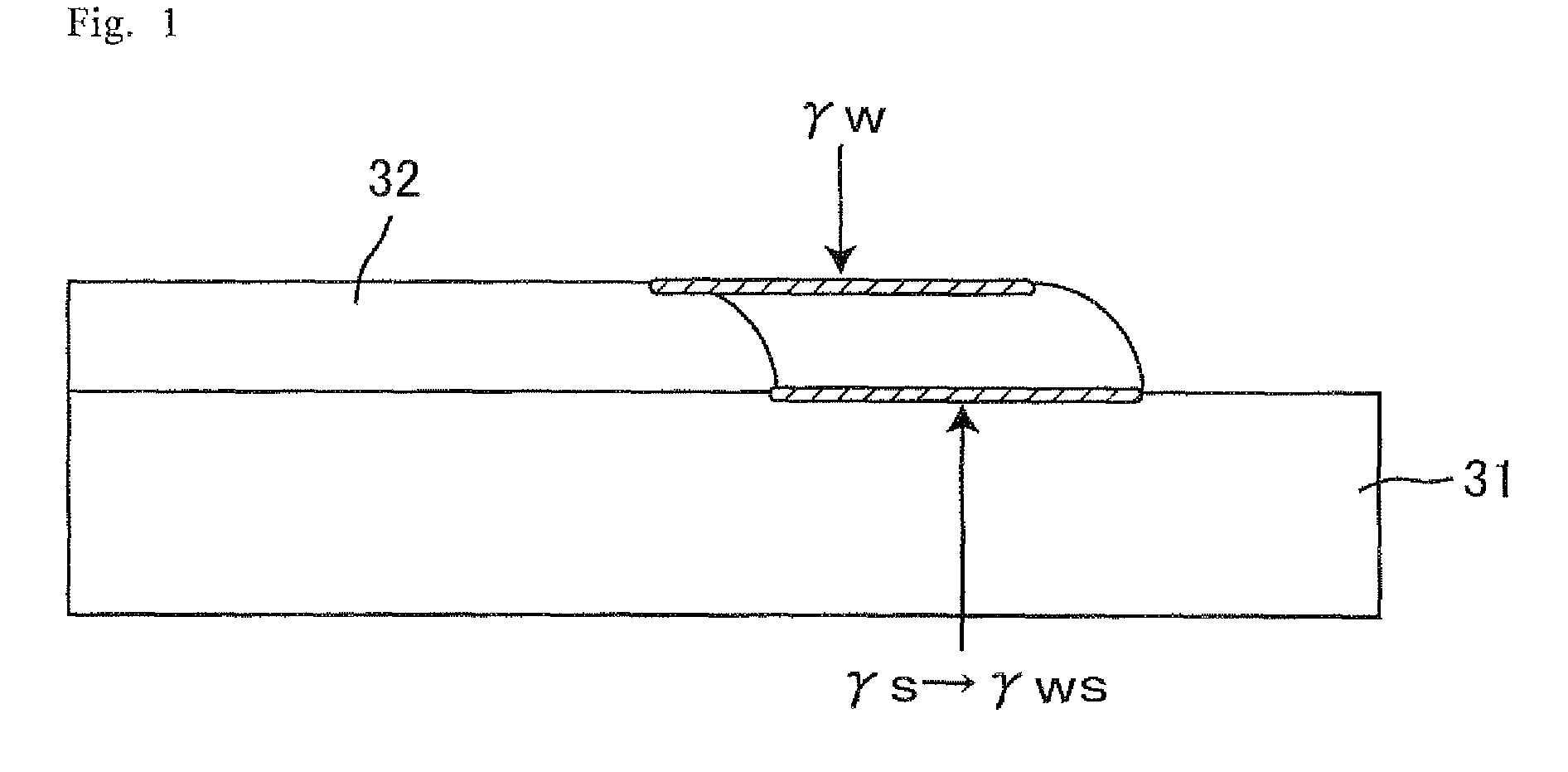

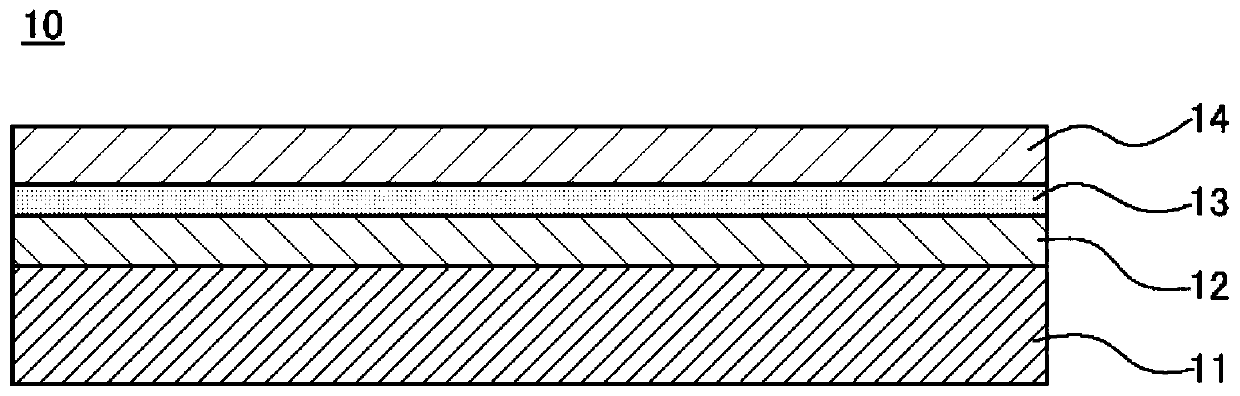

Surface decoration structure provided with silver mirror film layer and method for forming same

PendingCN110431005AWith surface decoration structureTransportation and packagingMetal-working apparatusDiisobutylketoneAliphatic hydrocarbon

A surface decoration structure 10 according to one embodiment of the present invention is obtained by forming a primer coating film 12, a silver mirror film layer 13 and a top coating film 14 on the surface of a substrate. The silver mirror film layer 13 is formed by laminating nanometer-sized silver particles, the surfaces of which are covered with a polymer dispersant; the top coating film 14 isformed using a coating material that contains, as a solvent, at least one substance selected from among aliphatic hydrocarbon compounds, aliphatic hydrocarbon compound solutions containing 10% by mass or less of an aromatic compound, and diisobutyl ketone. At least one of the primer coating film 12 and the top coating film 14 may contain a rust inhibitor; and the silver mirror film layer 13 may also contain a rust inhibitor. According to this embodiment, a surface decoration structure which has good luster, while being provided with a silver mirror film layer having good corrosion resistanceis able to be achieved.

Owner:SHIMANO INC

Method for synthesizing methyl isobutyl ketone and diisobutyl ketone by acetone gas-phase one-step method

InactiveCN101830787BSimple preparation processSuitable for mass productionOxygen-containing compound preparationOrganic compound preparationHydrogenMethyl isobutyl ketone

The invention relates to a method for synthesizing methyl isobutyl ketone and diisobutyl ketone by an acetone gas-phase one-step method, which relates to a chemical solvent. A Pd / MgO-Al2O3-ZrO2 catalyst is used in the method, comprises the components of 1wt% of Pd, 55wt% of MgO, 10wt% of Al2O3 and 34wt% of ZrO2 and is prepared from a PdMgAlZr four-element houghite compound. under the condition that the reaction temperature is 150-200 DEG C,the liquid air speed is 4.8ml / gcat.h, and