Process for producing methylisobutylketone and diisobutyl ketone by using acetone

A technology of methyl isobutyl ketone and diisobutyl ketone, applied in the field of preparation of chemical solvents, can solve the problems of large number of equipment, long process flow, large investment, etc., and achieve the effect of high activity and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

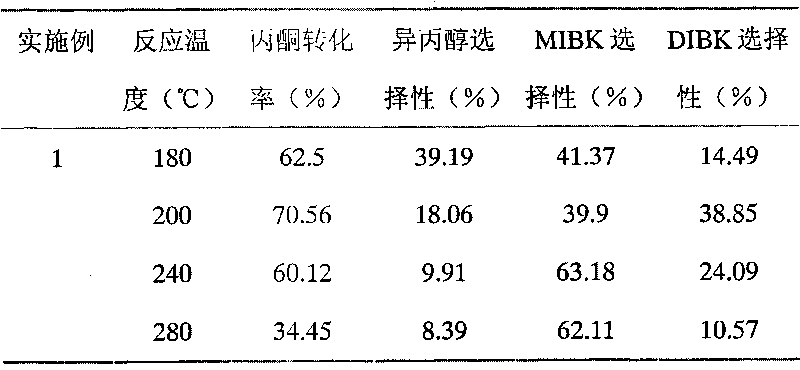

Embodiment 1

[0015] Use freshly boiled distilled water to prepare 1.0mol / L Ni(NO 3 ) 2 , Mg(NO 3 ) 2 , Al(NO 3 ) 3 and 0.5mol / L of Zr(NO 3 ) 4 Metal salt solution; prepare another 1.0mol / L NaOH solution and 0.5mol / L NaOH solution 2 CO 3 solution. According to the catalyst composition Ni: 5.5wt%, MgO: 51wt%, Al 2 o 3 : 9.5wt%, ZrO 2 : 34wt%, Ni, Mg, Al, Zr four kinds of nitrate solutions are made into a mixed solution, and the solution is denoted as A. A certain amount of Na was added to the beaker in advance 2 CO 3 Solution [CO 3 2- The molar weight of = 0.5 (Al 3+ +Zr 4+ ) molar weight], solution A and NaOH solution are simultaneously titrated into the beaker, the rate of addition is controlled, and the stirring is continued to keep the pH between 9 and 10. After the dropwise addition, stir and age in a constant temperature water bath at 60°C for 12 hours, wash and centrifuge until the pH is around 7, perform suction filtration, put the filter cake in an oven, and dry at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com