Patents

Literature

41results about How to "Adjust dwell time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

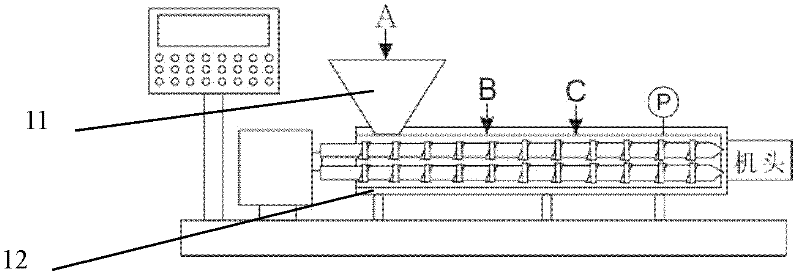

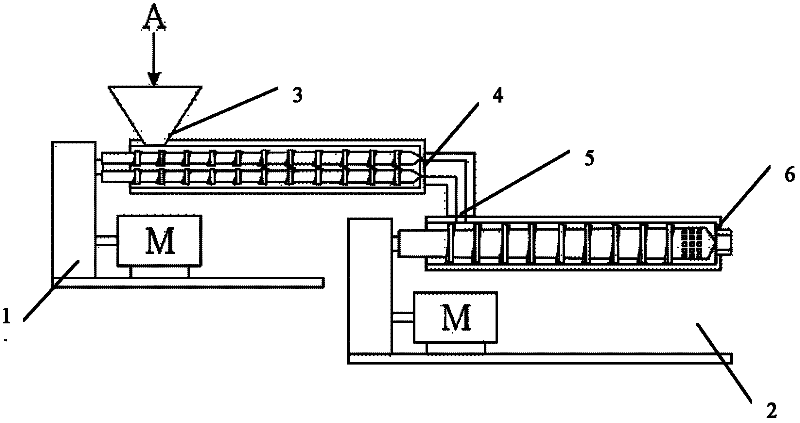

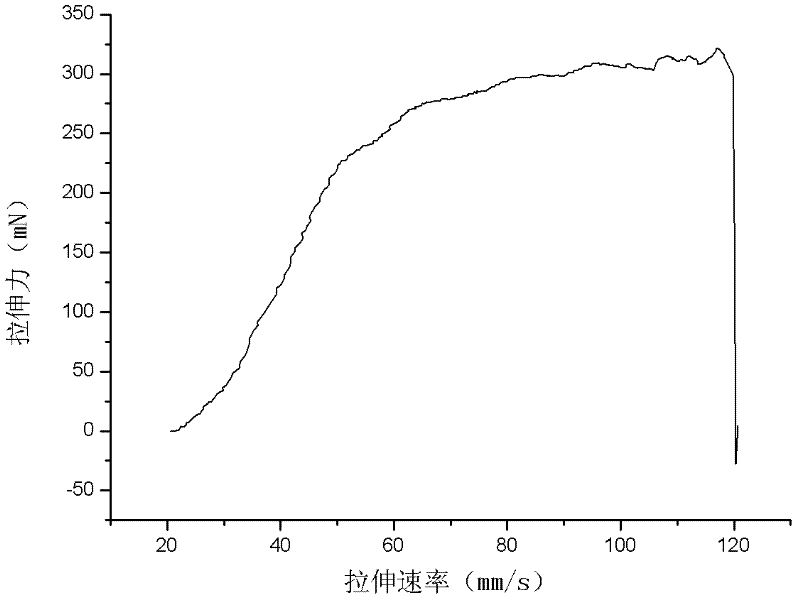

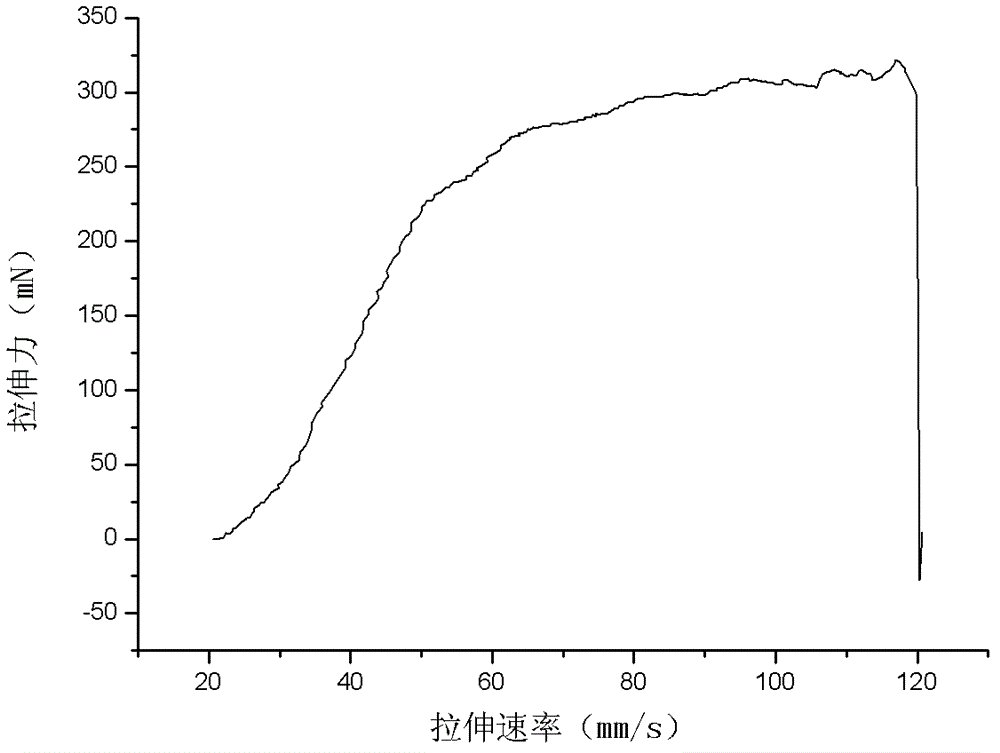

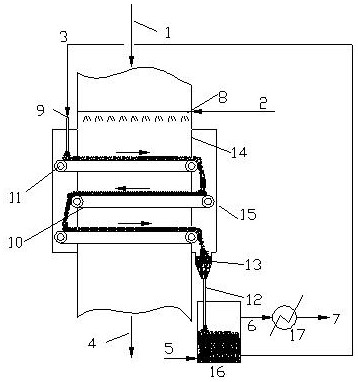

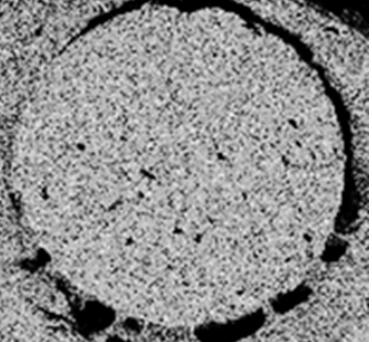

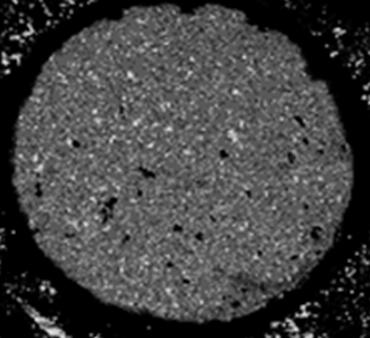

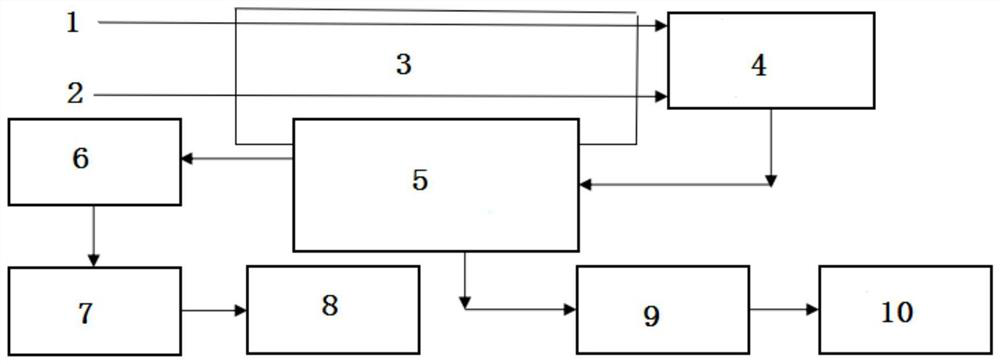

Preparation method for high melt strength poly lactic acid, and extruder thereof

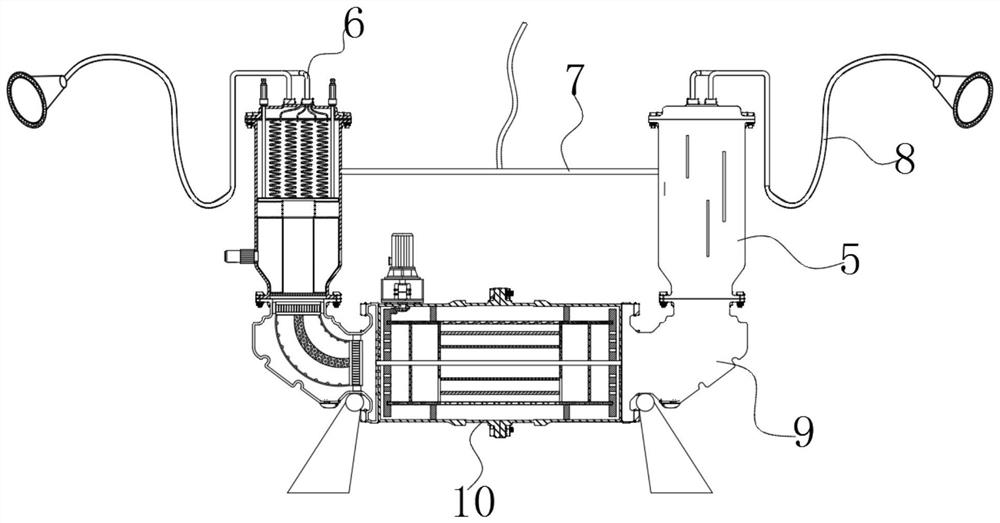

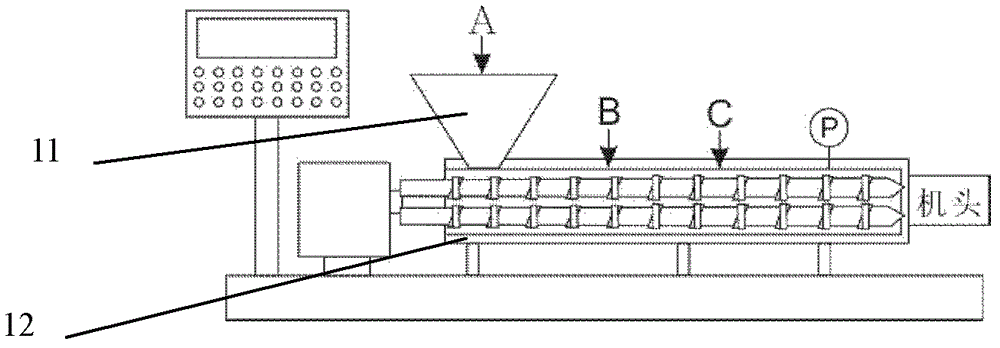

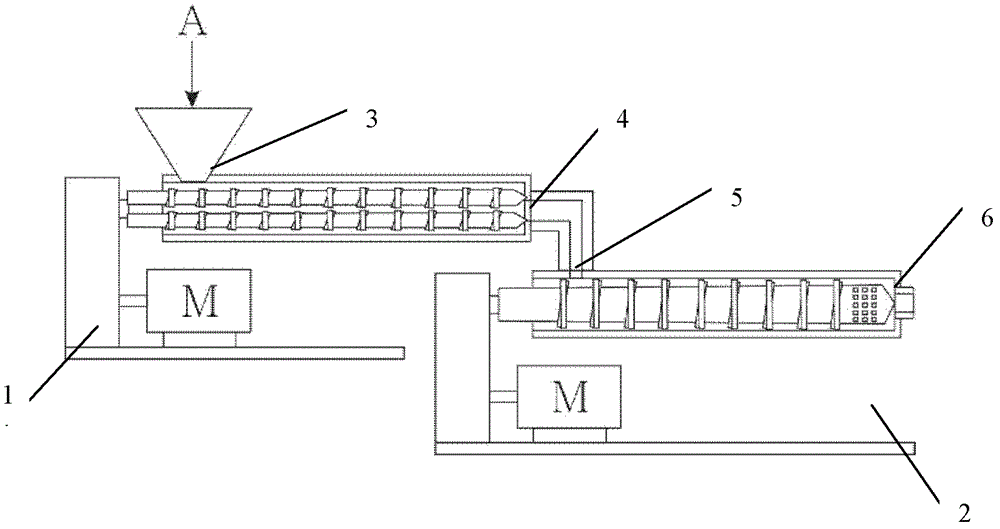

The invention relates to a preparation method for high melt strength poly lactic acid, and an extruder thereof. The raw materials comprise, by weight, 100 parts of a poly lactic acid resin, 1-3 parts of a reaction chain extender, and 0.1-3 parts of an antioxidant. The preparation method comprises: drying the poly lactic acid resin, mixing the poly lactic acid resin, the reaction chain extender and the antioxidant according to the weight part ratio, adding the resulting mixture to an extruder, and carrying out extruding through the extruder to obtain the high melt strength poly lactic acid, wherein the extruder comprises a primary stage extruder and a secondary stage extruder, the primary stage extruder and the secondary stage extruder are respectively provided with a temperature sensor and a heating device, the primary stage extruder is a twin screw extruder, the secondary stage extruder is a single screw extruder, the primary stage extruder is provided with a first material inlet and a first material outlet, the secondary stage extruder is provided with a second material inlet and a second material outlet, and the first material outlet is connected with the second material inlet. With the method of the present invention, the production method and the device thereof are provided, wherein the method adopts the double-single series reaction extruder structure to prepare the high melt strength poly lactic acid material, and is suitable for continuous mass production of the poly lactic acid material with the long chain branched structure.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

