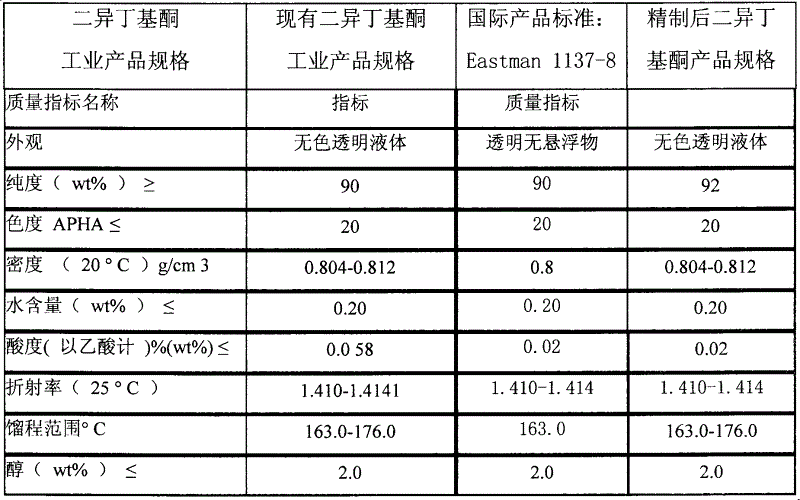

Application of inorganic alkaline and fixed-bed adsorption technique to deacidification and purification of diisobutyl ketone

A technology of fixed bed adsorption and diisobutyl ketone, which is applied in the separation/purification of carbonyl compounds, organic chemistry, and other chemical processes, etc., to achieve the effect of large product loss, low material loss, and small equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1 Inorganic Alkali Sorbent Industrial Manufacturing Process

[0021] Raw materials for industrial production of inorganic alkali adsorbent: 70% by weight of activated alumina, 15% of magnesium hydroxide, 8% of aluminum flakes reacted with nitric acid to prepare aluminum sol, 4% of carbonate bicarbonate, 3% of glycol and deionized Water, fully mixed into a plastic body in the noodle mixer, extruded into a cylindrical strip of 2.5mm×3~10mm in the extruder, dried in the oven at 110°C for 10 hours, and sifted out the powder The material was sent into the converter and rapidly raised to 550°C for 5 hours of roasting. produce 2m 3 Inorganic alkali adsorbent finished product.

Embodiment 2

[0022] Industrial scale-up of embodiment 2 fixed-bed adsorption process

[0023] Manufacture an industrially designed adsorption tower model device that effectively removes the heat of adsorption. According to the laboratory test of 62.1J. / g, the industrial wetting capacity is large, the temperature rises, gasification, and disturb the bed layer, and the cooling coil is designed in the model device tower . Diisobutyl ketone industrial products have low acid content, simulating the industrial conditions of deacidification refined diisobutyl ketone industrial products, with a bulk density of 520Kg / m 3 . The volume of the mode adsorption tower is 0.2m 3 , the space velocity is 0.6~0.8 / h. Using inorganic alkali adsorbent and fixed bed adsorption technology to solve the problem of unqualified organic free acid content in diisobutyl ketone products, a large number of industrial samples with DIBK free acid content of 0.058% were repeatedly processed on the model device, and DIBK w...

Embodiment 3

[0026] Embodiment 3 Inorganic Alkali Sorbent Industrial Regeneration Technology

[0027]After unloading the saturated inorganic alkali adsorbent from the model adsorption tower, the centrifuge removes diisobutyl ketone, dries at 70°C for 10 hours, sieves out the crushed powder, and sends it into the converter to raise the temperature to 300°C2 hours later. Rapidly raise the temperature to 550°C for 6 hours in the converter. After cooling to normal temperature, the industrial regeneration technology of inorganic alkali adsorbent was investigated by using the model device. Measure the physical and chemical indicators such as alkalinity, adsorption capacity, activity stability and mechanical strength of the regenerated adsorbent, and measure the static deacidification efficiency and acid capacity of the adsorbent after activation and regeneration. Repeat 10 times and each index recovers to more than 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com