Anti-wool felt wear-resistant matte PU coating as well as preparation method and application thereof

A wool felt and coating technology, used in polyurea/polyurethane coatings, coatings, devices for coating liquids on surfaces, etc. Abrasion, paint film is not shiny, good performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

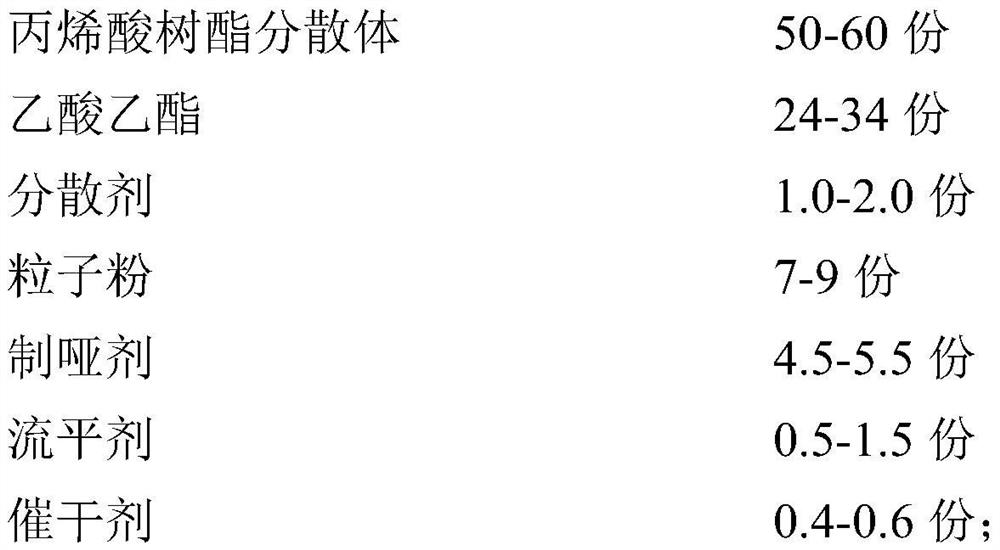

[0038]A component: 100 parts

[0039]B component: 20 parts

[0040]Thinner component: 100 parts

[0041]The A component is composed of the following quality components:

[0042] Acrylic resin dispersion 50 Ethyl acetate 34.5 DISPERBYK2023 1.5 GR-800T 8.0 OK520 5.0 BYK333 0.5 T3000.5

[0043]The B component is composed of the following quality components:

[0044] Hexamethylene diisocyanate 55 Butyl acetate45

[0045]The diluent component consists of raw materials of the following quality components:

[0046]

[0047]The preparation of the coating and the preparation of the coating are carried out according to the above ratio, and the specific steps are as follows:

[0048]1. Preparation of paint:

[0049]Preparation of component A: Mix ethyl acetate, DISPERBYK2023, GR-800T and OK520 thoroughly, add the acrylic resin dispersion while stirring, and after the acrylic resin dispersion is completely dissolved, add BYK333 and T300 and stir evenly to get A component;

[0050]Preparation of component B: miscible hexamet...

Embodiment 2

[0055]A component: 100 parts

[0056]B component: 20 parts

[0057]Thinner component: 100 parts

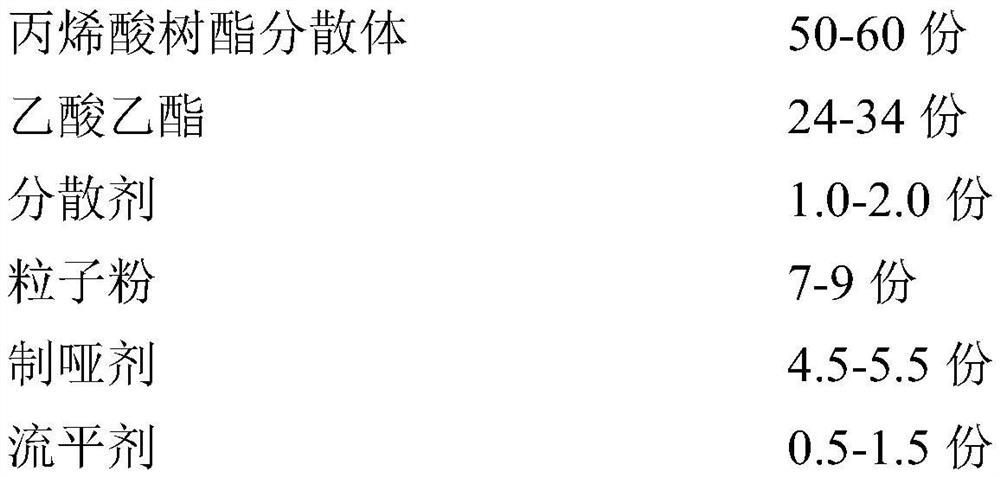

[0058]The A component is composed of the following mass parts of raw materials:

[0059] Acrylic resin dispersion 55 Ethyl acetate 29.5 DISPERBYK2023 1.5 GR-800T 8 OK520 5 BYK333 0.5 T3000.5

[0060]The B component is composed of the following quality components:

[0061] Hexamethylene diisocyanate 55 Butyl acetate45

[0062]The diluent component consists of raw materials of the following quality components:

[0063]

[0064]1. Preparation of paint:

[0065]Preparation of component A: Mix n-ethyl acetate, DISPERBYK2023, GR-800T and OK520 thoroughly, add the acrylic resin dispersion while stirring, after the acrylic resin dispersion is completely dissolved, add BYK333 and T300, and stir evenly. Get A component;

[0066]Preparation of component B: miscible hexamethylene diisocyanate and butyl acetate, mix thoroughly, and obtain component B of curing agent;

[0067]Preparation of the diluent component: butyl acetate, e...

Embodiment 3

[0071]A component: 100 parts

[0072]B component: 20 parts

[0073]Thinner component: 100 parts

[0074]The A component is composed of the following mass parts of raw materials:

[0075] Acrylic resin dispersion 60 Ethyl acetate 24.5 DISPERBYK2023 1.5 GR-800T 8 OK520 5 BYK333 0.5 T3000.5

[0076]The B component is composed of the following quality components:

[0077] Hexamethylene diisocyanate 55 Butyl acetate45

[0078]The diluent component consists of raw materials of the following quality components:

[0079]

[0080]1. Preparation of paint:

[0081]Preparation of component A: Mix ethyl acetate, DISPERBYK2023, GR-800T and OK520 thoroughly, add the acrylic resin dispersion while stirring, and after the acrylic resin dispersion is completely dissolved, add BYK333 and T300 and stir evenly to get A component;

[0082]Preparation of component B: miscible hexamethylene diisocyanate and butyl acetate, mix thoroughly, and obtain component B of curing agent;

[0083]Preparation of the diluent component: butyl acetate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com