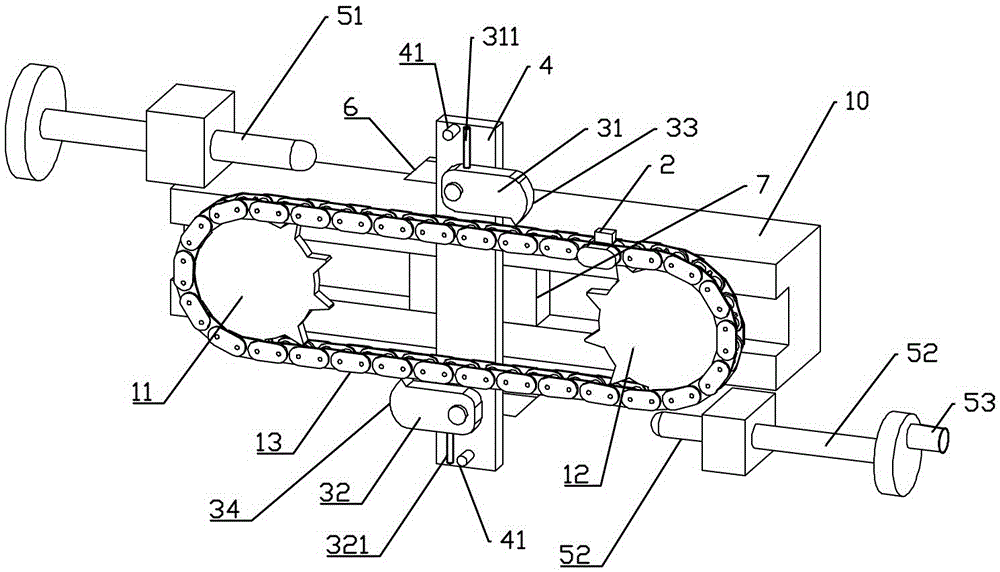

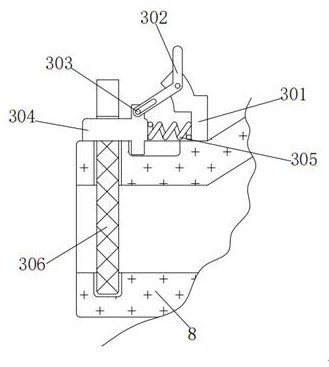

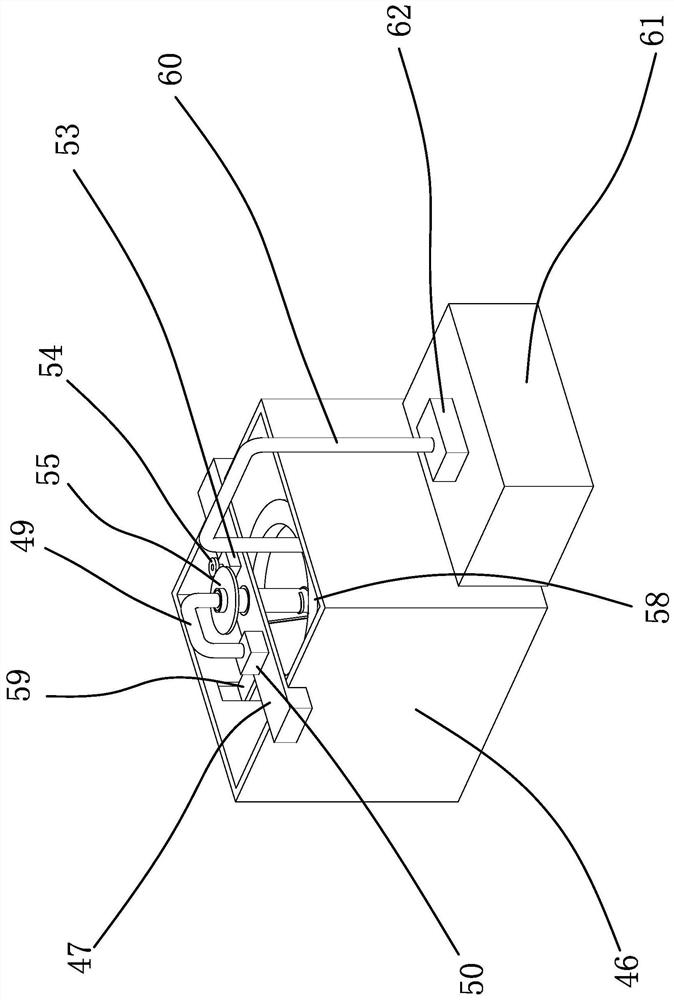

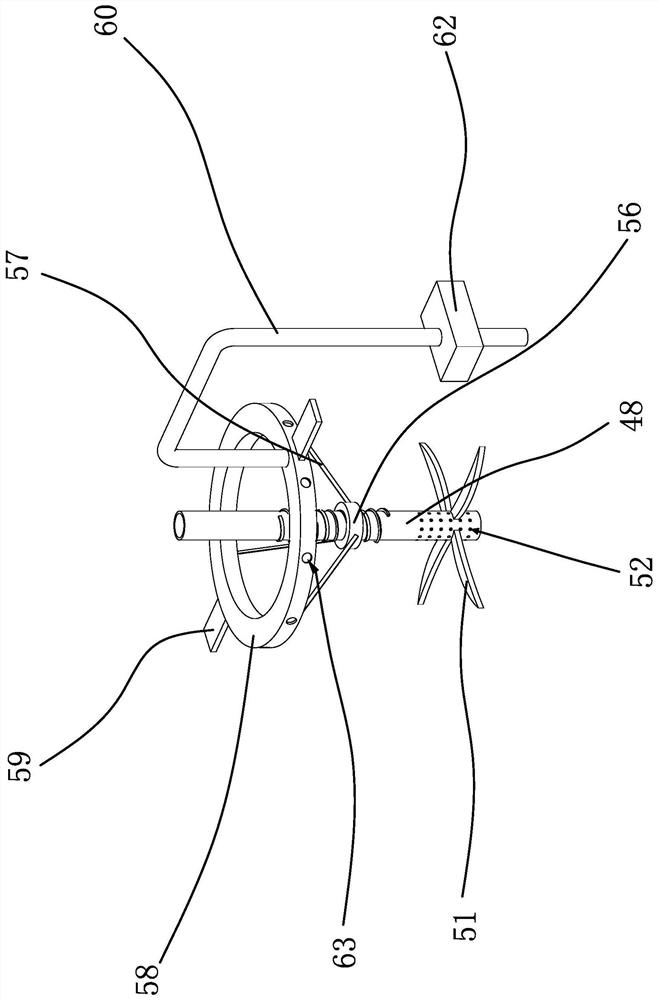

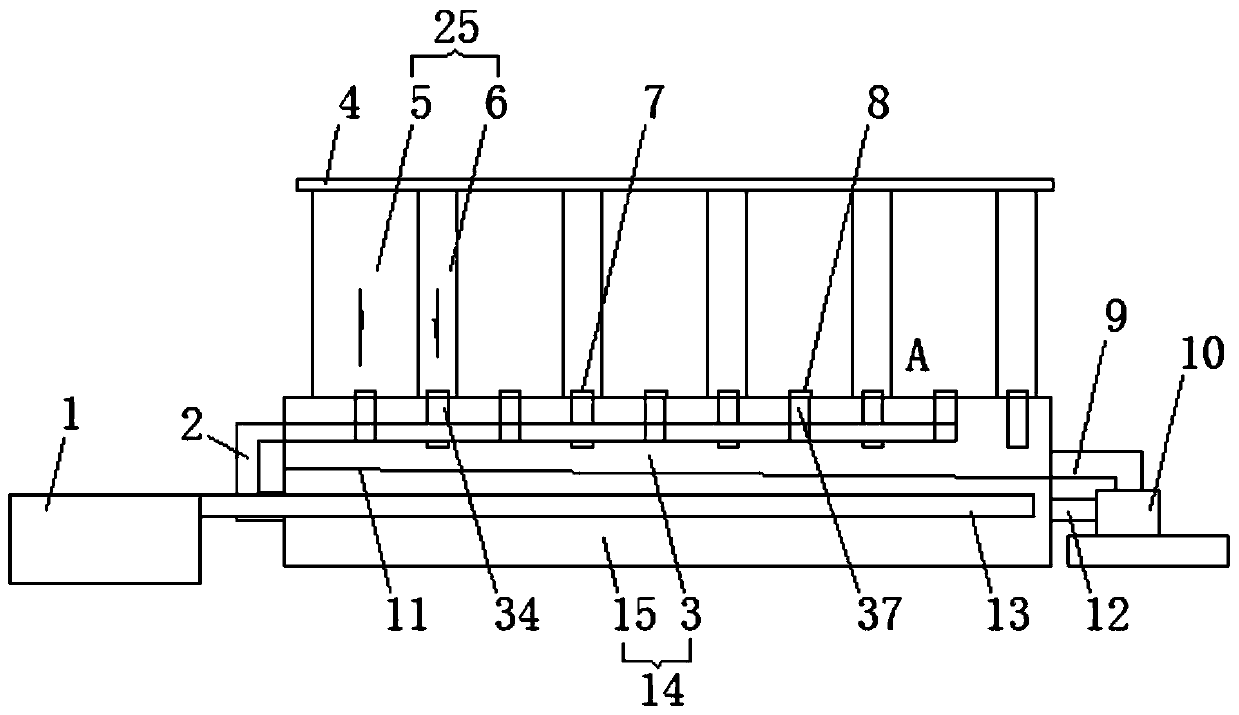

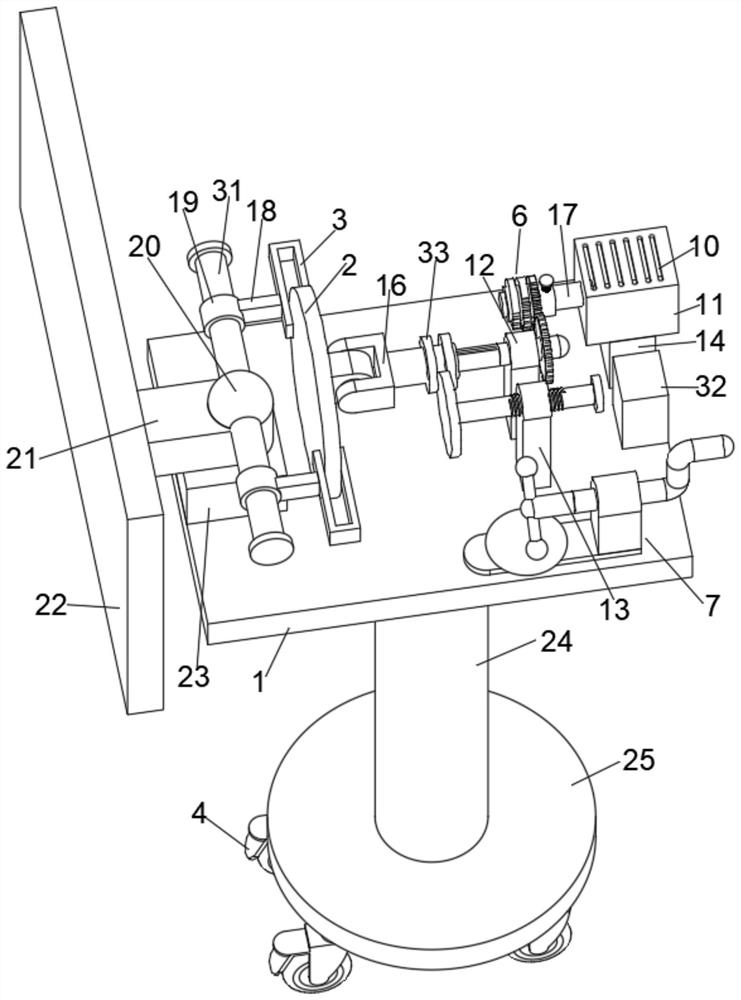

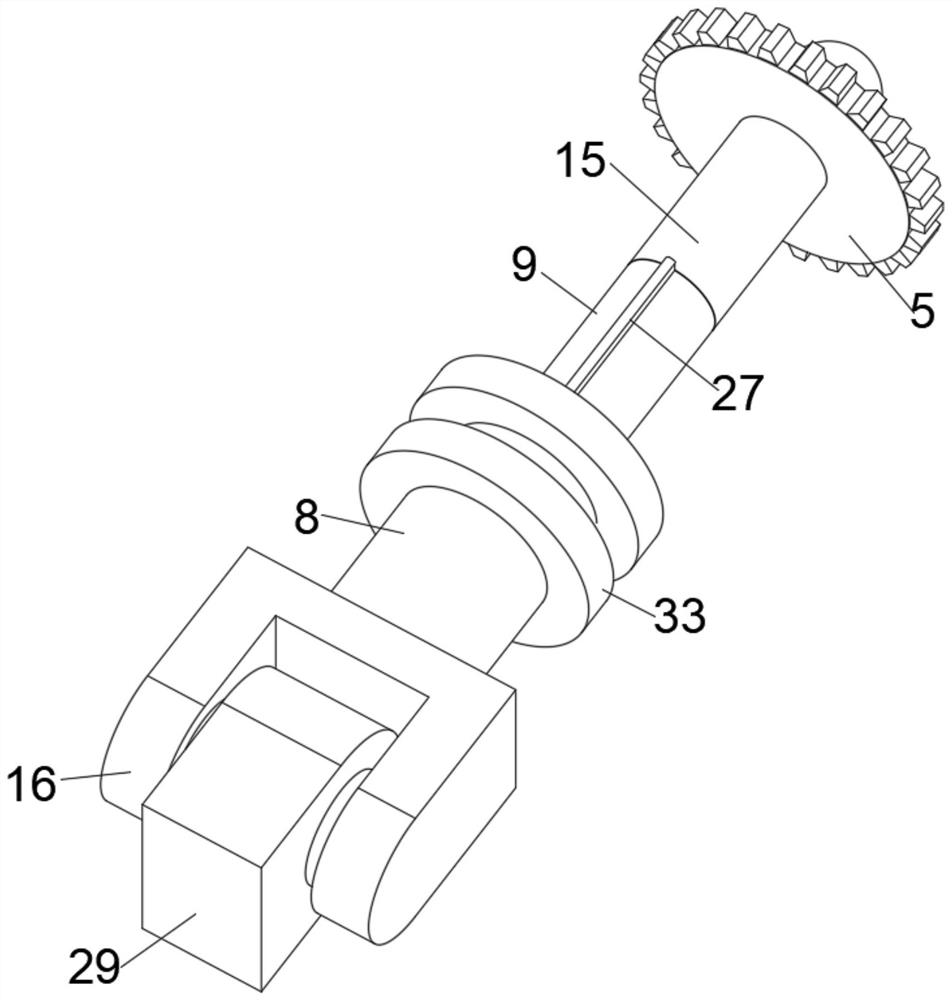

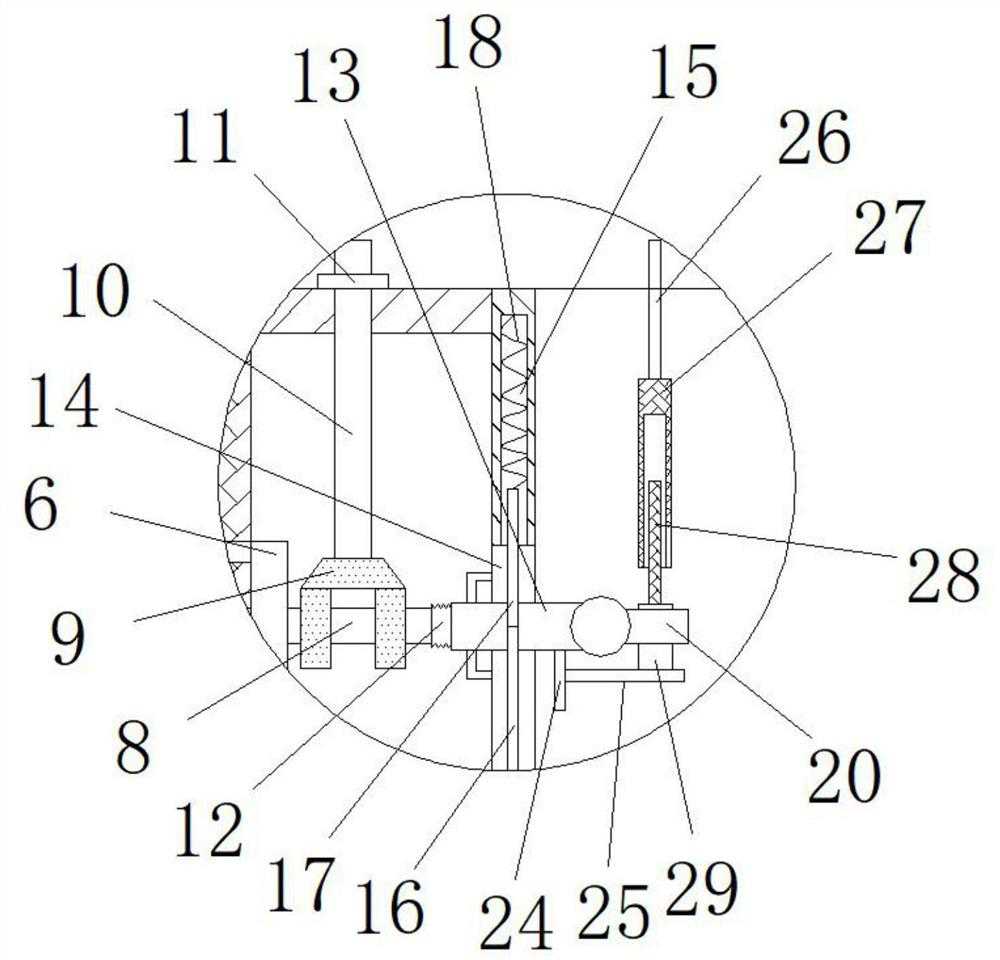

Cutting machine with adjustable staying duration

The invention relates to a transmission mechanism of a paper cutting device, in particular to a cutting machine with an adjustable staying duration. The cutting machine comprises a rack, a motor, a transmission mechanism and a cutting knife. The transmission mechanism comprises a drive chain wheel, a driven chain wheel, a transmission chain, a driven mechanism, a first stop rod, a second stop rod and a cutter. The drive chain wheel is equal to the driven chain wheel in size. The driven mechanism comprises a sliding block, a driven rod, a first triggering claw and a second triggering claw. The motor is connected with the drive chain wheel. The transmission chain is arranged outside the drive chain wheel and the driven chain wheel in a sleeving manner. A triggering block is fixed to the transmission chain. The invention aims at providing the purely-mechanical cutting device of which the cutting knife can stay for a period of time after primary cutting is finished.

