Patents

Literature

840 results about "Cascade reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A cascade reaction, also known as a domino reaction or tandem reaction, is a chemical process that comprises at least two consecutive reactions such that each subsequent reaction occurs only in virtue of the chemical functionality formed in the previous step. In cascade reactions, isolation of intermediates is not required, as each reaction composing the sequence occurs spontaneously. In the strictest definition of the term, the reaction conditions do not change among the consecutive steps of a cascade and no new reagents are added after the initial step. By contrast, one-pot procedures similarly allow at least two reactions to be carried out consecutively without any isolation of intermediates, but do not preclude the addition of new reagents or the change of conditions after the first reaction. Thus, any cascade reaction is also a one-pot procedure, while the reverse does not hold true. Although often composed solely of intramolecular transformations, cascade reactions can also occur intermolecularly, in which case they also fall under the category of multicomponent reactions.

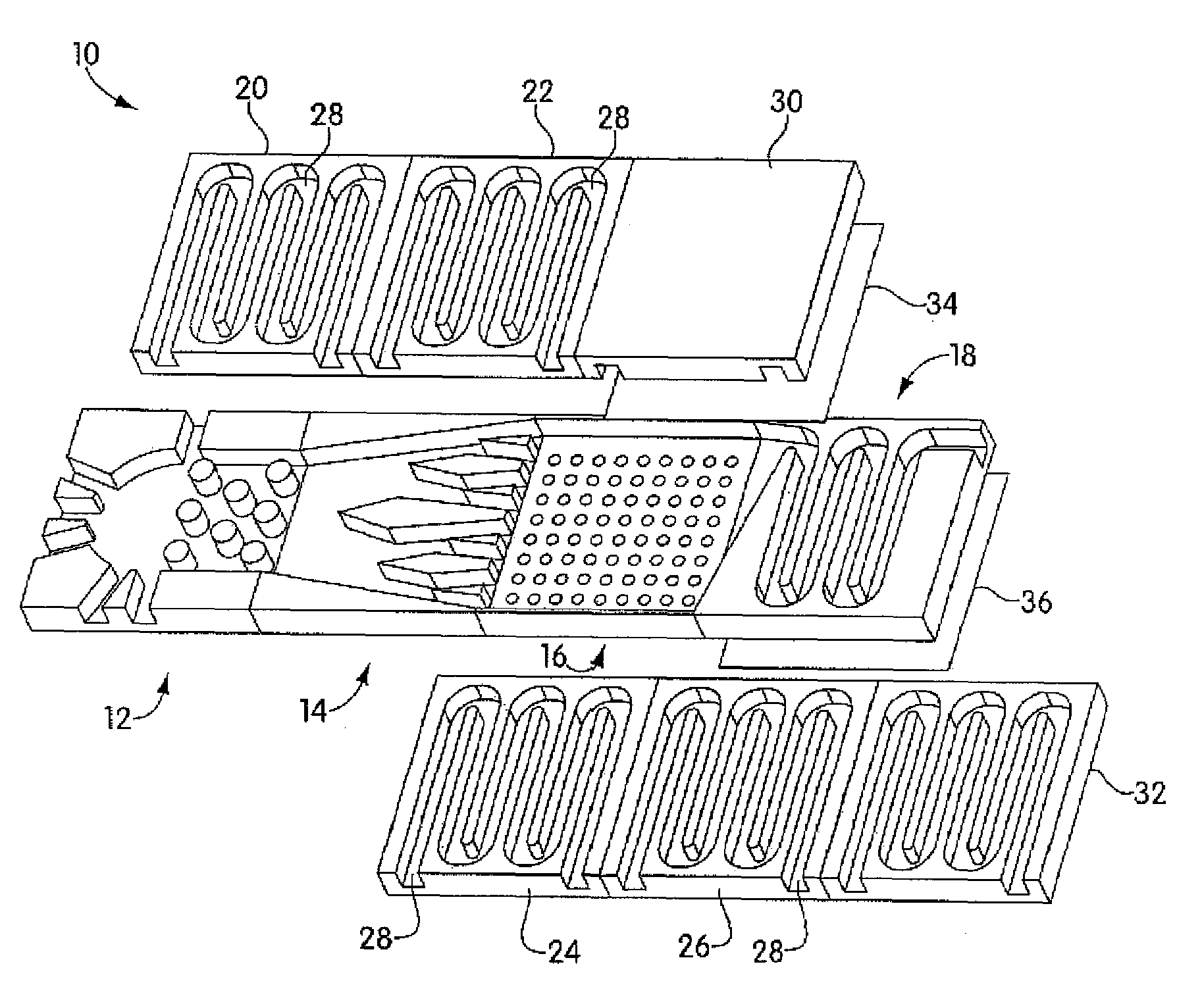

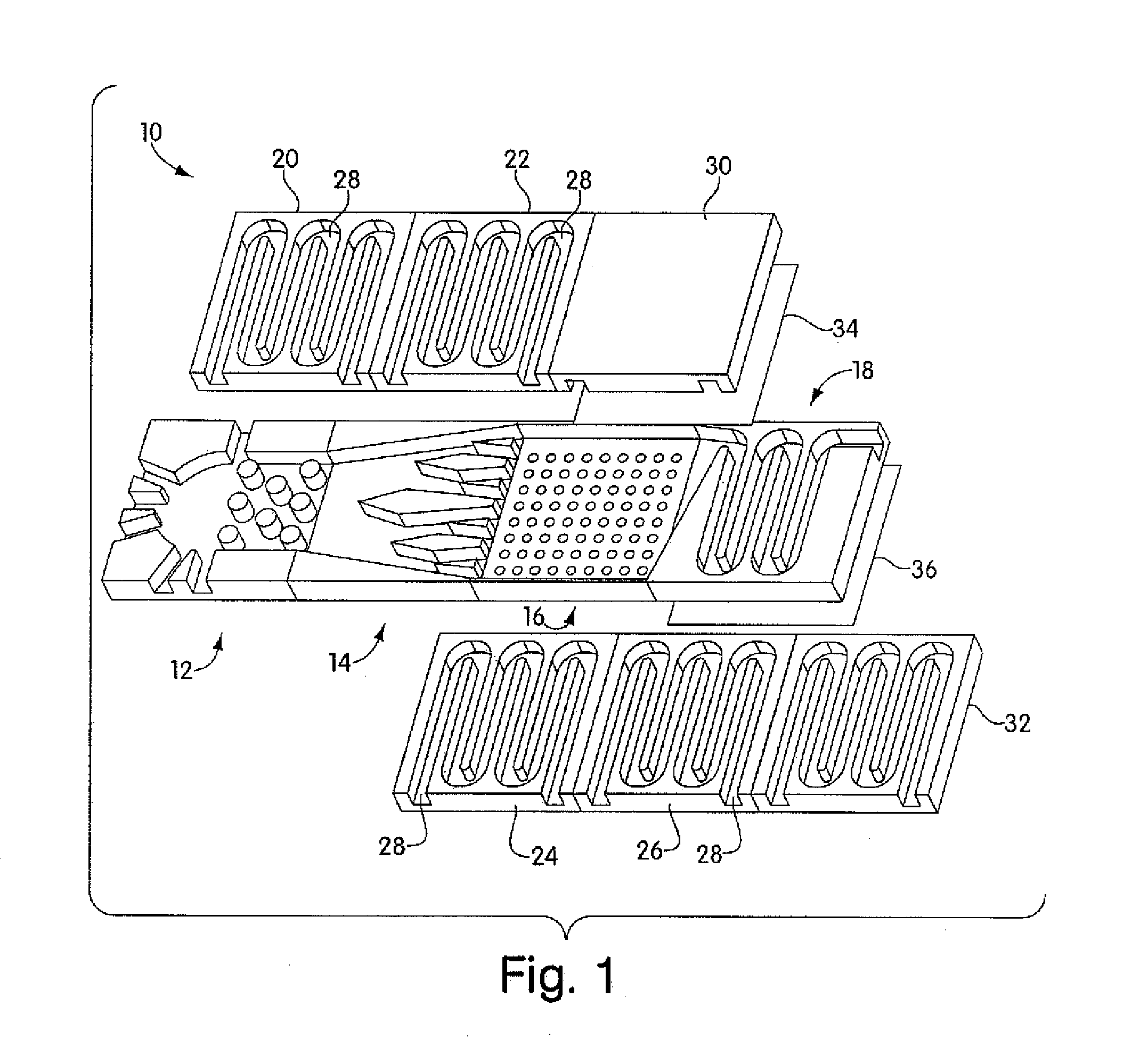

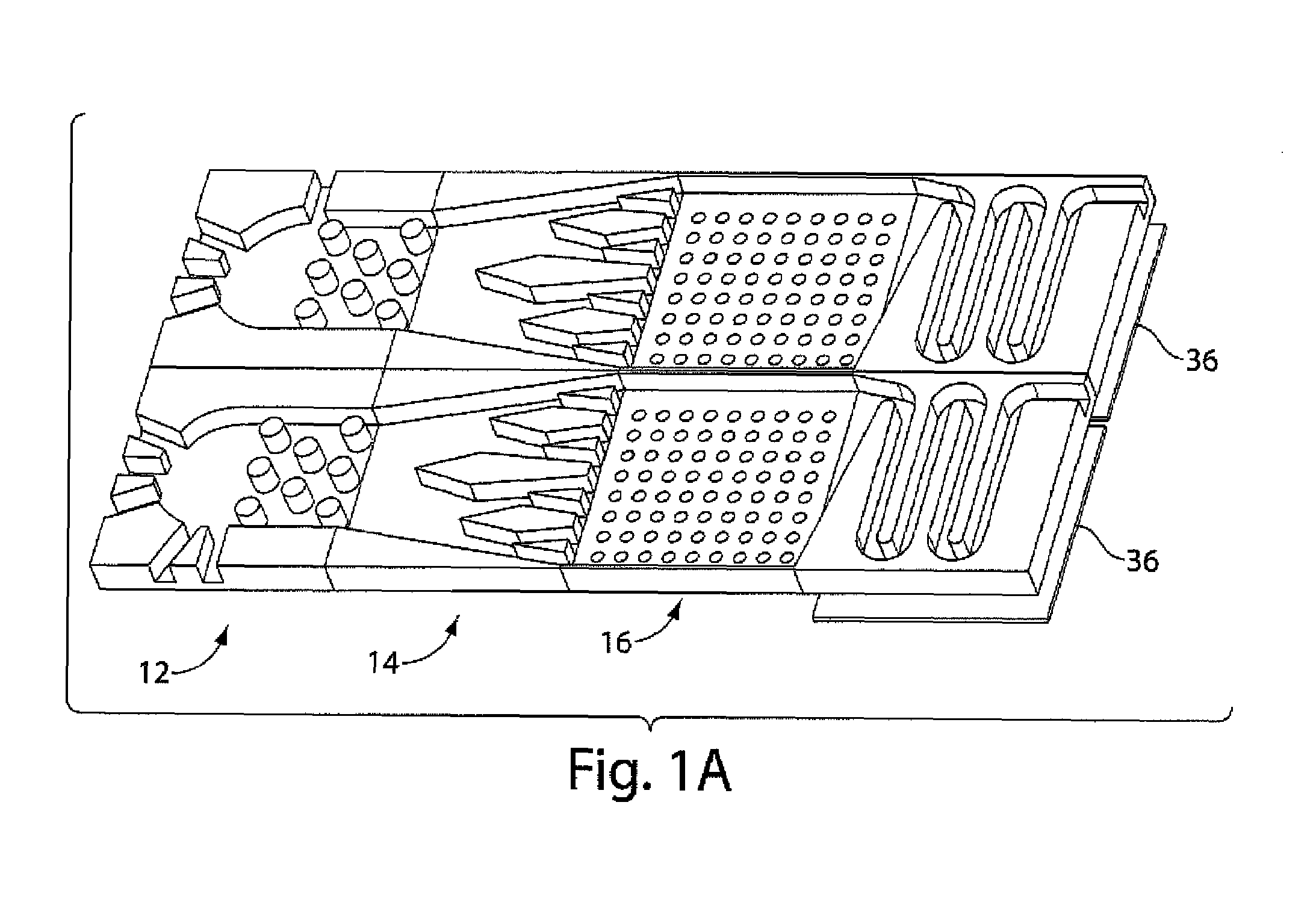

Microreactor

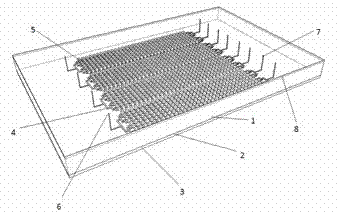

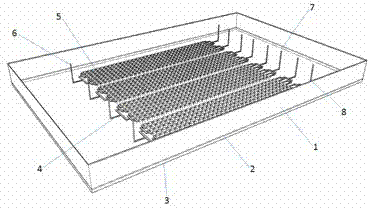

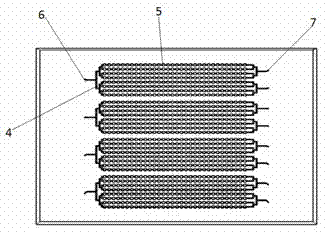

Chemical and biological reactors, including microreactors, are provided. Exemplary reactors include a plurality of reactors operable in parallel, where each reactor has a small volume and, together, the reactors produce a large volume of product. Reaction systems can include mixing chambers, heating / dispersion units, reaction chambers, and separation units. Components of the reactors can be readily formed from a variety of materials. For example, they can be etched from silicon. Components are connectable to and separable from each other to form a variety of types of reactors, and the reactors can be attachable to and separable from each other to add significant flexibility in parallel and / or series reactor operation.

Owner:BIOPROCESSORS CORP

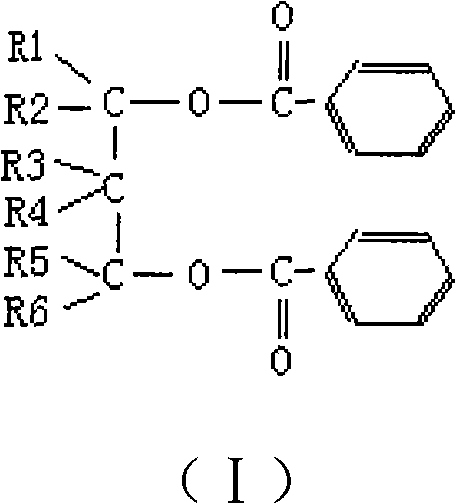

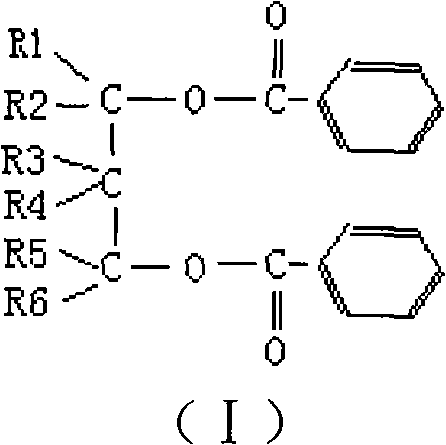

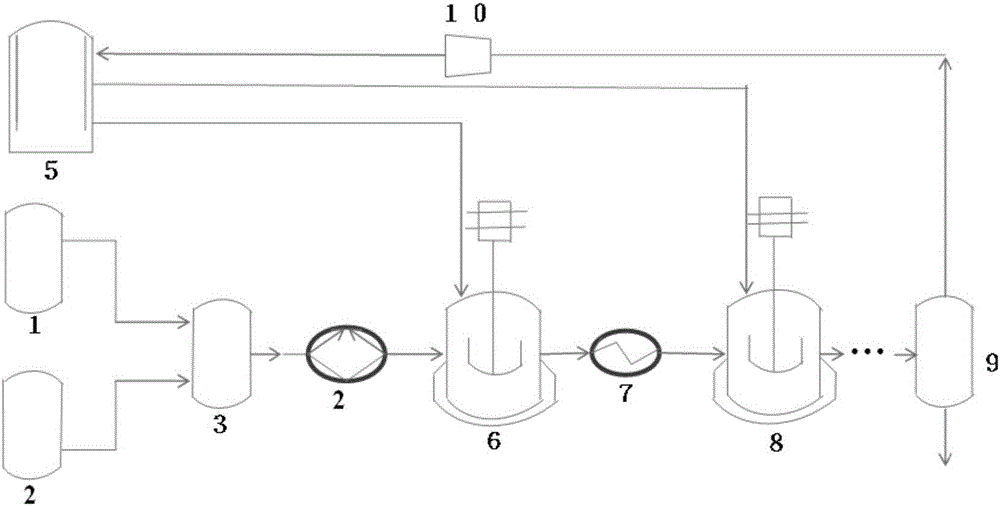

Preparation method of polypropylene with wide molecular weight distribution and polymer thereof

The invention provides a preparation method of molecular weight distribution polypropylene and a polymer thereof. By using the method, polymerization reaction is carried out in a single reactor or a plurality of series reactors in the presence of catalysts, wherein the catalysts are reactants containing the following components: (1) at least one solid catalyst component comprising magnesium, titanium, halogen and at least two electron donors of a and b, wherein the electron donor a is selected from a diol ester compound; the electron donor b is selected from unitary or multi-element aliphatic carboxylic ester, aromatic aliphatic carboxylic ester or diether compounds; and the weight ratio of the electron donor a to the electron donor b is 2-80; (2) an alkyl aluminum compound; and (3) optimally, an external electron donor component. The acrylic polymer has the advantages of wide molecular weight distribution, high isotacticity and the like; meanwhile, the preparation method has simple operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

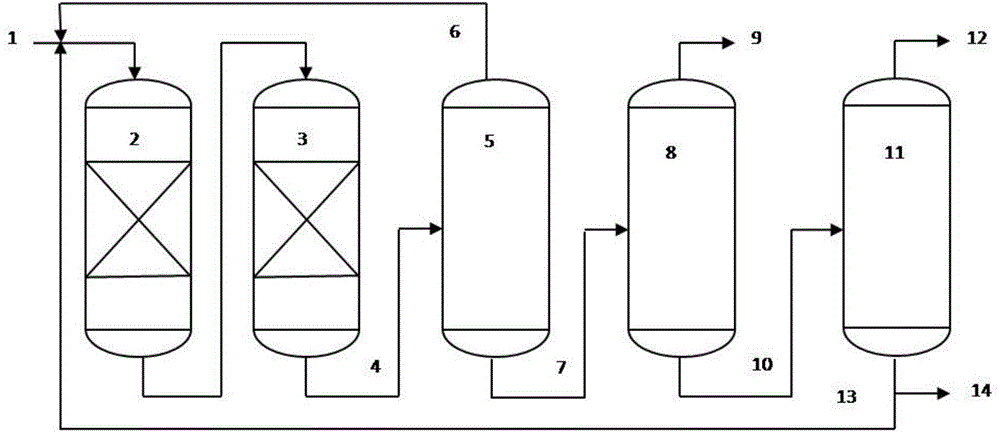

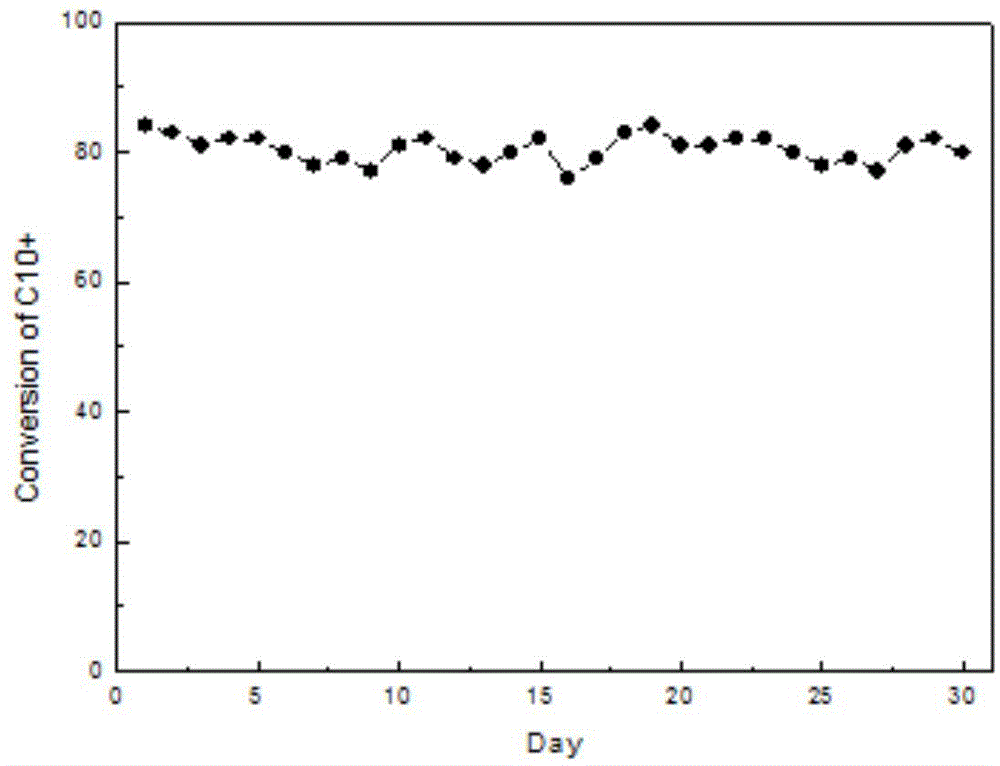

Method for conversion of C10+ heavy aromatics into light aromatics by virtue of hydrogenation

ActiveCN104357083AHigh quality feedHigh activityTreatment with hydrotreatment processesBenzeneHydrogen

The invention relates to a method for conversion of C10+ heavy aromatics into light aromatics by virtue of hydrogenation. The method is characterized by comprising the following steps: preheating heavy aromatics raw material through a heating furnace, performing oil-gas mixing on the preheated heavy aromatics raw material and hydrogen, respectively performing pre-hydrogenation saturation and hydrocracking reaction through two reactors in series connection in order; isolating benzene, toluene and light alkane mixture from reaction product through one-step rectification, isolating C8-C9 aromatics crude product or light fraction before 205 DEG.C for high-octane petrol blending component from tower bottom material through rectification, and circularly reacting tower bottom heavy fraction. The method can be used for processing byproduct C10+ heavy aromatics of a reformer or a steam cracking device in a refinery plant, and increasing the production of light aromatics or high-octane petrol blending component. The method provided by the method has the features of high heavy aromatics conversion activity, good catalyst stability and flexible product on the process.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Power source-free and valve-free type single molecule detection chip and applications thereof

ActiveCN103071548AReduce consumptionAutomatic fast and even dispersionBioreactor/fermenter combinationsBiological substance pretreatmentsReaction layerFluorescence

The present invention provides a power source-free and valve-free type single molecule detection chip, which comprises a reaction layer, a modification layer, a sealing layer, a main channel, small reaction chambers, a sample inlet, a sample outlet and a heat resistant adhesive tape, wherein the reaction layer is formed by connecting the main channel and the reaction small chambers in series, the reaction small chambers are positioned above or below the main channel, the sample inlet and the sample outlet are positioned on both ends of the main channel, the modification layer is pre-connected with the sealing layer, the reaction layer is sealed with the sealing layer through the modification layer to form a microfluidic chip assembly, and the heat resistant adhesive tape is adhered on the upper surface of the reaction layer. According to the present invention, miniaturization is achieved, such that consumption of reagents and samples are reduced, and cost is low; a small amount of liquid can be assigned to hundreds of the independent small chambers without an external connection drive system and valve switching control equipment so as to reduce complexity of chip production and use; and the operation is simple, other control devices are not required, application cost is low, and the chip can be used in real-time fluorescence quantitative polymerase chain reactions and digital nucleic acid amplification.

