High-fillibility high-rubbing property primer and preparation method thereof

A filling and sanding technology, which is applied in the field of high-filling and high-grinding primers and their preparation, can solve the problems of difficult sanding of primers, rough surfaces of materials, and difficulties in covering rough surfaces, and achieve recoating and spraying The effect of convenient and fast topcoat, excellent filling and excellent sanding of primer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for preparing a high-filling and high-grinding primer suitable for various PP+GF materials, the method comprising the following process steps:

[0026] (1) Component preparation:

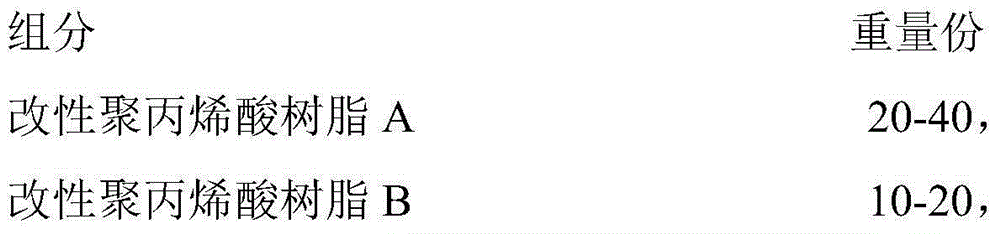

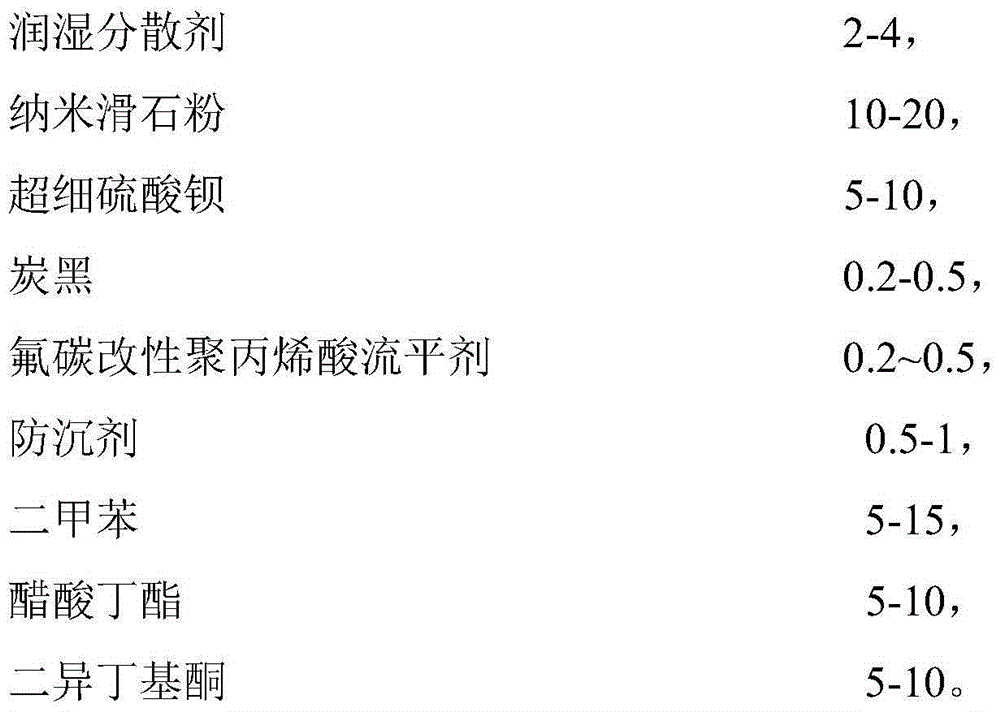

[0027]

[0028] In addition to the leveling agent, the others are put into the cylinder in sequence, stirred at 600-800 rpm for more than 30 minutes, put into the grinder and ground to a fineness of less than 10 microns, and the material is discharged, and then add 0.5 of the leveling agent, at 600-800 rpm / min stirring for 30 minutes to complete.