Owner:DINGSHENG CORP

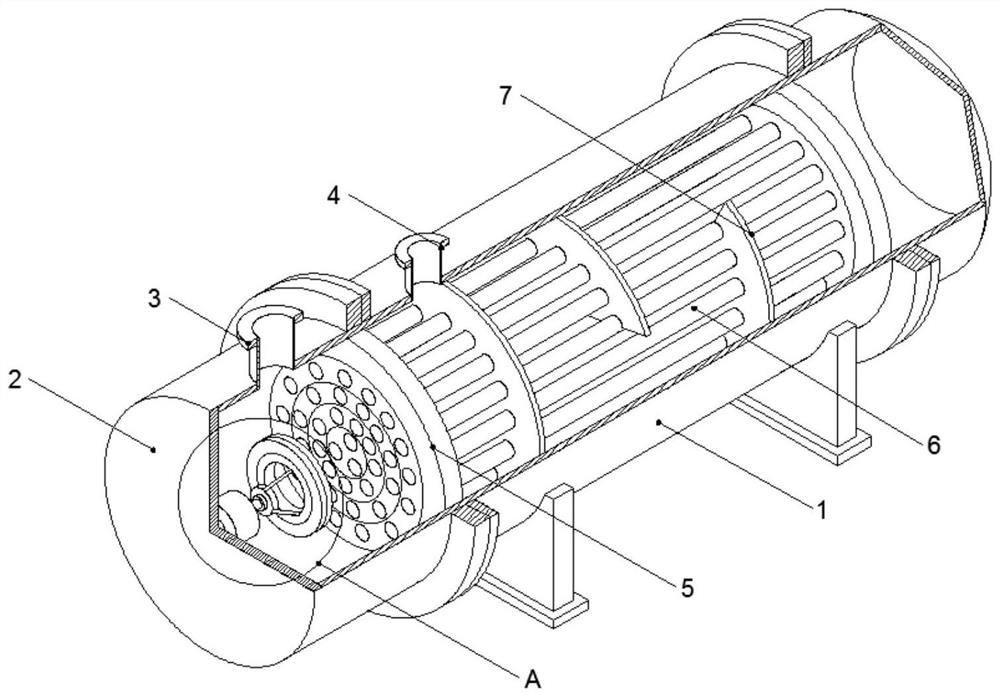

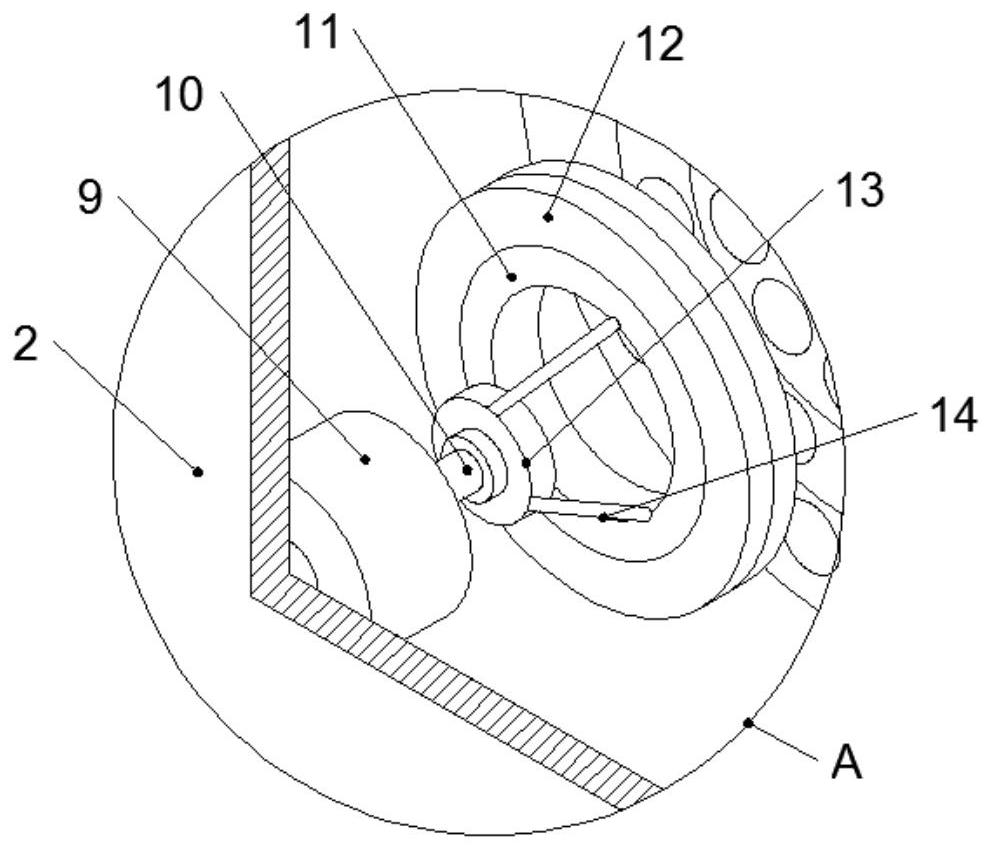

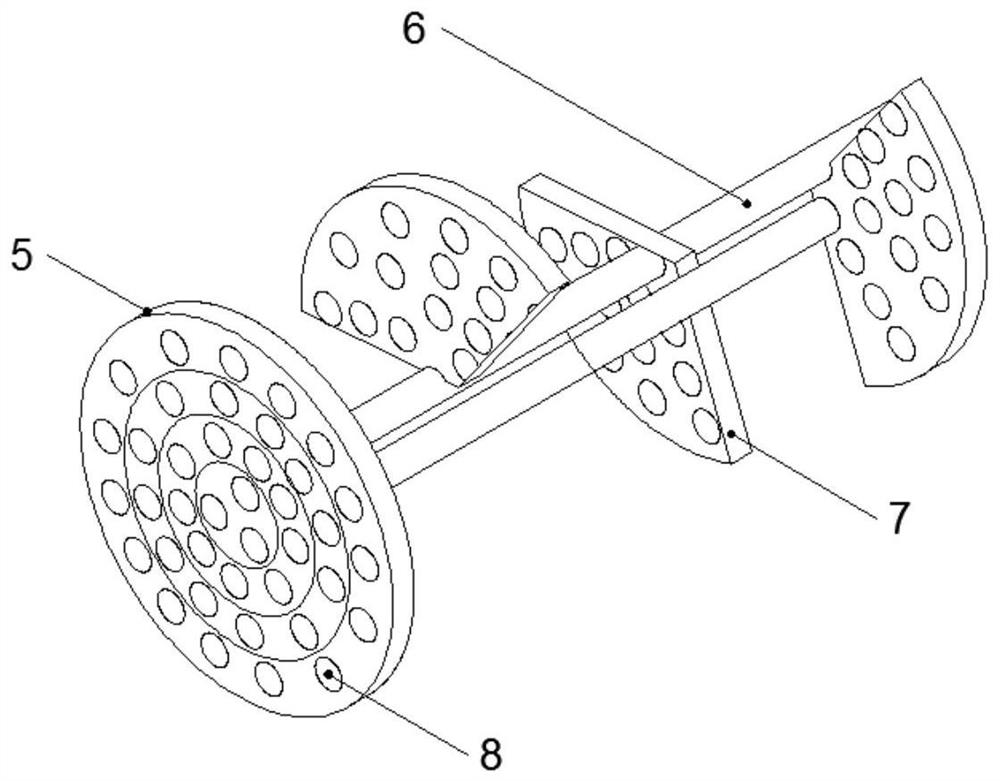

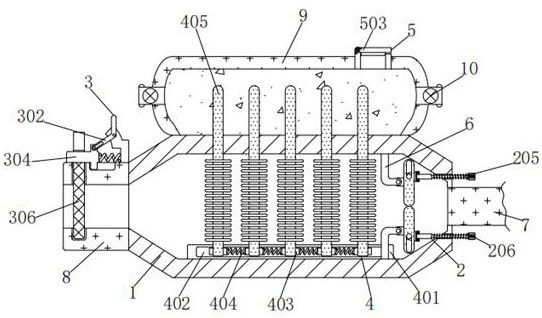

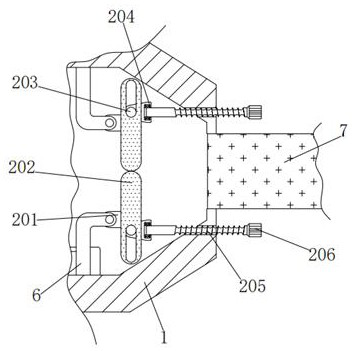

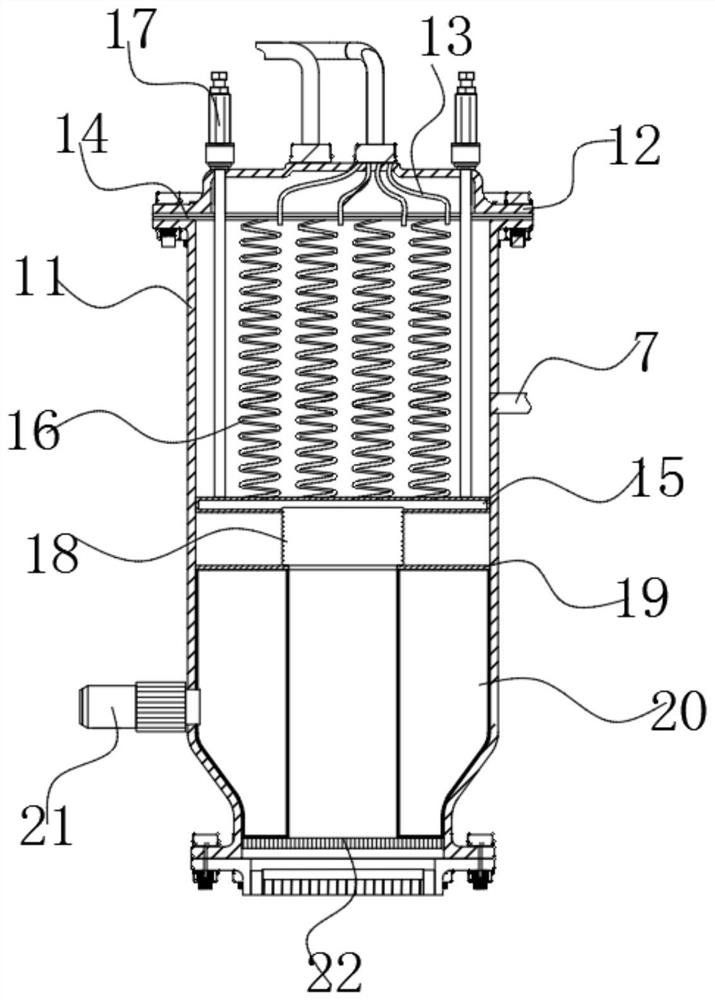

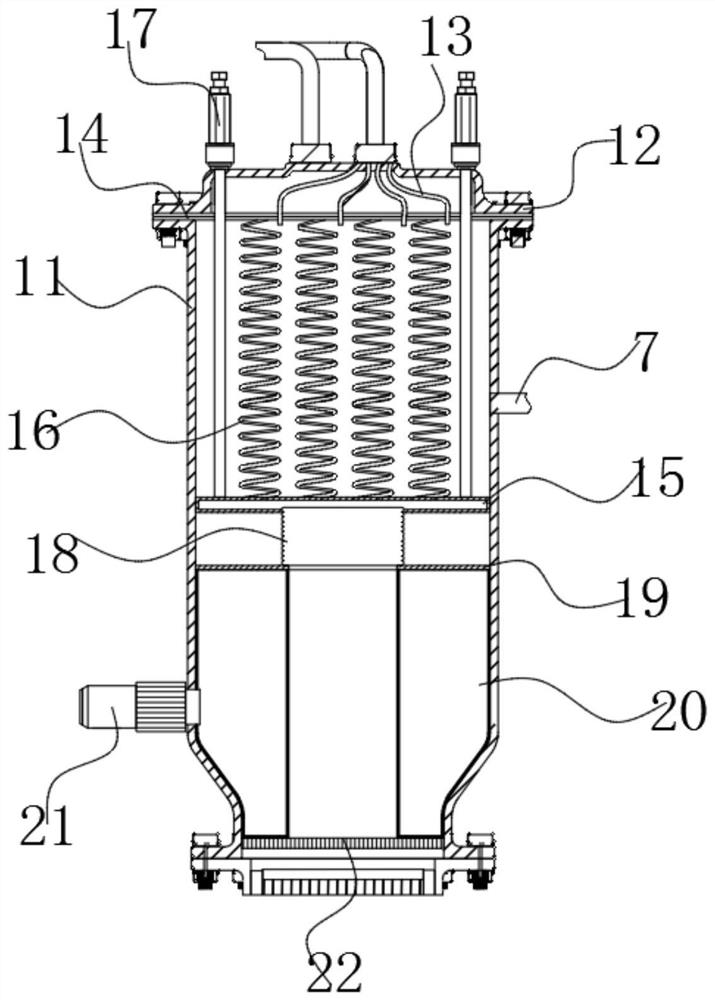

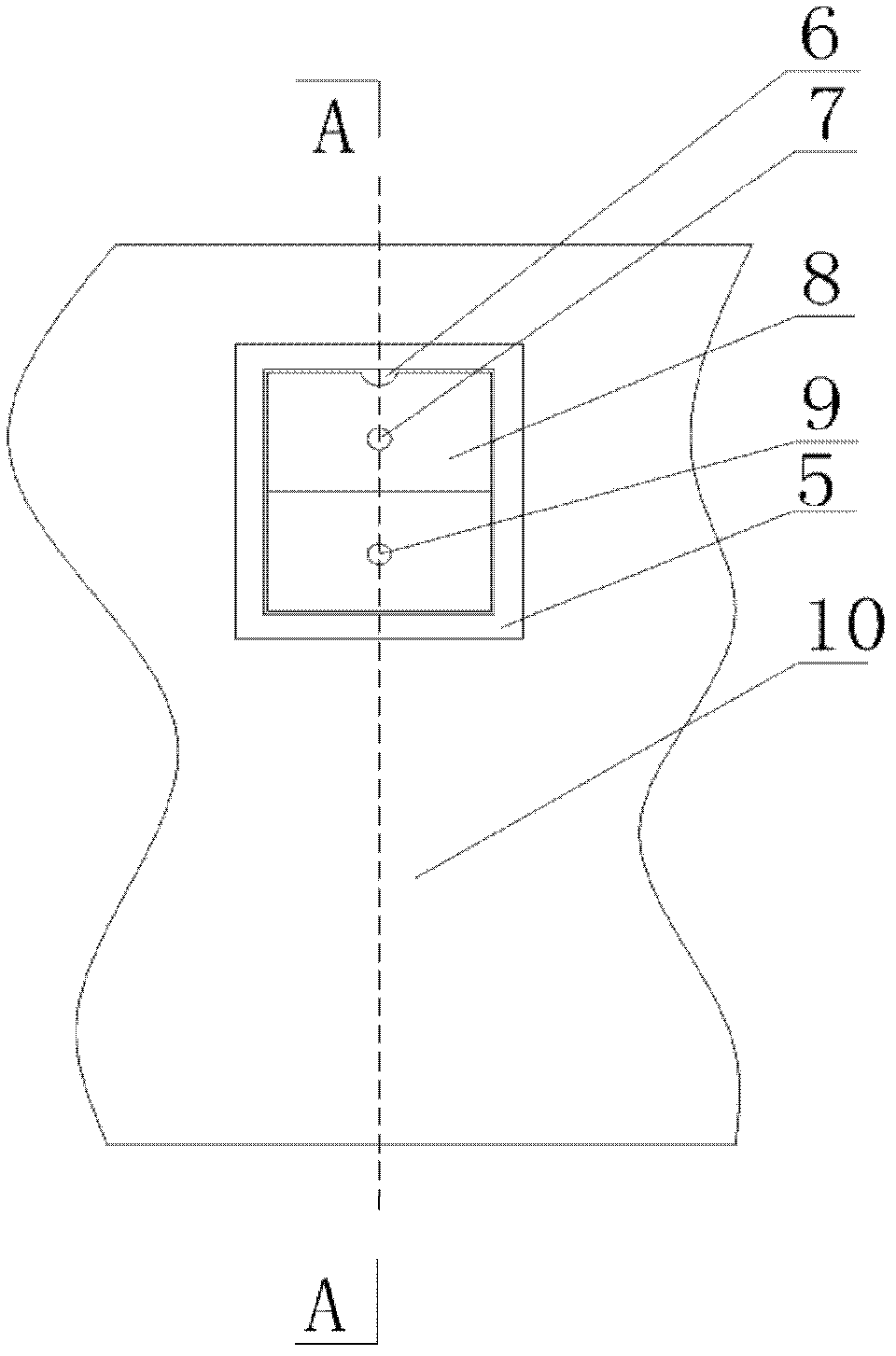

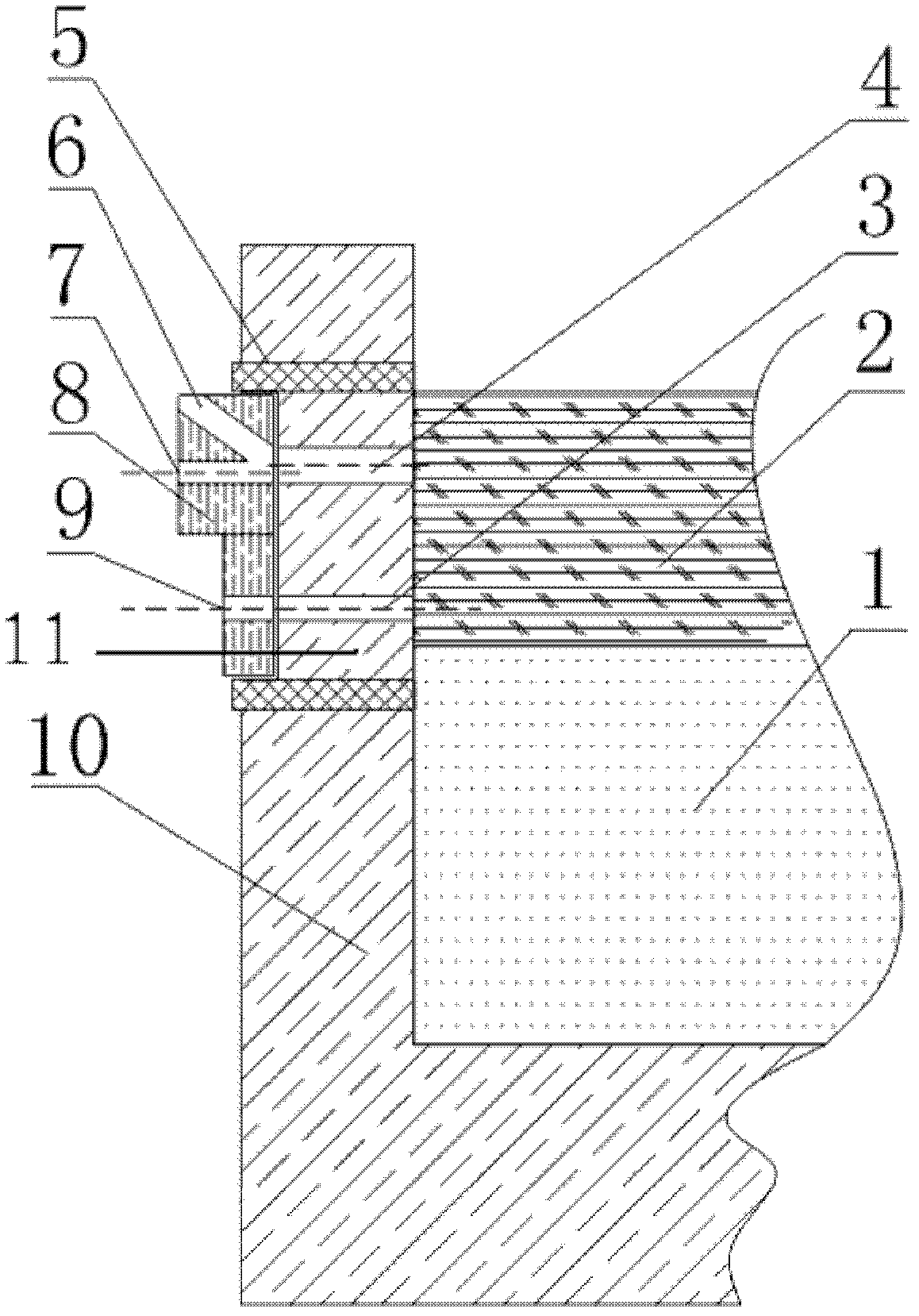

Adjustable heat transfer heat exchanger

ActiveCN111854479AAdjust dwell timeReduce lossChemical industryVibration cleaningMechanical engineeringThermal efficiency

The invention discloses an adjustable heat transfer heat exchanger. The adjustable heat transfer heat exchanger comprises a main shell which is cylindrical, end sockets are mounted at the two ends ofthe main shell in a sealed mode correspondingly, a cold fluid inlet is fixedly formed in the top end of the end socket at one end, a cold fluid outlet is formed in the bottom of the end socket at theother end, pipe plates are mounted at the positions, close to the end sockets, of the interior of the main shell in a sealed mode, a plurality of heat transfer pipes are connected between the pipe plates, a plurality of baffle plates are fixedly mounted on the outer side, close to the heat transfer pipes, of the main shell, a plurality of mounting holes used for mounting the heat transfer pipes are formed in the baffle plates, phonon rings are fixedly embedded in the mounting holes, and inner rings of the phonon rings are in sealed connection with the outer walls of the heat transfer pipes. According to the adjustable heat transfer heat exchanger, the inner walls of the heat transfer pipes and the outer walls of the baffle plates are rapidly descaled and prevented from being scaled throughthe phonon rings inside the baffle plates, and the problems that dirt is extremely likely to be deposited on the pipe walls, and the heat exchange efficiency of the heat exchanger is reduced are effectively solved.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