Owner:杭州三济生物科技有限公司

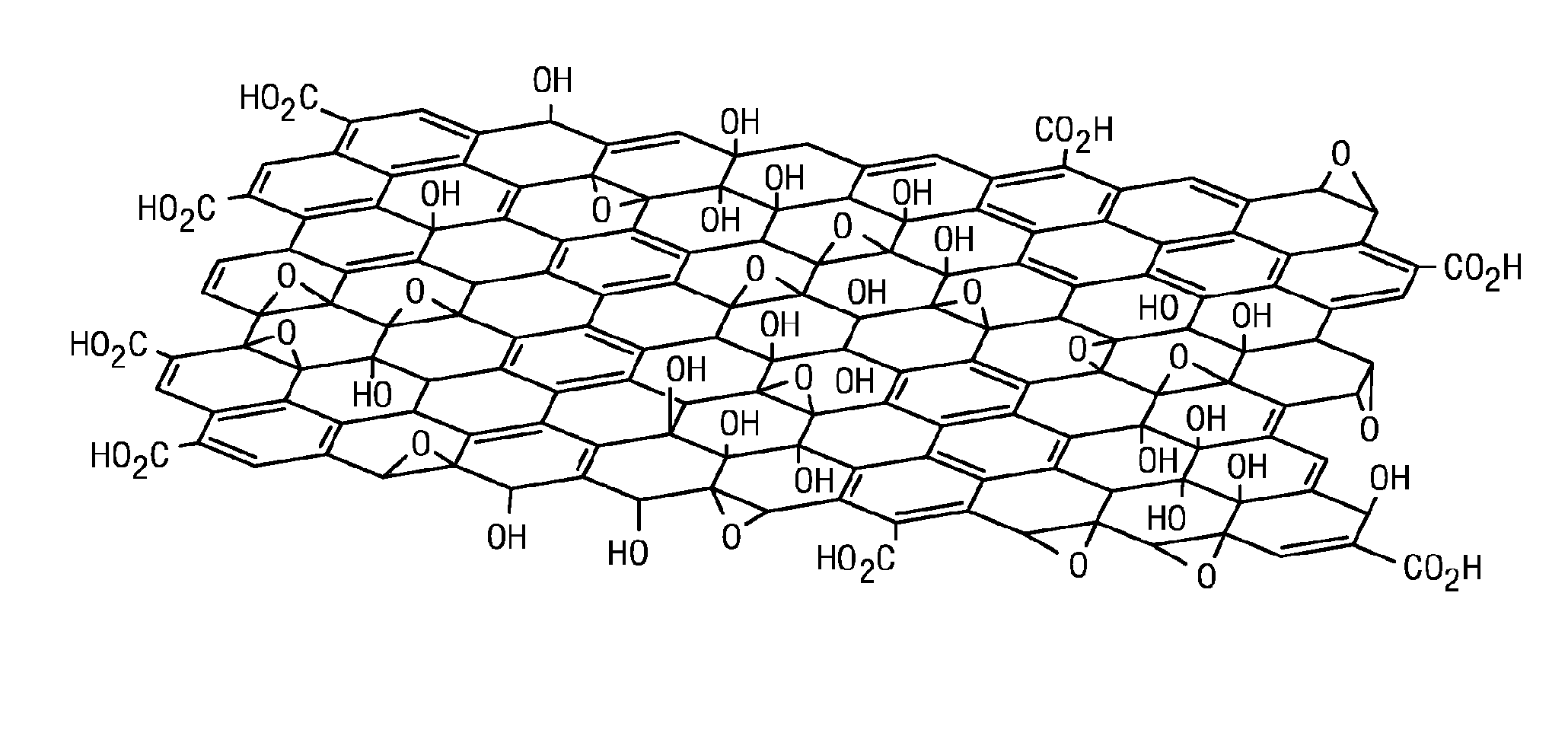

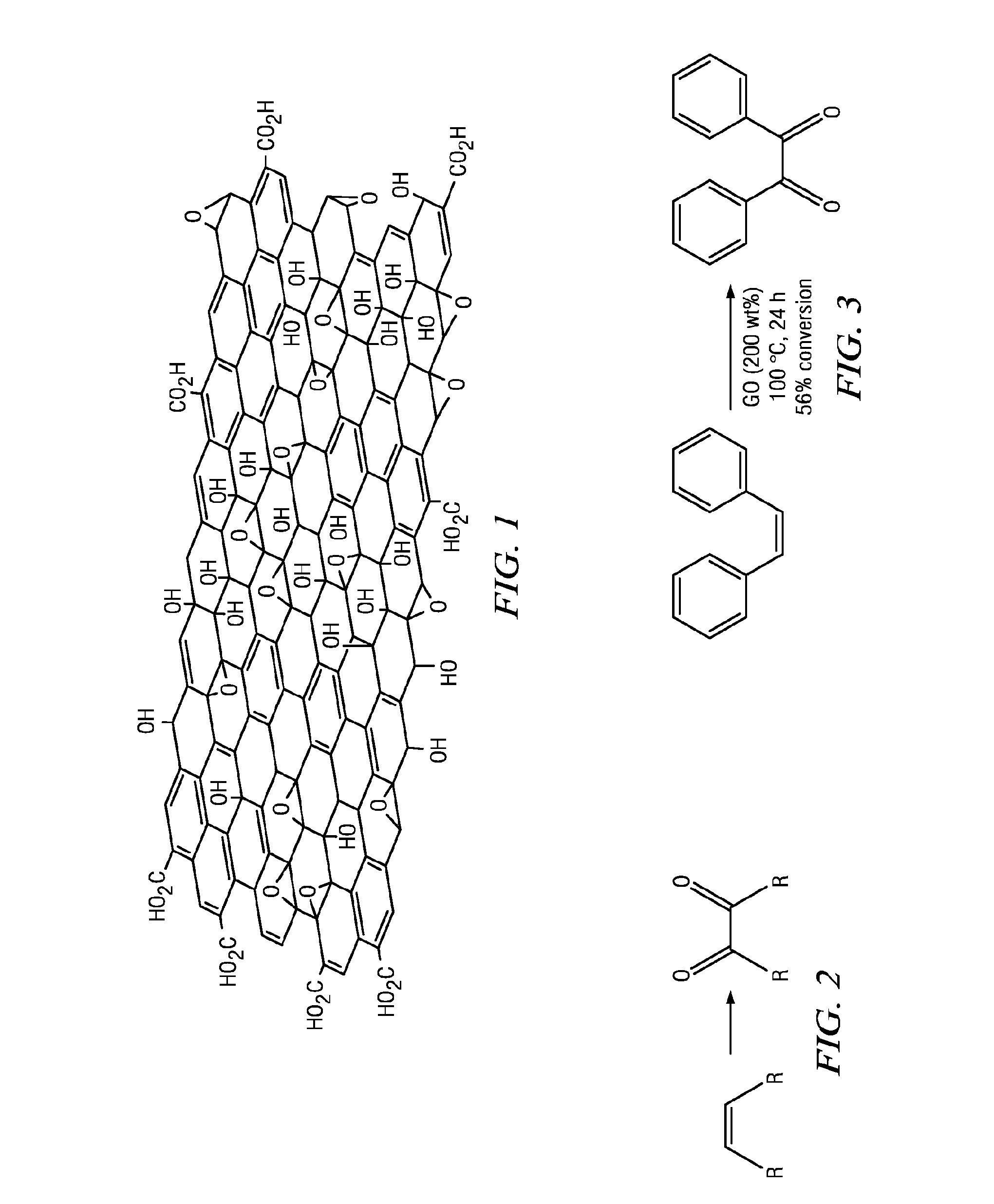

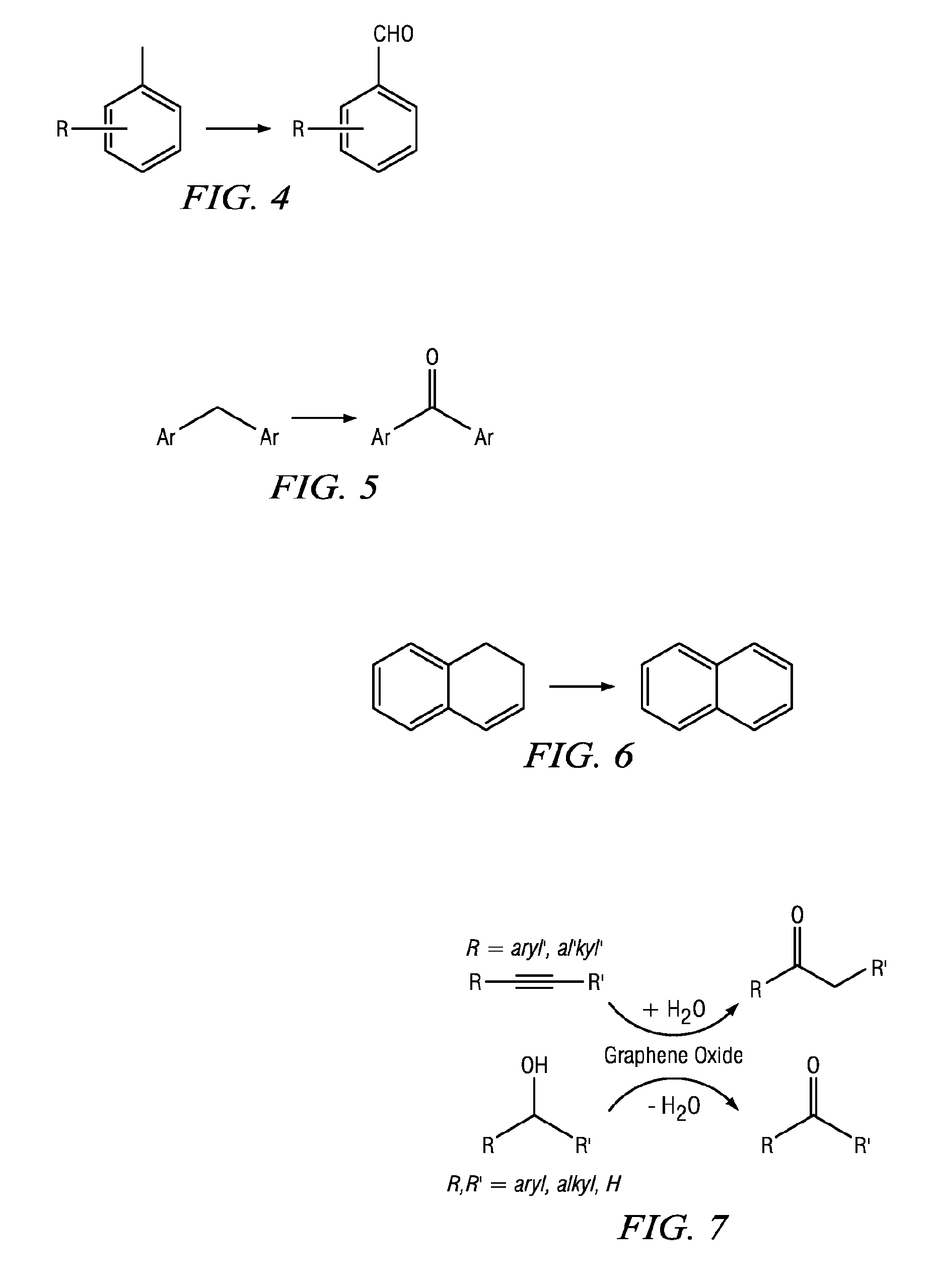

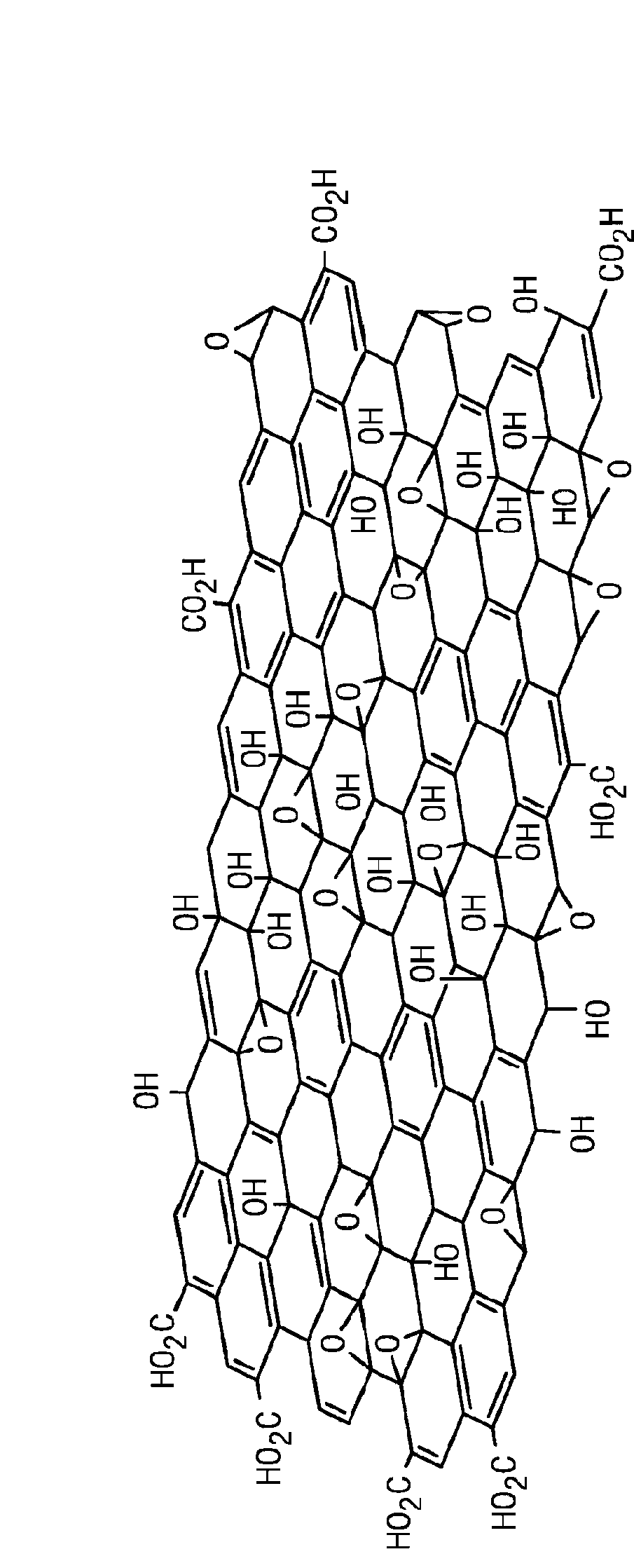

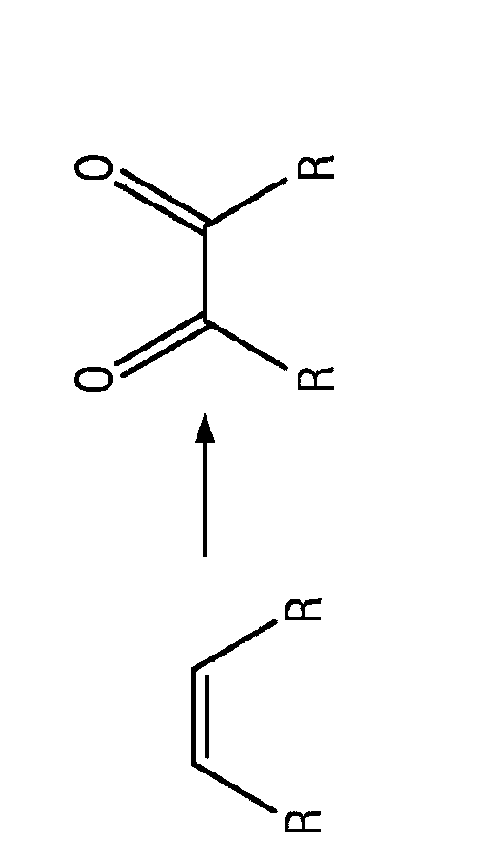

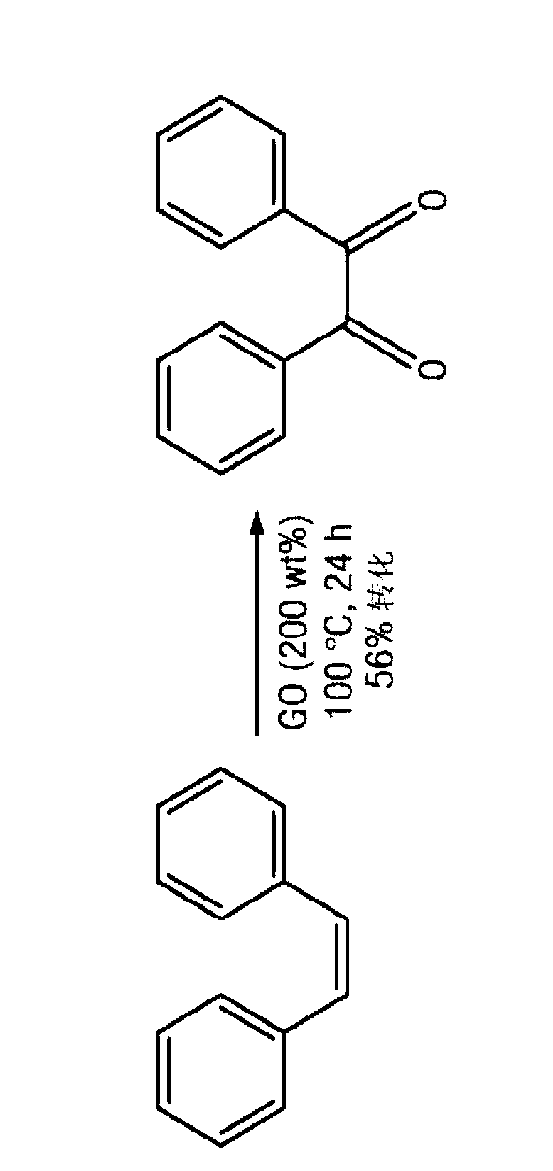

Carbocatalysts for chemical transformations

InactiveCN103025685AMaterial nanotechnologyOrganic compound preparationHydration reactionChemical reaction

The disclosure relates to catalytically active carbocatalysts, e.g., a graphene oxide or graphite oxide catalyst suitable for use in a variety of chemical transformations. In one embodiment, it relates to a method of catalyzing a chemical reaction of an organic molecule by reacting the organic molecule in the presence of a sufficient amount of graphene oxide or graphite oxide for a time and at a temperature sufficient to allow catalysis of a chemical reaction. According to other embodiments, the reaction may be an oxidation reaction, a hydration reaction, a dehydrogenation reaction, a condensation reaction, or a polymerization reaction. Some reactions may include auto-tandem reactions. The disclosure further provides reaction mixtures containing an organic molecule and graphene oxide or graphite oxide in an amount sufficient to catalyze a reaction of the organic molecule.

Owner:GRAPHEA

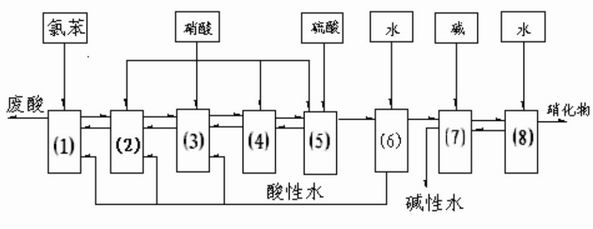

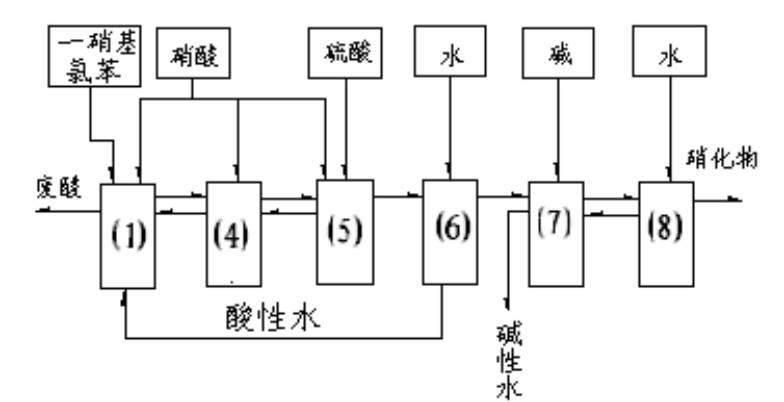

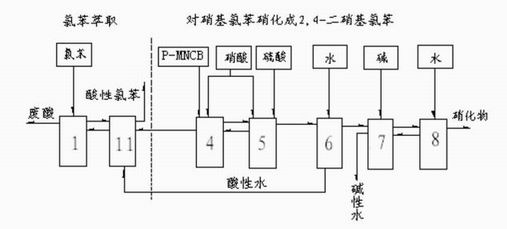

Method for continuously preparing dinitrochlorobenzene

ActiveCN102070457AIncrease profitIncrease production capacityNitro compound preparationNitrateChlorobenzene

The invention discloses a method for continuously preparing dinitrochlorobenzene. Multiple dinitration reactors are connected in series for reaction, and mononitrochlorobenzene is continuously added to the first dinitration reactor, and continuously flows through all the dinitration reactors and flows out; a mixed acid nitrating agent is prepared from 75-85% of sulfuric acid, 2-7% of nitric acid and 5-15% of water; the reaction temperature is 40-95 DEG C; and each dinitration reactor is provided with a separation device for separating an organic phase from an inorganic phase, and the inorganic phase is returned into the reactor, thereby keeping the inorganic phase and the organic phase in the required proportion. In the invention, the dinitrochlorobenzene is prepared by continuous reactions, and the reactions are continuously carried out and sequentially completed; chlorobenzene is used for extracting nitrates and nitric acid in an acid phase, thereby lowering the content of the nitric acid in the acid phase and recycling the nitrates in the acid phase; by the invention, the dinitrochlorobenzene can be continuously prepared from two raw materials (chlorobenzene and p-nitrochlorobenzene) by using one set of devices; and the invention has the advantages of low raw material consumption and high production capacity.

Owner:LIANYUNGANG DIPU CHEM

Method for preparing epoxy propane

ActiveCN103724299AMaximize activityMaximize stabilityOrganic chemistryChemical recyclingHigh energyTitanium

The invention relates to a method for preparing epoxy propane, which mainly solves the problems of low selectivity of epoxy propane, high energy consumption and poor continuous production capacity in the prior art. According to the method for preparing epoxy propane, provided by the invention, a propylene material is mixed with a methanol solvent, and then mixed with a hydrogen peroxide material, and the obtained mixture enters each reactor of a device comprising n series-wound reactors, and is in contact with a catalyst which comprises a TS-1 type titanium silicalite and positioned in each reactor, so that products containing epoxy propane are produced, and the product flow can selectively enter the follow-up separation work section and / or at least one of the rest reactors, wherein n is equal to or greater than 2; after the catalyst in one of the reactors is inactivated, the reactor can be separated from the device to perform catalyst regeneration operation, and the above problems can be solved better through the technical scheme of catalyst regeneration operation; the method can be used for preparing epoxy propane.

