Large-torque hollow rotating platform

A technology of rotating platform and high torque, which is applied in the direction of machine/support, cleaning method using gas flow, supporting machine, etc. It can solve the problems of large vibration of motor and damage of hollow rotating platform, so as to achieve enhanced stability and easy fixing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

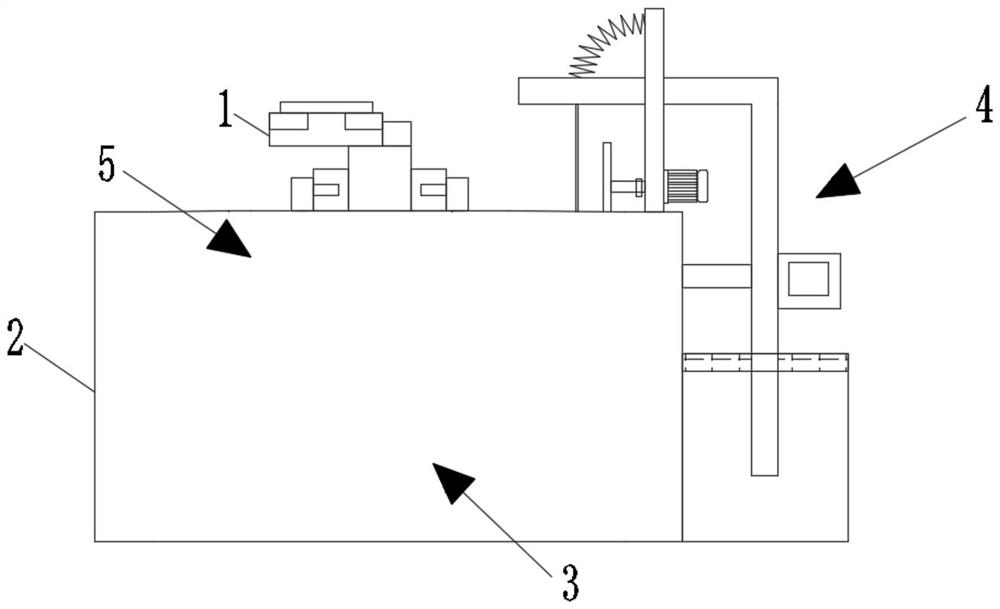

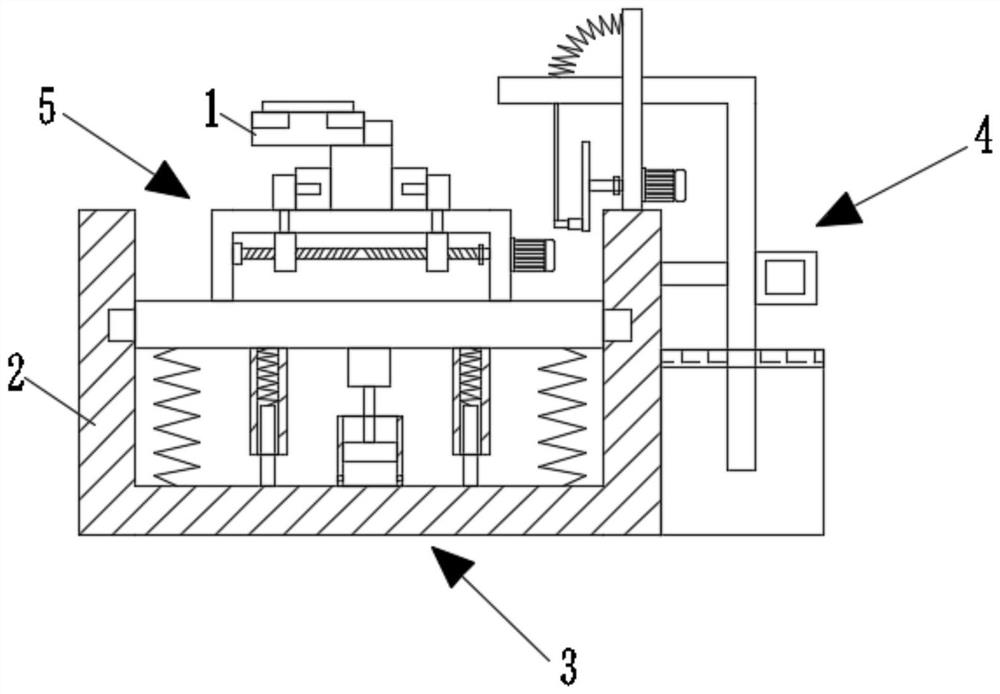

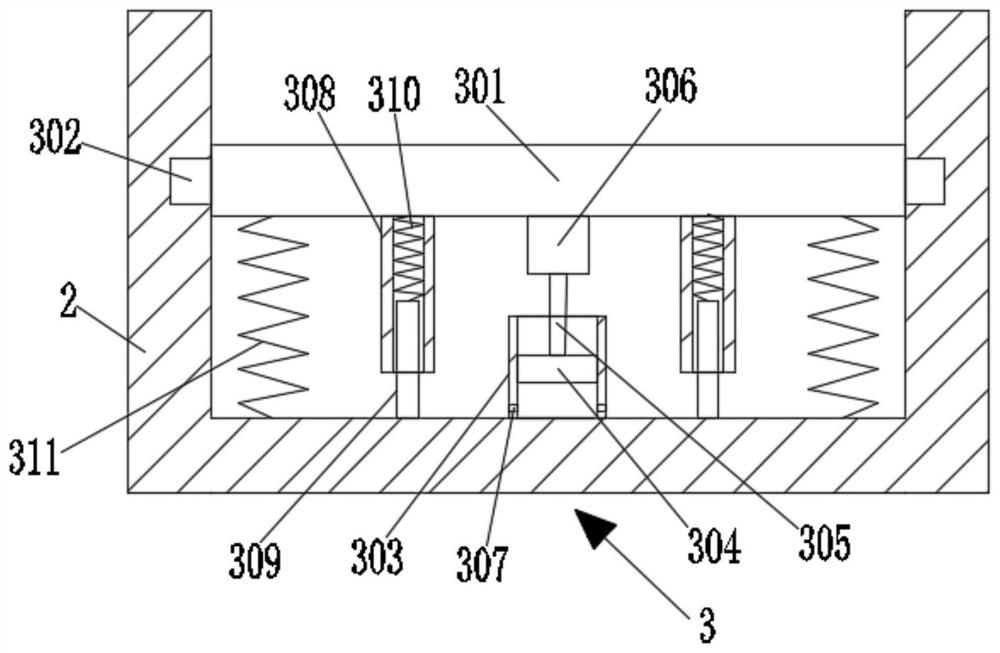

[0023] like Figure 1-6As shown, the present invention provides a technical solution: a high-torque hollow rotating platform, comprising a hollow rotating platform body 1 and a box body 2, the top of the box body 2 is provided with an opening, and the hollow rotating platform body 1 is arranged on the box body 2. Above the box body 2, a vibration damping device 3 is arranged inside, and the vibration damping device 3 includes a vibration damping plate 301, a slider 302, an air pipe 303, a piston 304, a connecting rod 305, a fixed block 306, an exhaust hole 307, a fixed pipe 308, the fixing rod 309, the No. 1 spring 310, the No. 2 spring 311, the number of the sliders 302 is two, the two sliders 302 are respectively fixed and installed on the outer walls of the left and right sides of the vibration damping plate 301, and the left and right sides of the box body 2 are fixed. The side inner walls are provided with chutes, and the two sliders 302 are respectively slidably connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com