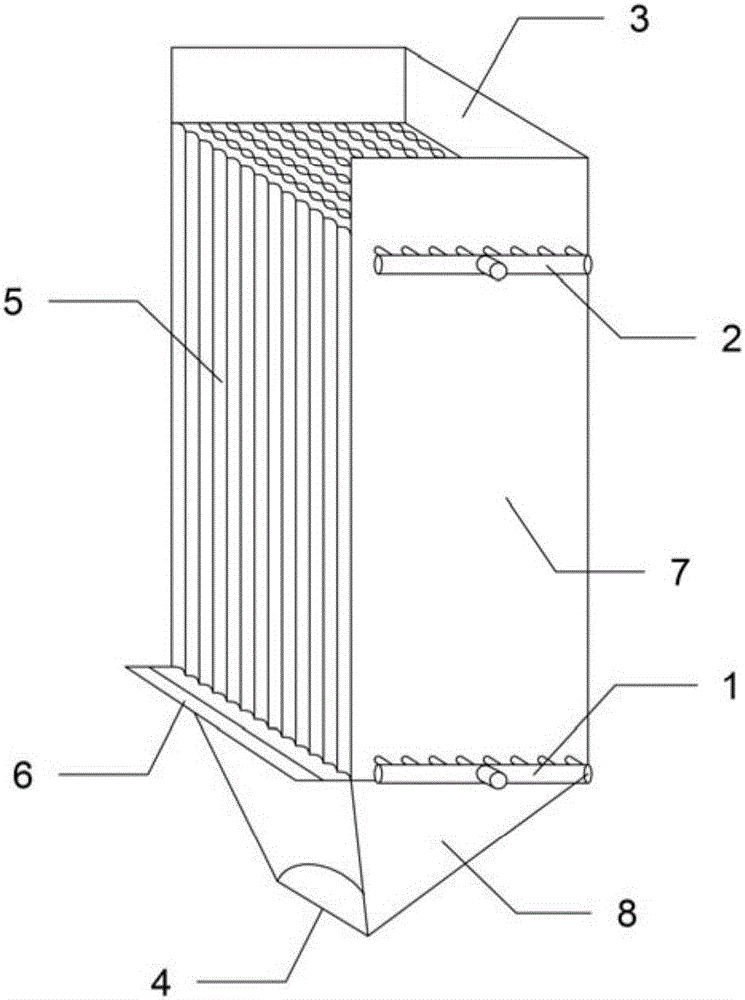

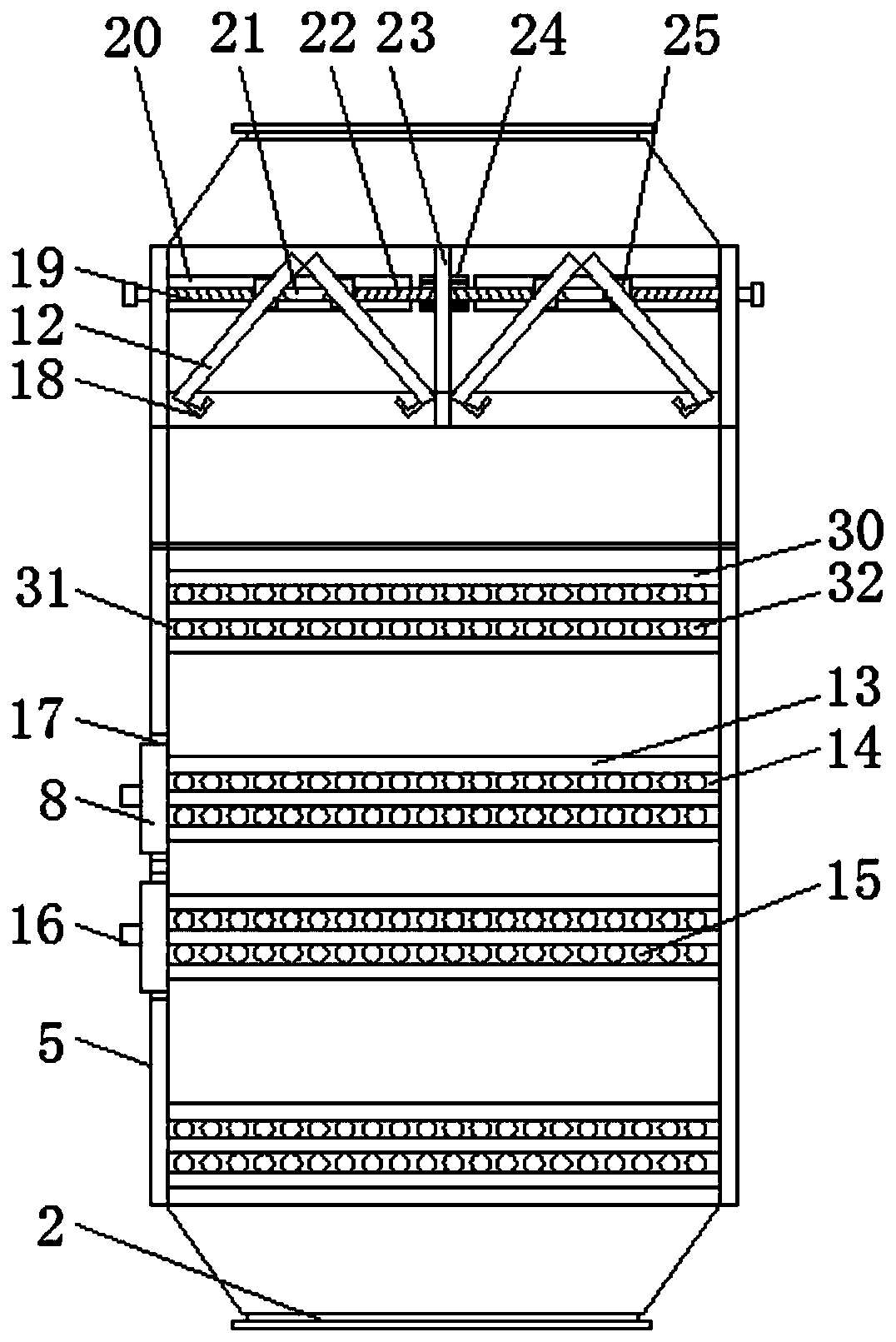

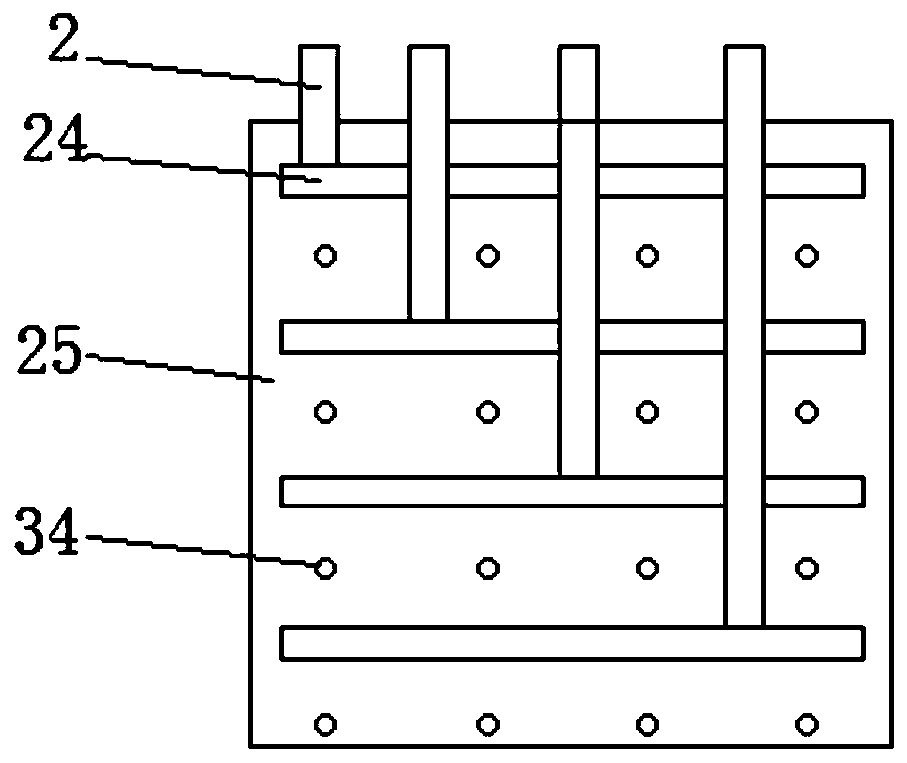

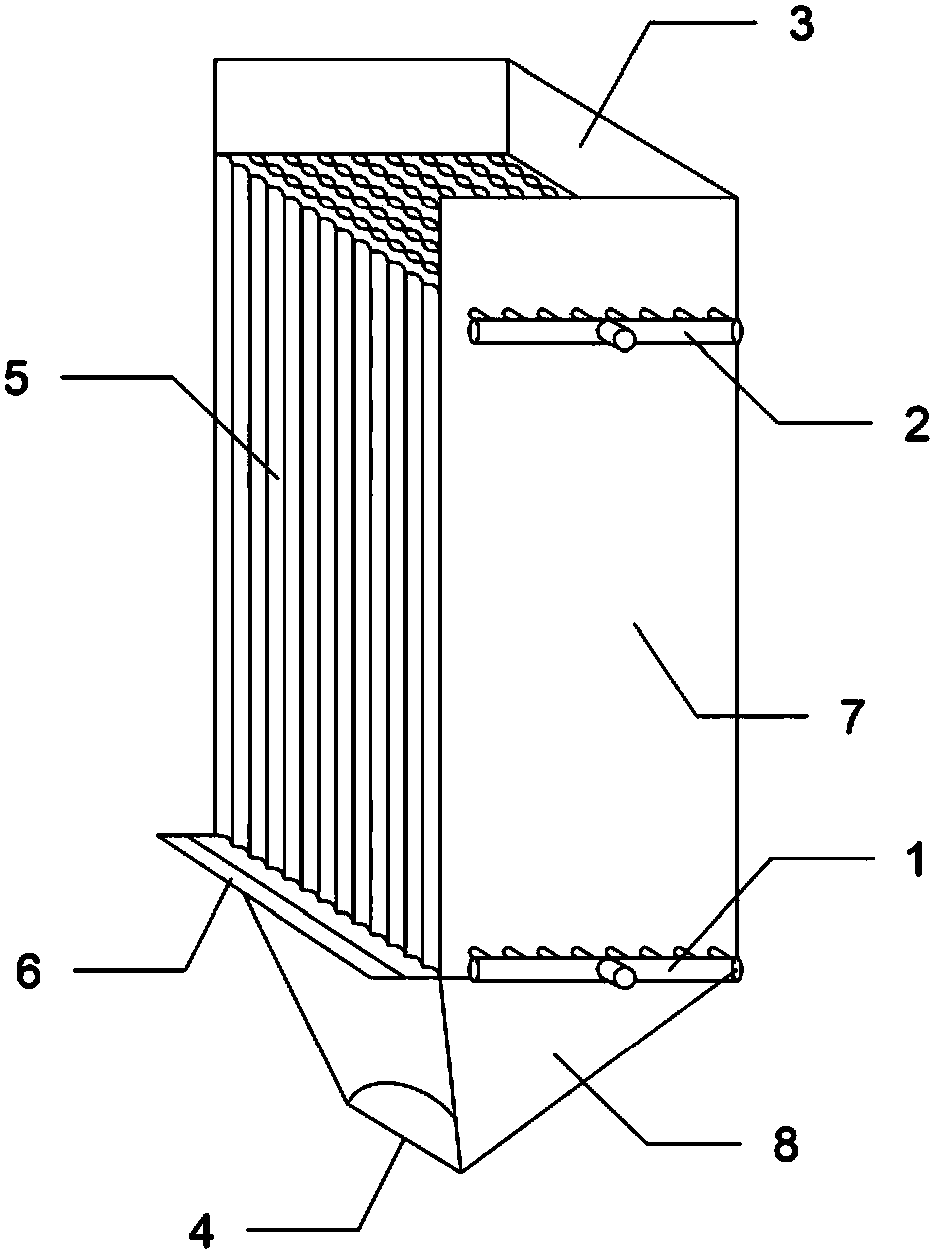

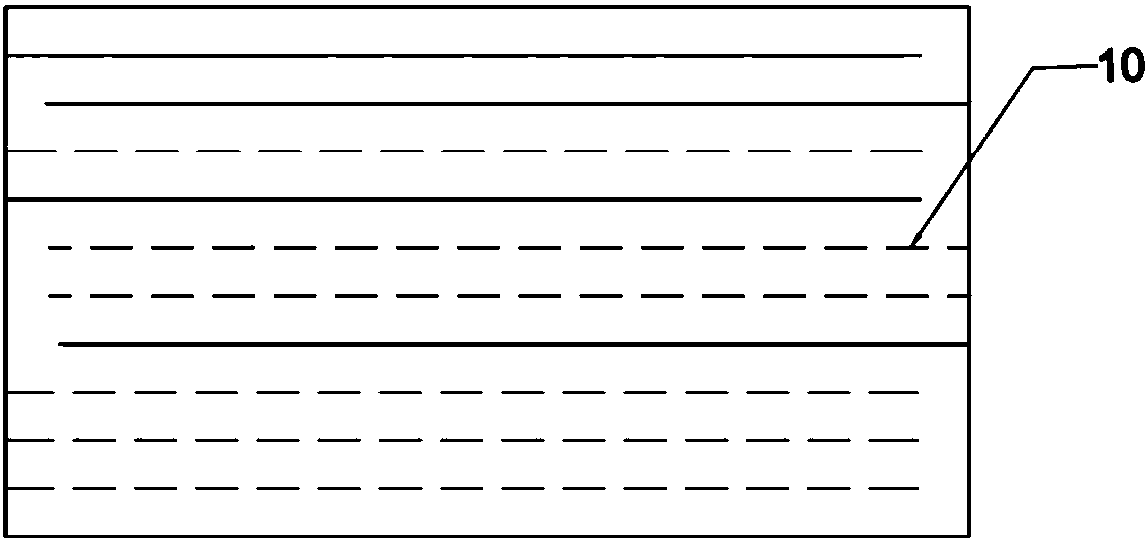

Blast furnace slag sensible heat recovery slag cooler

ActiveCN106834571AImprove heat recovery efficiencyImprove utilization efficiencyIncreasing energy efficiencyWaste heat treatmentSlagWater cool

The invention relates to a blast furnace slag sensible heat recovery slag cooler which is used for furnace slag waste heat recovery, and belongs to the field of heat exchange. The blast furnace slag sensible heat recovery slag cooler comprises a plate or tube type heat exchange core, a furnace slag inlet, a louver type furnace slag outlet baffle, a furnace slag outlet hopper, a furnace slag outlet, a cooling water inlet, a steam outlet, a shell and a heat preservation layer; the heat exchange core of the blast furnace slag sensible heat recovery slag cooler is formed by stacking a plurality of plate bundles or tube bundles according to a certain manner. High-temperature furnace slag particles are poured in from the upper portion of the slag cooler, evenly flow downwards, and sweep past a heat exchange plate tube, and heat is transferred to water in the plate tube through a plate wall or tube wall. Cold water flows in a channel in the plate or tube, cross flow or adverse flow is formed between the cold water and the flowing direction of the furnace slag, and entering water is heated to form steam to be discharged out from an upper header. The cooled slag particles are discharged from an outlet in the lower portion. The flowing speed of the slag particles can be adjusted according to the louver type furnace slag outlet baffle at the lower portion of the slag cooler. The water cooling type slag cooler is simple and compact in heat exchange structure, running operation is convenient, the waste heat using efficiency is higher, and secondary losses of heat are avoided.

Owner:TONGJI UNIV

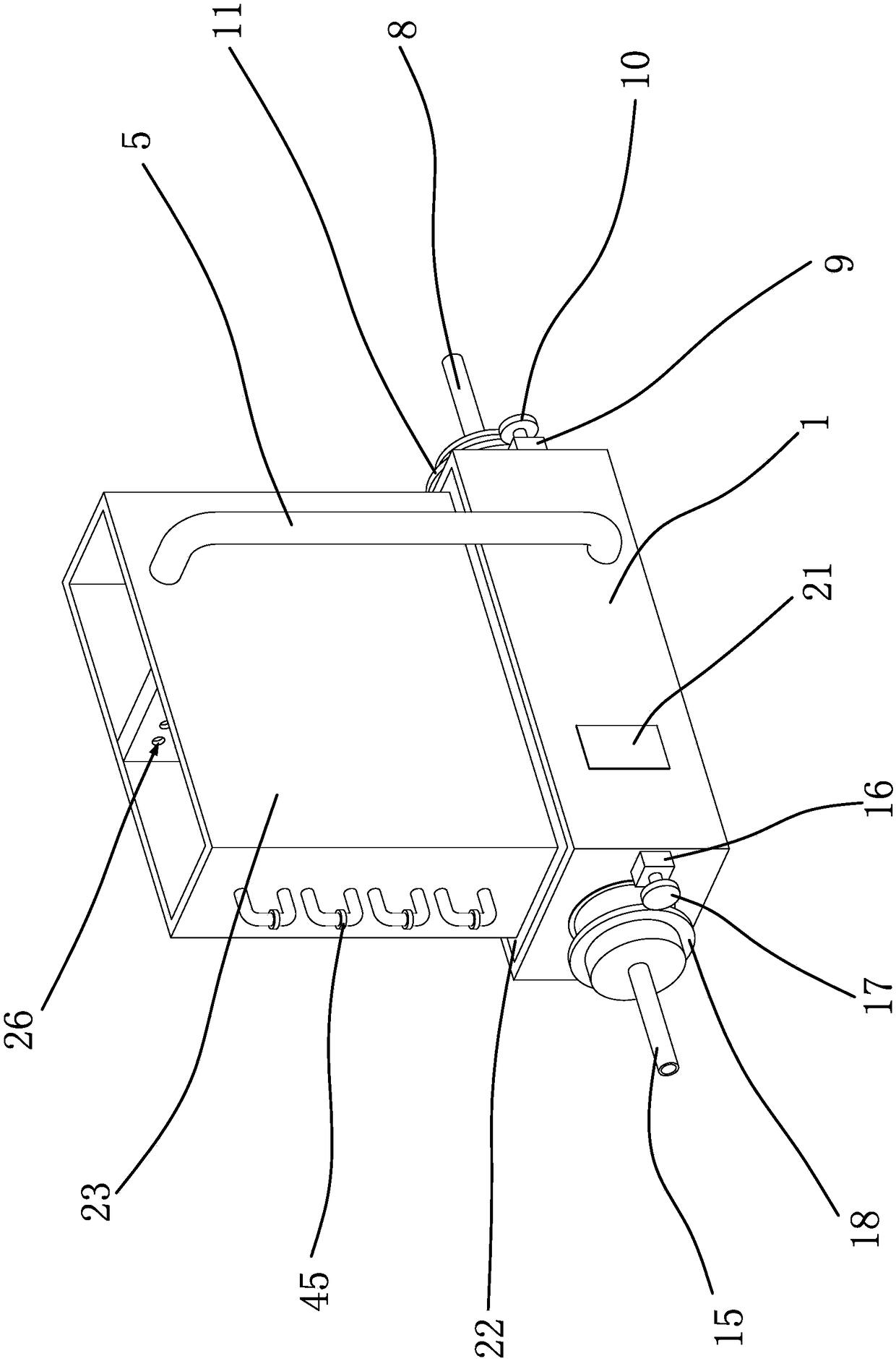

Intelligent efficient steady-state one-time heat exchange type waste heat recycling machine

InactiveCN111678160AAdjust dwell timeAvoid direct outflowRecuperative heat exchangersCombustion technology mitigationFlue gasMechanical engineering

The invention discloses an intelligent efficient steady-state one-time heat exchange type waste heat recycling machine. The intelligent efficient steady-state one-time heat exchange type waste heat recycling machine comprises a furnace body, wherein brackets are fixed connected to the upper and lower right sides of the inner wall of the furnace body, adjusting mechanisms are mounted on right sidesof the two brackets, each adjusting mechanism comprises a short plate, a vertical plate, a first round plate, a triangular plate, a threaded rod and a grip, front sides of the two short plates are rotationally connected with the right sides of the rear end surfaces of the two brackets respectively, and the right sides of the two short plates are fixedly connected with the left sides of the vertical plates respectively. According to the intelligent efficient steady-state one-time heat exchange type waste heat recycling machine, the adjusting mechanisms control the vertical plates to rotate toadjust size of a flue gas outlet, flue gas is prevented from flowing out directly, and heat utilization is guaranteed; second springs in a heat transfer mechanism protect square blocks, so that shaking of heat transfer pipes is weakened, the heat transfer pipes are prevented from being damaged, the service life is prolonged, a filter screen in a fixing mechanism filters the flue gas, so that the heat transfer pipes are prevented from getting dirty, troubles in cleaning are omitted, normal use is ensured, practicability is improved, and popularization is facilitated.

