Motor cooling ventilation controlled valve and motor cooling ventilation automatic control method

A technology for motor cooling and electromagnetic valves, which is applied in the direction of cooling/ventilation devices, electric components, machines/engines, etc. It can solve the problems of increasing the workload of motor maintenance and low efficiency, so as to avoid manual operation of opening and closing valves and realize real-time Monitor and improve the effect of maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

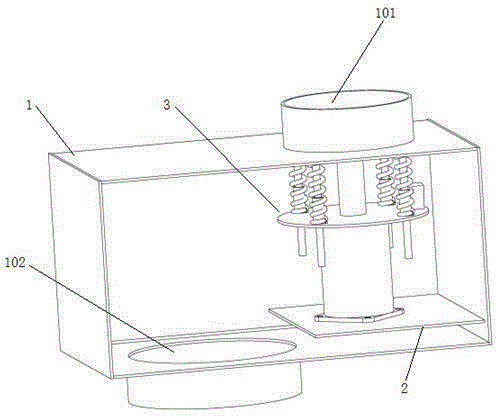

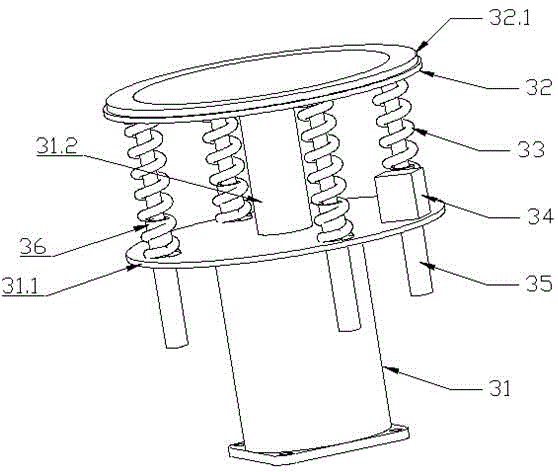

[0029] like Figure 1 to Figure 4 As shown, the motor cooling and ventilation controllable valve is installed in the redundant space 1 of the motor cooling and ventilation pipeline, including the mounting plate 2 and the electromagnetic valve 3, the mounting plate 2 is fixed in the redundant space 1, and the electromagnetic valve 3 is installed on the mounting plate 2, the top of the electromagnetic valve 3 is against the ventilation inlet of the redundant space 1; the electromagnetic valve 3 includes an electromagnet 31 connected to the motor power supply system, a valve 32 arranged directly above the electromagnet 31, and a valve 32 arranged on the electromagnet 31 and the elastic compression member 33 between the valve 32 and the contact sensor switch 34 arranged on the upper surface of the electromagnet 31 and connected with the motor control system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com