Preparation method for producing monocalcium phosphate slurry by using wet phosphoric acid slurry process

A technology of calcium dihydrogen phosphate and wet-process phosphoric acid, which is applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve problems such as unfavorable packaging, storage and transportation, incomplete reaction, reheating and agglomeration, and achieve good economic benefits. and environmental benefits, saving production costs and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

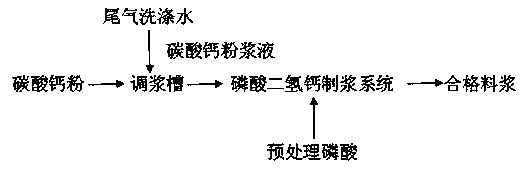

[0014] A preparation method for producing calcium dihydrogen phosphate slurry by a wet-process phosphoric acid slurry method, comprising the steps of:

[0015] (1) Calcium carbonate powder with a purity of more than 98% and a fineness of more than 200 meshes and tail gas cleaning solution (the solute is mainly calcium dihydrogen phosphate) and calcium carbonate powder / tail gas cleaning solution of 0.9 are mixed evenly to prepare calcium carbonate powder slurry;

[0016] (2) Prepare pretreated phosphoric acid by adding defluorinating agent at 5% to 10% of concentrated phosphoric acid with phosphorus pentoxide content of 48% or more, and adding arsenic agent at 0.1% to 0.3% for impurity purification;

[0017] (3) Calcium carbonate powder slurry and pretreated phosphoric acid were mixed at a phosphorus-to-calcium ratio of 1.70, thoroughly mixed in a multi-stage series reaction system, and reacted for 4 hours to prepare calcium dihydrogen phosphate slurry.

[0018] Reduce the amou...

Embodiment 2

[0020] A preparation method for producing calcium dihydrogen phosphate slurry by a wet-process phosphoric acid slurry method, comprising the steps of:

[0021] (1) Calcium carbonate powder with a purity of more than 98% and a fineness of more than 200 meshes and tail gas washing liquid (the solute is mainly calcium dihydrogen phosphate) and calcium carbonate powder / tail gas washing liquid of 0.8 are mixed evenly to prepare calcium carbonate powder slurry;

[0022] (2) Prepare pretreated phosphoric acid by adding defluorinating agent at 5% to 10% of concentrated phosphoric acid with phosphorus pentoxide content of 48% or more, and adding arsenic agent at 0.1% to 0.3% for impurity purification;

[0023] (3) Calcium carbonate powder slurry and pretreated phosphoric acid are mixed at a phosphorus-to-calcium ratio of 1.65, fully mixed in a multi-stage series reaction system, and reacted for 4 hours to prepare calcium dihydrogen phosphate slurry.

[0024] Reduce the amount of calciu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com