Owner:赵国栋

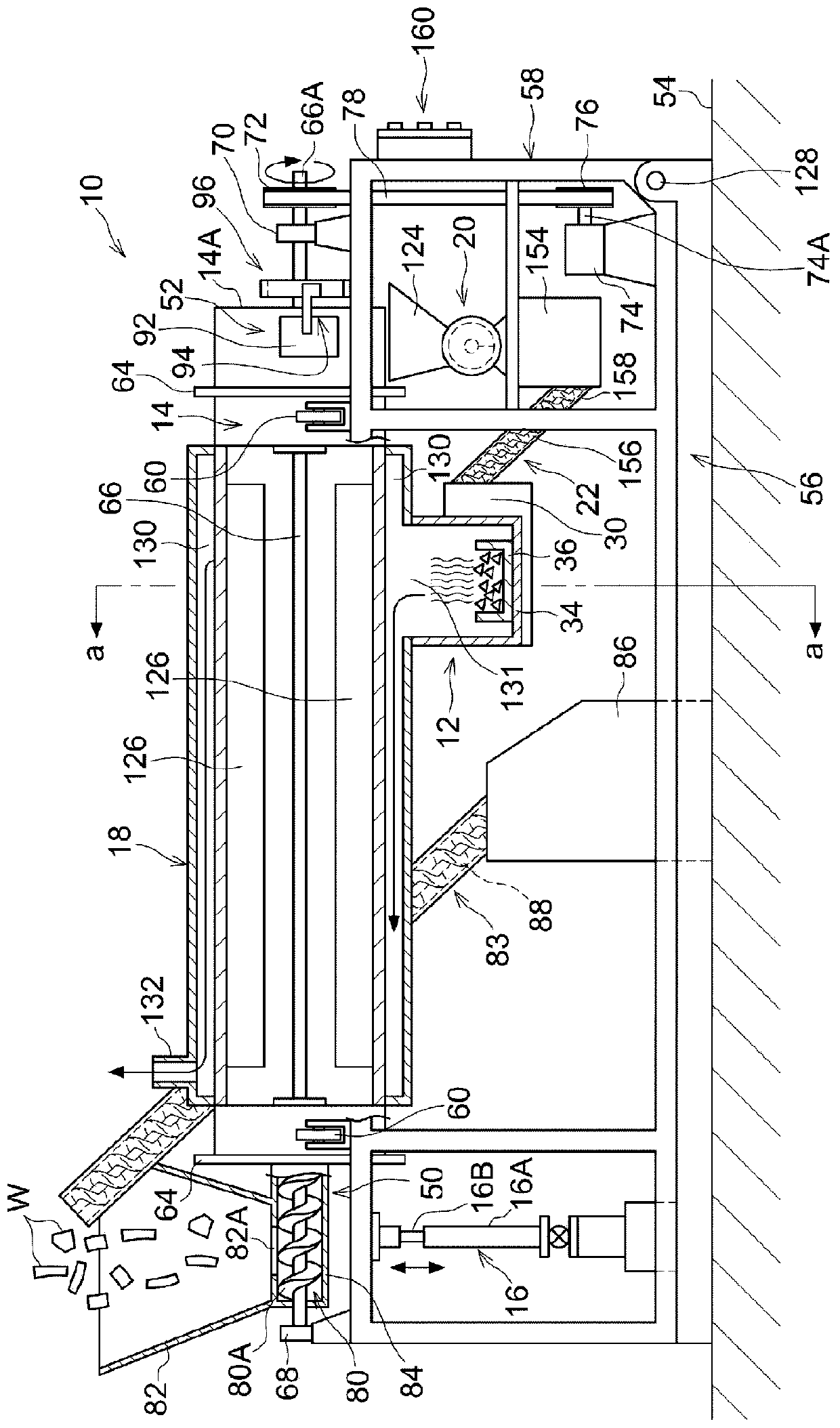

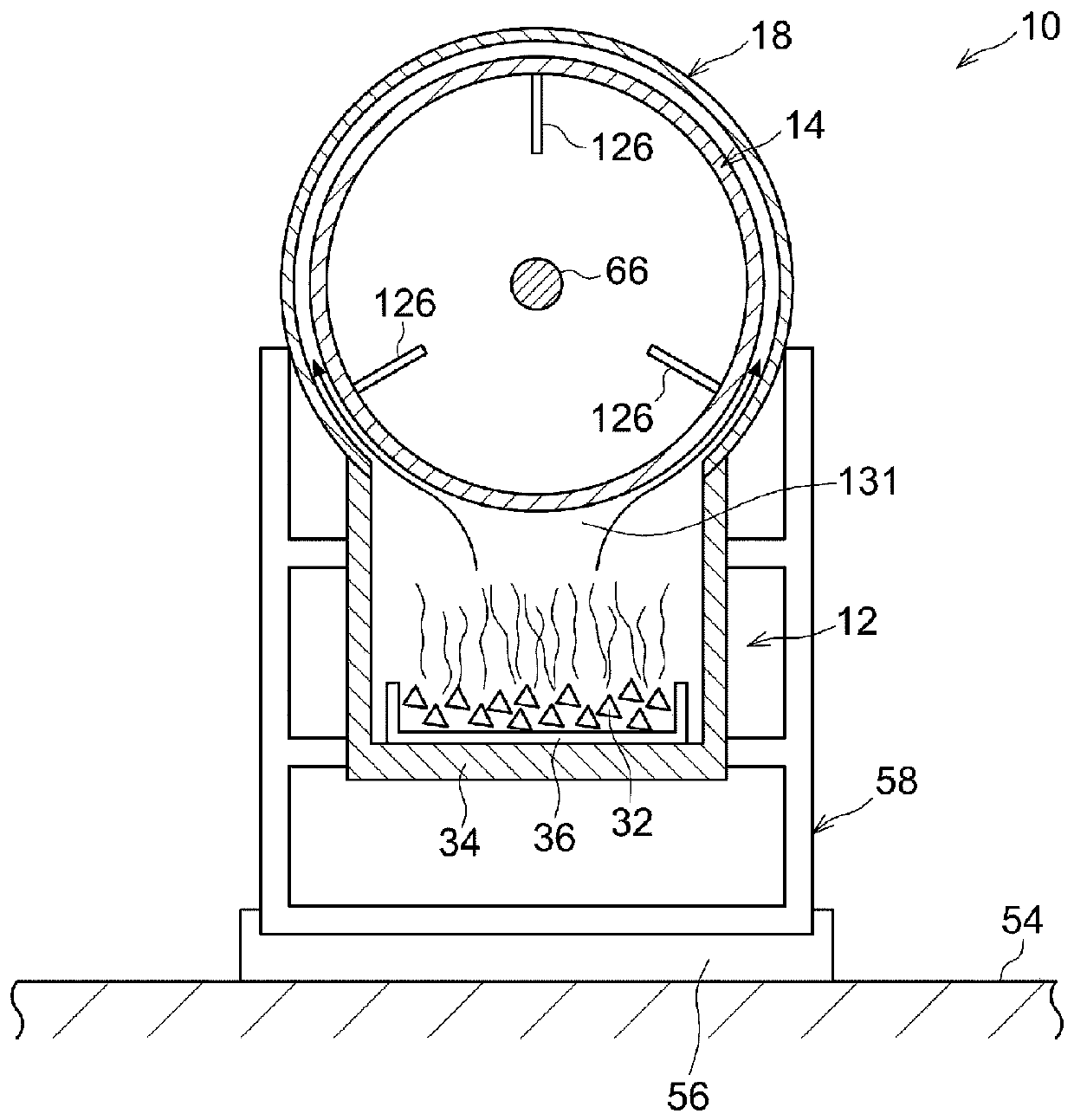

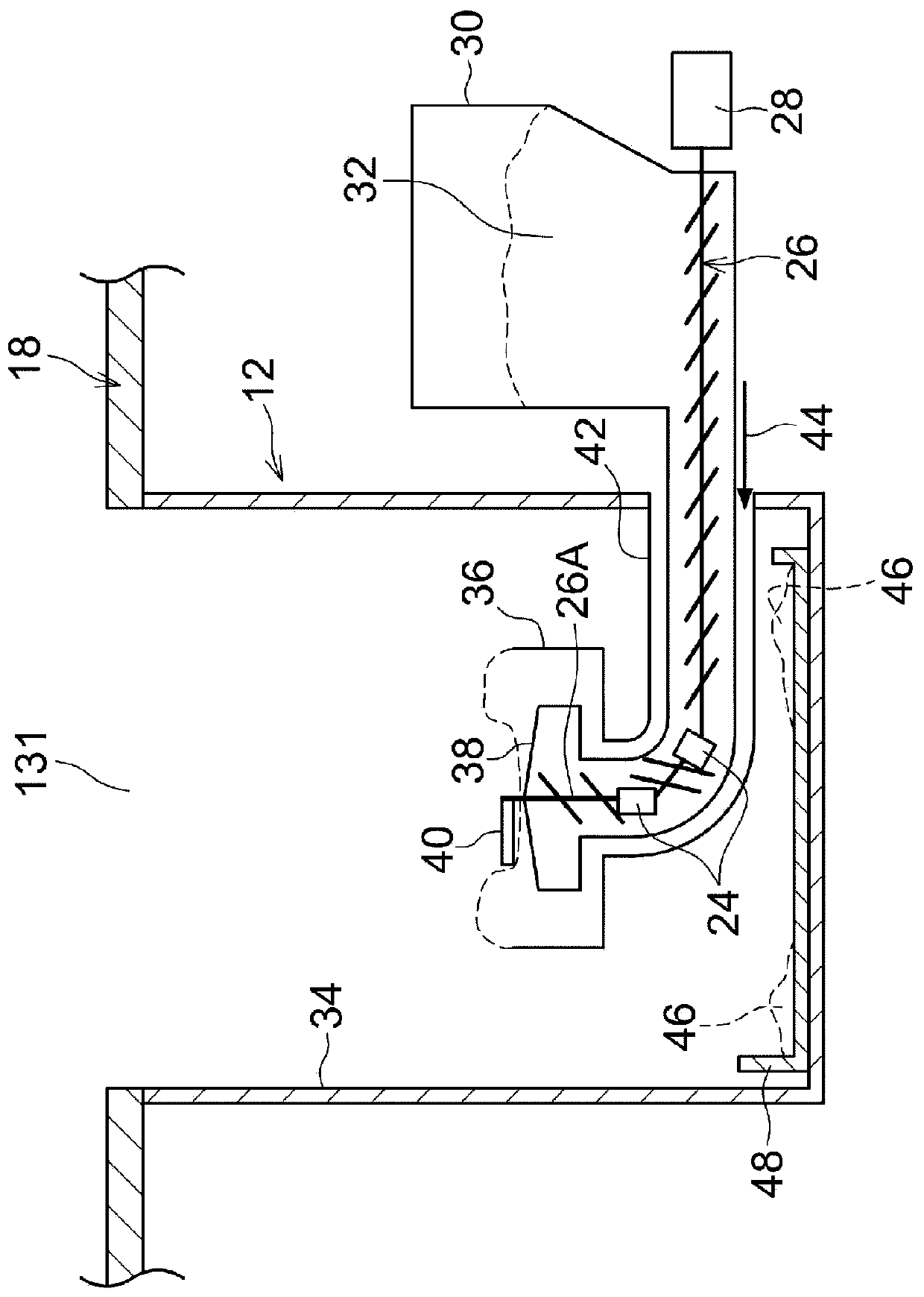

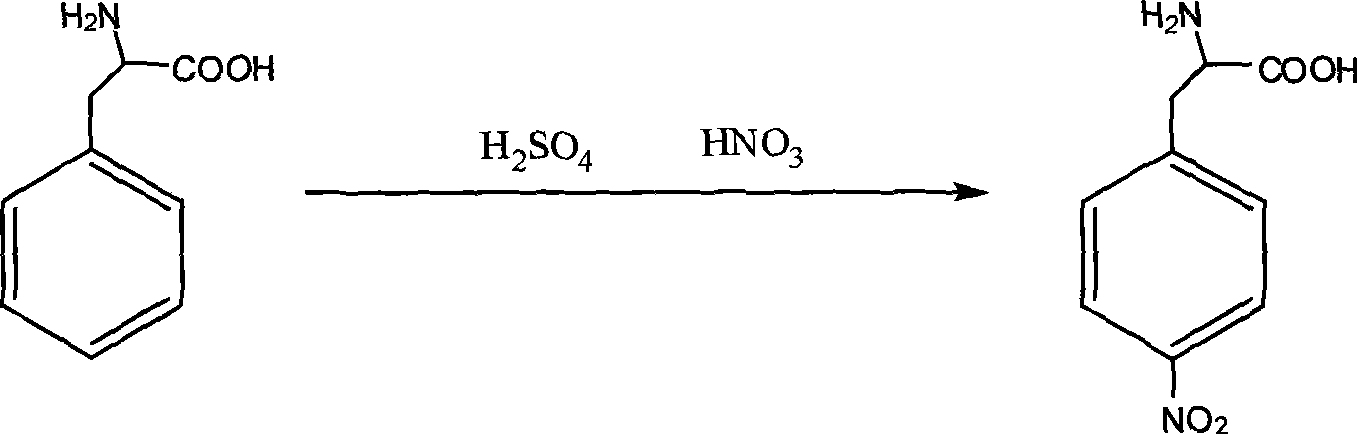

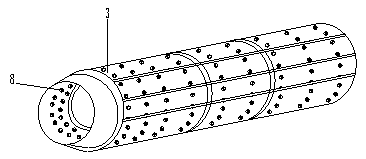

Device for producing biomass fuel

To solve problems concerning the unevenness in shape or size of a biomass fuel produced and concerning fluctuations in the degree of drying / carbonization of the biomass fuel caused by the kind of rawbiomass materials. A device comprising: a combustion furnace 12; a rotating drum 14 which includes a feed part 50 for raw biomass materials and a discharge part 52 for a biomass fuel 32 and in which drying / carbonization is conducted with the heat of the discharge gas generated in the combustion furnace 12; a tilting means 16 for tilting the rotating drum 14; a flue cover 18 for forming, between itself and the rotating drum 14, a flue for the discharge gas generated in the combustion furnace 12; a processing line 20 for making the shape and size of the biomass fuel uniform; and a return line 22through which some of the biomass fuel is returned to the combustion furnace 12. The feed part 50 is equipped with a screw conveyor 80 which feeds the raw biomass materials to the inside of the rotating drum 14 while rotating at the same speed as the rotating drum 14.

Owner:雨谷智昭

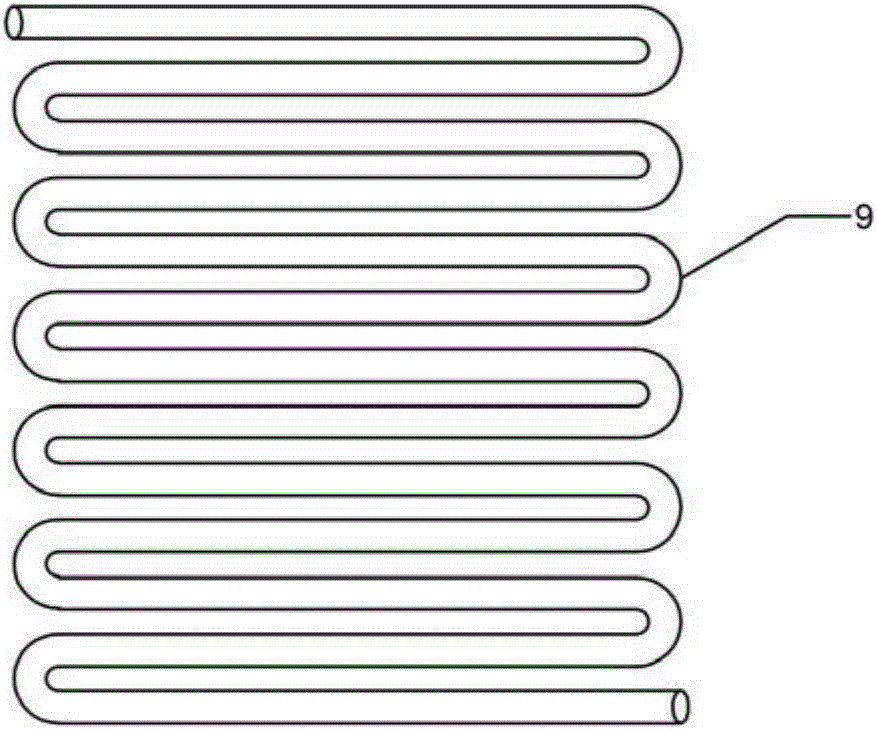

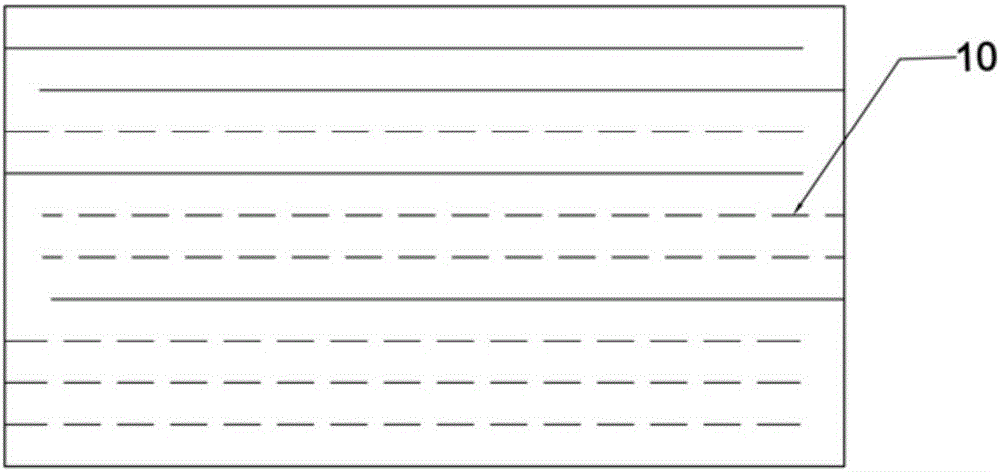

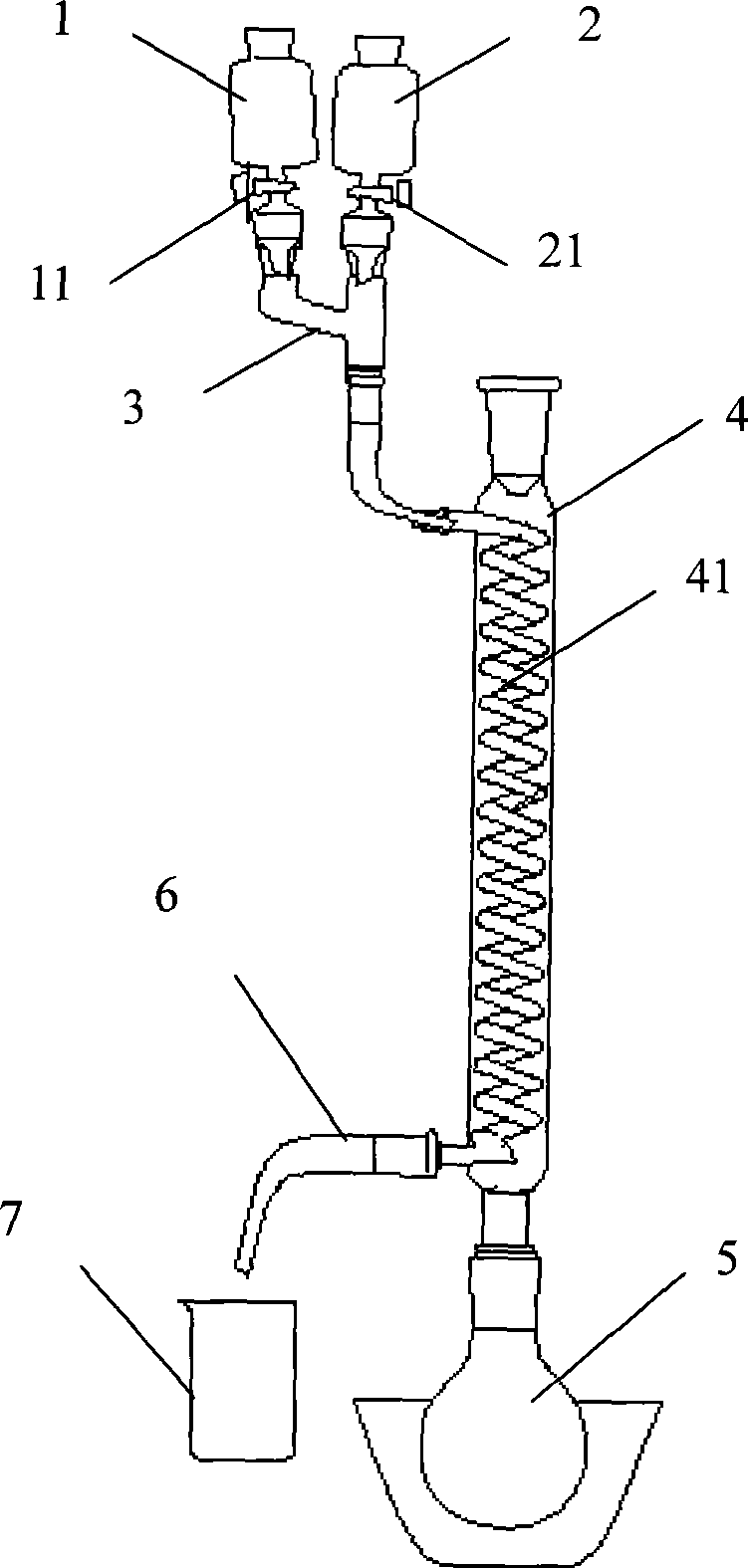

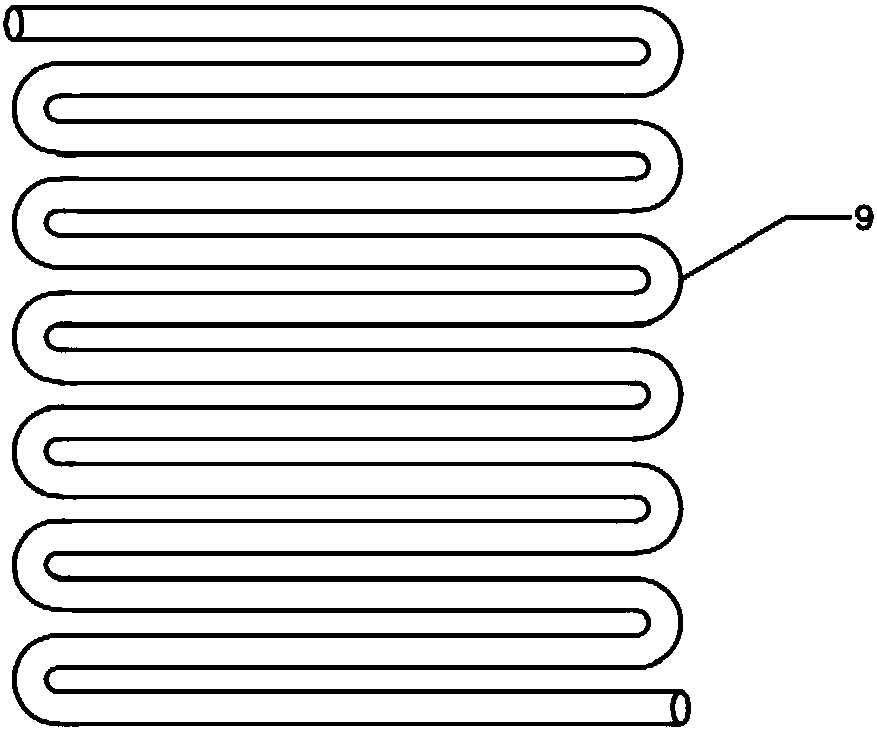

Synthesis method of L-p-nitrophenylalanine

InactiveCN101417959AAdjust dwell timeShort production timeOrganic compound preparationAmino-carboxyl compound preparationIce waterRetention time

The invention discloses a method for synthesizing 4-Nitro-L-phenylalanine monohydrate, which comprises the following steps: 1) a mixed liquid formed by mixing L-phenylalanine, concentrated sulfuric acid and concentrated nitric acid flows into a coil reactor to react, the reaction temperature is between 25 and 100 DEG C, the retention time of the mixed liquid in the coil reactor is between 3 and 10min, and the reaction pressure is normal pressure; and 2) a reaction product flowing out of the coil reactor is mixed with an ice-water mixture to be stirred and kept stand, the pH value of the obtained liquid is adjusted to between 7 and 8 and is kept stand and filtered, and the obtained white solid is the 4-Nitro-L-phenylalanine monohydrate. The method for synthesizing the 4-Nitro-L-phenylalanine monohydrate has the characteristics of good safety, short reaction time, and favorable continuous production.

Owner:ZHEJIANG UNIV

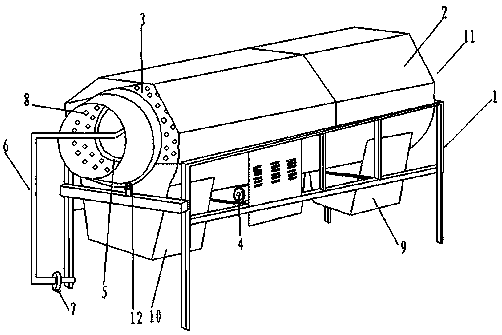

Kitchen waste integrated sorting machine and method

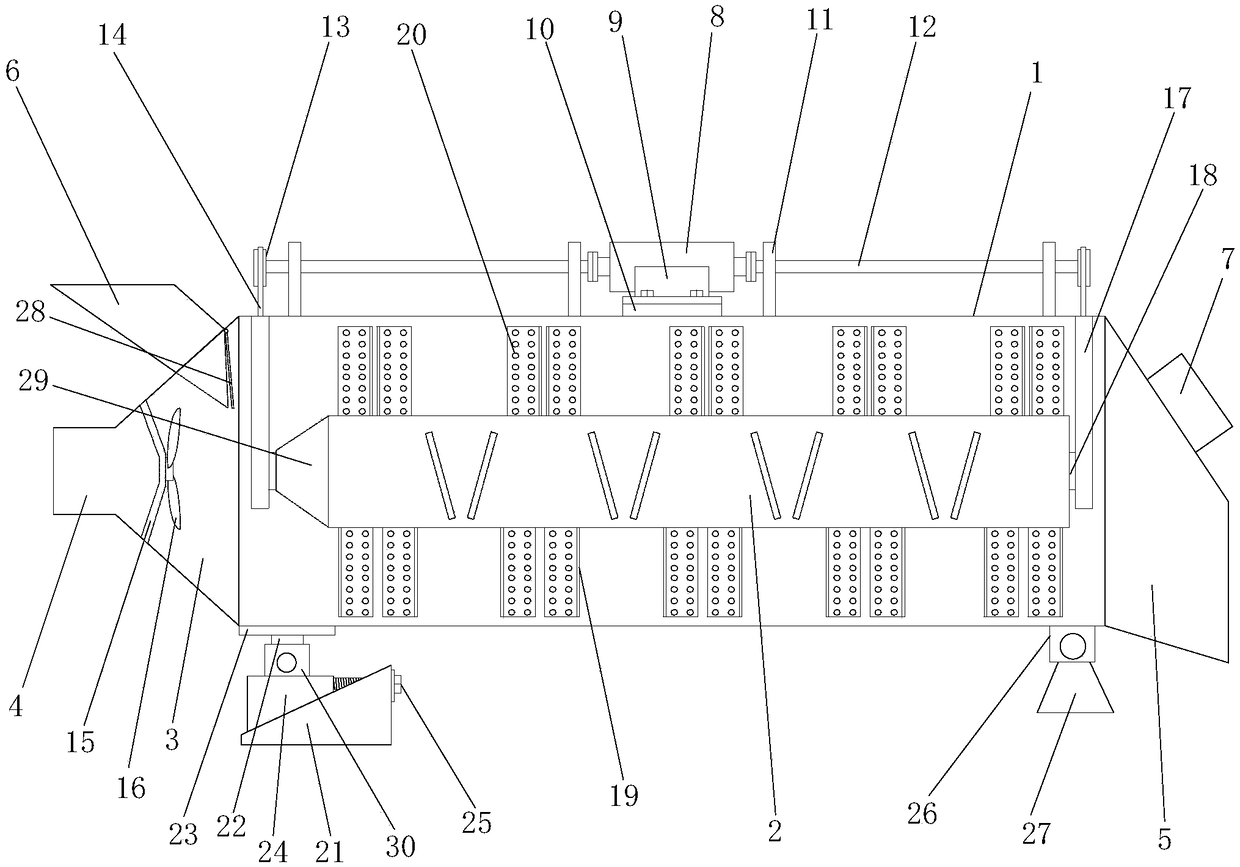

InactiveCN108994054ASimple structureEasy to manufacture and maintainGas current separationSolid waste disposalPulp and paper industryTreatment unit

The invention discloses a kitchen waste integrated sorting machine. The kitchen waste integrated sorting machine is characterized in that a screen cylinder is arranged on a machine base, an outer cover is arranged outside the screen cylinder, the outer wall of the screen cylinder is connected with a motor through a transmission device, and the screen cylinder rotates on the machine base; a fan isarranged in the part, located below one side of a front inlet of the screen cylinder, of the machine base, the fan communicates with an air pipe, and an air outlet of the air pipe extends into the screen cylinder from an inlet of the screen cylinder; and a material guide spiral plate is fixed on the inner wall of the screen cylinder, screen holes are formed in the wall of the screen cylinder, a first swill recovery box and a second swill recovery box are arranged at the bottom of the outer cover, and the tail part of the screen cylinder is provided with a solid material outlet. A sorting method comprises the following steps that 1) kitchen waste is fed from the inlet of the screen cylinder; 2) the kitchen waste undergoes bag breaking and screening toward the interior of the screen cylinder under the action of the material guide spiral plate and the screen inclination angle; 3) when screening is carried out in a first screening section, swill is leaked from the screen holes; 4) after the bag breaking process is completed, the kitchen waste enters a second screening section for screening; and 5) liquid after screening is collected by the swill recovery box, and solid materials are conveyed to a subsequent processing unit. According to the kitchen waste integrated sorting machine and method, the characteristics of being simple in structure, high in working efficiency and environment-friendly are achieved.