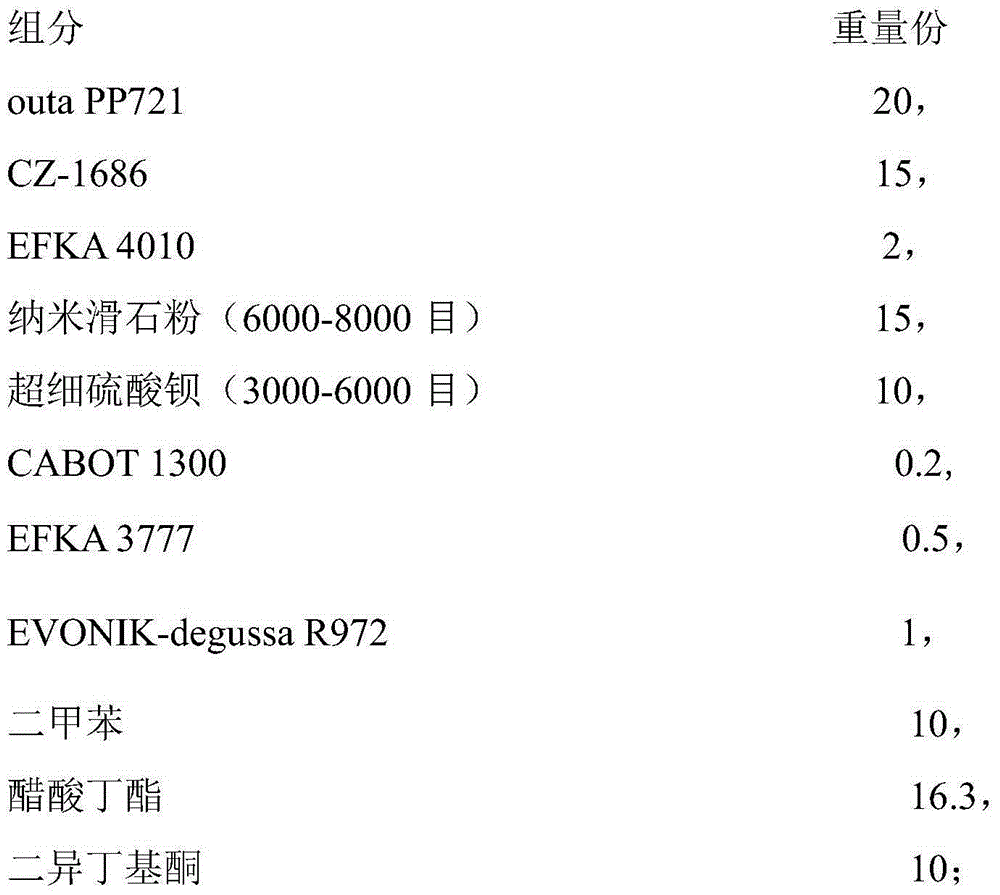

[0029] Appeal Example Coating Performance Results

[0030]

[0031]

Embodiment 2

[0033] A method for preparing a high-filling and high-grinding primer suitable for various PP+GF materials, the method comprising the following process steps:

[0034] (1) Component preparation:

[0035]

[0036] Put the others into the tank in order except the leveling agent, stir at 600-800 rpm for more than 30 minutes, put it into the grinder to grind to a fineness of 10 microns, and then discharge the material, add 0.5 of the leveling agent, and stir at 600-800 rpm / min stirring for 30 minutes to complete.

[0037] Above-mentioned embodiment coating performance result

[0038]

Embodiment 3

[0040] A method for preparing a high-filling and high-grinding primer suitable for various PP+GF materials, the method comprising the following process steps:

[0041] (1) Component preparation:

[0042]

[0043]

[0044] Put the others into the tank in order except the leveling agent, stir at 600-800 rpm for more than 30 minutes, put it into the grinder to grind to a fineness of 10 microns, and then discharge the material, add 0.5 of the leveling agent, and stir at 600-800 rpm / min stirring for 30 minutes to complete.

[0045] Above-mentioned embodiment coating performance result

[0046]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com