Owner:SINOPEC SHANGHAI ENG +1

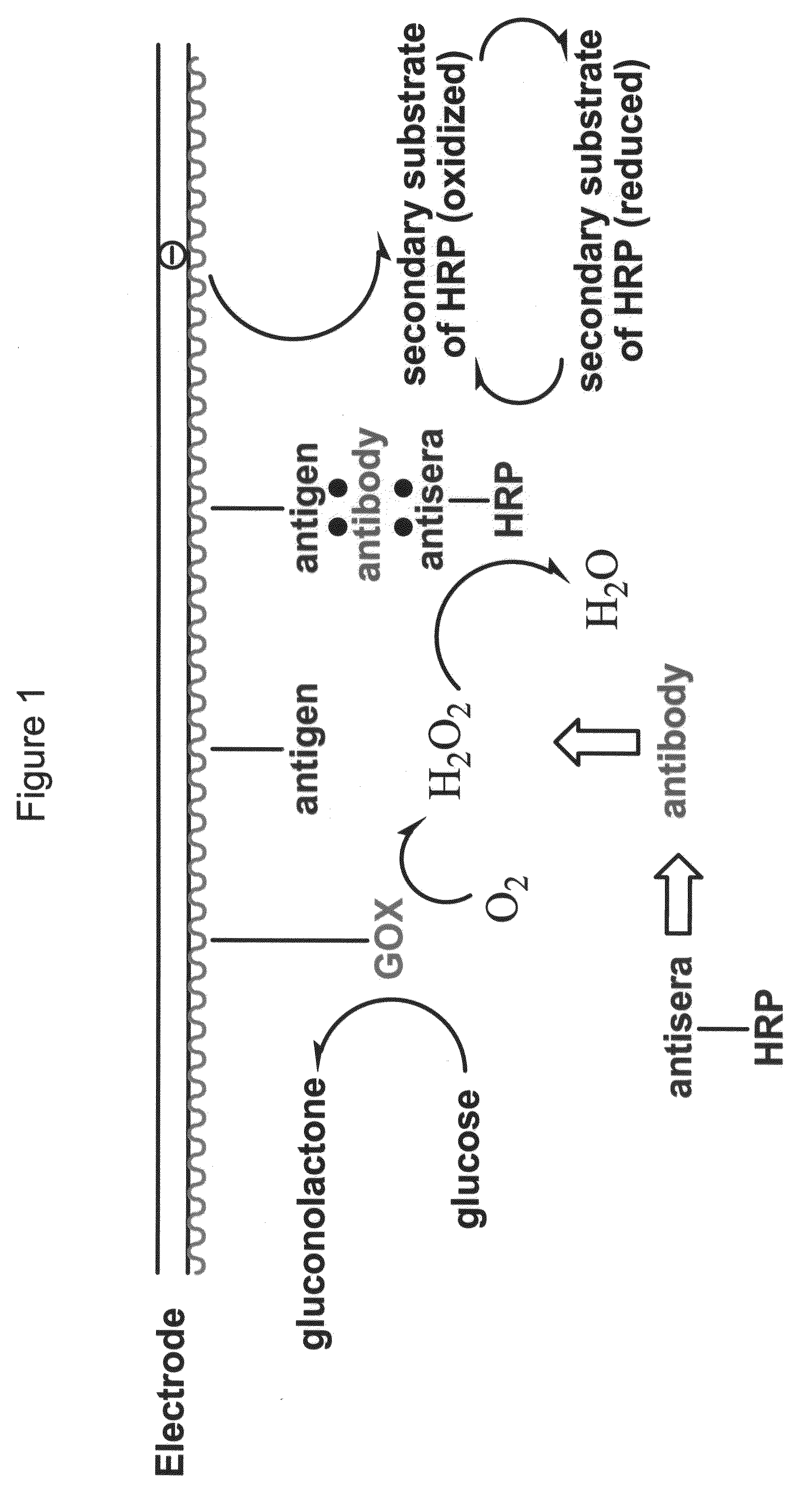

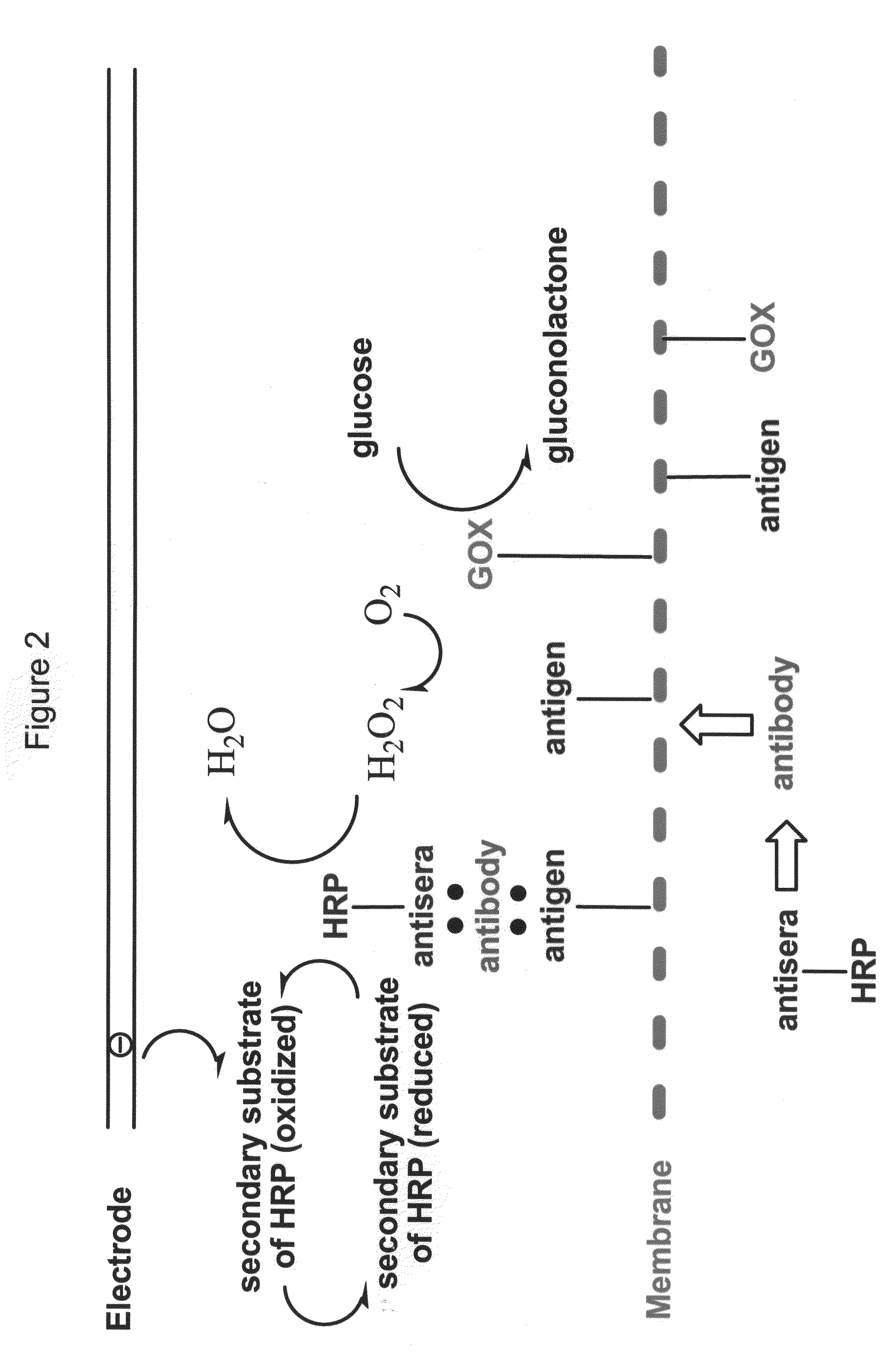

Enzyme-Channeling Based Electrochemical Biosensors

InactiveUS20090061524A1Efficient use ofBioreactor/fermenter combinationsBiological substance pretreatmentsElectrochemical biosensorAnalyte

Low-cost, non-toxic and fast immunoassay systems (immunosensors) and uses thereof as analytical and diagnostic tools for detecting an immune response in a subject are disclosed. The systems and methods disclosed are based on recording an electrochemical signal which is generated proportionally to an enzymatic cascade reaction (enzyme-channeling) upon detecting an analyte, and therefore can be used to determine the titer level of an antibody analyte in a liquid sample such as artificial media, serum or blood both qualitatively and quantitatively, in a one-step and separation free immunoassay. Systems and methods based on recording an electrochemical signal which is generated proportionally to an enzymatic cascade reaction (enzyme-channeling) upon detecting an analyte, which utilize a non-toxic secondary substrate such as acetaminophen are also disclosed.

Owner:RAMOT AT TEL AVIV UNIV LTD

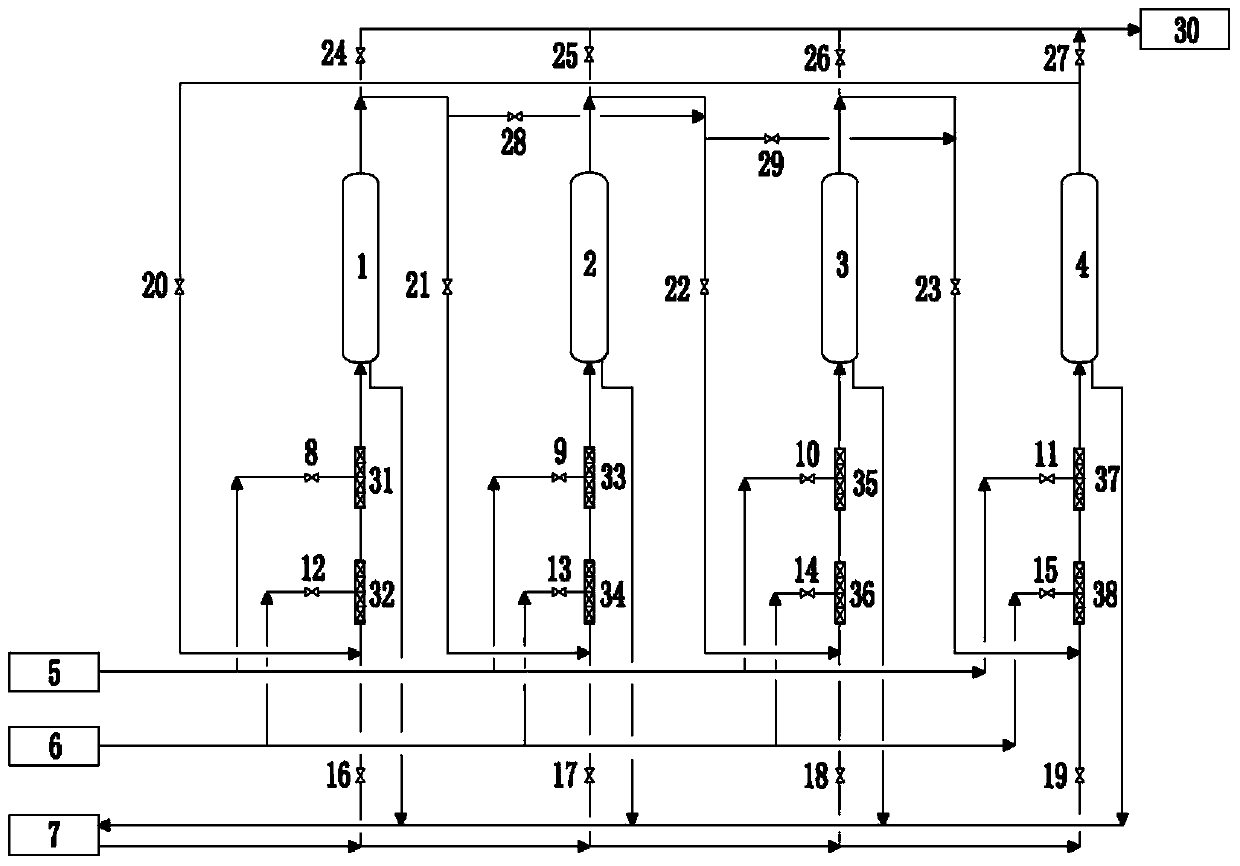

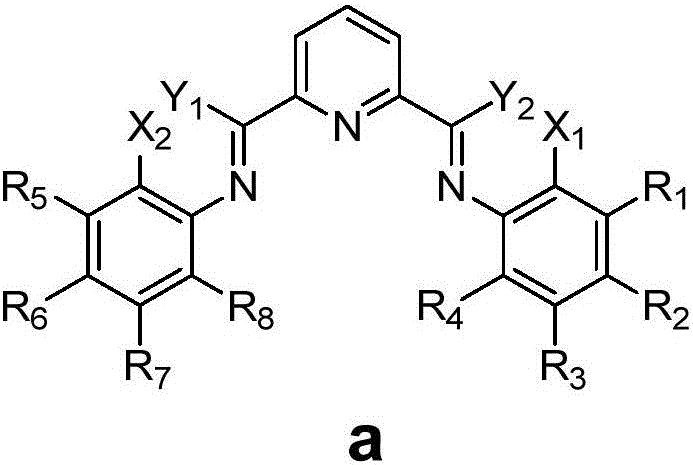

Ethylene oligomerization tanks-in-series technology

ActiveCN105693448ASolve the problem that the activity is too high and easy to overheatSmooth transitionHydrocarbon purification/separationCatalystsReaction temperatureEconomic benefits

The invention discloses an ethylene oligomerization tanks-in-series technology. A reaction medium, a promoter, an iron-based catalyst and a polyethylene wax inhibitor are introduced into a first reactor for pre-reaction at a low temperature, and the reaction materials are introduced into a second reactor after activity starts to be reduced; reaction temperature is increased to maintain high reaction activity for a long time; the reaction materials are sequentially introduced into an n reactor, and the temperature of the reactor is kept high (Tn-Tn-1>=10 DEG C); gas-liquid-solid separation and analysis are conducted on a product after reaction ends. By the adoption of the ethylene oligomerization tanks-in-series technology, catalyst deactivation due to temperature runaway caused by high reaction activity in the early stage of reaction can be effectively avoided, high catalyst activity is maintained for a long time, the catalysis efficiency of the catalyst is improved, and the yield of liquid-phase alpha-olefin is increased remarkably. The reaction technology is good for safety and stable operation of devices so that high economic benefits can be obtained.

Owner:ZHEJIANG UNIV

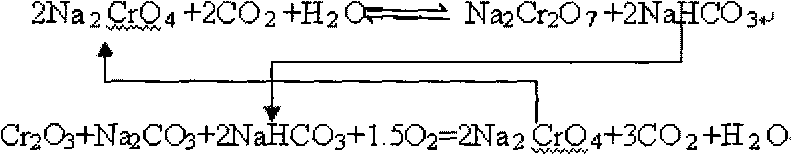

Process for preparing sodium dichromate

InactiveCN101693556AReduce Chloride ContentReduce Sulfate LevelsChromates/bichromatesCarbonizationSodium dichromate

The invention provides a process for preparing sodium dichromate, namely producing the sodium dichromate through a carbonization method comprising: converting sodium chromate into the sodium dichromate via carbon dioxide under pressurizing condition; delivering sodium chromate neutral liquor with impurities removed to a carbonization tower after a cascade reaction of more than three continuous towers; obtaining carbonizing liquor by controlling different gradient parameters (concentration and temperature of the carbonizing liquor, partial pressure of the carbon dioxide, carbonizing time and the like), continuously carbonizing and separating under pressure; obtaining sodium dichromate finished products through concentrating, filtering, evaporating, crystallizing and centrifugal dehydrating.

Owner:SICHUAN YINHE CHEM

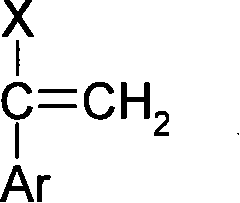

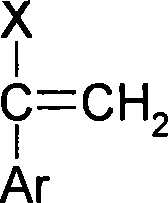

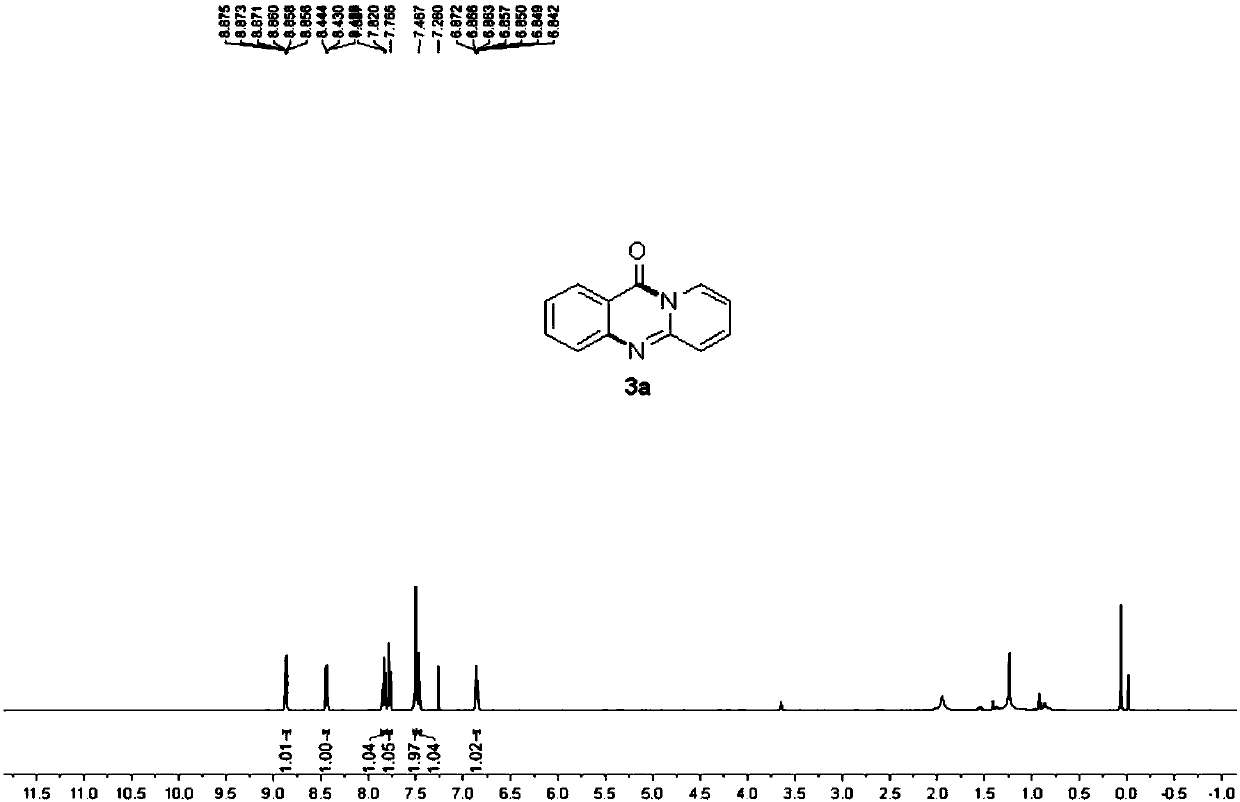

Synthetic method for aromatic[a]carbazole compounds

The invention discloses a synthetic method for aromatic[a]carbazole compounds, belonging to the technical field of organic synthesis. According to a technical scheme in the invention, the synthetic method comprises the following steps: dissolving a 2-phenylindole compound, 2-(naphth-1-yl)indole compound or 2-(thiazol-1-yl)indole compound and a diazo compound in a solvent together; then adding a catalyst and an additive; and carrying out a reaction at 100 to 140 DEG C so as to prepare a benzo[a]carbazole compound, naphtho[a]carbazole compound or thiazolo[a]carbazole compound. According to the invention, 2-substituted indole compounds and the diazo compound are used as raw materials and subjected to a one-pot cascade reaction so as to directly obtain the aromatic[a]carbazole compounds; and the synthetic method is simple and convenient in process, mild in conditions, wide in a substrate adaptability range and suitable for industrial production.