the hydrogen-ketone mol ratio is 1, in a fixed bed reactor, the acetone conversion rate is 30-73 percent, and theselectivity of the methyl isobutyl ketone and the diisobutyl ketone respectively reaches 50-60 percent and 23-30 percent. The catalyst has simple preparation process and is suitable for large-scale production. After the ZrO2 is added, the catalyst has proper acid-base property and higher activity. The catalyst can be simultaneously used for preparing the two products of the methyl isobutyl ketoneand the diisobutyl ketone.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Catalyst used for preparing methyl isobutyl ketone and diisobutyl ketone by acetone condensation as well as preparation method and application of catalyst

ActiveCN109718786AHigh activityHigh yieldOrganic compound preparationCarbonyl compound preparationReaction temperatureCobalt

The invention relates to a catalyst used for preparing methyl isobutyl ketone and diisobutyl ketone by acetone condensation as well as a preparation method and application of the catalyst, and belongsto the field of acetone condensation catalysts. The catalyst used for preparing the methyl isobutyl ketone and the diisobutyl ketone by the acetone condensation comprises the following components, inpercentages by weight: (1) 2%-25% of copper or an oxide of the copper, (2) 8%-35% of zinc or an oxide of the zinc, (3) 2%-40% of cobalt or an oxide of the cobalt, (4) 1%-10% of barium or an oxide ofthe barium, (5) 30%-80% of aluminum oxide, and (6) 1%-40% of silicon dioxide. The catalyst provided by the invention uses the copper, the zinc, the cobalt and the like as loading components, the balance of acidity and alkalinity of the catalyst is properly adjusted, and the catalyst with a suitable catalyst pore structure is prepared; the catalyst is used at a lower reaction temperature, and has avery high conversion rate of acetate, less by-products, a high product yield, and low subsequent separation energy consumption; and after long-term evaluation, the catalyst shows ideal stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing diisobutyl ketone