Owner:陕西云沃环保科技有限公司

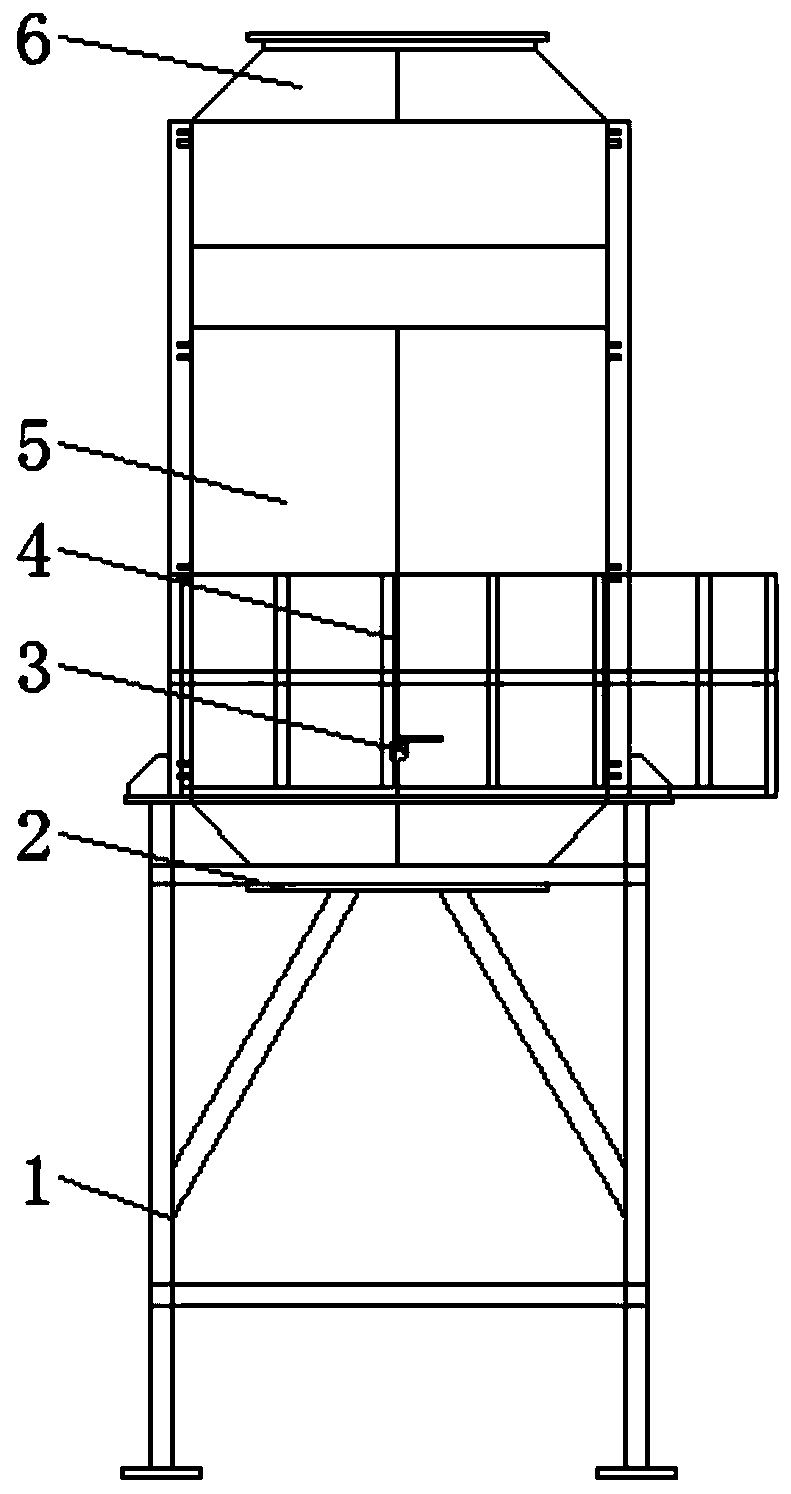

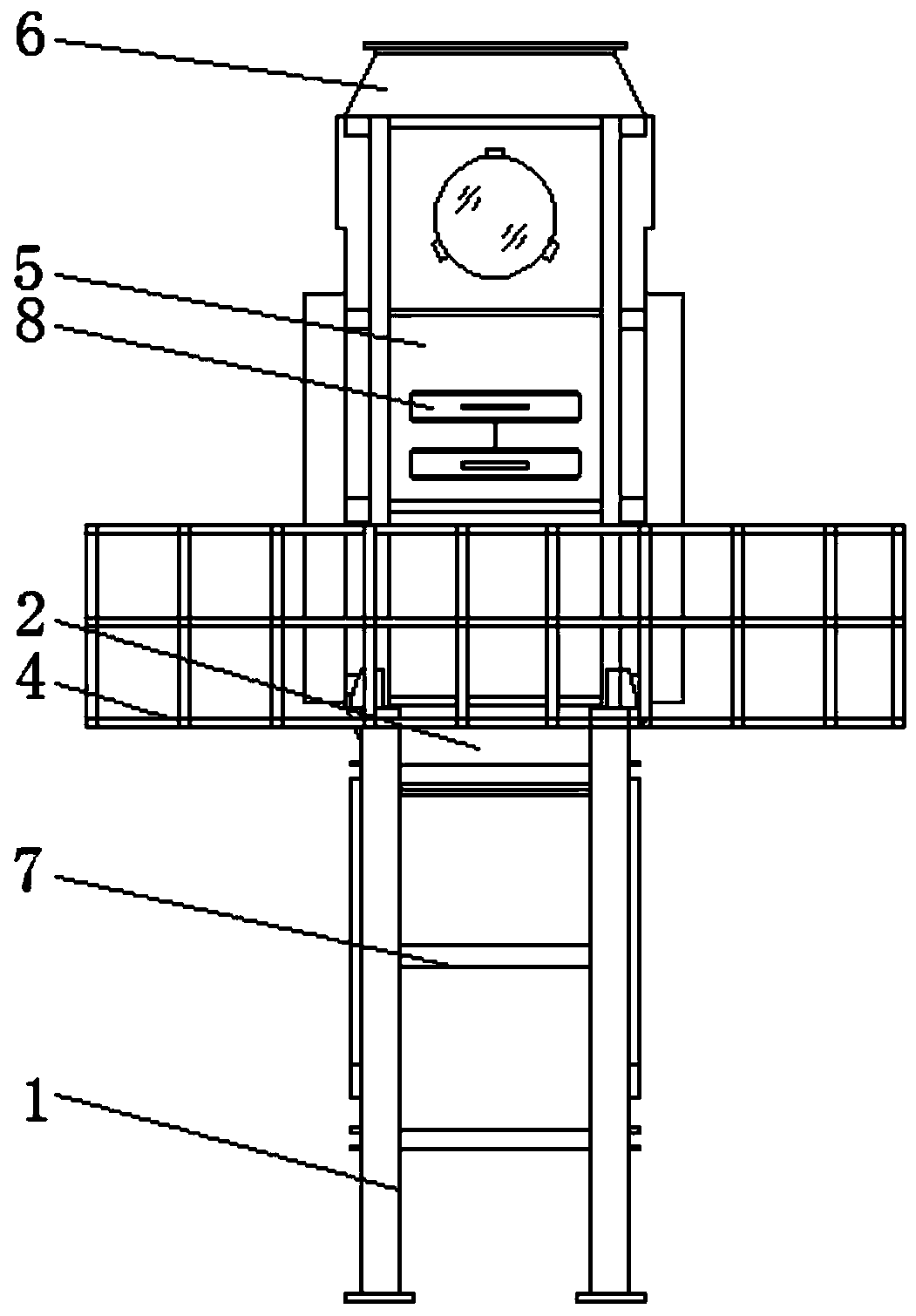

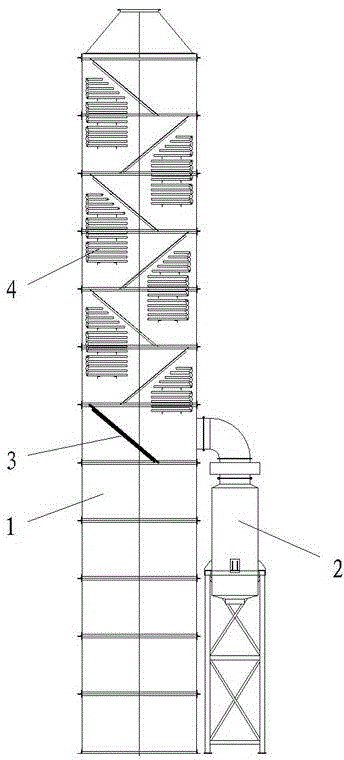

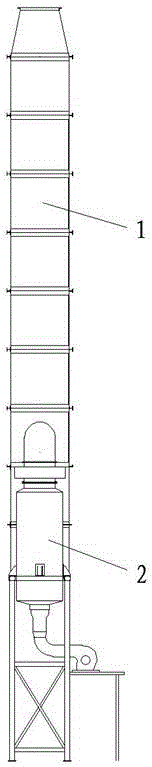

Vertical photocatalytic oxidation device with drainage water discharge function

InactiveCN109758906AEasy to useAvoid influenceDispersed particle separationWater dischargeEngineering

The invention discloses a vertical photocatalytic oxidation device with a drainage water discharge function. The vertical photocatalytic oxidation device comprises a support frame, wherein one end ofthe support frame is provided with a climbing ladder; an overhaul platform is arranged at the outer side of the top of the support frame; a casing is arranged in the middle position of the top of thesupport frame; an air inlet is formed in the bottom of the casing; an exhaust opening is formed in the top of the casing; a separation plate is arranged between the tops of the inner side of the casing; baffle plates are hinged to the inner side of the casing and the separation plate. A rotating rod is installed; through the matched use of positive screw threads and reverse screw threads on the rotating rod with the threaded holes in the first slide block arranged in the first slide groove, the first slide block can be simultaneously driven to move by the rotation of the rotating rod; throughthe connection with the second slide block through the connecting rod on the first slide block, the device can regulate the opening size of the baffle plate in the use process; the gas exhaust speed is controlled; the dwell time of the gas in the device is regulated; the use effect of the device is improved.

Owner:澳斯意环保工程(苏州)有限公司

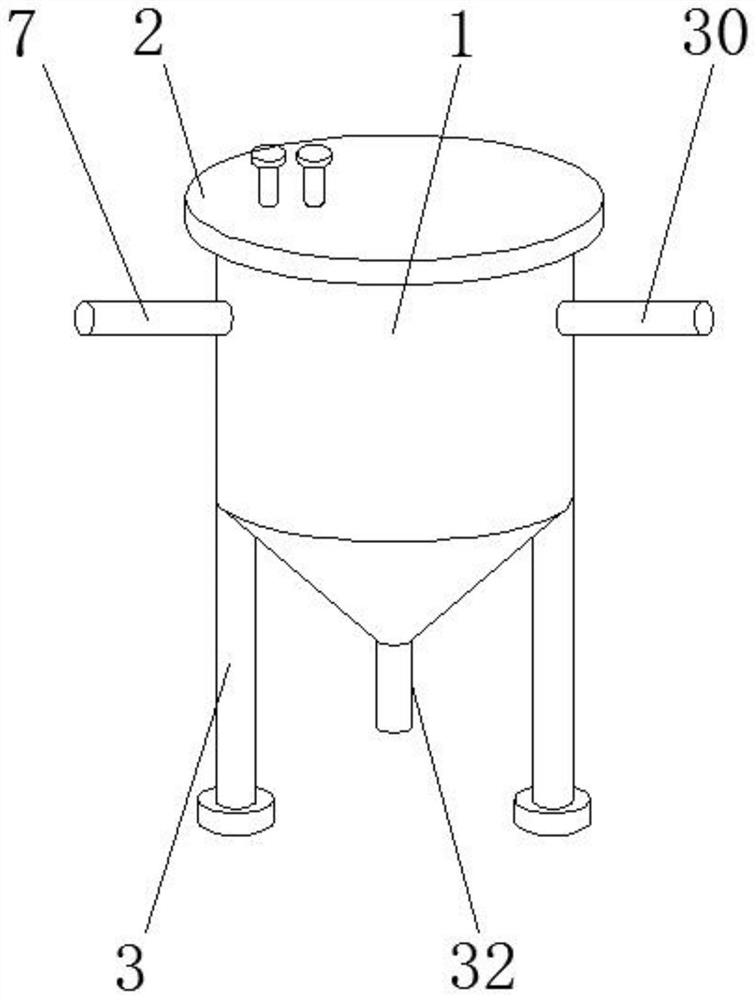

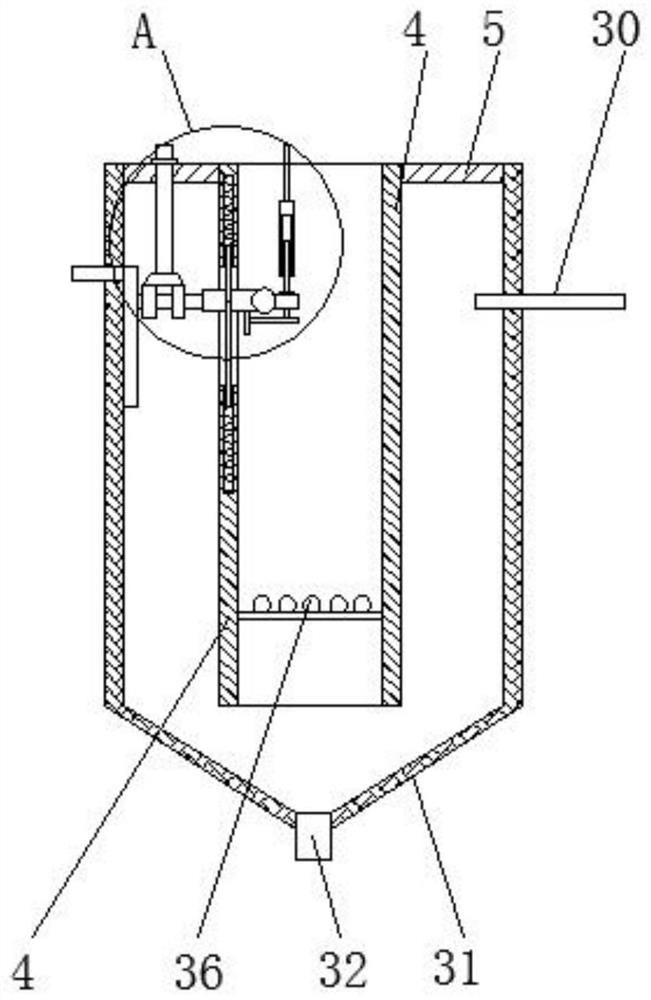

Environment-friendly type rotating drying system

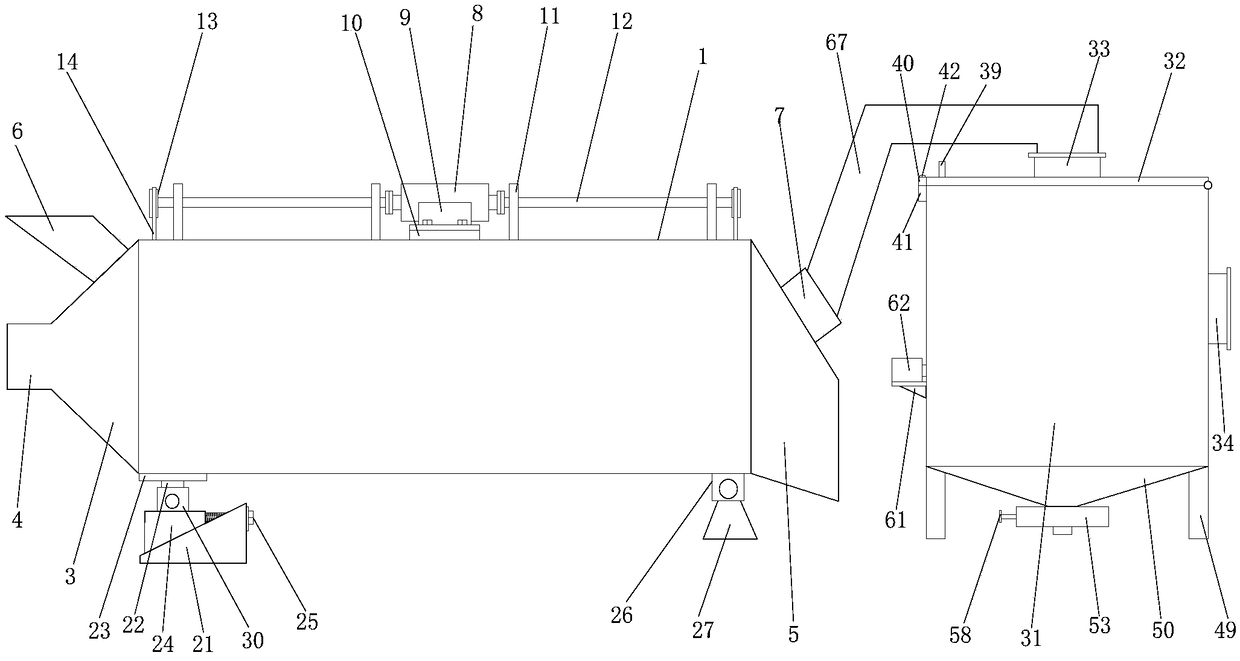

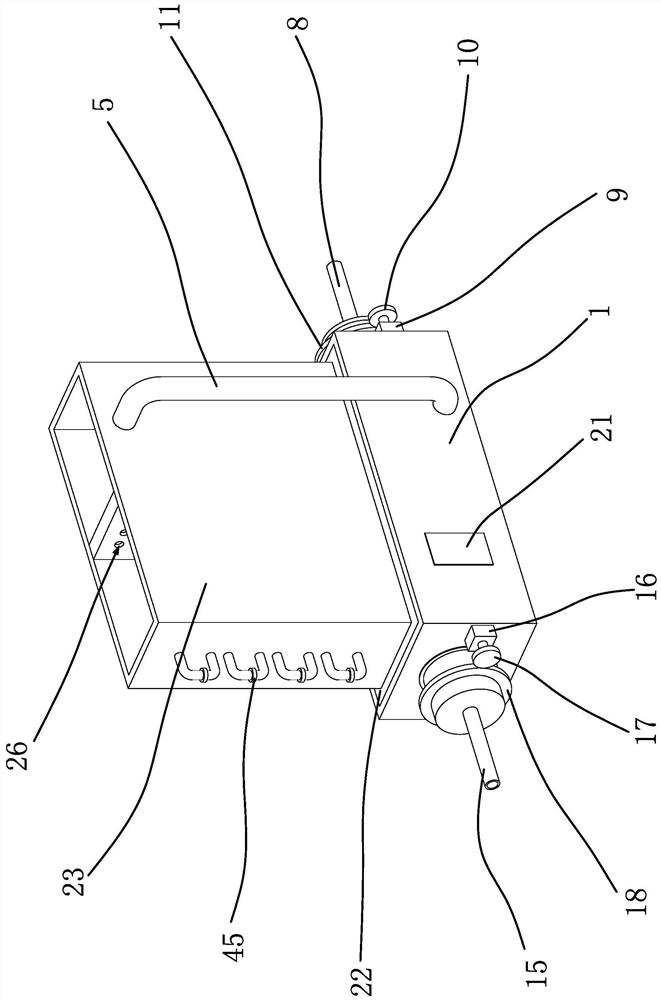

PendingCN109458813AAdjust dwell timeRealize suspension supportDispersed particle filtrationTransportation and packagingAir filterCam

The invention discloses an environment-friendly type rotating drying system. The environment-friendly type rotating drying system comprises a rotating barrel type dryer and a self-clearing type filterelement dust remover; the rotating barrel type dryer comprises a fixed cylinder, a rotating roller, a double-shaft-head driving motor, two driving rotating shafts, an air inflow conical cover and a material outflow channel; and the self-clearing type filter element dust remover comprises a cylindrical shell, an upper cover plate, a conical bottom, a vibrating driving motor, two transmission rotating shafts, a filtering assembly and a dust collecting mechanism. According to the environment-friendly type rotating drying system, the rotating roller is coaxially arranged in the fixed cylinder, and therefore an annular heating cavity is formed, so that wet materials are fully heated and dried in the annular heating cavity; the vibrating driving motor is used for driving the two transmission rotating shafts to rotate, so that a cam rotates and ceaselessly collides with the inner wall of the upper side of a ring sleeve, and therefore a cylindrical air filter element is vibrated up and down,internal dust is vibrated down, automatic clearing is achieved, and time and labor are saved.

