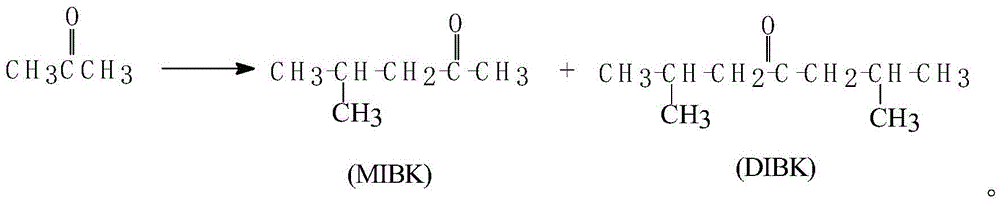

A polycondensation catalyst, a preparing method thereof, applications of the catalyst, a diisobutyl ketone preparing method and a diisobutyl carbinol preparing method

A polycondensation catalyst, the technology of diisobutyl ketone, applied in the preparation of carbon-based compounds, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve the problems of difficult catalyst regeneration, low conversion rate, and high reaction temperature, and achieve target product selection. High performance, high acetone conversion rate and high polycondensation activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

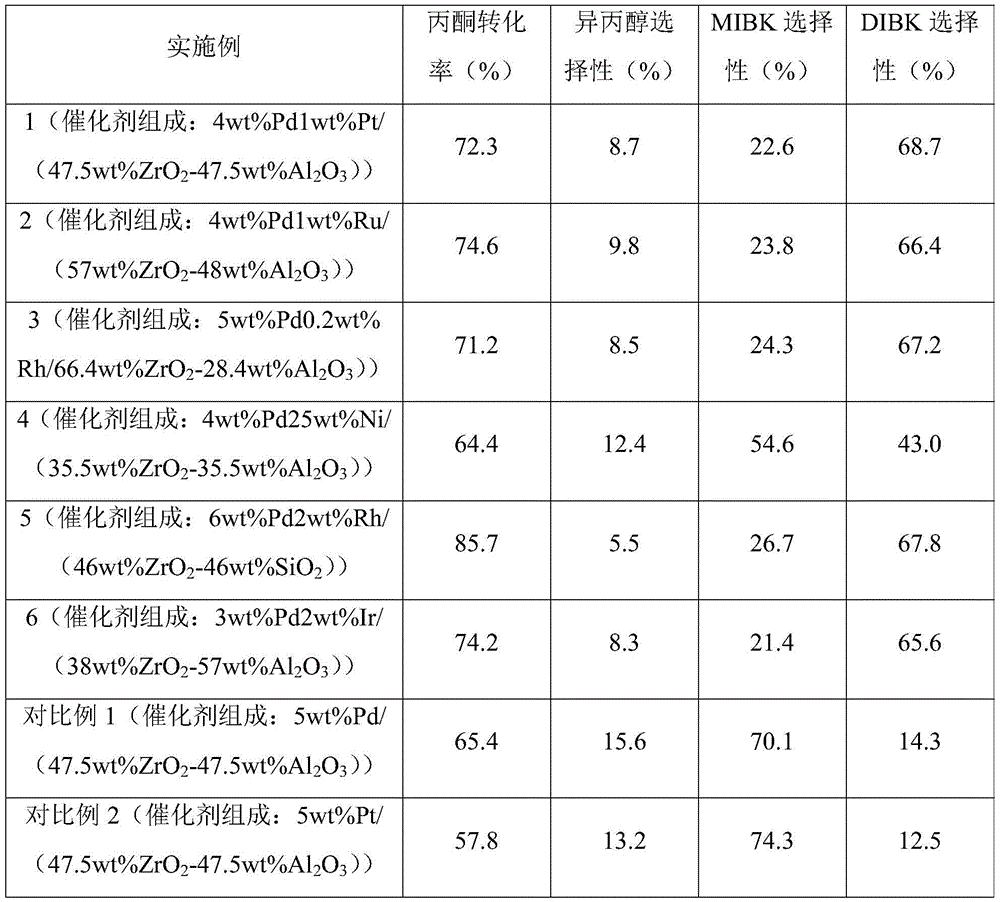

Embodiment 1

[0084] (1) Preparation of palladium-platinum / zirconia-alumina catalyst

[0085]Preparation of zirconia-alumina carrier: adding 0.5mol / LZrOCl dropwise to ammonia water with a concentration of 25% by weight 2 ·8H 2 O and Al(NO 3 ) 3 9H 2 O aqueous solution until pH = 6, then reflux at 100°C and 1 atmosphere for 10 hours, and wash the obtained precipitate with deionized water until neutral; dry in air at 100°C for 24h, and then roast to obtain the product ZrO 2 -Al 2 o 3 Carrier (ZrO 2 with Al 2 o 3 The weight ratio is 1:1).

[0086] Prepare 100mL of palladium chloride and chloroplatinic acid aqueous solutions with concentrations of 33.0g / l and 10.4g / l respectively, add 0.5g polyethylene glycol 200 and mix well, and add 50g ZrO 2 -Al 2 o 3 For the carrier, NaOH solution with a concentration of 5% by weight was added dropwise to adjust the pH to about 9, and aged at 30° C. for 8 hours under stirring. Dry at 110°C for 2 hours, and then calcinate at 400°C for 2 hours to...

Embodiment 2-3

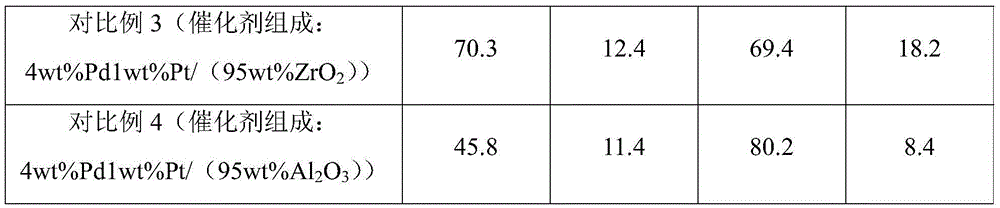

[0093] The polycondensation catalyst was prepared according to the method of Example 1, except that the amount of each raw material was adjusted, so that the composition of the prepared polycondensation catalyst was shown in Table 1 below, and the results for the acetone polycondensation reaction were shown in Table 1 below.

Embodiment 4

[0095] The polycondensation catalyst was prepared according to the method of Example 1, except that the amount of each raw material was adjusted, so that the composition of the prepared polycondensation catalyst was shown in Table 1 below, and the results for the acetone polycondensation reaction were shown in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com