Method and apparatus for forming a package comprising a stack of absorbent tissue paper material and a packaging

A technology of absorbent and tissue paper, applied in paper product packaging, transportation and packaging, thin paper/absorbent paper, etc., can solve problems such as the generation of rebound force, and achieve the effect of reducing the packaging volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

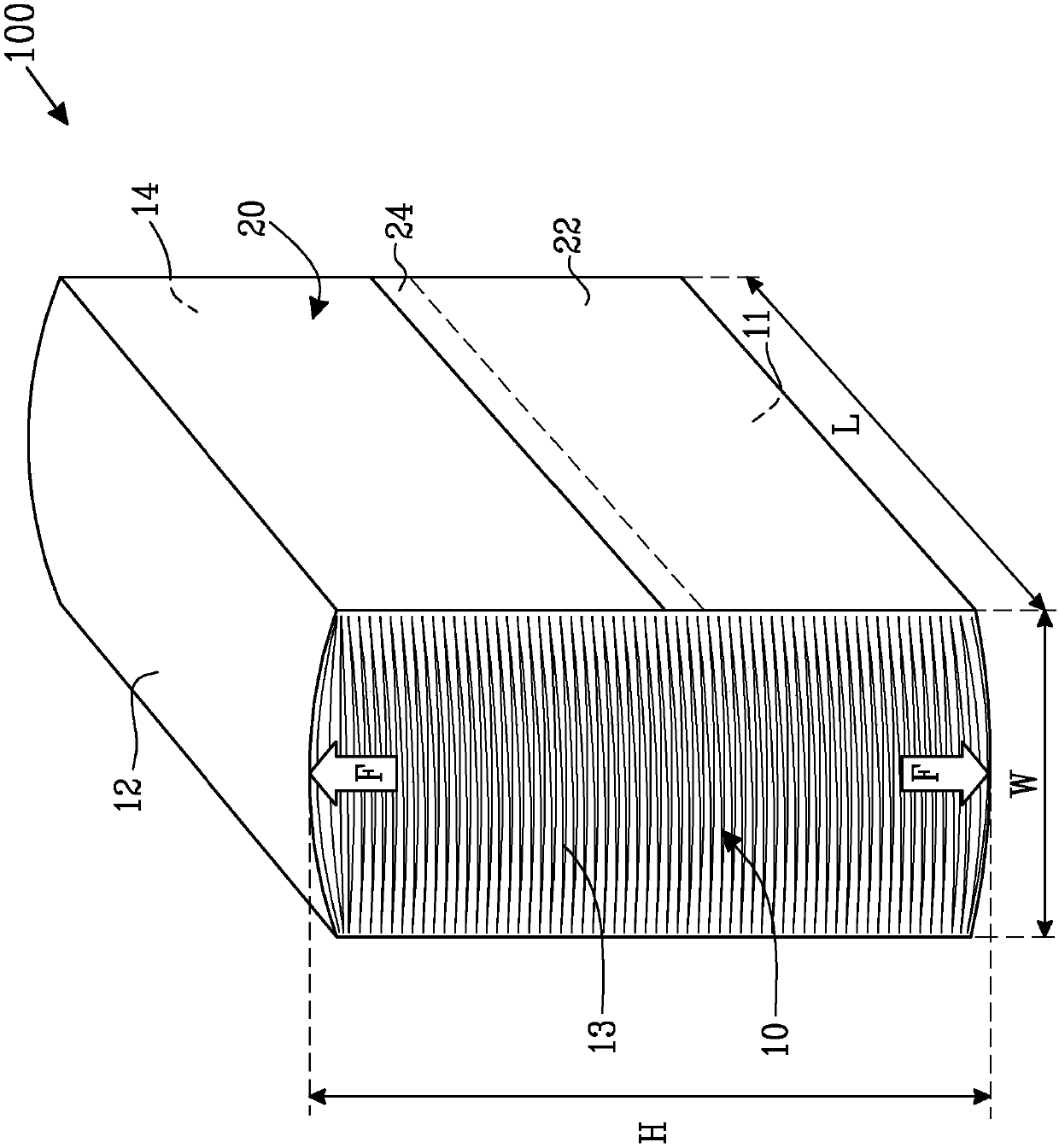

[0135] figure 1 An embodiment of a package 100 including a stack 10 of absorbent tissue material and a package 20 is schematically shown.

[0136] In the stack 10, the absorbent tissue material forms a panel having a length L and a width W perpendicular to the length L. The panels are stacked on top of each other to form a height H extending between the first end surface 11 and the second end surface 12 of the stack 10.

[0137] in figure 1 Among them, the absorbent tissue material is a continuous web material folded in a zigzag shape so that the fold lines extend along the length L of the stack, and the distance between the two fold lines along the web material corresponds to the width W of the stack.

[0138] The package 20 surrounds the stack 10 so as to maintain the stack 10 in the package 100 in a compressed state. Therefore, the stack 10 seeking to expand exerts a force F toward the package 20 in the direction of the stack height H. The force F will cause the package to bul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com