Owner:HENAN NORMAL UNIV

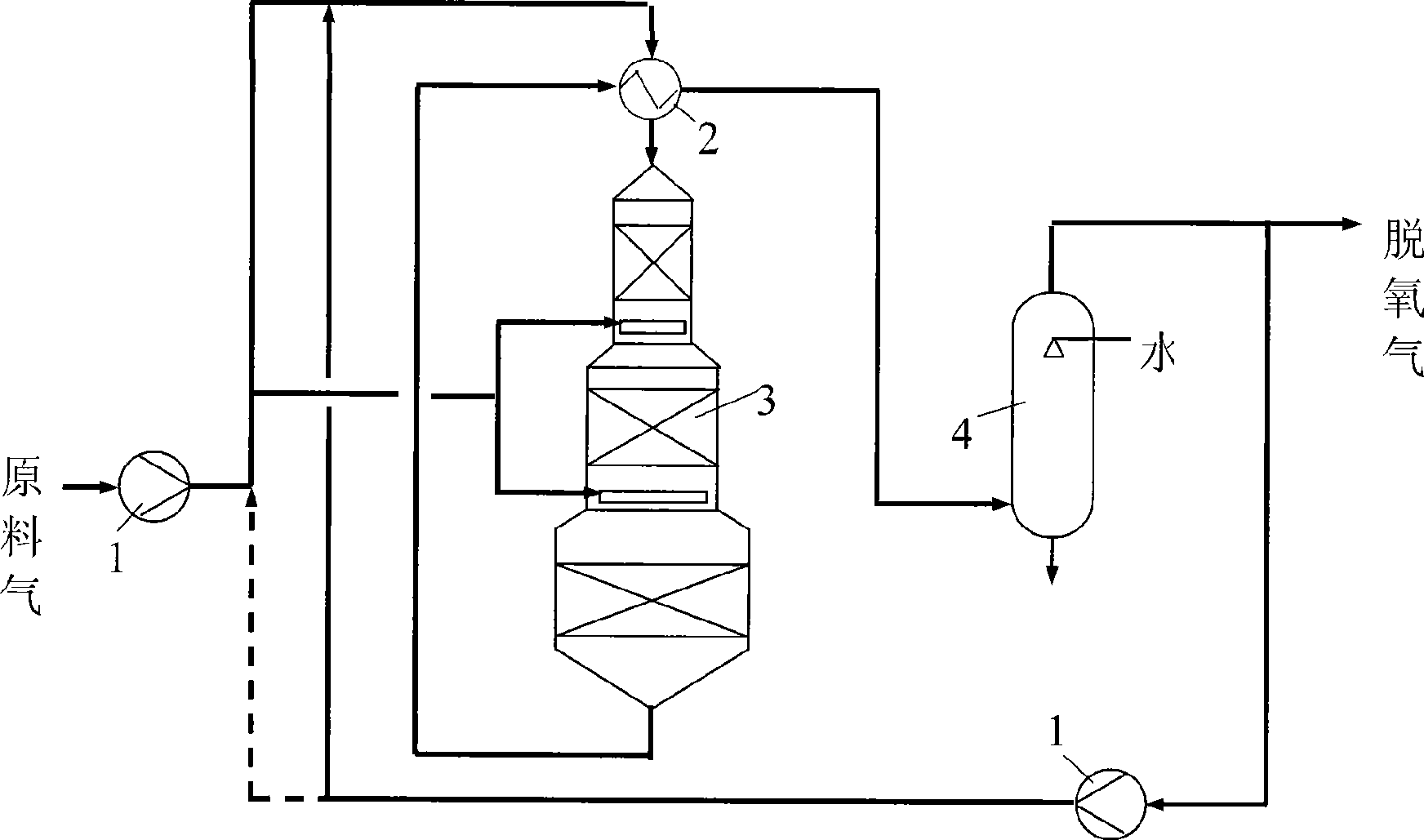

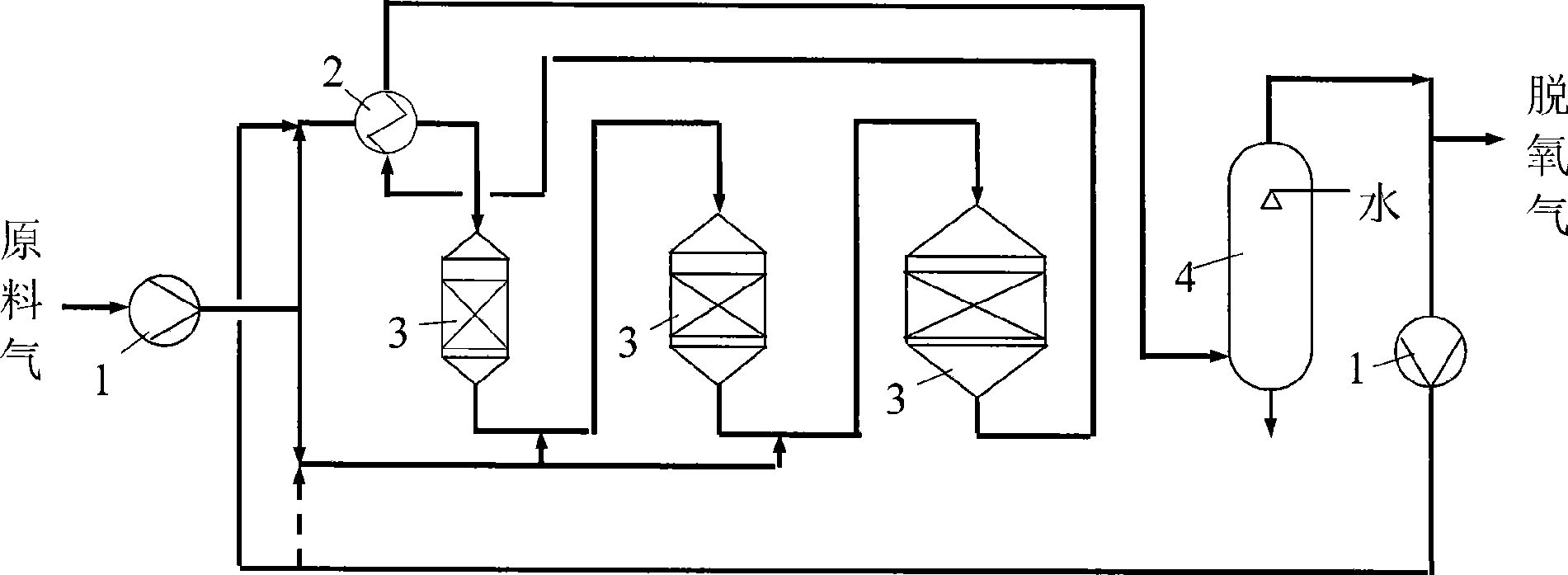

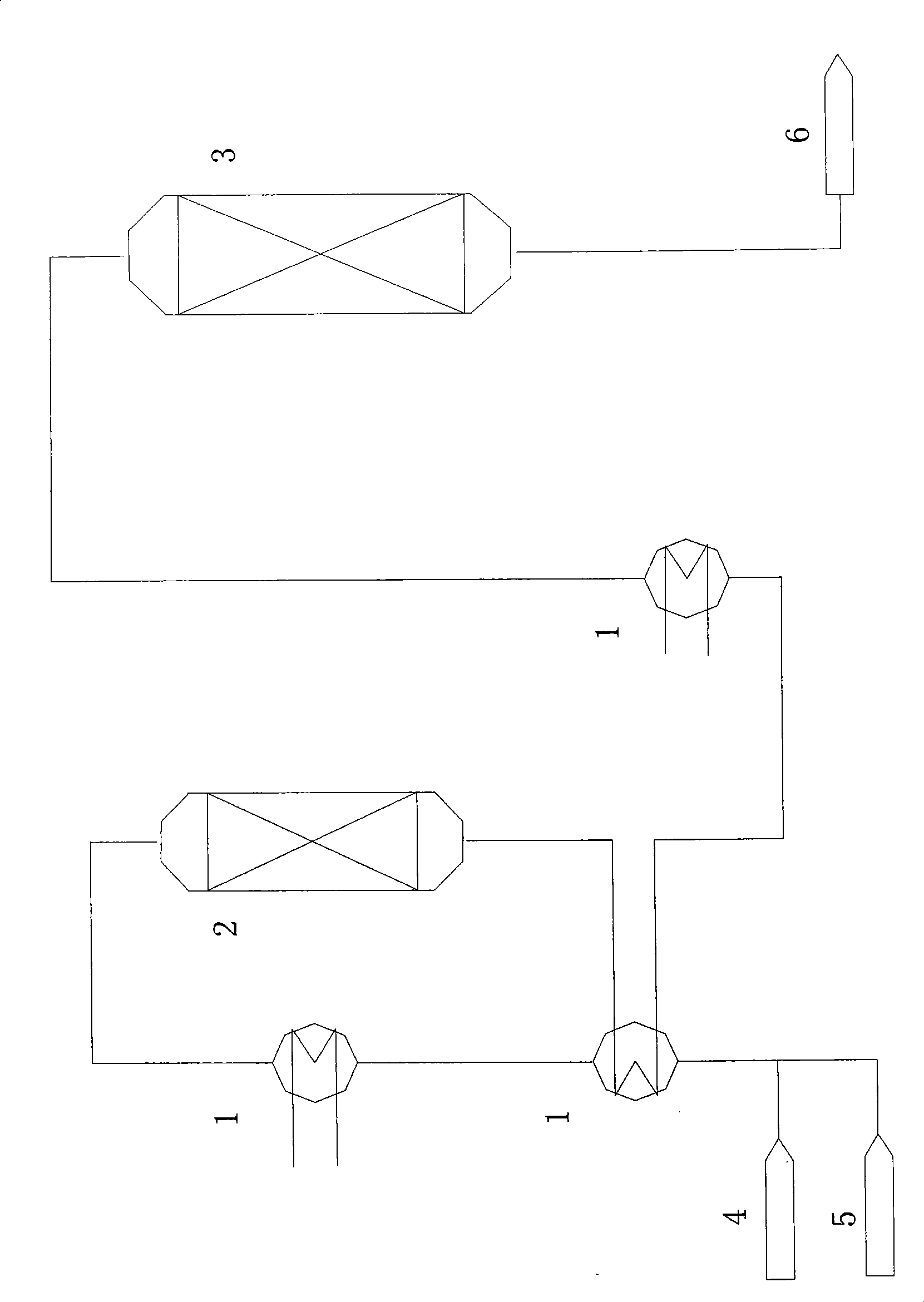

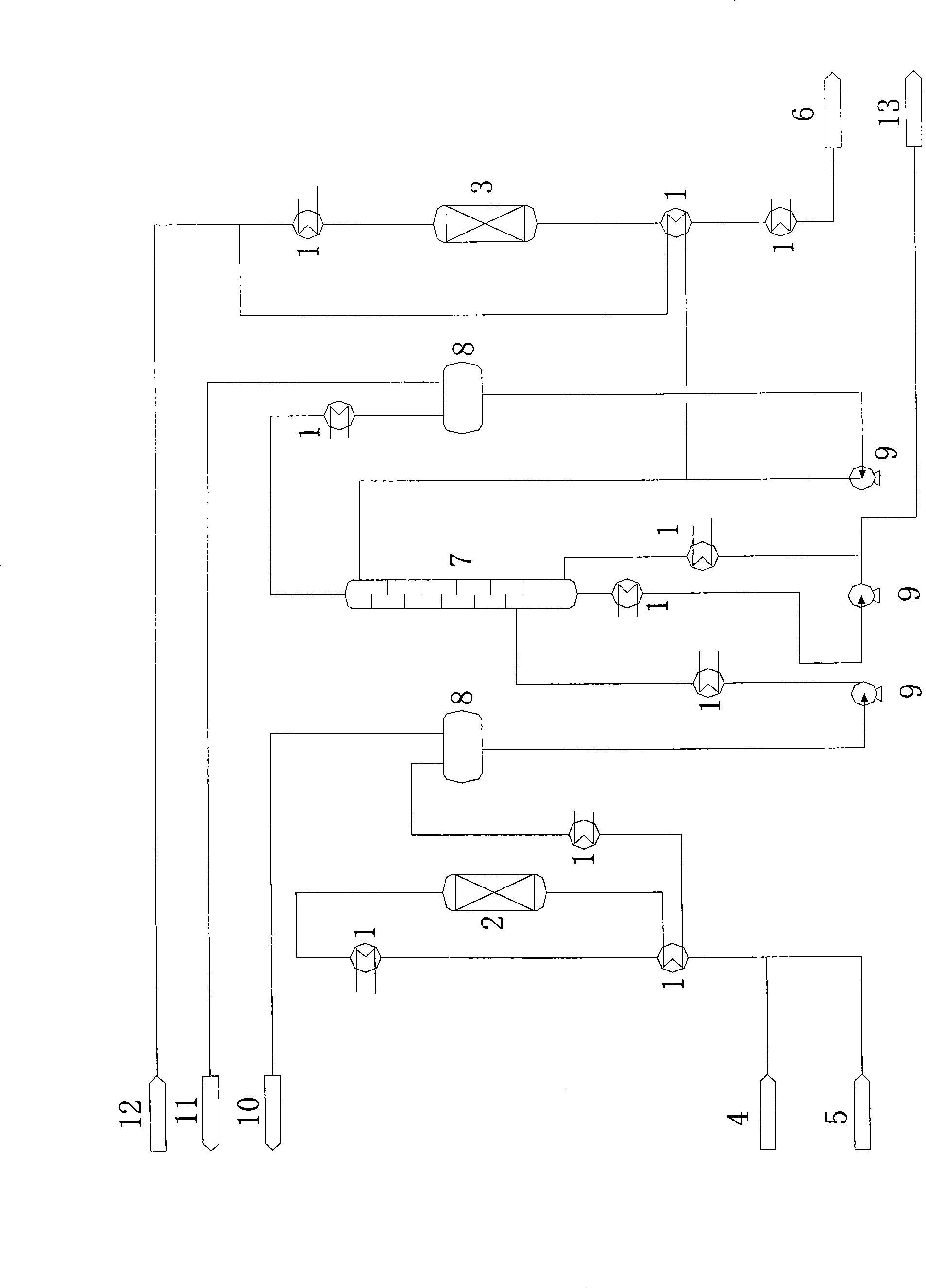

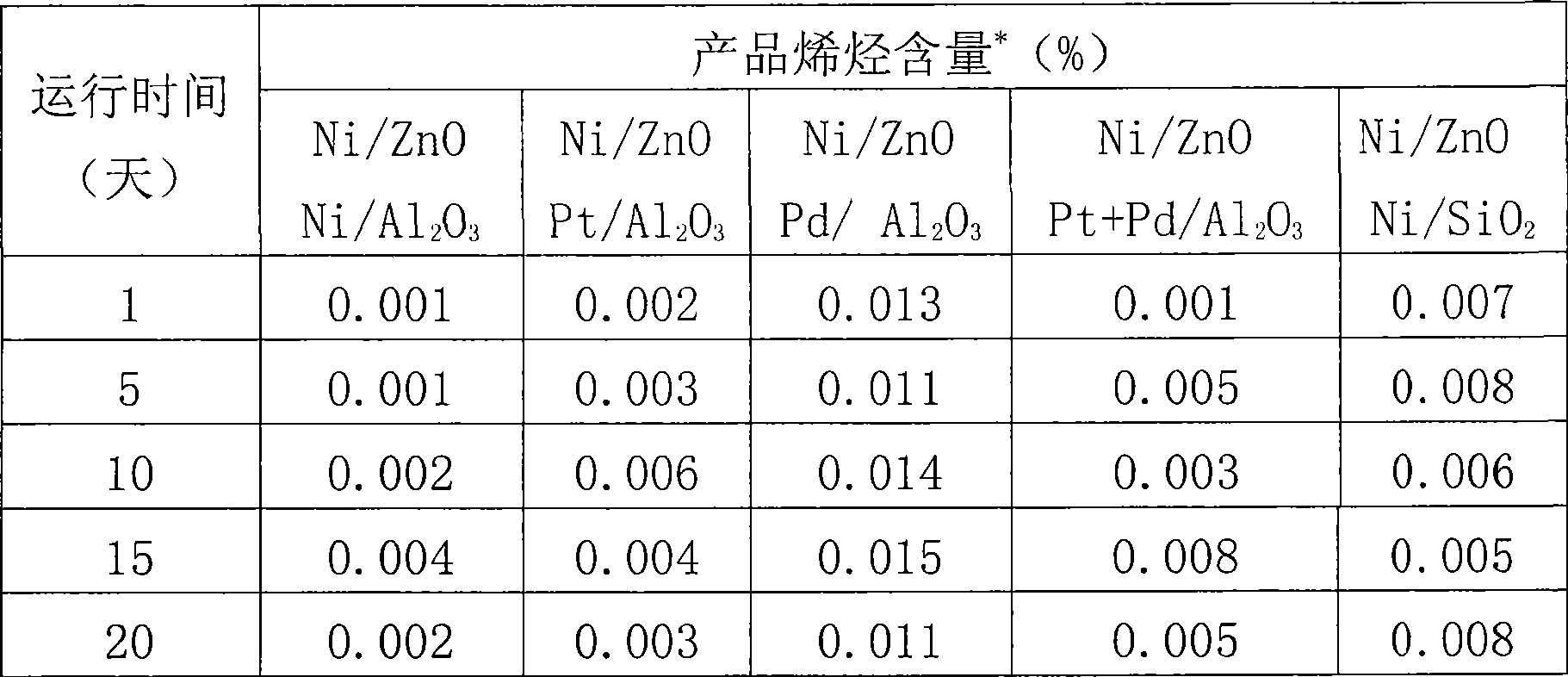

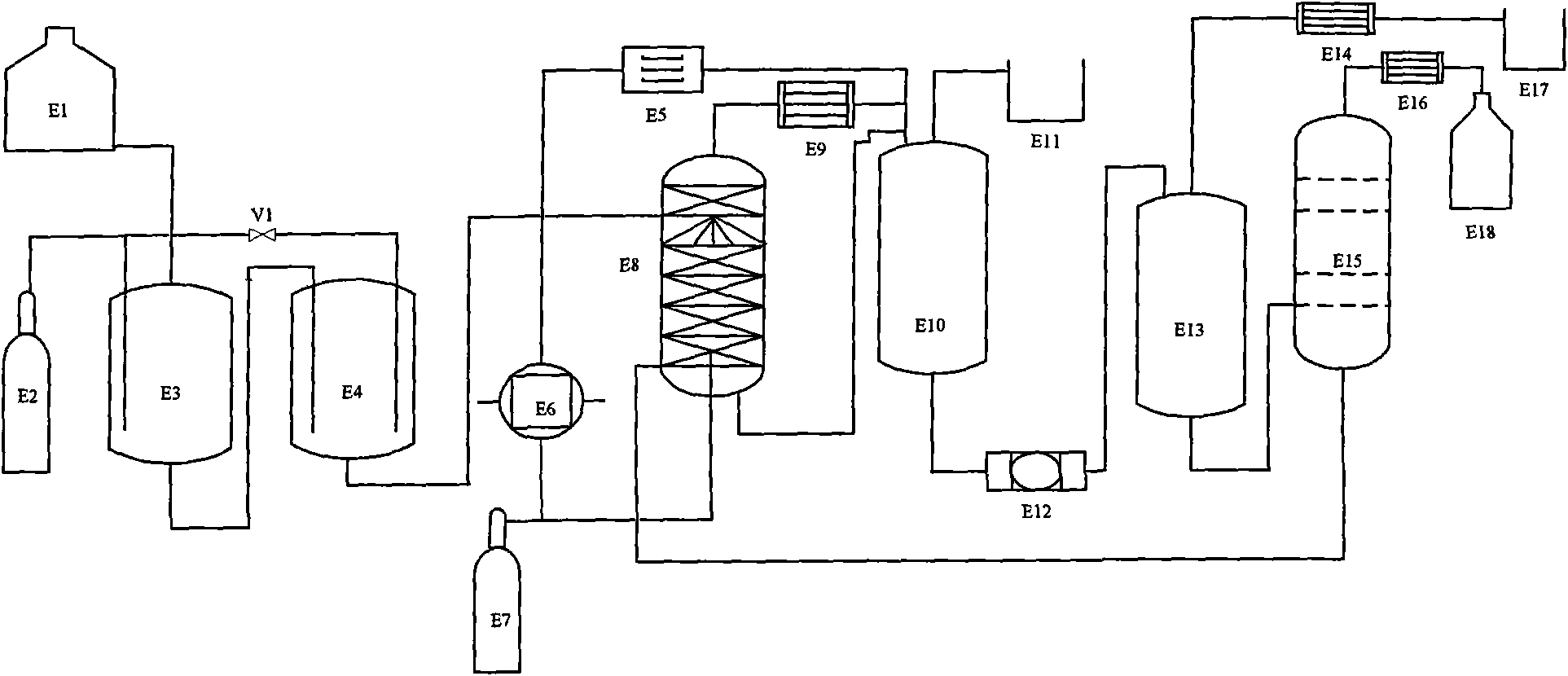

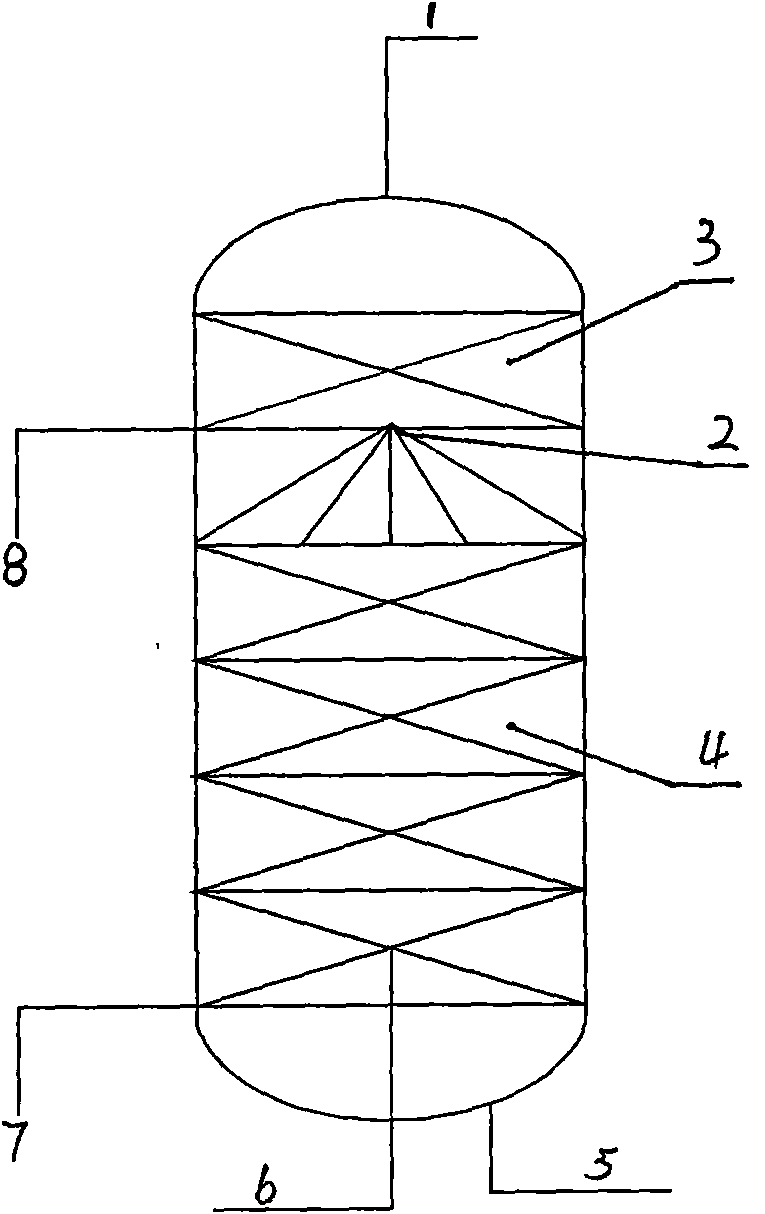

Mixture gas catalytic deoxidation process containing combustible gas

ActiveCN101423783AReduce usageSave energyGaseous fuelsChemical modification purification/separationCombustible gasProduct gas

The invention discloses a catalysis deoxidation process for mixed gas containing inflammable gas. In a reaction system, the inflammable gas in the mixed gas raw material is reacted with oxygen in a catalysis reactor filled with catalyst for deoxidation, and the catalysis reactor comprises a plurality of heat insulation reactors connected in series, wherein the last heat insulation reactor is the main reactor; the mixed gas raw material entered from the first heat insulation reactor is mixed with circulating gas and preheated before entering; and the mixed gas raw material entered from other reactors can directly enter or be mixed with the circulating gas and enter the reactors without preheating. The invention can also be realized in another mode, namely a plurality of reactors connected in series are superimposed to form a multi-layer reactor. The process greatly reduces the consumption of the circulating gas, and achieves the effects of reducing the consumption of catalyst, reducing the sizes of a circulator, a heat exchanger and a pipe, lowering cost, reducing the energy consumption of the circulator and cooling water, increasing byproduct vapor and so on.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

2-aryl-5-arylselenenyl-1,3,4-oxadiazole compound and preparation method

The invention relates to a 2-aryl-5-arylselenenyl-1,3,4-oxadiazole compound and a preparation method. The preparation method comprises the following steps: in an organic solvent, taking 2-aryl-1,3,4-oxadiazole and aryl iodide as reaction raw materials and taking elemental selenium as an selenylation reagent; carrying out serial reaction under a common promotion effect of a copper catalyst and an alkali to obtain the 2-aryl-5-arylselenenyl-1,3,4-oxadiazole compound. The method provided by the invention has a wide substrate range, simple reaction conditions and relatively high yield and purity of a product; novel synthesis route and method are developed for the 2-aryl-5-arylselenenyl-1,3,4-oxadiazole compound; the method has good application potential and research value.

