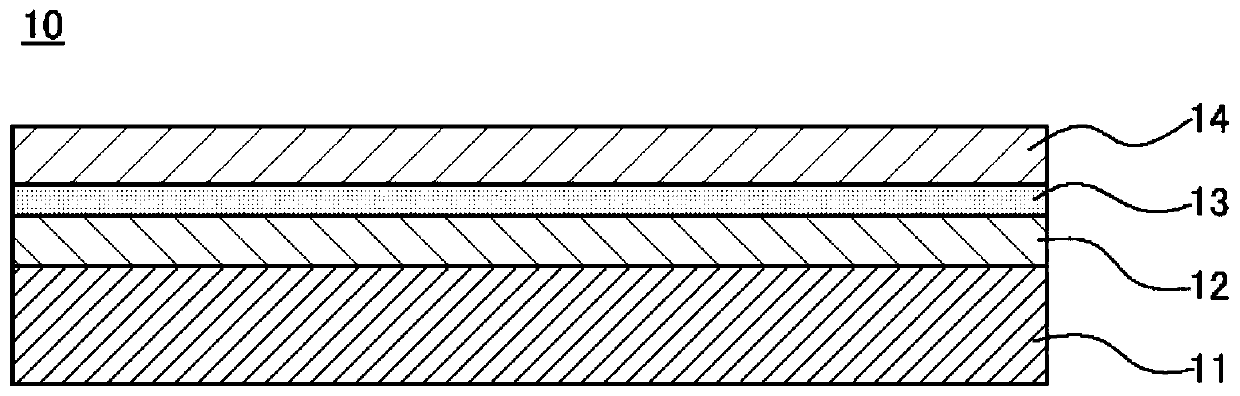

Surface decoration structure provided with silver mirror film layer and method for forming same

A technology for surface decoration and silver mirror, which is applied in the field of surface decoration structure with silver mirror film layer and its formation, and can solve the problems of uneven film thickness, peeling off of silver mirror coating surface and high defect rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0115] (primer coating film)

[0116] The silicon oligomer containing alkoxy group (GLANZCOAT Type RT BlackPrimer G, FECT (stock)) as the main ingredient of the primer paint is 6 parts by mass, ethanol as a solvent is 7 parts by mass, and the hardener (GLANZCOAT typeRT Primer G Hardener U, FECT (stock)) was uniformly stirred and mixed at a ratio of 1 part by mass to prepare a primer paint. The primer coating was spray-coated on the surface of a standard test piece as a base material, and then forced-dried at 100° C. for 30 minutes to obtain a standard test piece sample with a primer coating film formed thereon.

[0117] (silver mirror coating)

[0118]As the composition liquid for forming the silver mirror film layer, use the commercially available combination liquid (GLANTZCOAT TypeRT Silver) prepared based on the patent document 3, and utilize the thinner (GLANTZCOAT TypeRT Silver thinner T2) to form the silver mirror film layer. It was diluted to 2 times and sprayed, and ...

experiment example 2

[0122] As the solvent of the primer paint and the top paint paint, use isopropanol instead of ethanol, in addition, in the same manner as in the case of Experimental Example 1, a primer paint film and a silver mirror film layer were formed on the surface of the standard test piece. And the silver mirror film layer of the experimental example 2 of topcoat film forms the sample.

experiment example 3

[0124] As the solvent of primer paint and topcoat paint, butanol is used instead of ethanol, except that, in the same manner as the situation of Experimental Example 1, a primer paint film, a silver mirror film layer, and a primer film are formed on the surface of the standard test piece. The silver mirror film layer formation sample of Experimental Example 3 of the topcoat film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com