A catalyst for the condensation of acetone to prepare methyl isobutyl ketone and diisobutyl ketone, its preparation method and application

A technology of methyl isobutyl ketone and diisobutyl ketone, which is applied to the catalyst for preparing methyl isobutyl ketone and diisobutyl ketone by acetone condensation and the field of preparation thereof, can solve the problem of shortening the technological process and the intolerant of resin. High temperature regeneration, short life and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

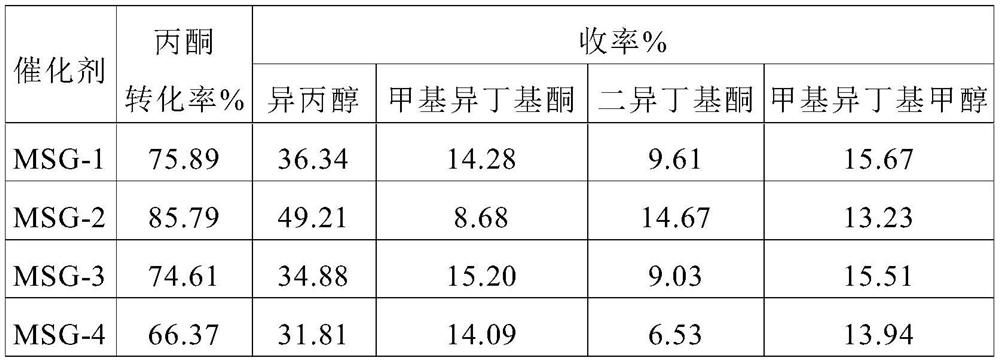

Examples

Embodiment 1

[0041] Pour 240g of pseudo-boehmite into a kneader, then add 6g of celadon powder, knead and mix. Then add 60g of silica sol, 10g of dilute nitric acid with a volume fraction of 20%, knead into a block, extrude, then dry at 120°C and roast at 400°C for 4 hours to obtain a carrier, which is crushed to 0.5-3mm for later use. Silica sol is produced by Shandong Ocean Chemical Co., Ltd., the model is JN-30. Pseudoboehmite is produced by Jiangsu Sanji Industrial Co., Ltd., with a specific surface area of 290m 2 / g, the pore volume is 0.9mL / g.

[0042] 31.5 g of copper nitrate, 25.5 g of cobalt nitrate, 50.5 g of zinc nitrate and 10 g of barium nitrate were dissolved in 45 g of water in a beaker to form a salt mixture solution. The mixed solution was poured into a beaker containing 60 g of the catalyst carrier, shaken evenly and allowed to stand for 3 hours, then dried at 120° C. and calcined at 450° C. for 3 hours to obtain the oxidation state of the catalyst. Before use, the c...

Embodiment 2

[0044] Pour 270g of pseudo-boehmite into a kneader, then add 6g of celadon powder, knead and mix. Then add 30g of silica sol, 10g of dilute nitric acid with a volume fraction of 20%, knead into a block, extrude, then dry at 120°C and roast at 450°C for 4 hours to obtain a carrier, which is crushed to 0.5-3mm for later use. Silica sol is produced by Shandong Ocean Chemical Co., Ltd., the model is JN-30. Pseudoboehmite is produced by Jiangsu Sanji Industrial Co., Ltd., with a specific surface area of 290m 2 / g, the pore volume is 0.9mL / g.

[0045] 25.5 g of copper nitrate, 28.5 g of cobalt nitrate, 40.0 g of zinc nitrate and 8 g of barium nitrate were dissolved in 40 g of water in a beaker to form a salt mixture solution. The mixed solution was poured into a beaker containing 60 g of the catalyst carrier, shaken evenly and allowed to stand for 2 hours, then dried at 120° C. and calcined at 450° C. for 3 hours to obtain the oxidation state of the catalyst. Before use, the ca...

Embodiment 3

[0047] Pour 290g of pseudo-boehmite into a kneader, then add 6g of fennel powder, knead and mix. Then add 10g of silica sol, 10g of dilute nitric acid with a volume fraction of 20%, knead into a block, extrude, then dry at 120°C and roast at 450°C for 4 hours to obtain a carrier, which is crushed to 0.5-3mm for later use. Silica sol is produced by Shandong Ocean Chemical Co., Ltd., the model is JN-30. Pseudoboehmite is produced by Jiangsu Sanji Industrial Co., Ltd., with a specific surface area of 290m 2 / g, the pore volume is 0.9mL / g.

[0048] 20.5 g of copper nitrate, 40.5 g of cobalt nitrate, 25.5 g of zinc nitrate and 3 g of barium nitrate were dissolved in 45 g of water in a beaker to form a salt mixture solution. The mixed solution was poured into a beaker containing 60 g of the catalyst carrier, shaken evenly and allowed to stand for 3 hours, then dried at 120° C. and calcined at 500° C. for 3 hours to obtain the oxidation state of the catalyst. Before use, the cat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com