Owner:WENZHOU MEDICAL UNIV

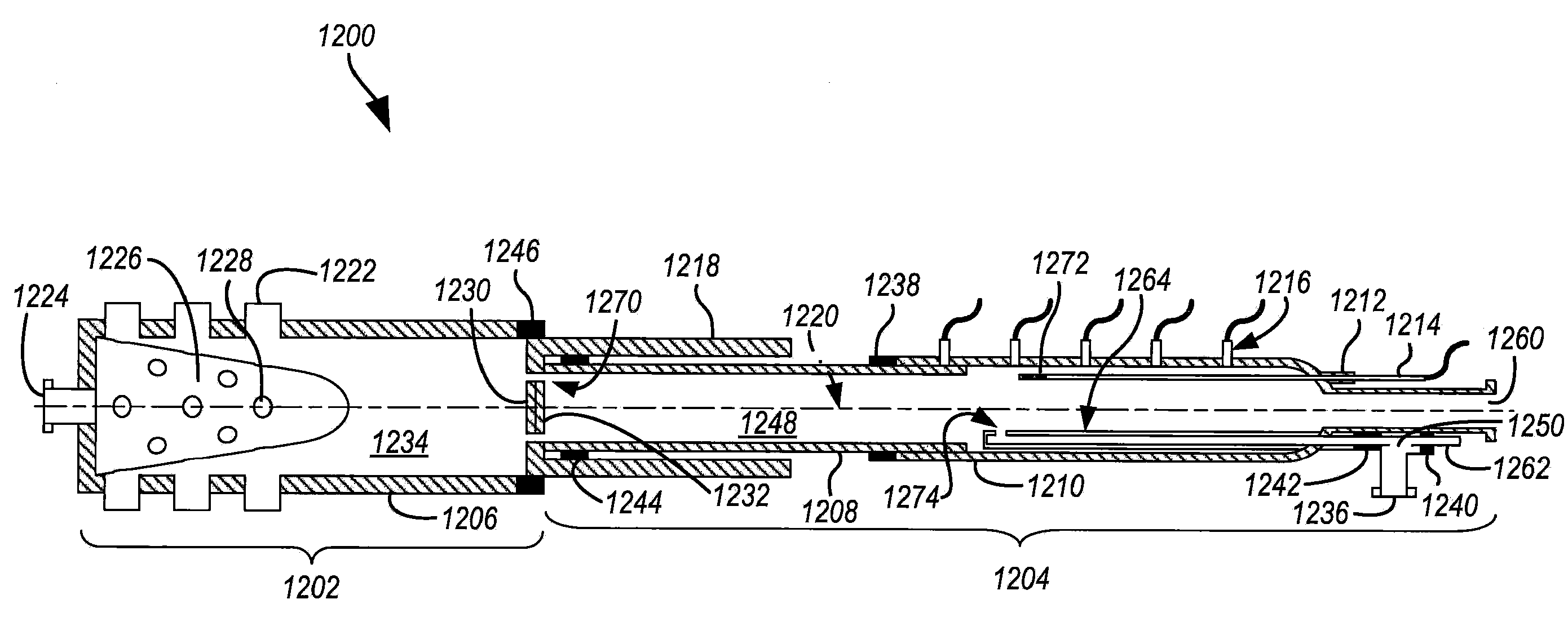

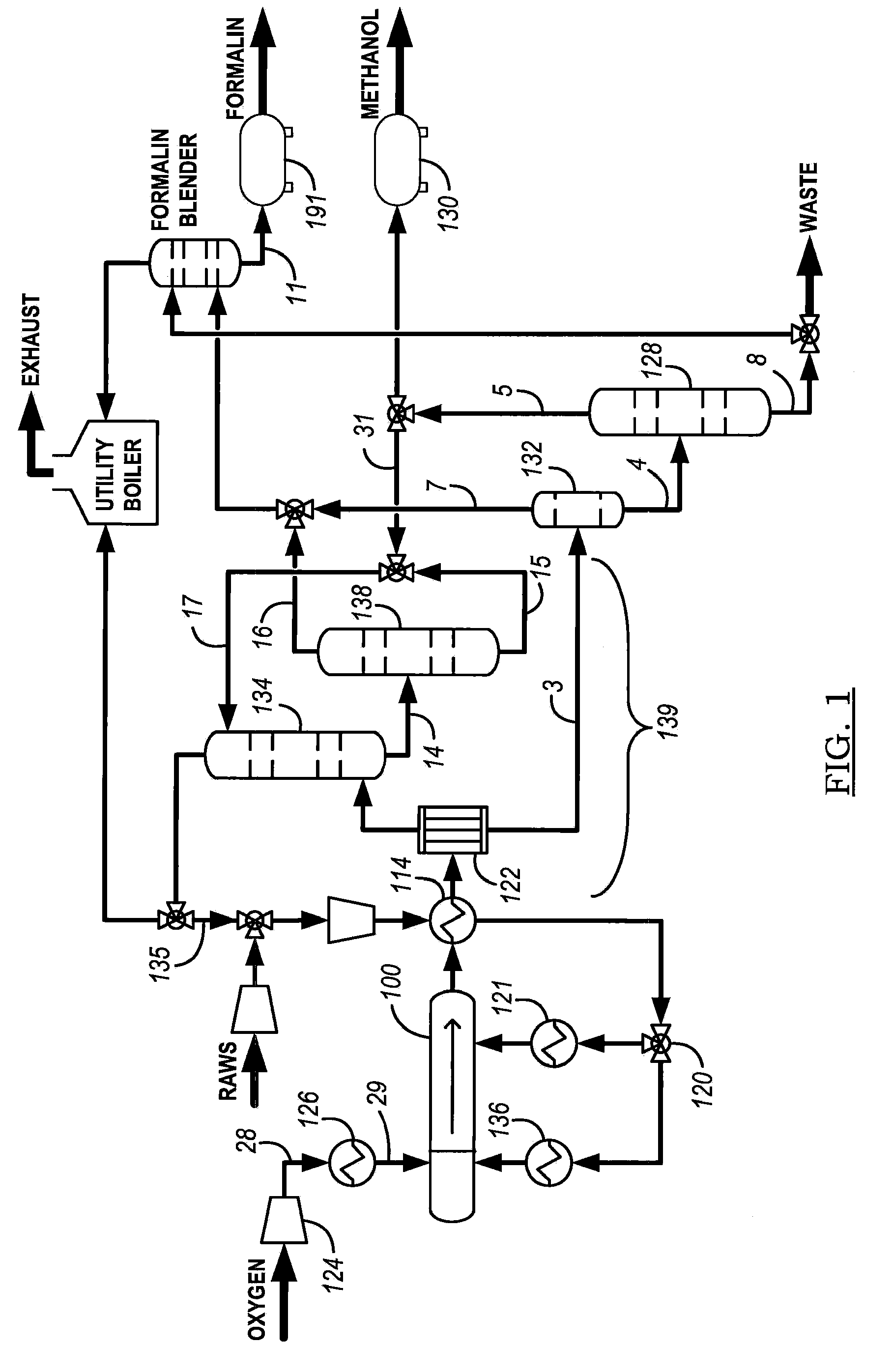

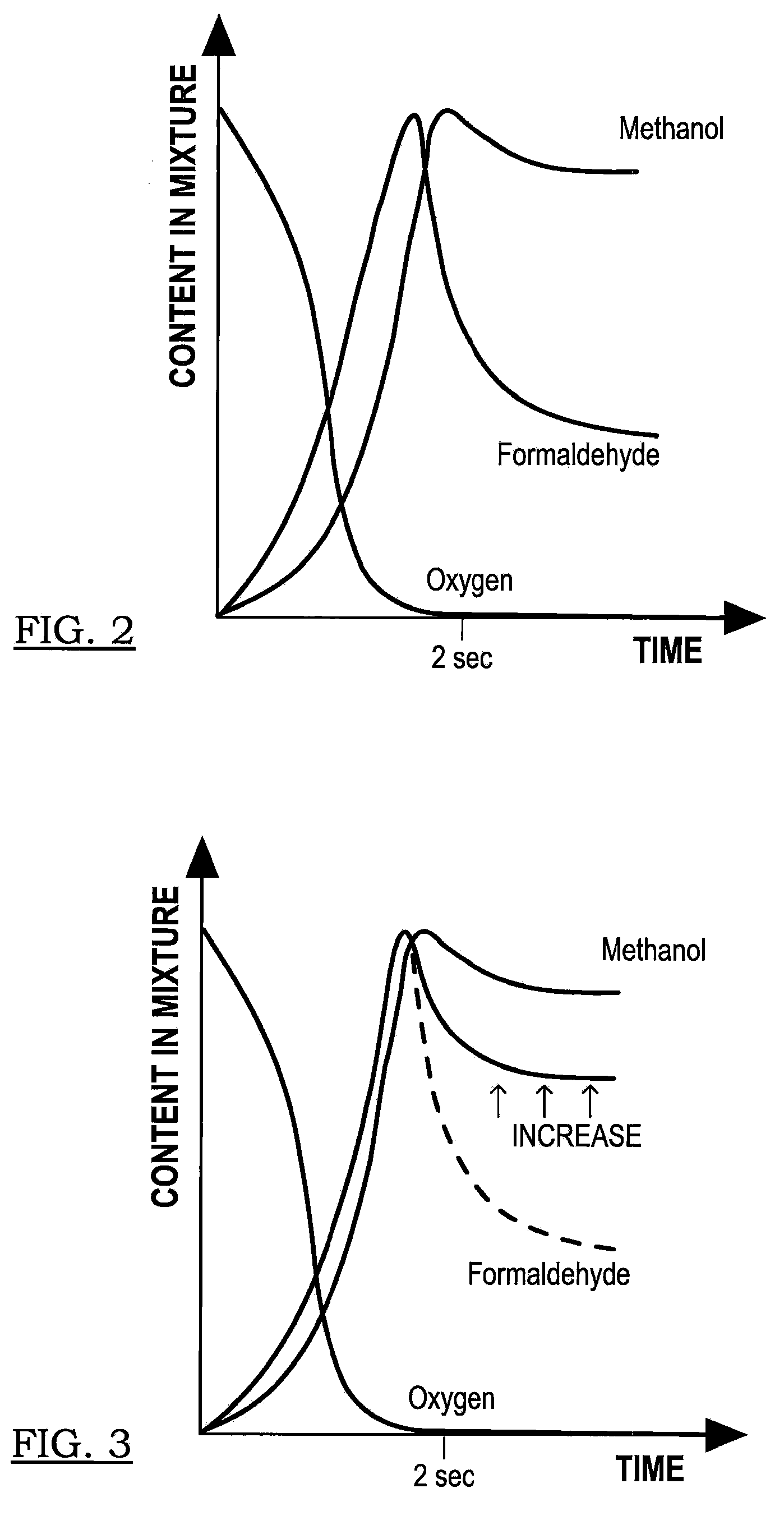

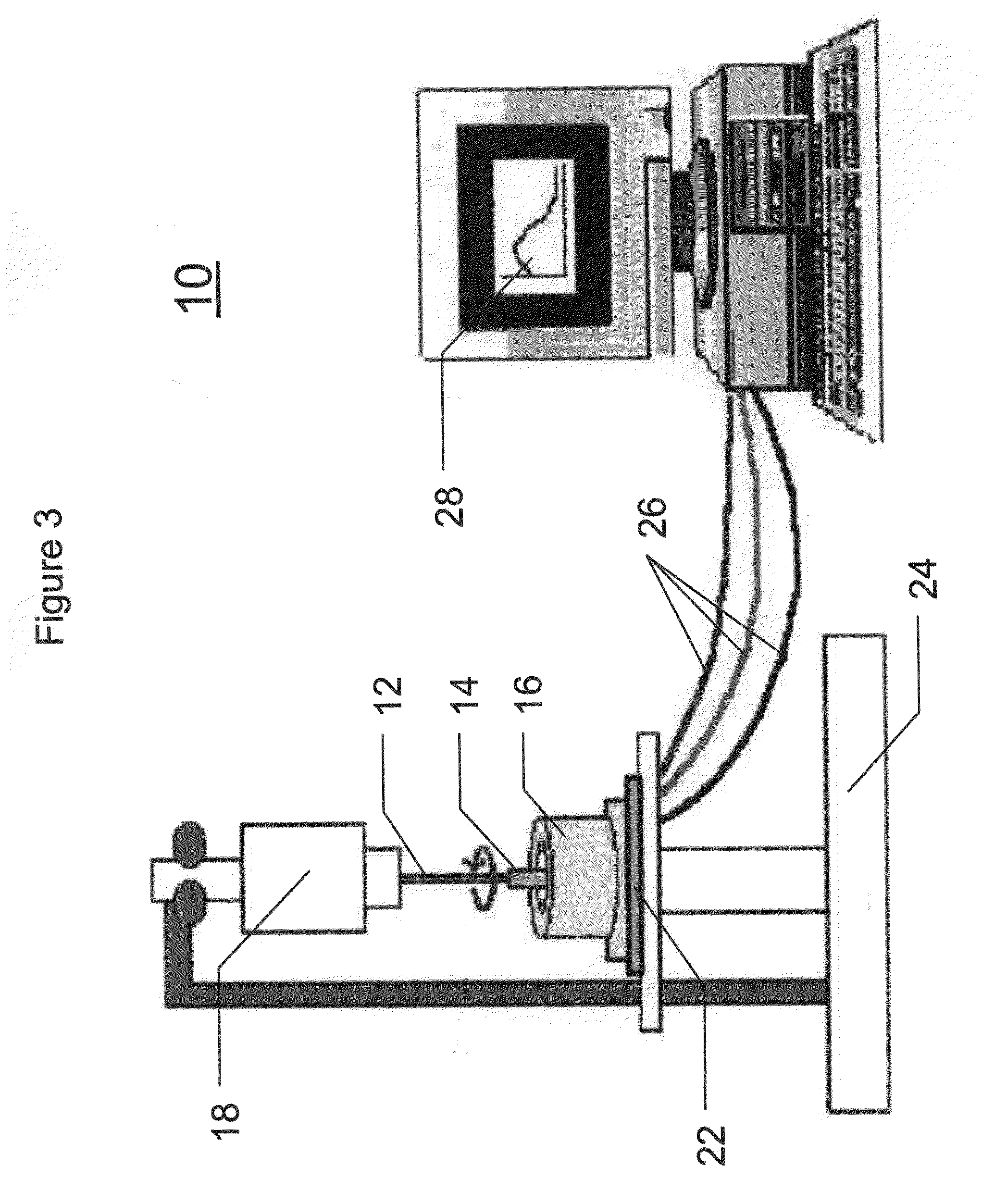

Tandem reactor system having an injectively-mixed backmixing reaction chamber, tubular-reactor, and axially movable interface

A reactor system for gas phase reacting of at least two fluid feed streams, where the reactor system has an injectively-mixed backmixing reaction chamber in fluid communication with a tubular-flow reactor. The injectively-mixed backmixing reaction chamber has a bulkhead that slides during real-time operation to either diminish or expand the internal volume of the backmixing reaction chamber. In one embodiment, the effective passageway space through the bulkhead is also variably adjustable. In another embodiment, the tubular-flow reactor shares the bulkhead so that axial bulkhead movement commensurately expands one reaction space while diminishing the other reaction space. Input gas streams enter the backmixing reaction chamber with sufficient velocity to turbulently agitate the contents of the injectively-mixed backmixing reaction chamber by injective intermixing of the alkane-containing gas feed stream and the oxygen-containing gas feed stream. A focal application is for direct (partial) oxidative conversion of natural gas to alkyl oxygenates.

Owner:GAS TECH

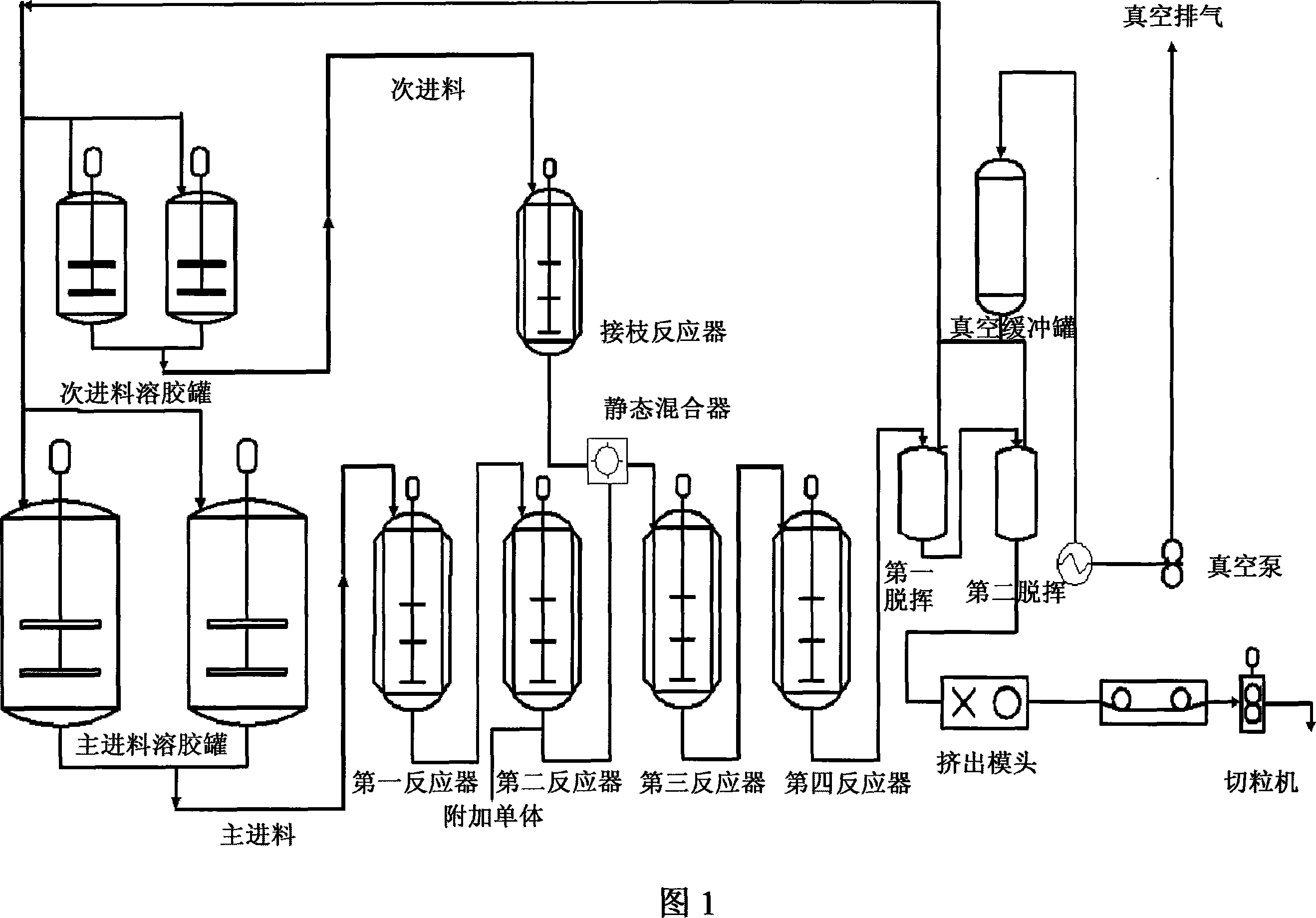

Method of preparing high gloss injection moulding level ACS polymer based on continuous noumenon method

The invention discloses a high glossiness injection moulding ACS polymer preparing method based on the continuous body method, which comprises the following steps: adding the whole or a part of the rubber solution dissolving in monoalkyl vinyl aromatic hydrocarbons monomer, unsaturated nitrile monomer mixture, marginal unsaturated monocarboxylic acid derivation, polywax to the first plunger reactor; regarding the input as 'the main input', adding the remainder to the aggregation system in the a position or a plurality of positions of the following 3-4 tandem reactors after the grafting reaction; regarding the input as' the secondary input'; achieving the different rubber particle diameter and distribution by 'the main input' and ' the secondary input' using the same or the different rubber varieties; getting a good combination property high glossiness injection moulding ACS polymer in the specific conditions.

Owner:中国中化股份有限公司 +1

Carbocatalysts for chemical transformations

InactiveUS20130123514A1Promote oxidationPromote hydrationMaterial nanotechnologyOther chemical processesHydration reactionChemical reaction

The disclosure relates to catalytically active carbocatalysts, e.g., a graphene oxide or graphite oxide catalyst suitable for use in a variety of chemical transformations. In one embodiment, it relates to a method of catalyzing a chemical reaction of an organic molecule by reacting the organic molecule in the presence of a sufficient amount of graphene oxide or graphite oxide for a time and at a temperature sufficient to allow catalysis of a chemical reaction. According to other embodiments, the reaction may be an oxidation reaction, a hydration reaction, a dehydrogenation reaction, a condensation reaction, or a polymerization reaction. Some reactions may include auto-tandem reactions. The disclosure further provides reaction mixtures containing an organic molecule and graphene oxide or graphite oxide in an amount sufficient to catalyze a reaction of the organic molecule.

Owner:MOSELEY SAMUEL G +8

Hydrogenation adsorption desulphurization and catalytic hydro-dearomatization cascade reaction process

ActiveCN101475836AReduce sulfide contentExtend the life cycleTreatment with hydrotreatment processesSulfideAromatic hydrocarbon

The invention discloses a cascade reaction process for hydrogenation adsorption desulfurization and hydro-dearomatization. A hydrogenation adsorption catalyst and a hydro-dearomatization catalyst are directly and serially filled, and a raw material is removed with sulfide through the hydrogenation adsorption catalyst under the condition of hydrogenation adsorption, and then is removed with aromatic hydrocarbon through the hydro-dearomatization catalyst under the condition of hydro-dearomatization. The process has the advantages that no hydrogen sulfide is generated in a first reactor, and thecontent of the sulfide in a product is lower, thereby prolonging the using period of a second hydro-dearomatization catalyst, reducing operation cost, reducing equipment, and saving the investment.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Polymerization of polyethylene having high molecular weight

