Catalyst for co-producing methyl isobutyl ketone and diisobutyl ketone

A technology of methyl isobutyl ketone and diisobutyl ketone is applied in the field of catalysts for synthesizing methyl isobutyl ketone, and can solve the problems of high catalyst usage cost, inability to produce or by-product diisobutyl ketone, and the like, Achieve low cost, easy handling, high stability and longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

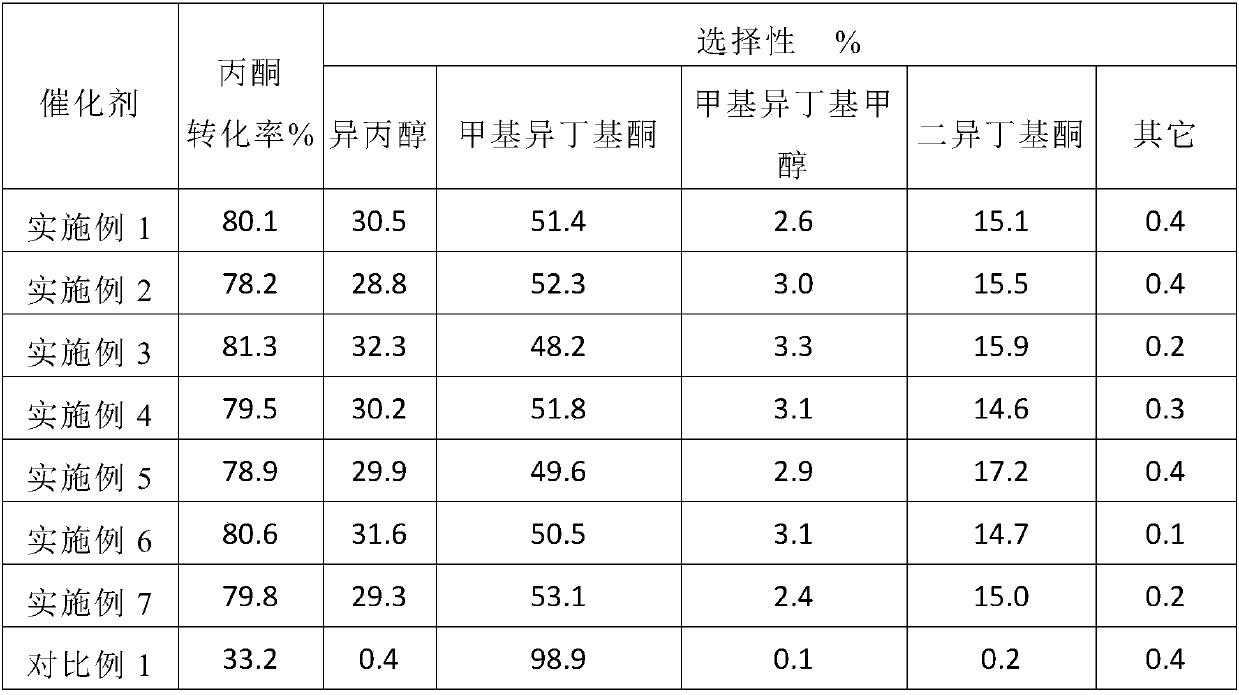

Examples

Embodiment 1

[0035] In a beaker, 148.2 grams of cobalt nitrate, 14 grams of lanthanum nitrate and 204.7 grams of zinc nitrate were dissolved in 850 grams of water to make aqueous solution I. Under stirring and at 70° C., titrated with 30 wt % sodium carbonate aqueous solution until the pH value of the reaction solution was 7.0. Then add 298 grams of pseudo-boehmite powder. Pseudoboehmite is produced by Jiangsu Sanji Industrial Co., Ltd., with a specific surface area of 300m 2 / g, the pore volume is 1.04mL / g.

[0036] Then aged at 75° C. for 3 hours, then suction filtered and washed until the sodium ion content was lower than 0.05%. The wet cake was dried, granulated, and then calcined at 420°C for decomposition. Finally, it is sliced into granules, and the particle size is

[0037] Then, the catalyst was reduced with hydrogen in a temperature-programmed manner, and the highest reduction temperature was 480°C. Constant temperature reduction at 480°C for 2 hours. After cooling ...

Embodiment 2

[0042] In a beaker, 74.1 grams of cobalt nitrate, 23.4 grams of lanthanum nitrate and 81.9 grams of zinc nitrate are dissolved in 420 grams of water to make aqueous solution I, and under stirring and at 72° C., titrate to the pH value of the reaction solution with 30 wt % sodium carbonate aqueous solution 7.5. Then add 363 grams of pseudo-boehmite powder. Pseudoboehmite is produced by Jiangsu Sanji Industrial Co., Ltd., with a specific surface area of 284m 2 / g, the pore volume is 0.88mL / g.

[0043] Then aged at 75° C. for 3 hours, then suction filtered and washed until the sodium ion content was lower than 0.05%. The wet filter cake is dried, granulated, and then roasted and decomposed at 380°C. Finally, it is sliced into granules, and the particle size is

[0044] Then, the catalyst was reduced with hydrogen in a temperature-programmed manner, and the highest reduction temperature was 450°C. Constant temperature reduction at 450°C for 3 hours. After cooling down,...

Embodiment 3

[0047] In a beaker, 192.7 grams of cobalt nitrate, 51.1 grams of cerium nitrate and 327.5 grams of zinc nitrate were dissolved in 1300 grams of water to make aqueous solution I. Under stirring and at 70° C., titrated with 30 wt % sodium carbonate aqueous solution until the pH value of the reaction solution was 7.2. Then add 215.9 grams of pseudo-boehmite powder. Pseudoboehmite is produced by Jiangsu Sanji Industrial Co., Ltd., with a specific surface area of 310m 2 / g, the pore volume is 0.95mL / g.

[0048] Then aged at 75° C. for 3 hours, then suction filtered and washed until the sodium ion content was lower than 0.05%. The wet filter cake is dried, granulated, and then roasted and decomposed at 380°C. Finally, it is sliced into granules, and the particle size is

[0049] Then, the catalyst was reduced with hydrogen in a temperature-programmed manner, and the highest reduction temperature was 460°C. Constant temperature reduction at 460°C for 3 hours. After coolin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com