Owner:江苏普杰环保科技有限公司

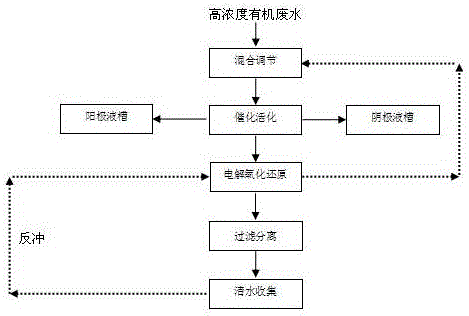

Multi-dimensional electrolysis sewage treatment process

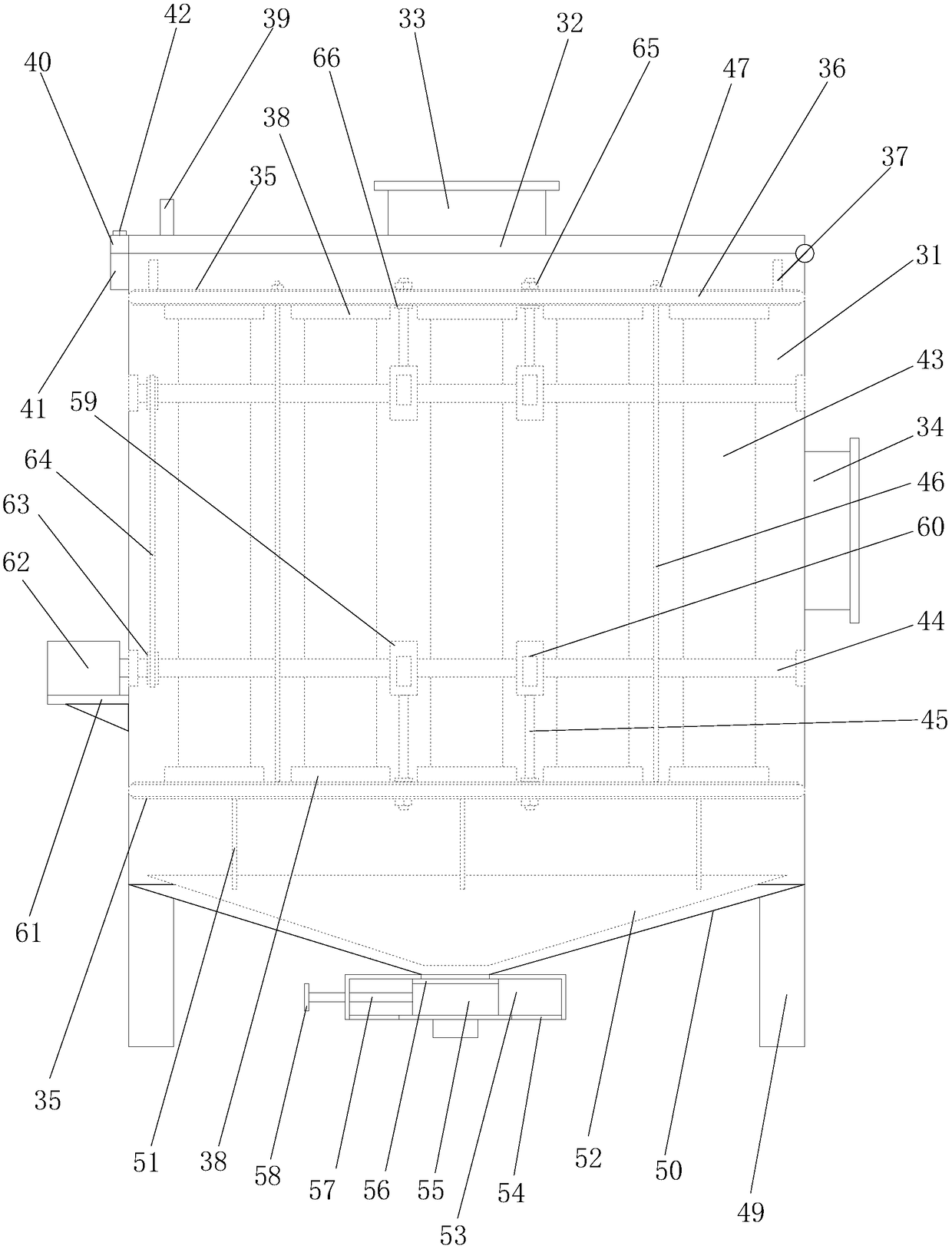

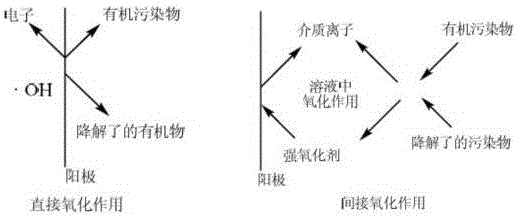

InactiveCN105948184AHigh removal rateAdjust dwell timeWater contaminantsDispersed particle separationHigh concentrationElectrolysis

The invention provides a multi-dimensional electrolysis sewage treatment process used for treatment of high-concentration organic matter and high-salinity wastewater in the industries such as chemical engineering, printing and dyeing, pharmacy, papermaking, oil fields, food processing and refuse leachate. The process is characterized by including the steps of mixed regulation, catalytic activation, cation and anion separation, electrolytic oxidation reduction and filtering separation; treated water is drained after it is detected that the treated water reaches the standard, due to the fact that organic matter is completely decomposed, no sludge residue is left, a multi-dimensional electrolysis sewage treatment device is adopted for electrolytic catalytic oxidation, and removal of organic matter and NH3-N of multi-dimensional electrolysis in a catalytic electrolysis method is achieved through a direct oxidation effect of an anode and an indirect oxidation effect of a catalyst solution. The process has the advantages of being low in operating cost, small in occupied area, small in amount of generated sludge, low in disposal cost of the sludge and the like.

Owner:上海澄华环境科技有限公司

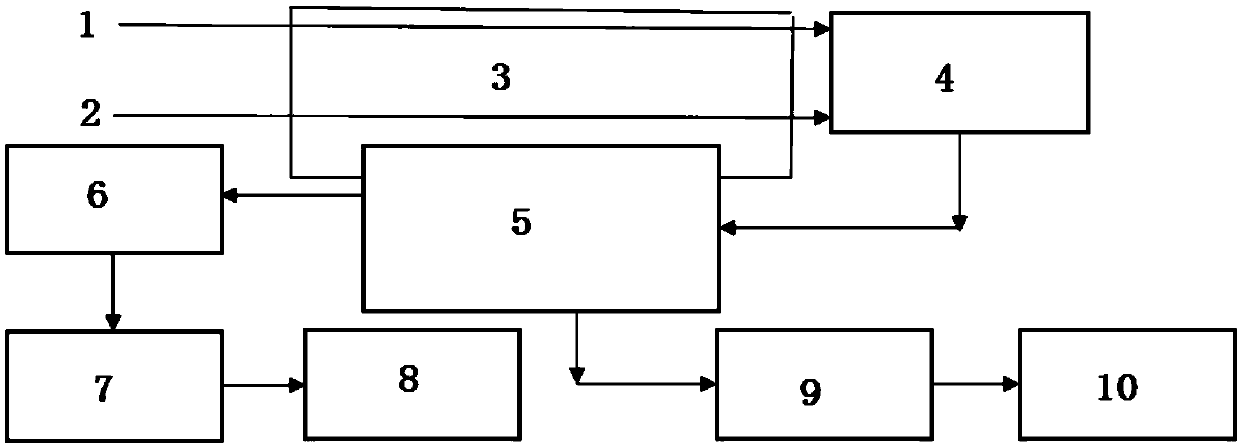

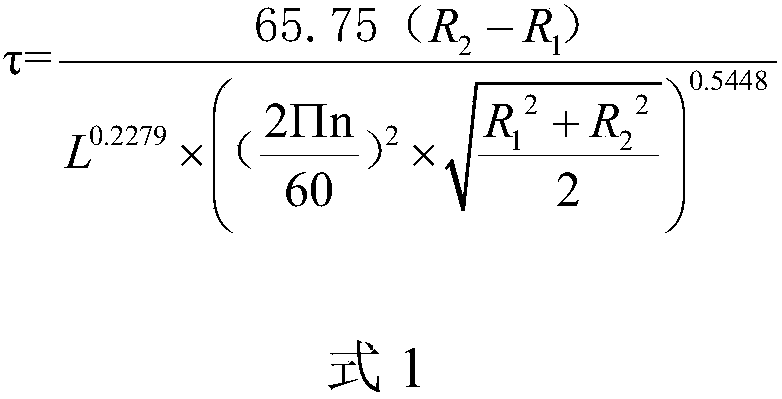

Method for synthesizing acetone condensation compound from acetone and hydrogen

ActiveCN110903179AChange selectivityHigh selectivityOrganic compound preparationChemical industryPtru catalystLiquid state

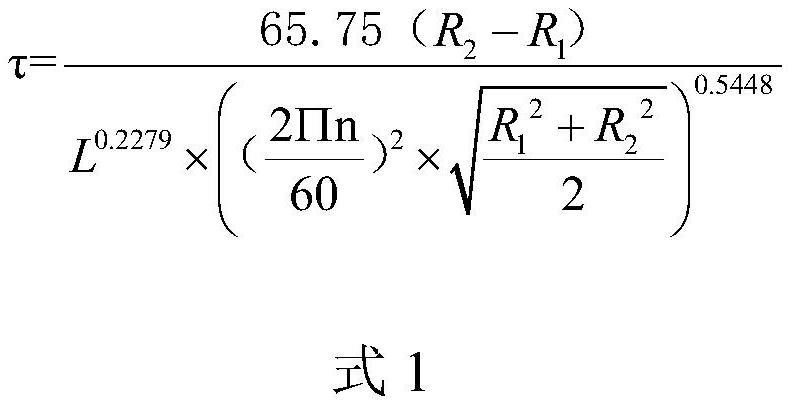

The invention belongs to the field of chemical engineering, and discloses a method for synthesizing an acetone condensation compound from acetone and hydrogen. The method comprises the following steps: mixing acetone and hydrogen, introducing into a supergravity rotating bed, contacting a catalyst bed layer arranged on the rotor of the supergravity rotating bed, and reacting to obtain a liquid-phase component containing the acetone condensation compound and a gas-phase component, wherein the residence time tau of the liquid-phase component in the catalyst bed layer is less than or equal to 20s. According to the invention, the supergravity rotating bed reactor is introduced into the reaction for one-step synthesis of the acetone condensation compound from acetone and hydrogen, so that theretention time of the liquid-state product in the catalyst bed layer is remarkably shortened, the phenomenon of carbon deposition and coking in the catalyst along with the prolonging of the reaction time is relieved / eliminated, the service life of the catalyst is prolonged, and the conversion rate of reactants and the selectivity of the product are changed.

Owner:CHINA PETROLEUM & CHEM CORP +1

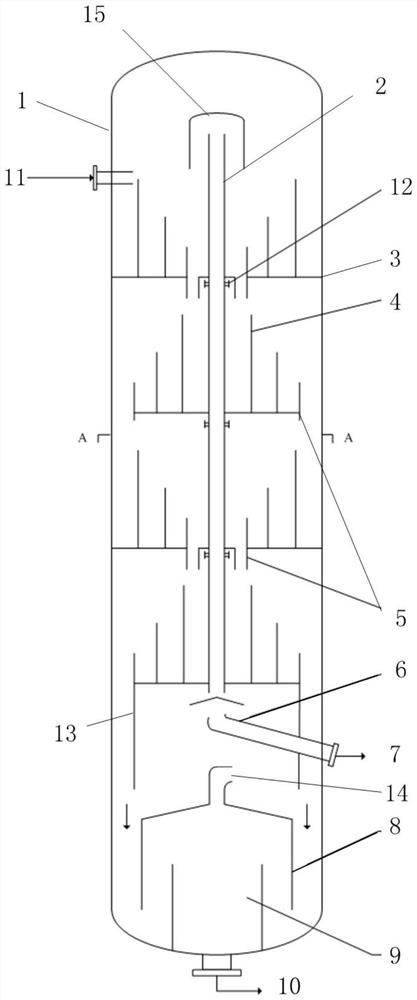

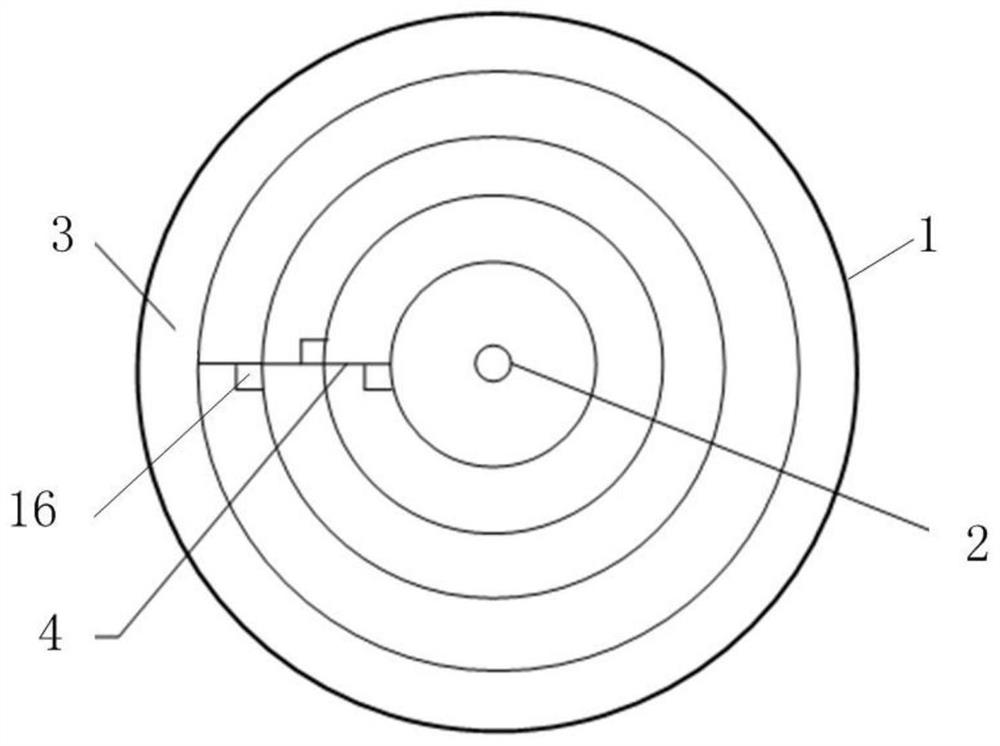

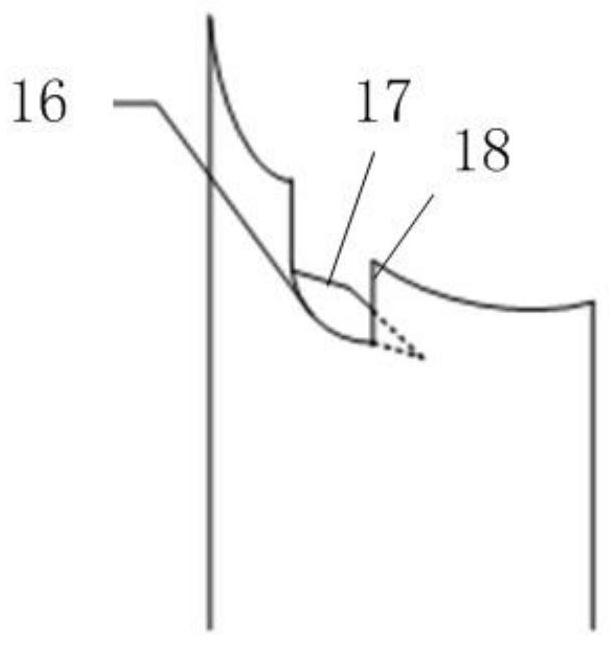

Tower type pre-polycondensation reactor

PendingCN114534624AIncrease contact areaIncrease the number of updatesProductsReagentsEngineeringTower

The tower type pre-polycondensation reactor comprises a tower body, a material inlet and a material outlet are formed in the top and the bottom of the tower body respectively, a vacuum pipe with a plurality of first vacuum ports is arranged at the central axis in the tower body, and a vacuum pipe outlet is formed in the side wall of the tower body; a plurality of tower trays are arranged between the vacuum pipe and the tower body, baffle plates are arranged on the tower trays, the heights of the baffle plates are gradually increased or decreased from the position close to the tower body to the position far away from the tower body, and the height change directions of the adjacent upper and lower baffle plates are opposite; and each layer of tower tray is provided with a downcomer, and the downcomer is positioned at the lowest baffle plate in each layer. According to the invention, materials are baffled / overflowed back and forth on each layer of tower tray, and liquid film flow can be realized at the overflow port, so that the gas-liquid contact area is increased, and mass transfer evaporation of EG is facilitated; and the materials flow downwards in an annular waterfall manner on the inner sides of odd-numbered layers / the outer sides of even-numbered layers, so that the contact area between the materials and vacuum is quickly updated, the mass transfer efficiency is greatly improved, and the polymerization degree is greatly increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

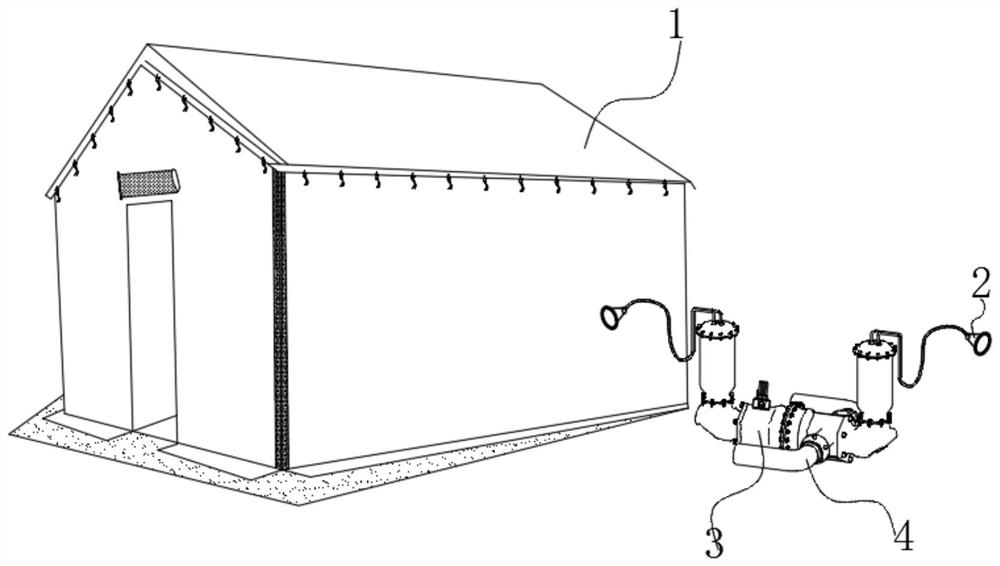

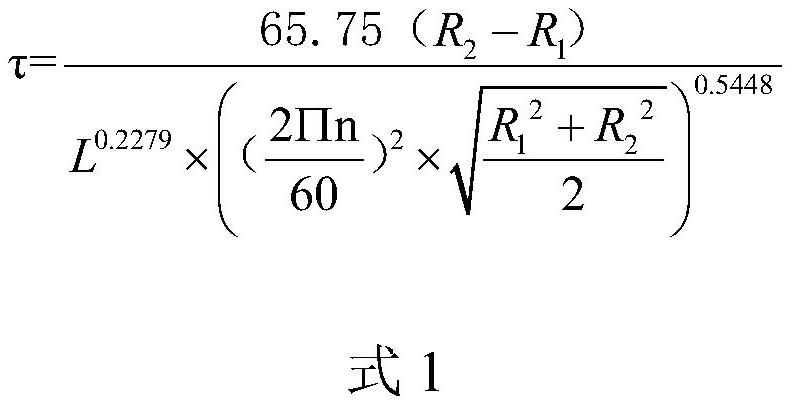

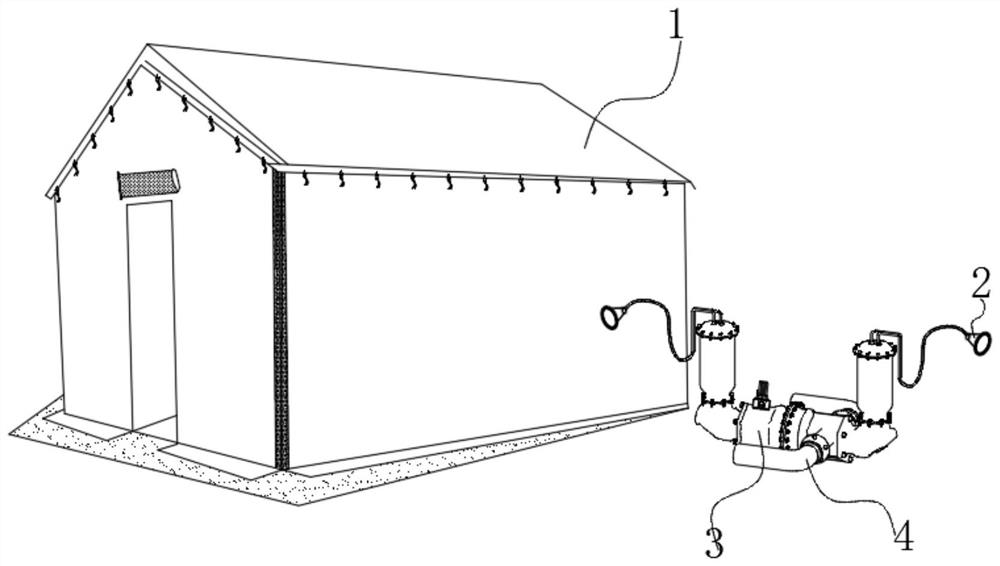

Air filtering structure for negative pressure isolation tent

ActiveCN113028562AImprove efficiencyLess consumablesMechanical apparatusLighting and heating apparatusAir filtrationAir filter