Owner:FINA TECH

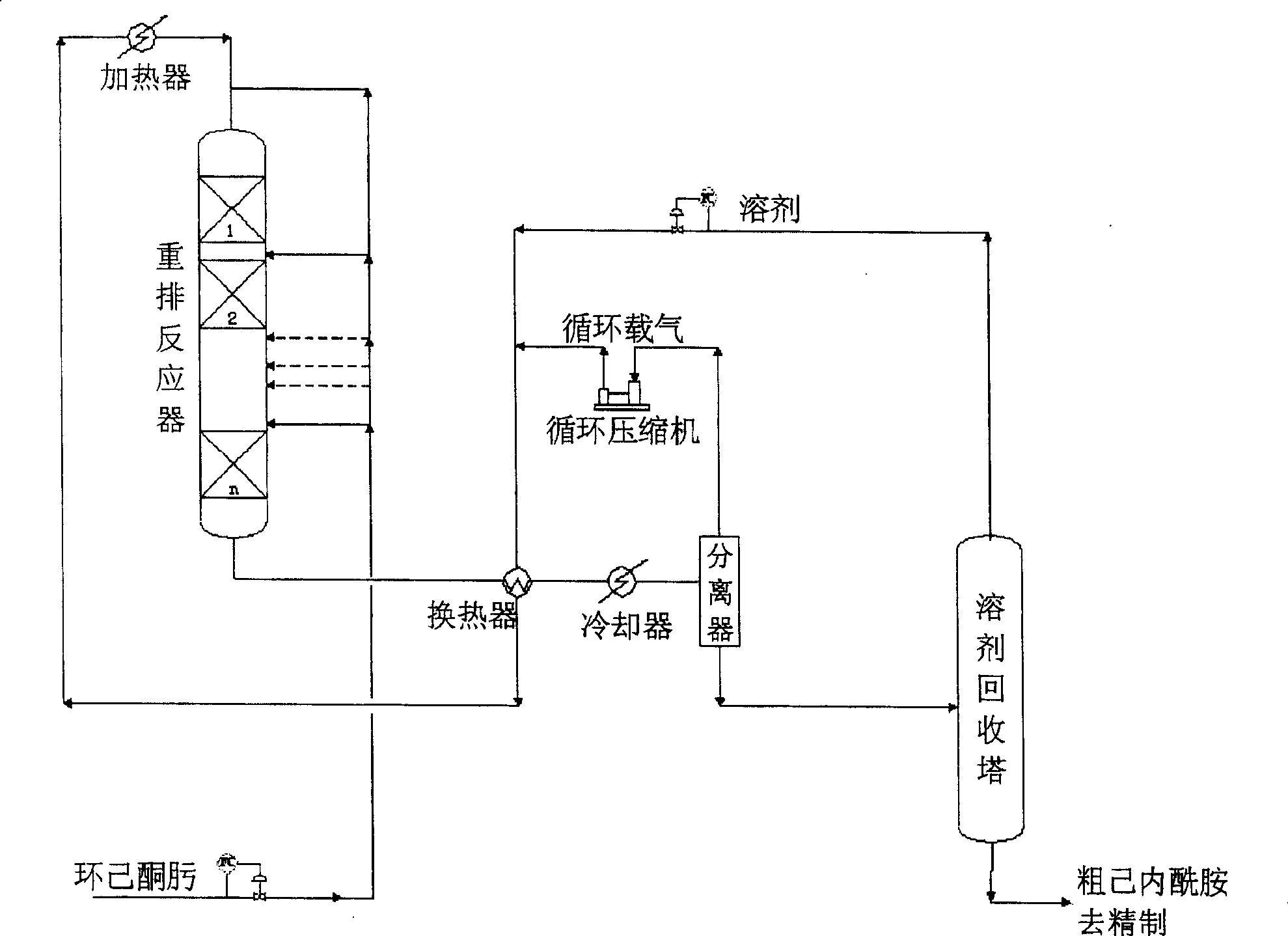

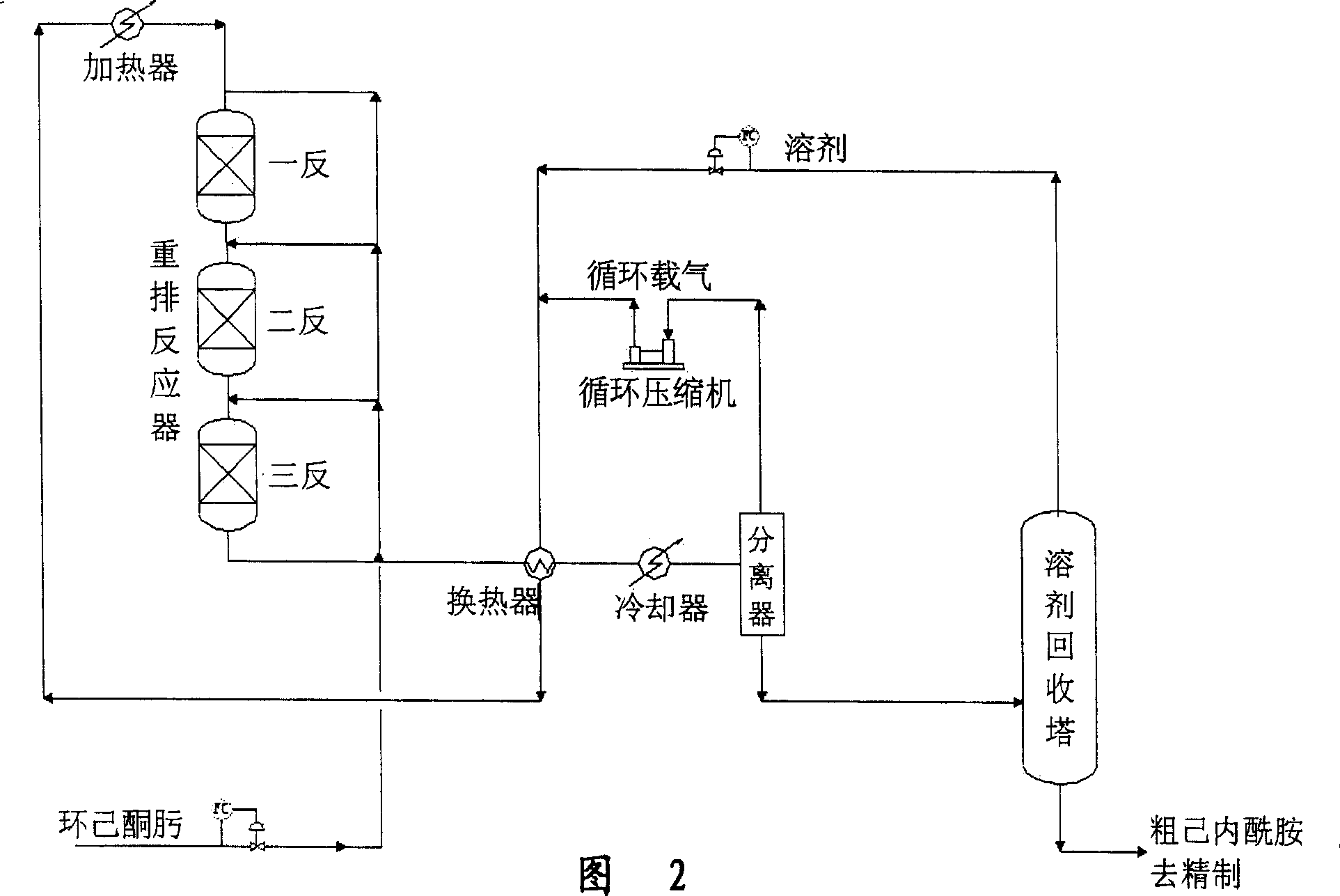

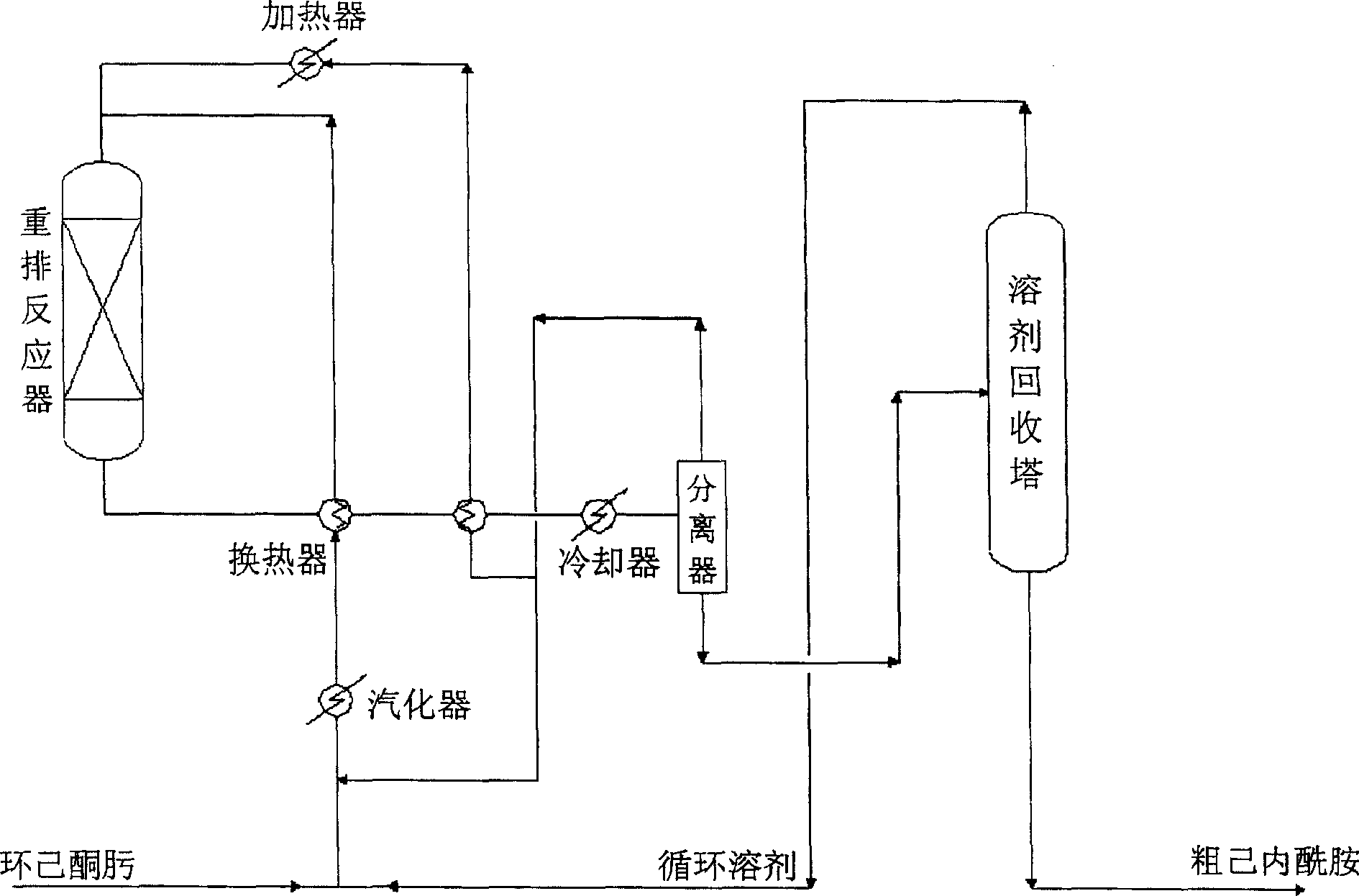

Method and equipment for preparing caprolactam from cyclohexanone oxime

ActiveCN101434569AExtend the life cycleReduce energy consumptionLactams preparationCyclohexanone oximeSolvent

The invention relates to a method for preparing caprolactam with cyclohexanone-oxime, and a device used in the method. The method includes the steps as follows: after being heated, inert supporting gas containing a solvent is continuously put into a supporting gas intake of a first-class reactor of a multi-stage series reactor provided with a catalyst. Cyclohexanone- oxime is directly divided into two parts which then enter all stages of the multi-stage series reactor, thereby ensuring that reaction effluents are cooled. The supporting gas is separated and recycled to the supporting gas intake of the first-class reactor, and then products from a liquid phase reaction are separated and purified.

Owner:CHINA PETROLEUM & CHEM CORP +1

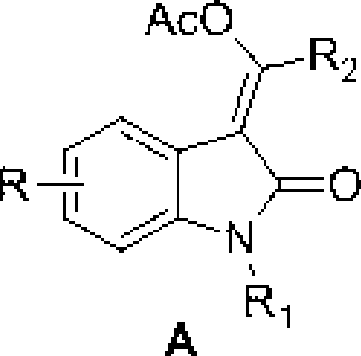

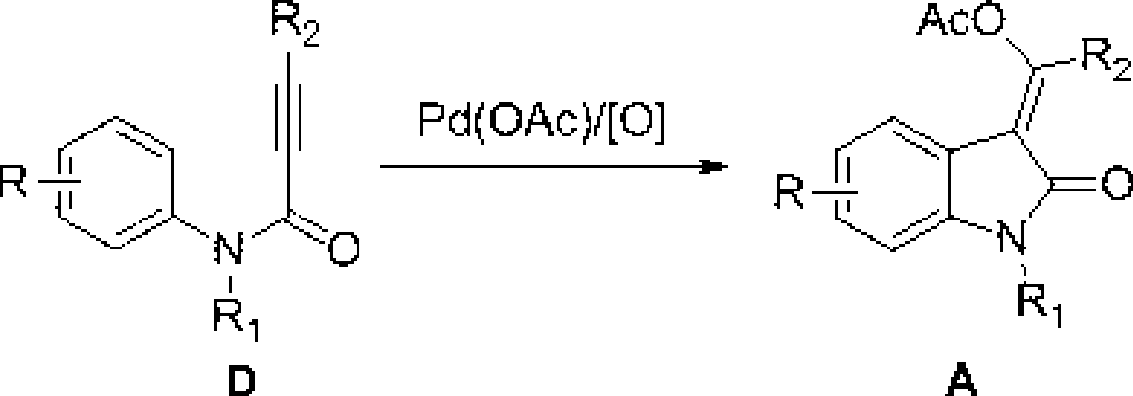

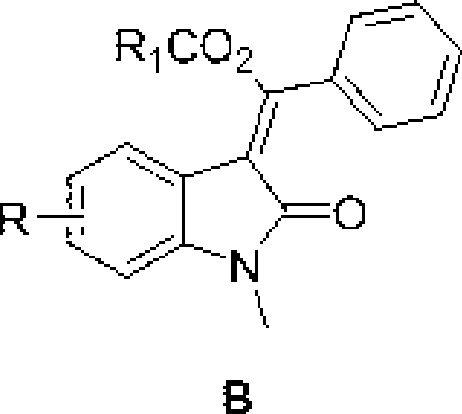

3-methylene-indol-2-one derivates and preparation method thereof

The invention relates to a 3-methylene-indole-2-ketone derivative and a preparation method thereof. The derivative is synthesized by taking N-methyl-N-phenyl-hydrocinnamamide or N-aryl phenylpropargyl acylamide and phthalic imide as substrates through tandem reactions such as C-H activation / acetylene hydrocarbon palladinization / cross coupling and so on, based on the catalysis of Pd<II> / Pd<IV> under the coaction of a palladium catalyst and an oxidizing agent, then ethyl acetate is added, the mixture is scrubbed by common salt, an aqueous phase is then extracted by the ethyl acetate, an organic layer is collected, and the 3-methylene-indole-2-ketone derivative is prepared through drying, condensation and column chromatography. The preparation method has the advantages of simple and convenient reaction operation, short reaction steps, simple conditions, short time, low cost, and high yield, and is worthy to be popularized and applied.

Owner:WENZHOU UNIVERSITY

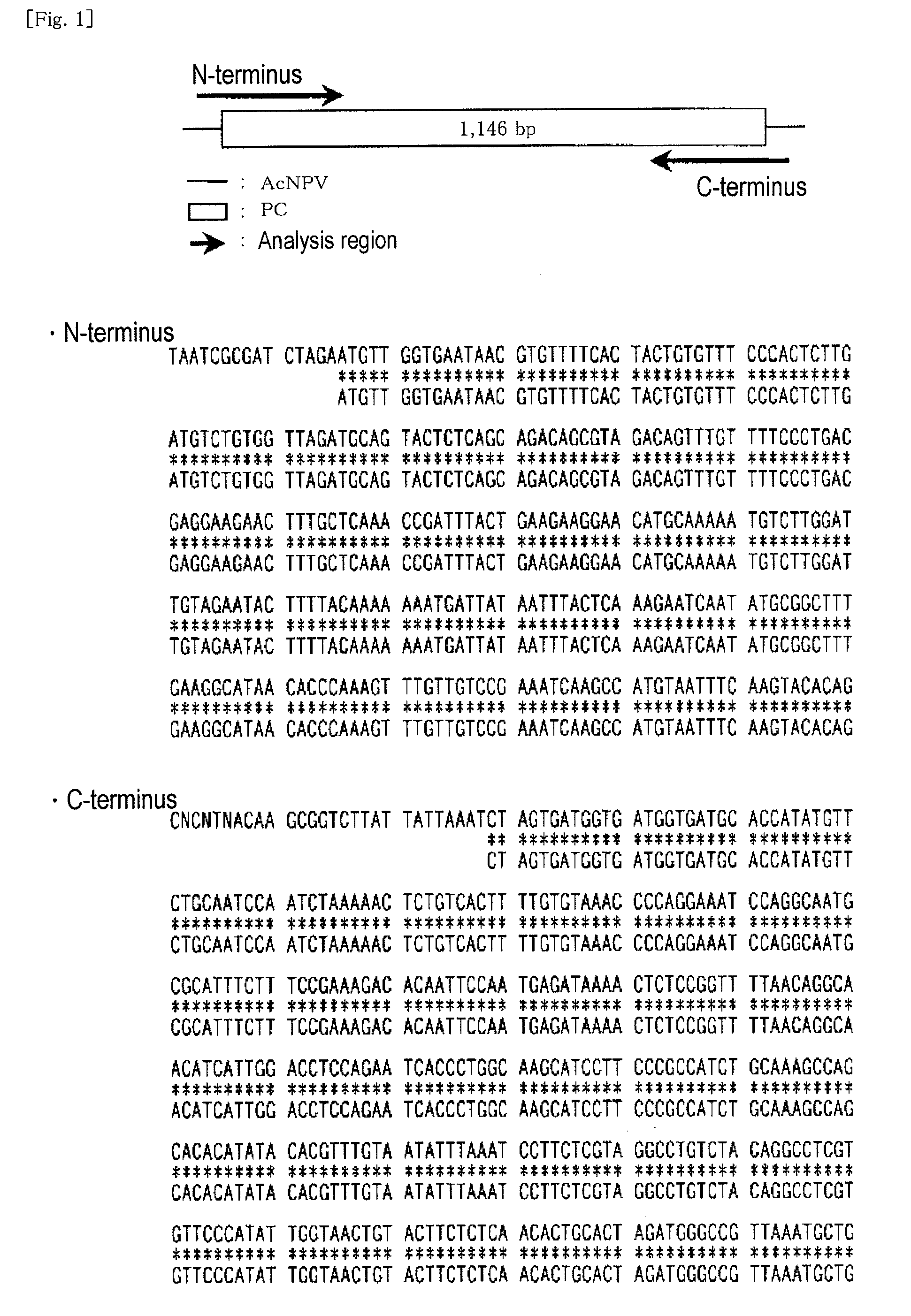

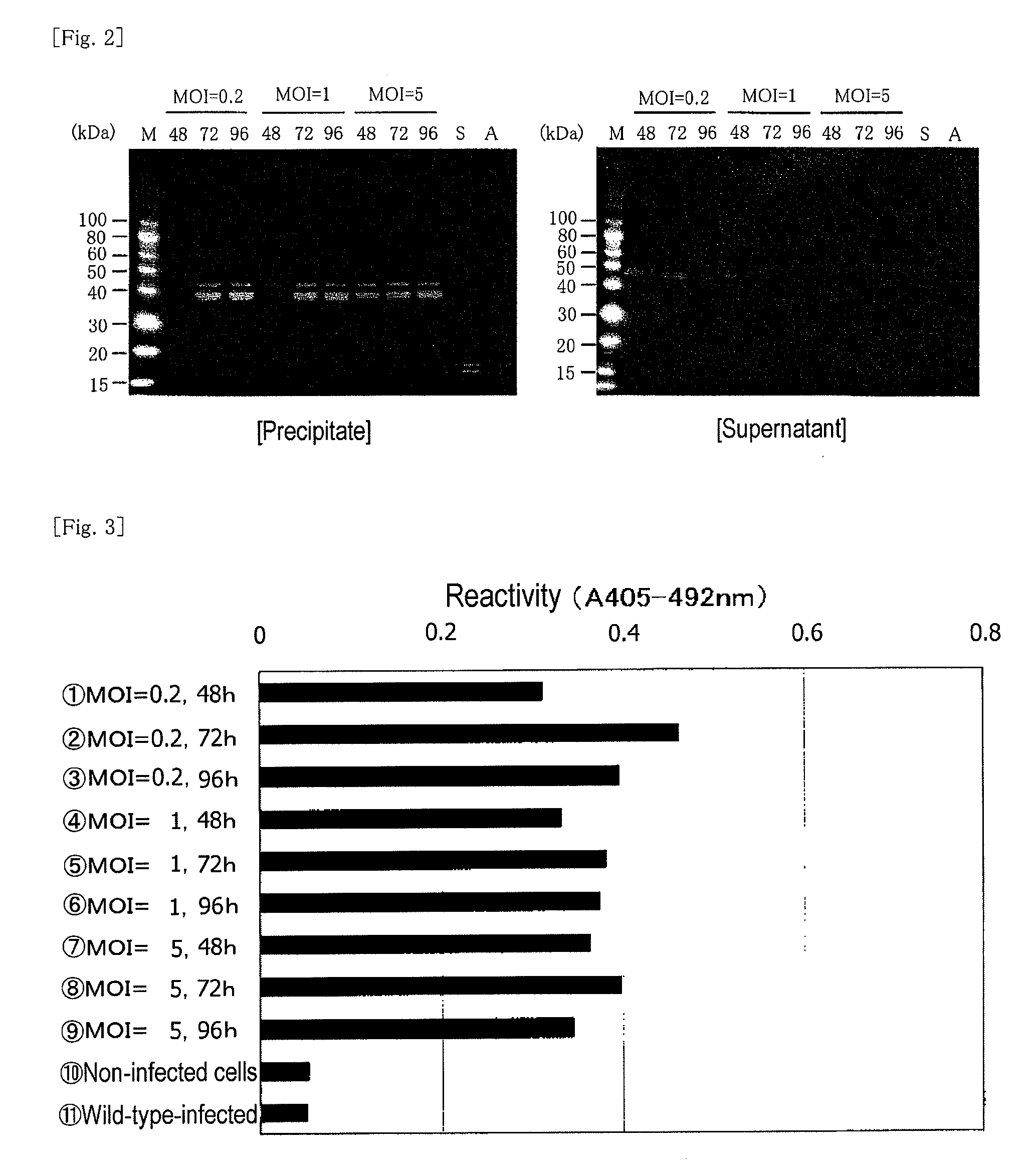

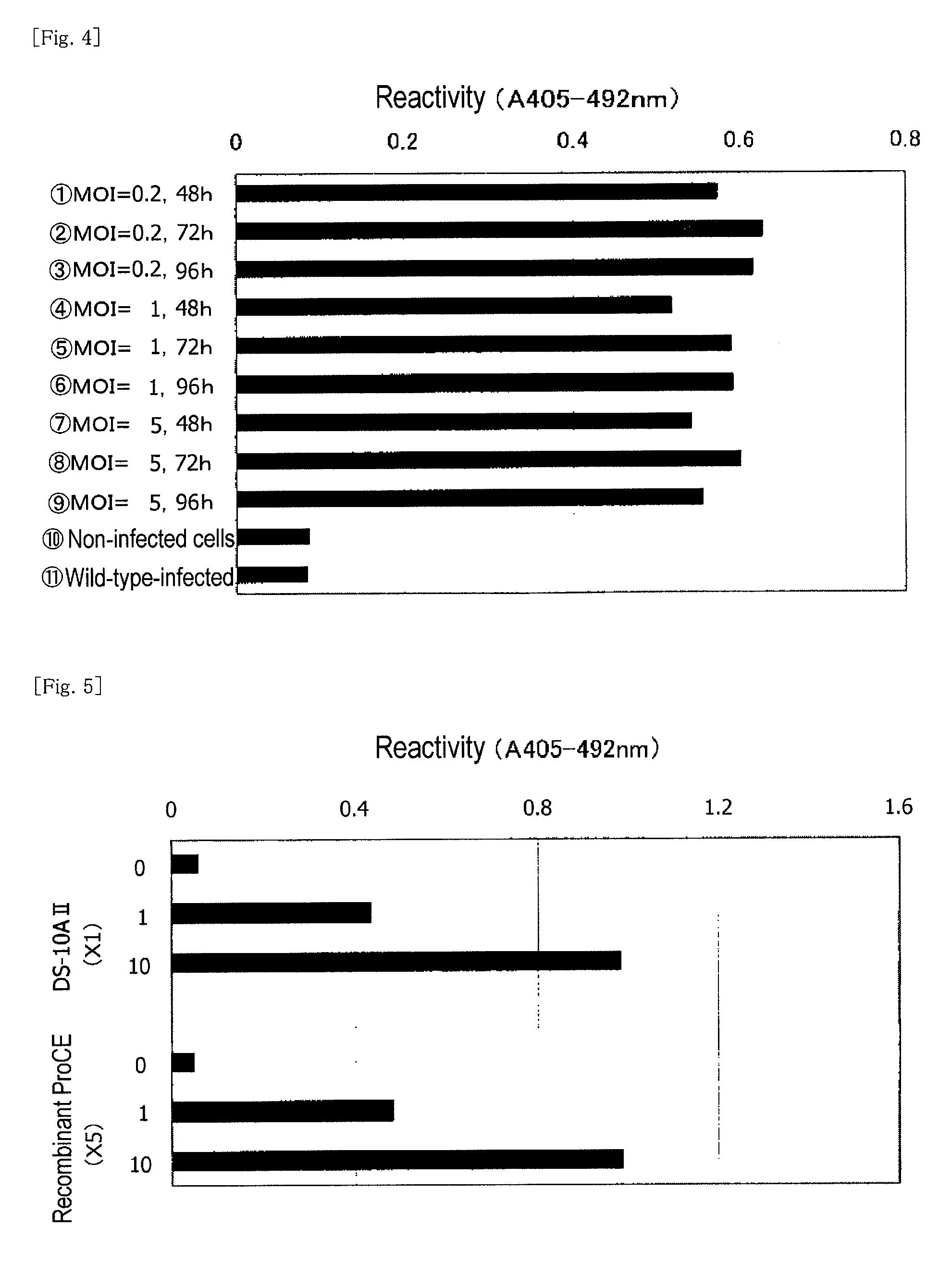

Pro-clotting enzyme, and method for detection of endotoxin or (1-3)-beta-d-glucan using the same

Objects of the present invention are to provide a DNA fragment encoding a limulus-derived pro-clotting enzyme, a virus harboring the DNA fragment, a cell harboring the virus, a method of producing the pro-clotting enzyme by use of the cell, and means for assaying an endotoxin or (1→3)-β-D-glucan employing the enzyme, wherein these elements are capable of producing an endotoxin or (1→3)-β-D-glucan assay reagent of satisfactory quality, steadily, at low cost, and on a large scale. In the present invention, for example, a DNA fragment encoding a protein having an amino acid sequence defined by SEQ ID NO: 4 is selected as a nucleic acid fragment encoding a limulus-derived pro-clotting enzyme, and the corresponding recombinant pro-clotting enzyme. Use of the enzyme can provide a high-sensitivity method and kit for detecting (1→3)-β-D-glucan and an endotoxin, utilizing a cascade reaction system in a horseshoe crab lysate.

Owner:SEIKAGAKU KOGYO CO LTD

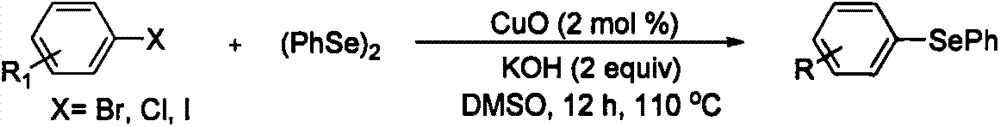

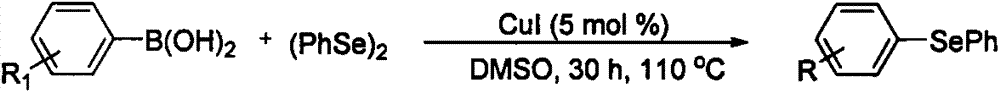

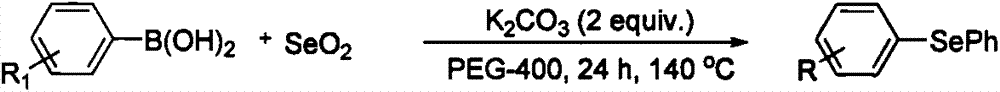

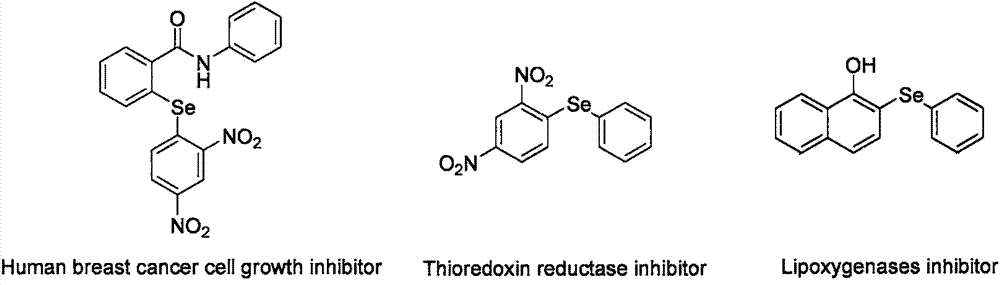

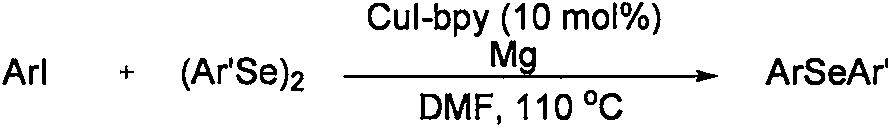

Method for synthesizing asymmetric diaryl mono-selenide compound

The invention relates to a method for synthesizing an asymmetric diaryl mono-selenide compound. The method comprises the following steps: taking aryl carboxylic acid and aryl iodide as reaction materials under oxygen conditions in an organic solvent, taking elemental selenium as a selenium based reagent, carrying out a cascade reaction under the combined promotion action of a copper catalyst, a ligand and alkali, thereby obtaining the asymmetric diaryl mono-selenide compound. The method is cheap and readily available in aryl carboxylic acid substrate, aryl iodide and copper catalyst, wide in substrate range, simple in reaction conditions and high in product yield and purity, develops a novel synthetic route and method for the asymmetric diaryl mono-selenide compound and has excellent application potential and research value.