ActiveCN106083549ARaise the boiling point temperature differenceImprove distillation efficiencyCarbonyl compound separation/purificationMethyl isobutyl ketoneDiisobutylketone

The invention discloses a method for preparing diisobutyl ketone. The method comprises the following steps: 1, transferring a mixture raw material extracted from a tower kettle of a methyl isobutyl ketone light component tower and mainly containing diisobutyl ketone into a reaction tank; 2, adding a silica-gel drier into the reaction tank, and performing stirring at rotating speed of 100 revolutions / min; 3, filtering the mixture raw material in the reaction tank by virtue of a filter; 4, delivering filtrate obtained by filtration into a preheater for preheating at preheating temperature of 76 to 94 DEG C; 5, delivery the preheated filtrate into a rectification tower for rectification, wherein the temperature of the top of the tower is controlled to be 104 to 126 DEG C, the side stream temperature is 156 to 177 DEG C, and the temperature of a tower kettle is 167 to 189 DEG C; 6, producing a diisobutyl ketone finished product from a side stream of the rectification tower, and charging the diisobutyl ketone finished product. According to the method, the temperature difference of boiling points of each substance is increased, and the rectification efficiency of the rectification tower is favorably improved, so that the purity of the diisobutyl ketone is improved on the premise of simplifying a purification process, and the economic benefits of the diisobutyl ketone are further greatly improved.

Owner:ZHEJIANG OCEANKING DEVELOPMENT CO LTD

A catalyst for the condensation of acetone to prepare methyl isobutyl ketone and diisobutyl ketone, its preparation method and application

ActiveCN109718786BOrganic compound preparationCarbonyl compound preparationPtru catalystMethyl isobutyl ketone

Owner:CHINA PETROLEUM & CHEM CORP +1

Drag reducing agent and method of use

ActiveUS8106114B2Increase DRA polymer solid loadingImprove impactOther chemical processesPipeline systemsDiisobutylketonePropylene carbonate

The present invention relates to a drag reducing agent, composition, compound, product, process and method of use for use in petroleum pipelines and the like. A preferred embodiment of the present invention provides a cryogenically-ground polyalphaolefin polymer at 15-25 wt. % of the commercial product formulation. The bulking agents comprise ethylene bis-stearamide alone or in combination with other polyethylene and / or polypropylene polymers at 2.0-5.0 wt. % of the commercial product formulation. In addition, diisobutyl ketone 20-60 wt. % of the commercial product formulation and propylene carbonate 2.8-8.4 wt. % of the commercial product formulation are used.

Owner:FLOWCHEM LLC

Method for separating zirconium and hafnium

ActiveCN102453801BLess mass transferLarge extraction capacityProcess efficiency improvementSolubilityHafnium

The invention relates to a method for separating zirconium and hafnium, which specifically comprises the following steps of: using the acidic water solution of a zirconium compound as a raw material, extracting hafnium in the material liquid into an organic phase by using diisobutyl ketone (DIBK) or the synergism of DIBK with a neutral phosphorous extracting agent or the synergism of DIBK with anacidic phosphorus-containing extracting agent, and washing and stripping the oganic phase to produce a hafnium-rich liquid such that the separation of zirconium and hafnium is realized; respectively precipitating the hafnium-rich liquid and the remaining organic phase by using ammonia water, and washing and roasting the precipitates to obtain atomic energy level zirconium oxide and hafnium oxide.In the technical method provided by the invention, low content of hafnium in zirconium hafnium is preferably extracted, and the method has simple process and high extraction efficiency. The extraction system used in the method reaches the same zirconium and hafnium separation performance to MIBK (Methyl Isobutyl Ketone) but has smaller water solubility, high boiling point and flashing point and smaller toxicity compared with MIBK, and the problems of great solvent loss, easy outbreak of fire, environmental pollution and the like in the MIBK extraction separation method are solved.