Owner:WENZHOU MEDICAL UNIV

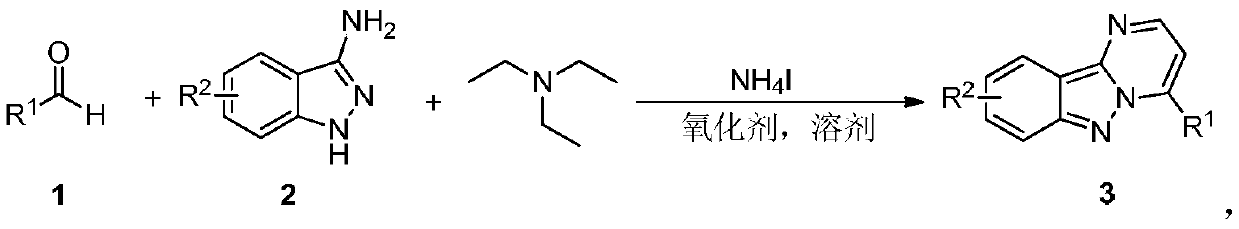

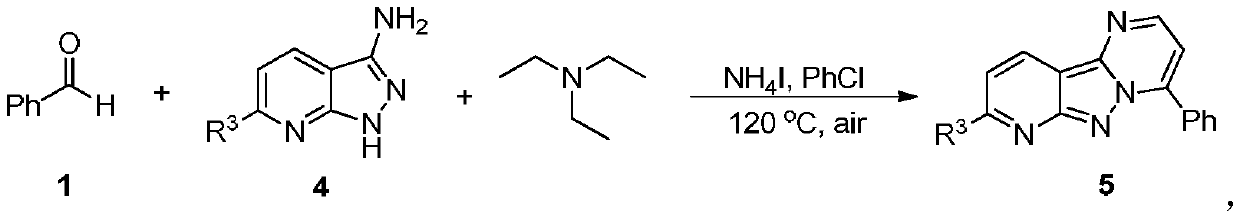

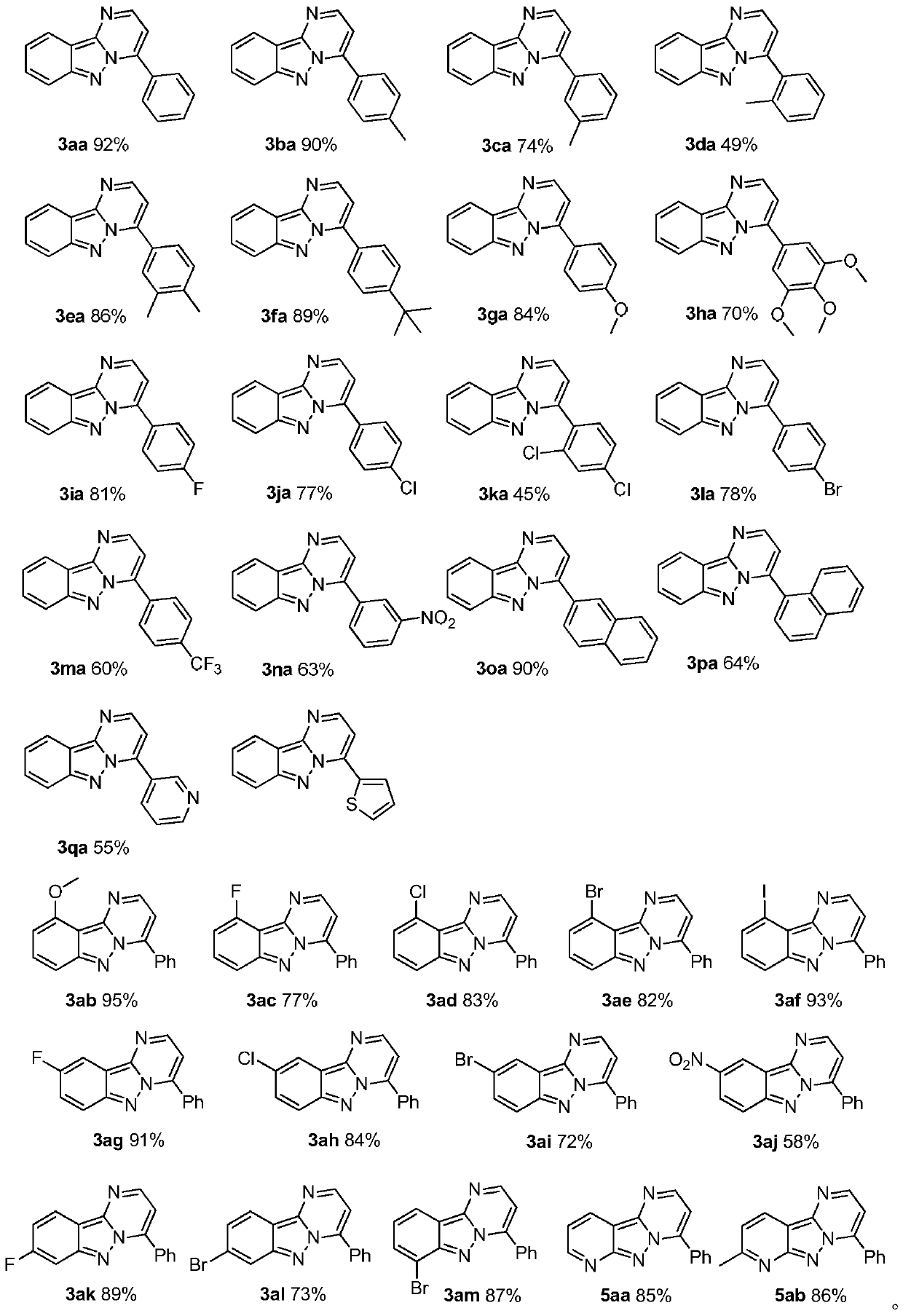

Synthesis method of pyrimido-indazole compound

The invention discloses a synthesis method of a pyrimido-indazole compound and belongs to the technical field of organic synthesis. The key point of the technical scheme is as follows: the synthesis method of the pyrimido-indazole compound particularly comprises the following steps: dissolving an aromatic aldehyde compound, a 3-amnioindazole derivative and triethylamine into a solvent, adding NH4Iand an oxidizing agent, and reacting at 110 to 150 DEG C to prepare a target product pyrimido-indazole compound. The synthesis process is simple and efficient, the pyrimido-indazole compound is directly prepared at one step through one-pot cascade reaction without transition metal catalysis, resource waste and environmental pollution caused by the use of various reagents in multi-step reaction aswell as purification treatment on a reaction intermediate at each step are avoided, the synthesis process is convenient to operate, the raw materials are simple, the reaction condition is mile, and the application range of substrates is wide; meanwhile the triethylamine serves as the raw materials, so that the production cost is greatly reduced.

Owner:XINXIANG MEDICAL UNIV

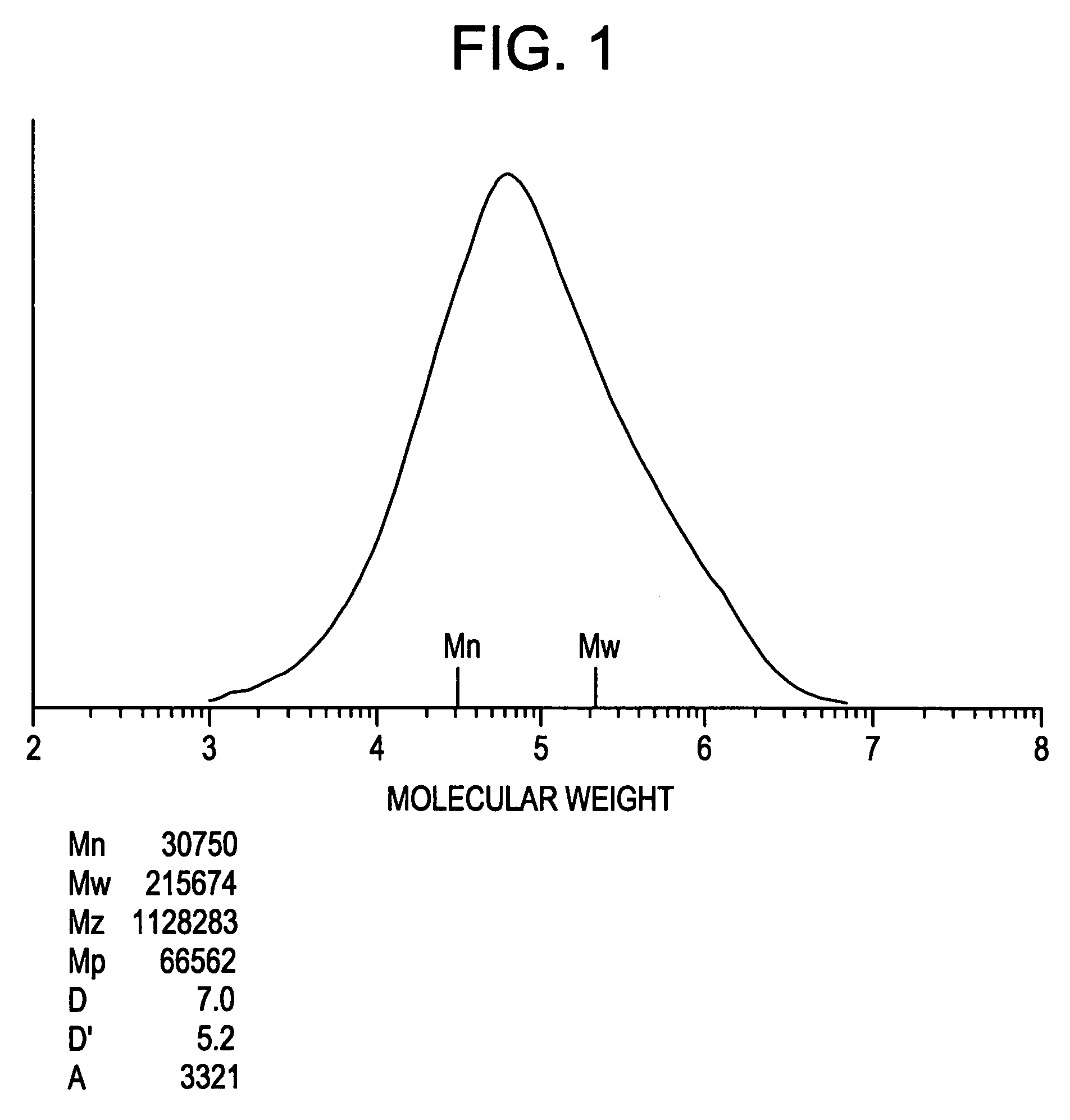

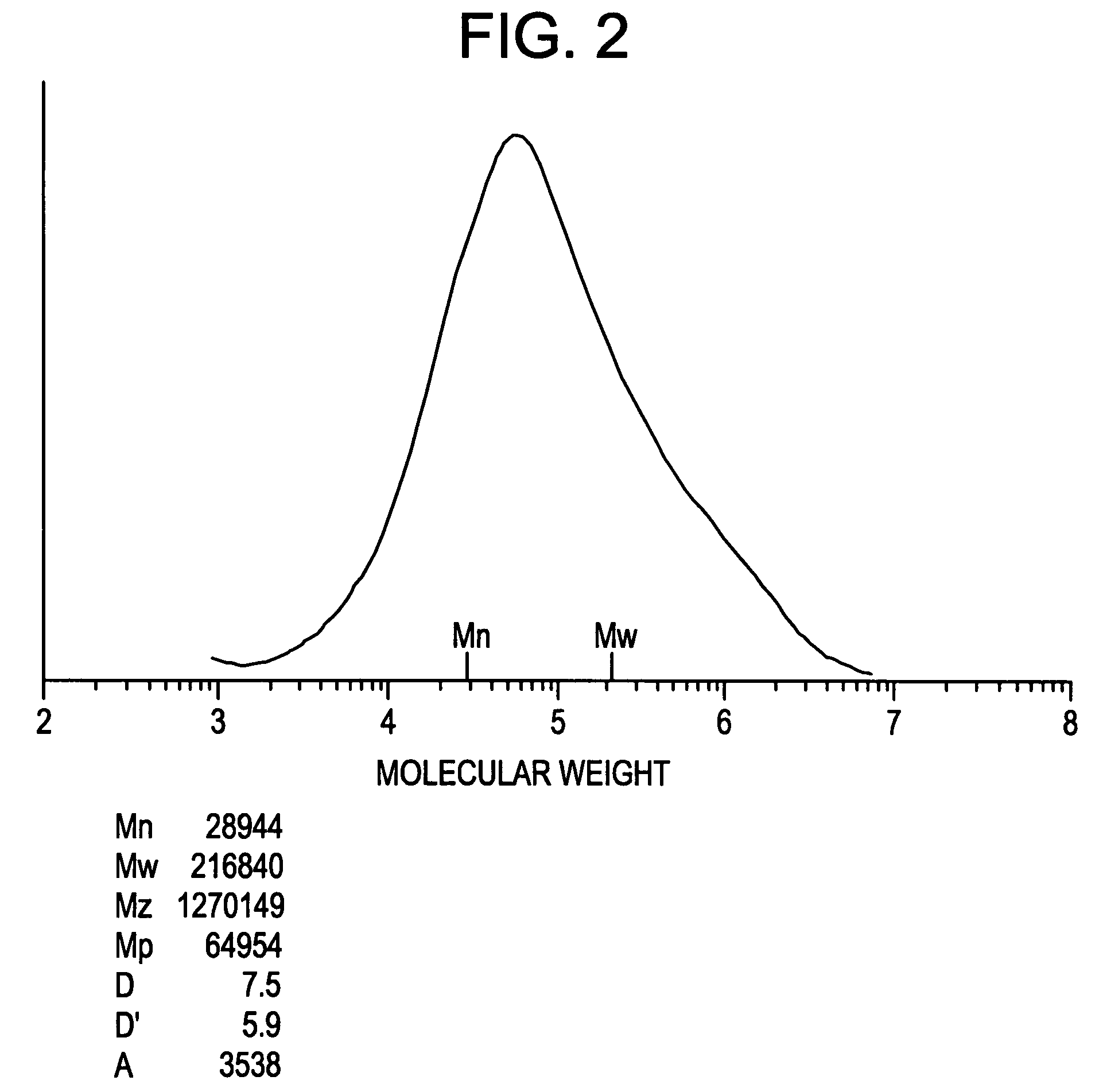

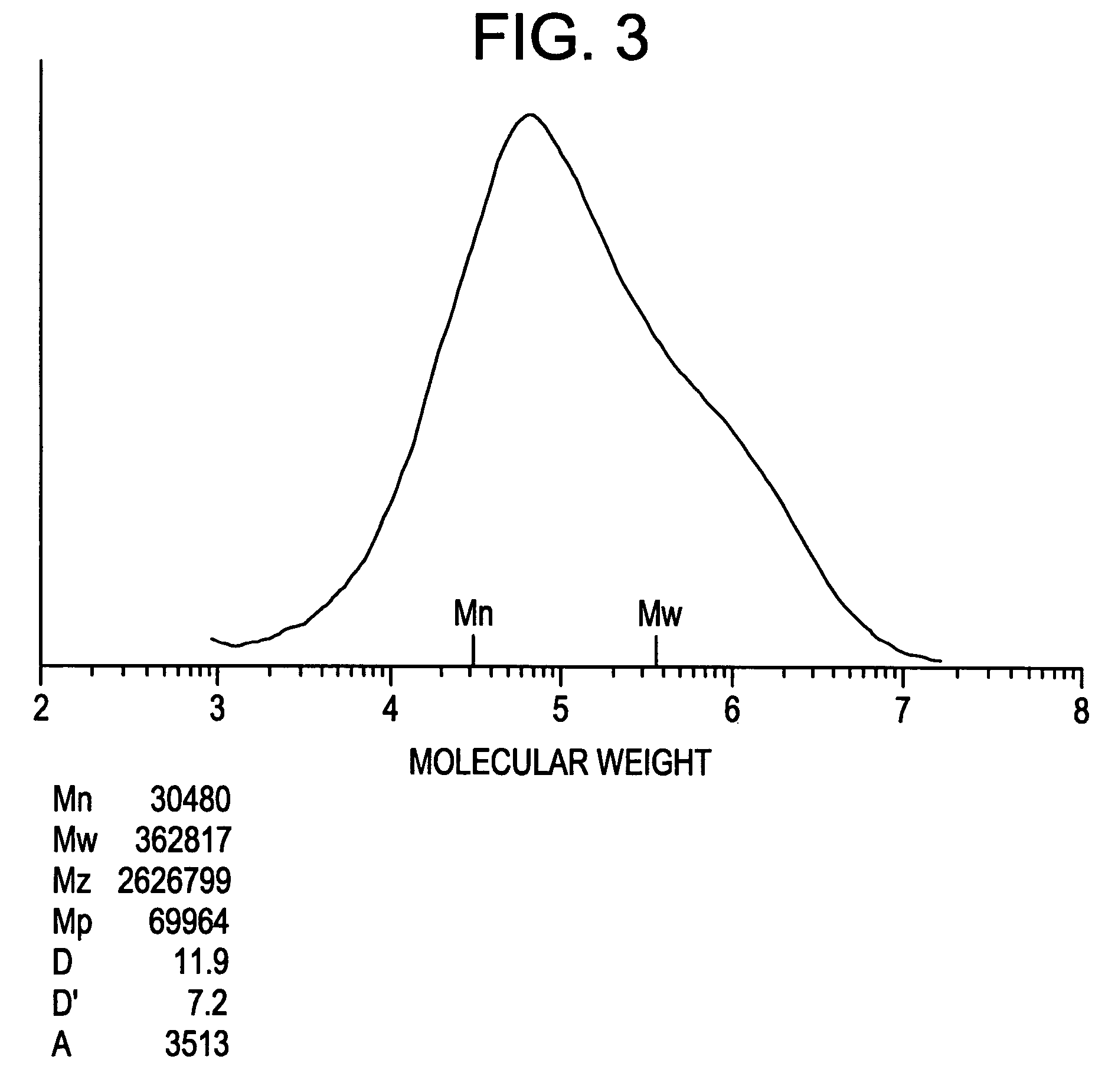

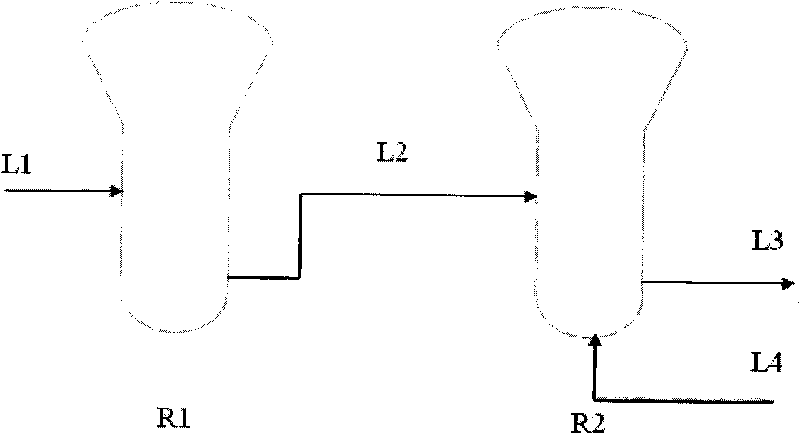

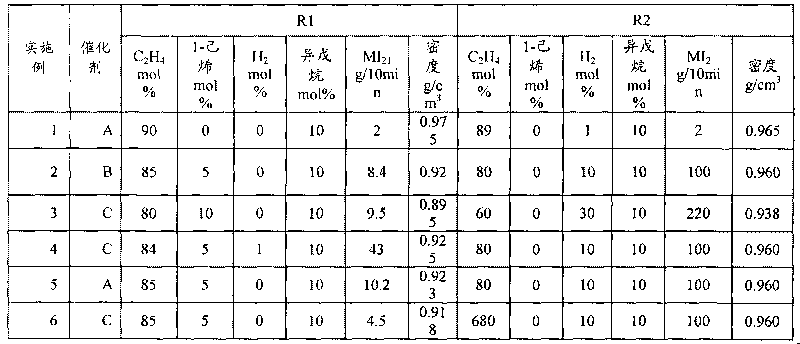

Double series reactor process for preparing polyethylene

InactiveCN101735348AResolve interactionSolve various problems caused byLow-density polyethylenePolymer science

The invention discloses a double series reactor process for preparing polyethylene, which comprises the following steps: ethylene and alpha-alkene comonomer react in a first reactor under the effect of a composite catalyst, the material in the first reactor after reaction is directly transferred to a second reactor, and ethylene and hydrogen react in the second reactor. The composite catalyst comprises: (1) a Ziegler Natta catalyst loaded on a carrier; (2) a polymer layer covered on the Ziegler Natta catalyst loaded on the carrier; and (3) a metallocene catalyst loaded in or loaded on the polymer layer. High molecular weight low-density polyethylene is produced in the first reactor, and low-molecular weight high-density resin is produced in the second reactor. No degasser is additionally arranged in the series polymerization process. The obtained polyethylene blend product has a melt flow ratio of about 40-500 and full density polyethylene of 0.900-0.975g / cm3.

Owner:CHINA PETROLEUM & CHEM CORP +1

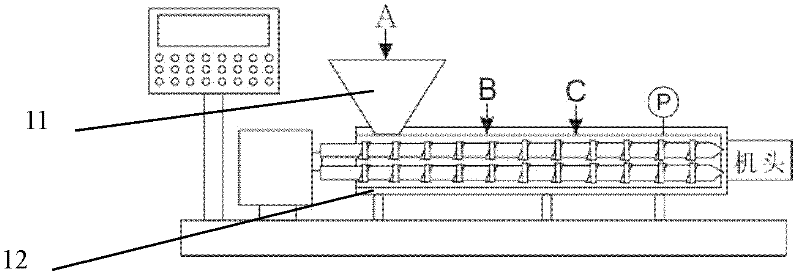

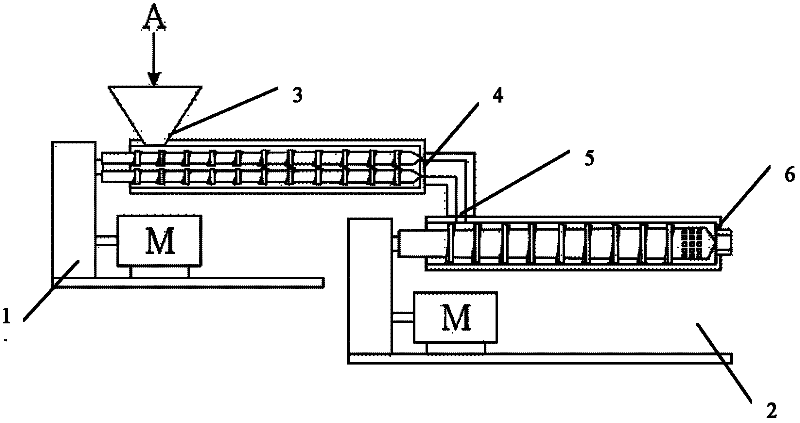

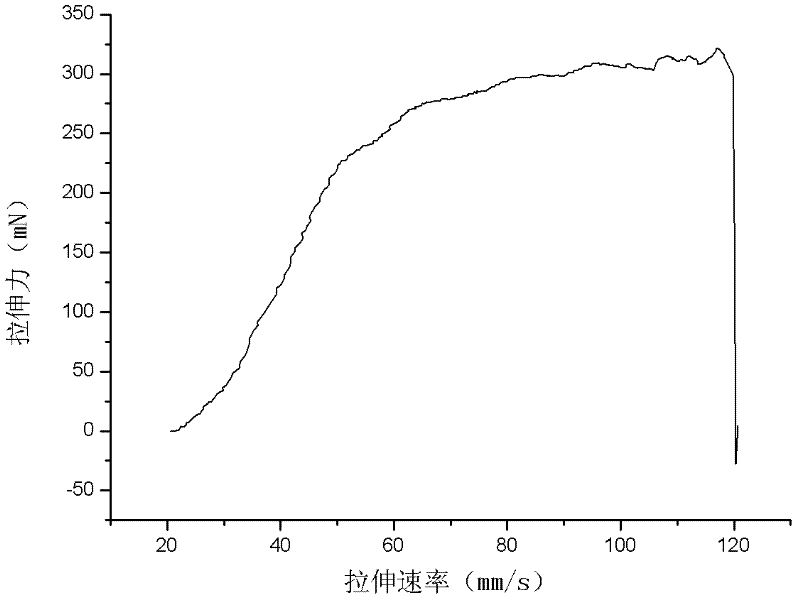

Preparation method for high melt strength poly lactic acid, and extruder thereof

The invention relates to a preparation method for high melt strength poly lactic acid, and an extruder thereof. The raw materials comprise, by weight, 100 parts of a poly lactic acid resin, 1-3 parts of a reaction chain extender, and 0.1-3 parts of an antioxidant. The preparation method comprises: drying the poly lactic acid resin, mixing the poly lactic acid resin, the reaction chain extender and the antioxidant according to the weight part ratio, adding the resulting mixture to an extruder, and carrying out extruding through the extruder to obtain the high melt strength poly lactic acid, wherein the extruder comprises a primary stage extruder and a secondary stage extruder, the primary stage extruder and the secondary stage extruder are respectively provided with a temperature sensor and a heating device, the primary stage extruder is a twin screw extruder, the secondary stage extruder is a single screw extruder, the primary stage extruder is provided with a first material inlet and a first material outlet, the secondary stage extruder is provided with a second material inlet and a second material outlet, and the first material outlet is connected with the second material inlet. With the method of the present invention, the production method and the device thereof are provided, wherein the method adopts the double-single series reaction extruder structure to prepare the high melt strength poly lactic acid material, and is suitable for continuous mass production of the poly lactic acid material with the long chain branched structure.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

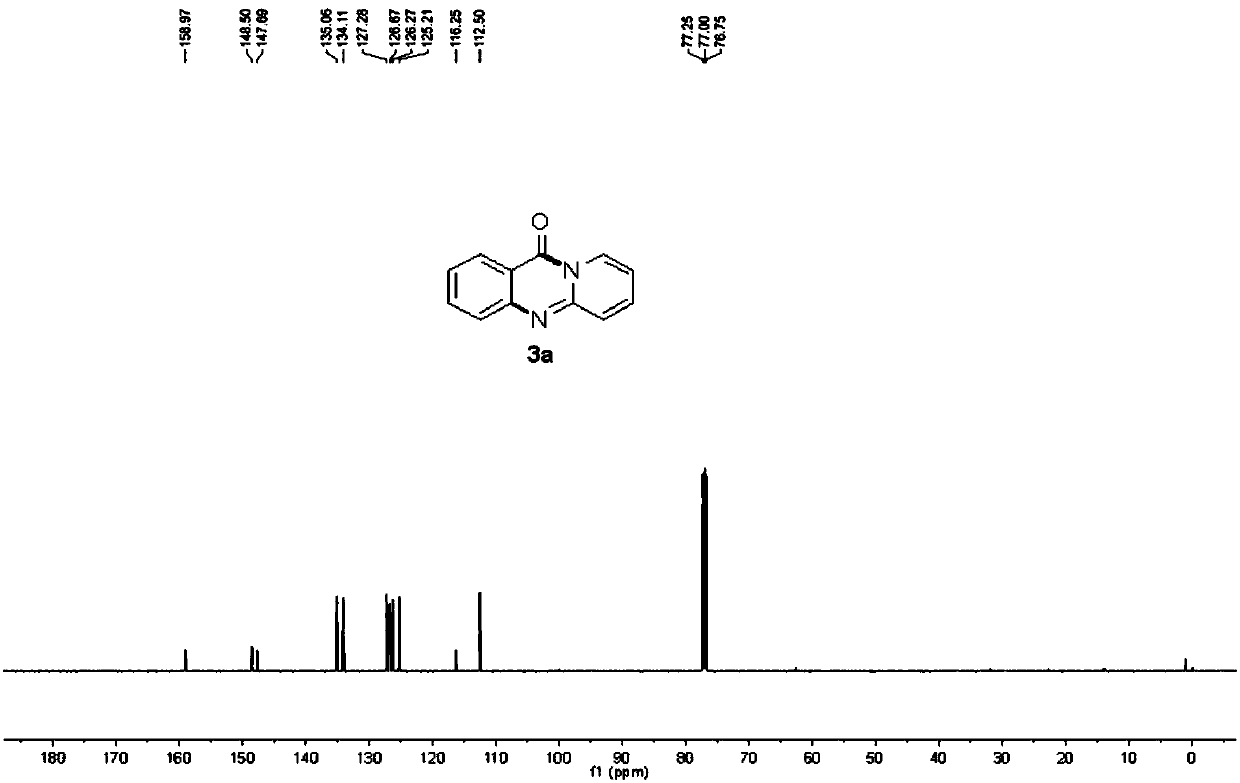

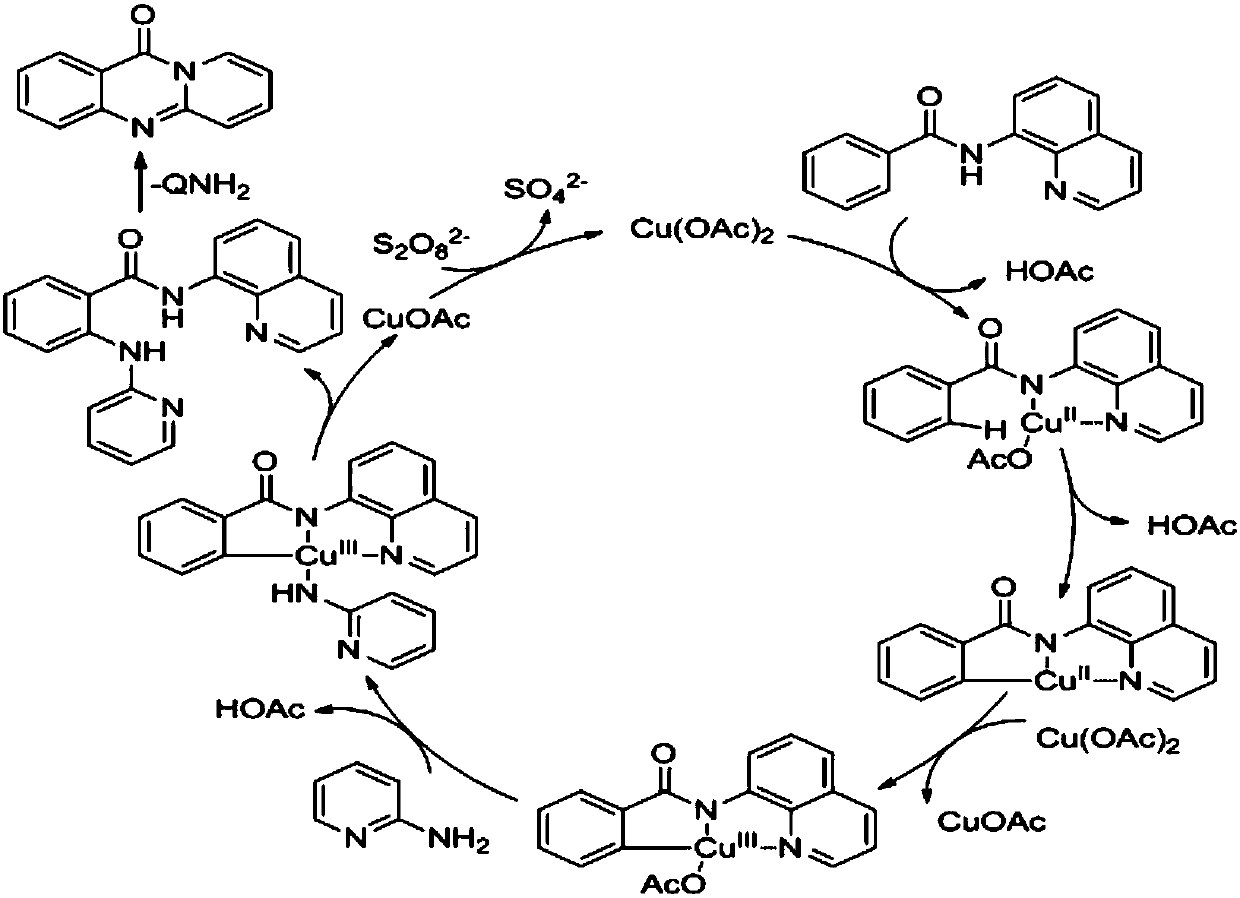

Method for preparing pyridinoquinazolinone compound through catalysis of copper compound

The invention belongs to the fields of organic synthesis and metal catalysis, and discloses a method for preparing a pyridinoquinazolinone compound through the catalysis of a copper compound. The method comprises the following steps: adding a benzamide derivative, a 2-aminopyridine derivative, a catalyst, an oxidizing agent and a solvent into a closed pipe in an air environment; then performing aheating reaction; and after the reaction is completed, purifying the obtained reaction solution to obtain the required pyridinoquinazolinone compound. According to the method, a C-H activation cascadereaction is performed on the benzamide derivative and the 2-aminopyridine derivative under the catalytic action of the copper compound in the presence of the oxidizing agent in the air environment and the closed environment, thereby generating the pyridinoquinazolinone; the method can be performed in the air environment; and the used raw materials, catalyst and oxidizing agent are simple and accessible, the reaction is simple to operate, and the yield is high, thereby being beneficial to industrial production.

Owner:GUANGZHOU UNIVERSITY

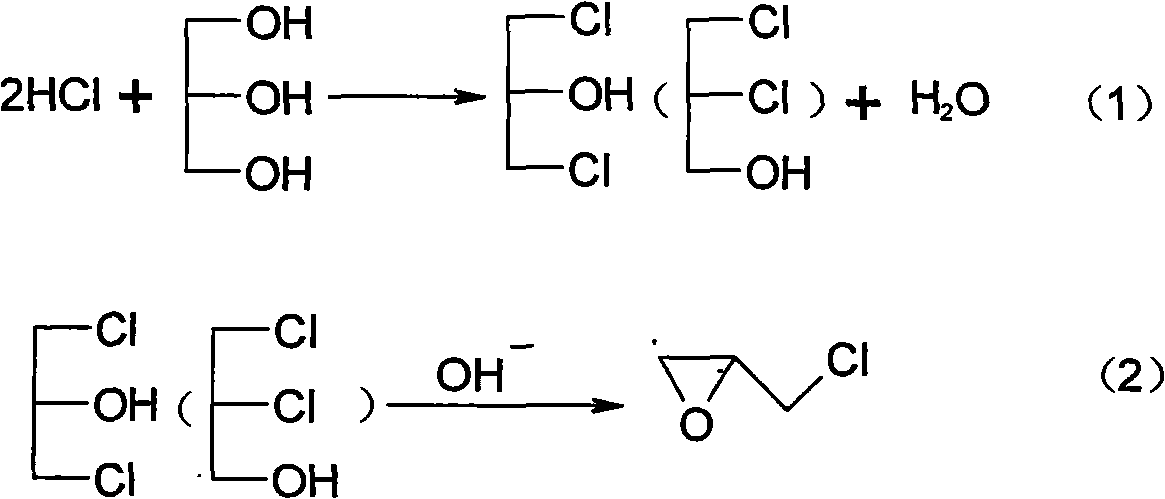

Method for preparing dichlorohydrin and reaction device

ActiveCN101774886ALow viscosityFully contactedPreparation by halogen introductionLiquid-gas reaction processesStrong acidsTower

The invention relates to improvement on a method for preparing dichlorohydrin by chlorinating glycerin and a reaction device. The chlorinating reaction is the series reaction of a reaction kettle and a sprinkling reaction tower which is filled with filler. The sprinkling reaction tower is sequentially provided with a placing filter zone, a hollow built-in sprinkling device zone and a placing filter zone from top to bottom. After viscosity decrease by kettle type preaction, the sprinkling reaction is carried out, the reaction contact is sufficient, the reaction time is long, the reaction efficiency is greatly enhanced, the conversion rate of the glycerin achieves 100%, and the reaction time is short and only needs 6-8 hours. The dichlorohydrin yield can be enhanced to more than 96%, and the yield can be enhanced to more than 99.0% by adding kreatine and strong acid mixing catalyst. The invention has the advantages of simple process flow, convenient reaction operation and high reaction efficiency.

Owner:江苏德纳化学股份有限公司 +1

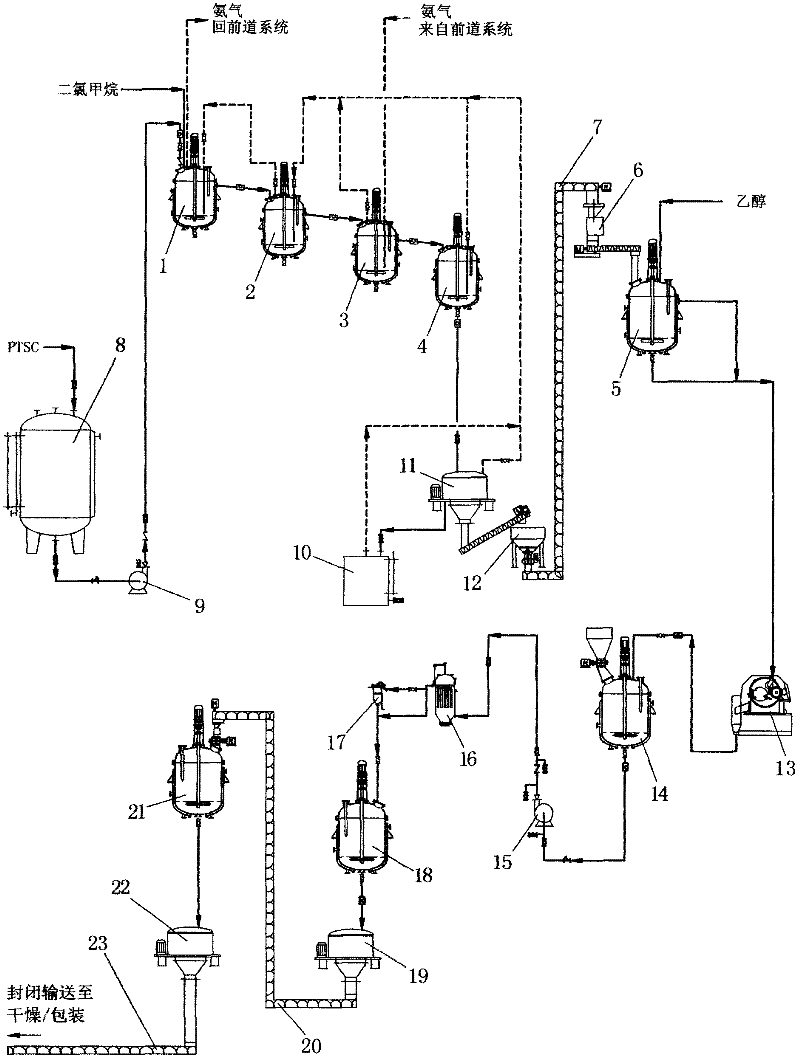

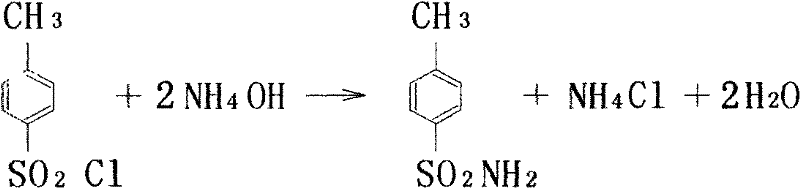

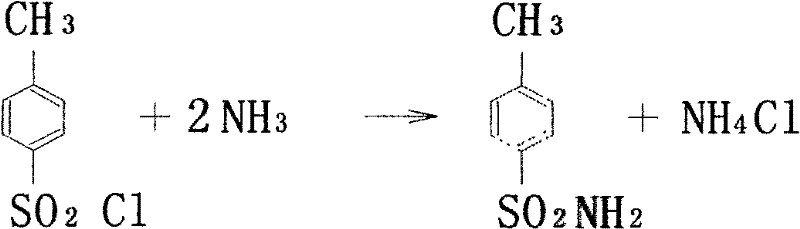

Industrial production method for toluene sulfonamide

ActiveCN102584647AReduce pollutionReduce labor intensityOrganic compound preparationSulfonic acid amide preparationMethylene DichlorideSide reaction

The invention discloses an industrial production method for toluene sulfonamide. Continuous amination is performed on paratoluensulfonyl chloride and ammonia gas in methylene dichloride solvent in a countercurrent absorbing way, then active carbon is used for decoloring, and through alcohol recrystallization and drying after water scrubbing, a qualified product can be obtained. Meanwhile, continuous production is achieved, that gas ammonia in tail gas is discharged within controlling index of national standards can be achieved, environment pollutions are reduced, and meanwhile, labor intensity is lowered. Solvent is adopted for replacing water for amination, the side reaction of hydrolyzation is stopped, and COD emission in waste water is lowered greatly while reaction conversion rate is improved.

Owner:浙江嘉化新材料有限公司

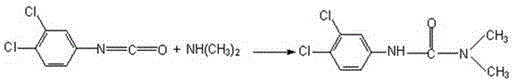

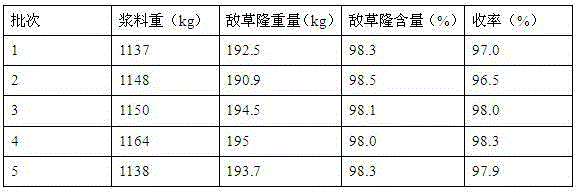

Industrial production method for continuously preparing Dailon

ActiveCN102746194AControl feed rateUrea derivatives preparationOrganic compound preparationMethods of productionCascade reaction

The invention relates to a production method of a pesticide product, particularly an industrial production method for continuously preparing Dailon. A multi-kettle-cascade reactor is adopted, the reaction raw materials isocyanate and dimethyl amine are continuously fed into the reaction kettle in the form of dilute solutions to react, and the product is discharged by overflow. The invention overcomes the defects of low productive capacity, low control stability and the like in the intermittent reaction apparatus, and has the characteristics of high yield and good product quality; and the reaction yield is higher than 97%, and the product content is higher than 98%.

Owner:JIANGSU YANGNONG CHEM GROUP +1

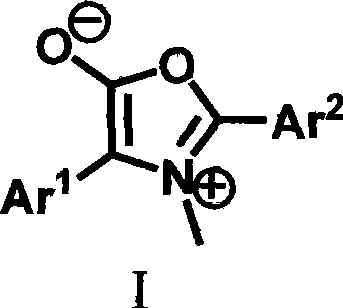

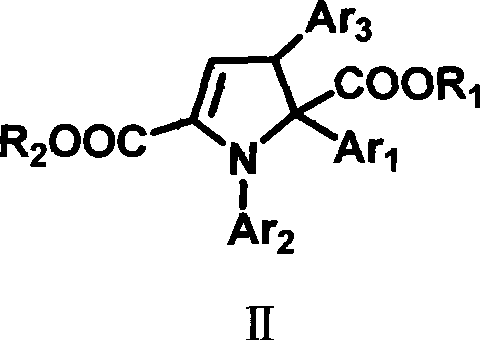

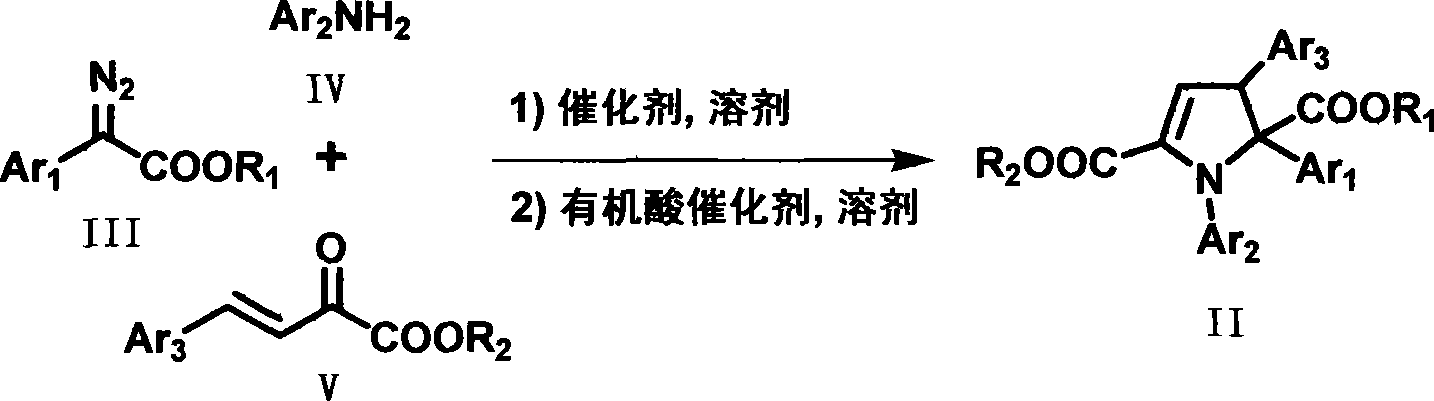

Method for preparing dihydro pyrrole derivates

InactiveCN101423488AAtom economy is highImprove efficiencyOrganic chemistryOrganic acidOrganic solvent

The invention discloses a method for preparing a pyrrolin derivative, and relates to a method for preparing the pyrrolin derivative by a one-pot process. The method comprises the following steps: taking beta, gamma-unsaturated-alpha-keto ester, amine, diazo compound, metallic Lewis acid catalyst and organic acid catalyst according to a molar ratio of 1 to 1.2 to 1.2 to 0.01 to 0.2; dissolving the amine, the beta, gamma-unsaturated-alpha-keto ester and the metallic Lewis acid catalyst in organic solvent together to form a reaction system, and dissolving the diazo compound in the organic solvent within 1 hour to form solution, dripping the solution into the reaction system, catalyzing the diazo compound by metallic Lewis acid to decompose and form metallic carbine through three-component cascade reaction, making amine ylide formed by the metallic carbine and amine in situ trapped by the beta, gamma-unsaturated-alpha-keto ester in a 1, 4-addition mode; and then carrying out water by a water segregator to obtain the corresponding pyrrolin derivative. The method has the advantages of high atom economy, high efficiency, high yield, and so on, and the operation is safe and simple. The pyrrolin derivative is widely applied in the field of medicine chemical engineering.

Owner:EAST CHINA NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Synthetic method for aromatic[a]carbazole compounds Synthetic method for aromatic[a]carbazole compounds](https://images-eureka.patsnap.com/patent_img/1ceef379-c79e-4323-87be-5b6f2e922b79/BDA0001160801260000011.png)

![Synthetic method for aromatic[a]carbazole compounds Synthetic method for aromatic[a]carbazole compounds](https://images-eureka.patsnap.com/patent_img/1ceef379-c79e-4323-87be-5b6f2e922b79/BDA0001160801260000021.png)

![Synthetic method for aromatic[a]carbazole compounds Synthetic method for aromatic[a]carbazole compounds](https://images-eureka.patsnap.com/patent_img/1ceef379-c79e-4323-87be-5b6f2e922b79/BDA0001160801260000022.png)