Owner:有研资源环境技术研究院(北京)有限公司

Anti-wool felt wear-resistant matte PU coating as well as preparation method and application thereof

ActiveCN112322165AImprove wear resistanceImprove performancePolyurea/polyurethane coatingsSpecial surfacesCyclohexanonePolymer science

Owner:卡秀万辉(无锡)高新材料有限公司

Nickel-based catalyst for one-step synthesis of downstream condensation products of acetone

ActiveCN107930661BLow costImprove stabilityPhysical/chemical process catalystsOrganic compound preparationPtru catalystMethyl isobutyl ketone

The invention relates to a catalyst, and belongs to the technical field of applications and development of acetone downstream products, wherein nickel is used as a main active component, phosphorous,lanthanum and / or neodymium are used as auxiliary agent components, aluminum oxide, silicon oxide or an aluminum oxide-silicon oxide composite carrier with rich pH value is selected to promote a reaction, the catalyst is used under a mild reaction condition, an acetone one-step production process is used, the yield of methyl isobutyl ketone in the application of the catalyst of the present invention is higher than the yield of methyl isobutyl ketone in the application of the palladium / resin catalyst used in the current industrial apparatus, and isopropanol and high added value diisobutyl ketoneare co-produced. According to the present invention, the obtained catalyst has the ideal stability, has the cost significantly lower than the cost of the existing palladium catalyst, and has good economic benefits.

Owner:CHINA PETROLEUM & CHEM CORP +1

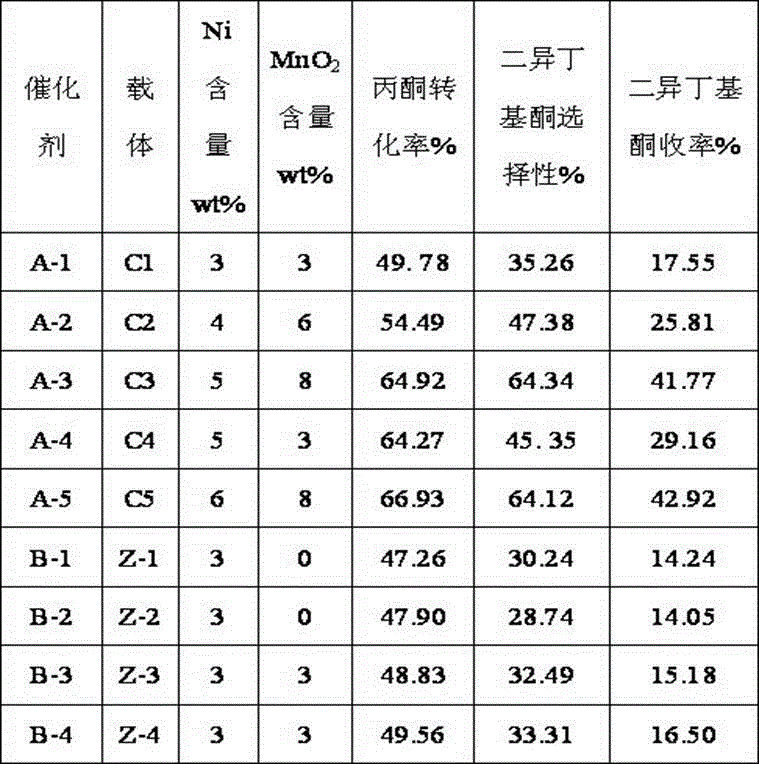

Catalyst for synthesizing diisobutyl ketone from acetone and preparation method thereof

ActiveCN104549348BPrevent crystallite meltingAvoid the phenomenon that the adsorption is hinderedOrganic compound preparationCarbonyl compound preparationDiisobutylketoneBULK ACTIVE INGREDIENT

The invention discloses a catalyst for synthesis of 2,6-dimethyl-4-heptanone from acetone and a preparation method for the catalyst. The catalyst comprises an active ingredient Ni and a carrier ZrO12-MnO2; based on the total weight of the catalyst, the content of the active ingredient Ni is 1 to 10 weight percent, preferably 3 to 6 weight percent, the content of MnO2 is 1 to 20 weight percent, preferably 5 to 10 weight percent, and the balance is ZrO2. The catalyst disclosed by the invention is applied to a reaction for synthesis of the 2,6-dimethyl-4-heptanone from the acetone, and has the characteristics that conversion rate of the acetone serving as a raw material is high; the selectivity of the 2,6-dimethyl-4-heptanone serving as a product is high, that is the yield of the 2,6-dimethyl-4-heptanone serving as a target product is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com