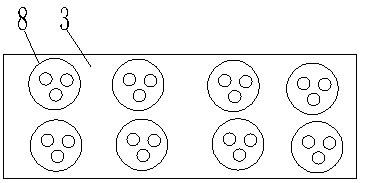

The invention discloses an air filtering structure for a negative pressure isolation tent. The air filtering structure comprises suction discs, an air filtering assembly and a discharging pipe, wherein the suction ends of the suction discs communicate with the tent so as to reduce the air pressure in the tent, and negative pressure is formed in the tent; the suction discs can suck air in the tent into the air filtering assembly and discharge the air through the discharging pipe; the two suction discs are symmetrically connected to the air filtering assembly; and the air filtering assembly comprises a high-temperature sterilization assembly, a middle-section sterilization assembly and a germ adsorption assembly, wherein the two suction discs suck the air in the corresponding tent and sequentially convey the air into the corresponding high-temperature sterilization assembly and the middle-section sterilization assembly, and the two strands of air share one germ adsorption assembly and are discharged through the discharging pipe, so that the reliability of overall sterilization is improved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

Preparation method for high melt strength poly lactic acid, and extruder thereof

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

A kind of denitrification catalyst and its preparation method and low temperature denitrification process

ActiveCN109420508BAvoid problems with clogged bedsReduce subsequent processesHeterogenous catalyst chemical elementsDispersed particle separationPtru catalystHydrogen Sulfate

The invention discloses a denitration catalyst, a preparation method and a low temperature denitration process. Denitration catalyst, based on catalyst weight, including: 75%~94% carbon-containing alumina carrier, 3%~20% Fe 2 O 3 and 3%~20%MnO 2 ; Based on the weight of the carbon-containing alumina carrier, the carbon content is 5wt%-35wt%, preferably 10wt%~30wt%, and the specific surface area is 250-750m 2 / g, the crushing strength is 100‑200N / cm. The denitration catalyst of the invention has larger pore volume, specific surface and mechanical strength, and can be used in low temperature denitration reaction, can effectively remove nitrogen oxides and sulfur oxides in flue gas, and will not cause ammonium hydrogen sulfate to block the bed The problem of the layer prolongs the operation cycle of the device.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of multi-level combined packing artificial wetland for sewage treatment

ActiveCN108840440BIncrease oxygen contentRealize rotation and stirringTreatment involving filtrationMultistage water/sewage treatmentConstructed wetlandSewage

The invention provides a multi-stage combined packing artificial wetland for sewage treatment, which belongs to the technical field of sewage treatment. The multi-stage combined packing artificial wetland used for sewage treatment includes artificial wetland. The artificial wetland includes a pretreatment pool, an inner pool and an outer pool. The pretreatment pool has a pretreatment tank. Stirring blades; the outer pool has a filter tank, and a partition plate 1 is vertically fixed in the filter tank of the outer pool. The partition plate 1 separates the filter tank into a first filter tank and a second filter tank, and The space is connected through the water inlet pipe; the inner pool has a purification tank, and a partition plate 2 is vertically fixed in the purification tank of the inner pool, and the partition plate 2 divides the filter tank into a first purification tank and a second purification tank. The invention has the advantage of being able to perform multiple cycle purification treatments on the sewage.

Owner:QUZHOU UNIV

A kind of method that acetone and hydrogen synthesize acetone condensate

ActiveCN110903179BEvenly distributedImprove mass transfer efficiencyOrganic compound preparationChemical industryChemical industryPtru catalyst

The invention belongs to the field of chemical industry, and discloses a method for synthesizing acetone condensate from acetone and hydrogen. The method comprises: mixing acetone and hydrogen, entering into a high-gravity rotating bed, and mixing with a rotor arranged on the high-gravity rotating bed. The catalyst bed layer is contacted, and after the reaction, a liquid phase component and a gas phase component containing acetone condensate are obtained; the residence time of the liquid phase component in the catalyst bed layer is τ≤20s. The present invention introduces a high-gravity rotating bed reactor into the reaction of acetone and hydrogen one-step synthesis of acetone condensation products, significantly reduces the residence time of liquid products in the catalyst bed, and alleviates / eliminates the prolongation of the reaction time. The phenomenon of carbon deposition and coking prolongs the service life of the catalyst, and at the same time changes the conversion rate of reactants and the selectivity of products.

Owner:CHINA PETROLEUM & CHEM CORP +1

An air filter structure for a negative pressure isolation tent

ActiveCN113028562BImprove efficiencyLess consumablesMechanical apparatusSpace heating and ventilationAir filtrationAir filter

The invention discloses an air filter structure for a negative pressure isolation tent, which comprises a suction pan, an air filter assembly and a discharge pipe, wherein the suction end of the suction pan communicates with the tent so as to lower the tent The air pressure in the tent creates a negative pressure inside; the suction plate can suck the air in the tent into the air filter assembly and discharge it through the discharge pipe; two suction plates are symmetrically connected to the air filter assembly The air filter assembly includes a high-temperature sterilization assembly, a middle-section sterilization assembly, and a germ adsorption assembly, wherein the two suction discs respectively suck the air in the corresponding tent and transmit it to the corresponding high-temperature sterilization assembly and In the middle section of the sterilization component, and the two airs share one of the germ adsorption components and are discharged through the discharge pipe, which improves the reliability of the overall sterilization.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

System used for processing domestic sewage with ecological technology

ActiveCN108793602AHigh activityEasy to disassemble and replaceWater aerationTreatment involving filtrationSewageConstructed wetland

The invention provides a system used for processing domestic sewage with ecological technology, and belongs to the technical field of sewage treatment. The system used for processing domestic sewage with ecological technology comprises a sedimentation basin, an aeration tank, a constructed wetland, and an ecological pool; the constructed wetland comprises an internal pool and an external pool; theexternal pool is provided with a filtering groove; an opening end of the filtering groove of the external pool is fixedly provided with an installation frame; the external wall of the lower end of the internal pool is fixedly arranged on the installation frame; the internal pool is provided with a purifying groove; the aeration tank is provided with an aeration groove; the aeration groove and a first filtering groove are connected through a water inlet pipe; the side wall of the aeration tank is provided with a cavity; the internal wall of the aeration tank is provided with a gas outlet communicated with the cavity; the sedimentation basin is provided with a sedimentation groove; a separating plate 3 is arranged in the sedimentation basin to divide the sedimentation groove into a first sedimentation groove and a second sedimentation groove; the ecological pool is provided with an ecological groove; and submerged plants are planted in the ecological groove. The system is capable of realizing purifying of domestic sewage with higher efficiency.

Owner:QUZHOU UNIV

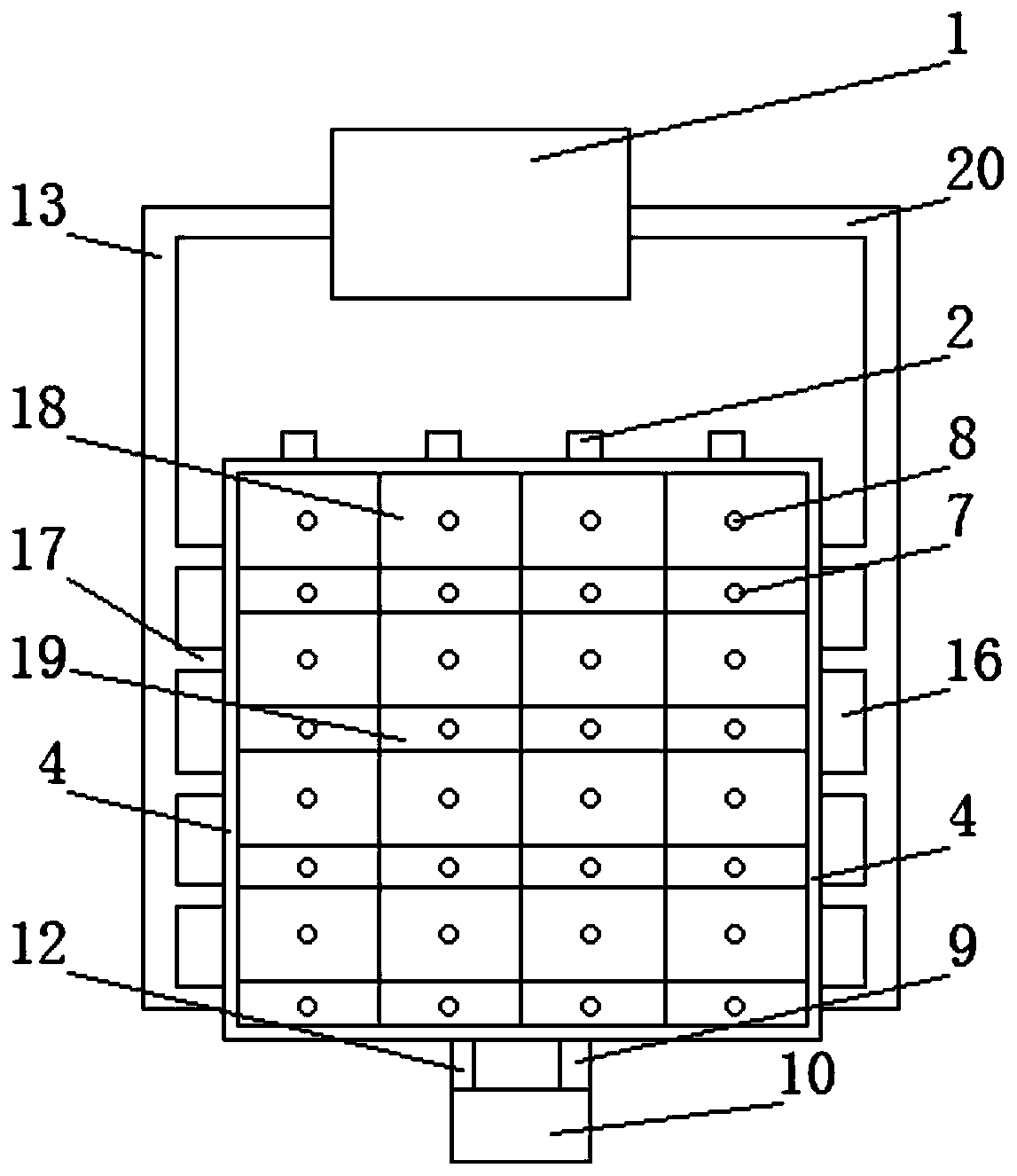

A cooling device for electronic products that improves the cooling efficiency of cooling water

ActiveCN109041509BAdjust dwell timeGuaranteed cooling effectCooling/ventilation/heating modificationsThermodynamicsElectronics cooling

The invention discloses a flow regulating device for electronic product cooling equipment, the device comprises a base and a cooling box, the cooling box is provided with a plurality of parallel and staggered cooling grooves and circulating grooves, the cooling groove and the circulating groove are respectively provided with a plurality of evenly distributed cooling sub-grooves and circulating sub-grooves, A base is arranged at the bottom of the cooling box, A collection tank and a water cooling tank are respectively arranged in the base from the top to the bottom, the collecting tank and thewater cooling tank are connected with each other by a first water pump, A liquid inlet pipe and a liquid outlet pipe are connected with the cooling water circulation tank on both sides of the water cooling tank through an inlet pipe and an outlet pipe, and valve are arranged on the liquid inlet pipe and the liquid outlet pipe, A handle is arrange on the valve, the bottom of the handle is connectedthrough a plurality of parallel distribute adjusting rods, one side of the adjusting rod is provided with an adjusting block, and a rack is arrange on the adjusting rod, an adjusting shaft meshing with the rack is arranged in the adjusting block, and an adjusting rotary table is arranged on the outer side of the adjusting shaft, which has strong comprehensive practicability and is easy to popularize and use.

Owner:安徽好润环保科技有限公司

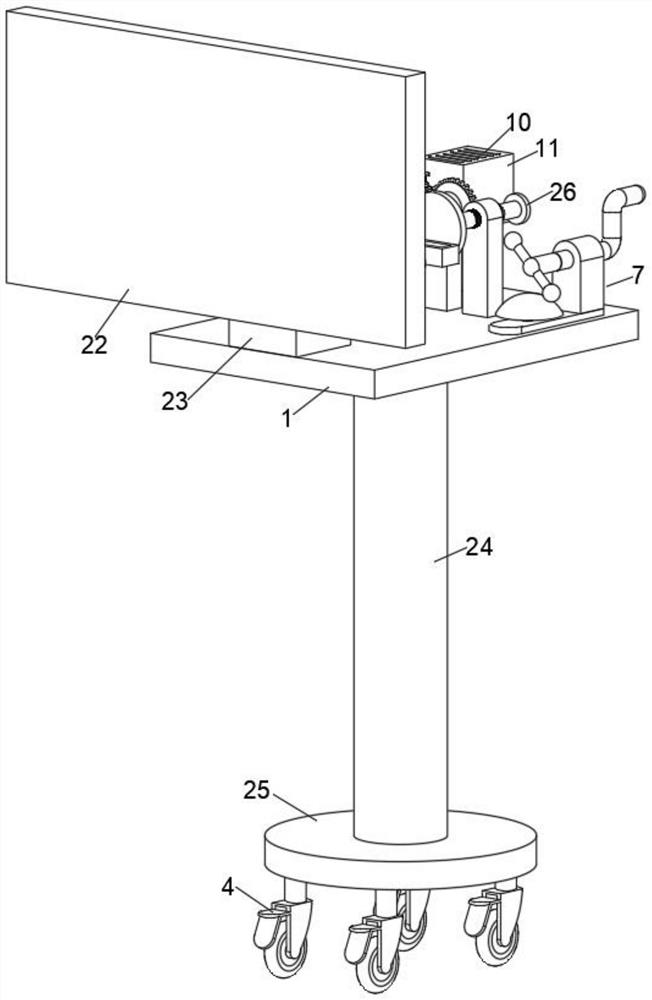

Showing stand for engineering consultation

InactiveCN114305010AImprove display effectMeet needsShow shelvesTeaching apparatusDisplay boardPhysical medicine and rehabilitation

The invention discloses a showing stand for engineering consultation, and belongs to the technical field of equipment for engineering consultant training. A showing stand for engineering consultation comprises a mounting plate, a containing block is arranged on the front side of the mounting plate, a bearing column is arranged on the rear side of the top face of the containing block, movable rods are arranged on the left side and the right side of the bearing column, sliding sleeves are arranged in the middles of the movable rods, bearing rods are arranged on the rear side of the outer wall of each sliding sleeve, U-shaped limiting sleeves are arranged at the rear ends of the bearing rods, and a swing disc is arranged between the two U-shaped limiting sleeves. A motor is arranged in the motor box; a main shaft is arranged at the end part of the output end of the motor; a timing assembly is arranged on the front side of the main shaft; and a warning assembly is arranged on the right side of the mounting plate. Through cooperation of the motor arranged in the motor box and the swing disc between the two U-shaped limiting sleeves, when an engineering consultation education training teacher gives a lesson, the bearing rod can drive the display board to swing left and right, so that all trained students can see engineering consultation data, and the display effect is improved.

Owner:马海威

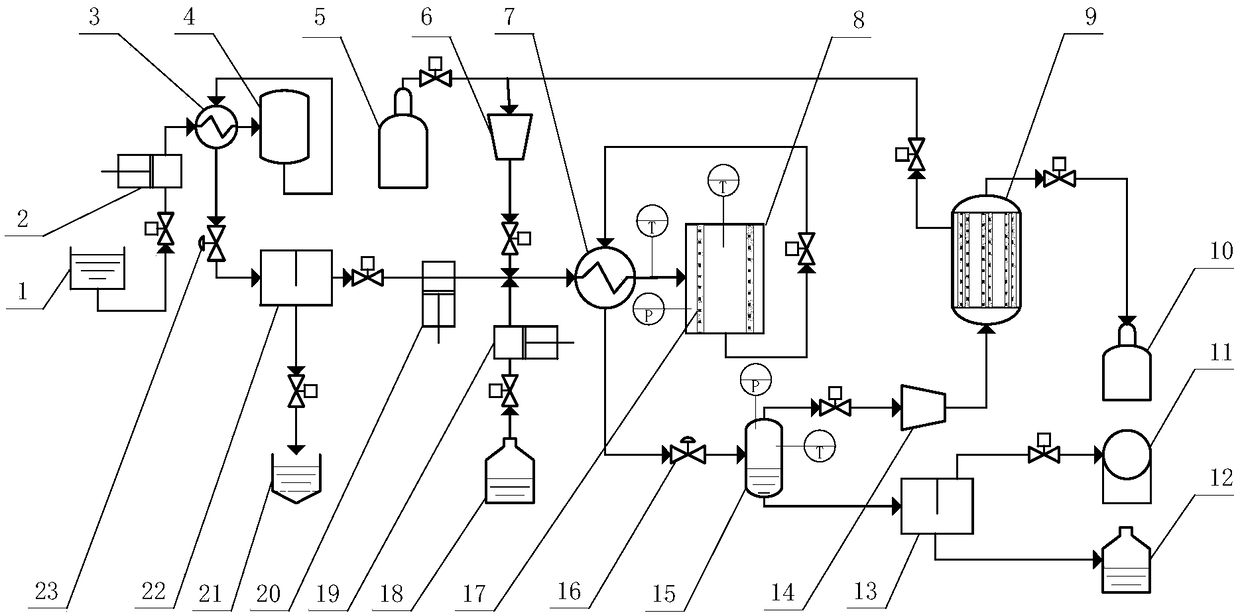

A continuous catalytic upgrading reaction system for microalgae liquefied oil

ActiveCN106987263BContinuous and efficient responseAchieve separationLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesVapor–liquid separatorHydrothermal liquefaction

Owner:XI AN JIAOTONG UNIV

A blast furnace slag sensible heat recovery slag cooler

ActiveCN106834571BEfficient use ofImprove heat recovery efficiencyIncreasing energy efficiencyWaste heat treatmentSlagWater flow

The invention relates to a blast furnace slag sensible heat recovery slag cooler which is used for furnace slag waste heat recovery, and belongs to the field of heat exchange. The blast furnace slag sensible heat recovery slag cooler comprises a plate or tube type heat exchange core, a furnace slag inlet, a louver type furnace slag outlet baffle, a furnace slag outlet hopper, a furnace slag outlet, a cooling water inlet, a steam outlet, a shell and a heat preservation layer; the heat exchange core of the blast furnace slag sensible heat recovery slag cooler is formed by stacking a plurality of plate bundles or tube bundles according to a certain manner. High-temperature furnace slag particles are poured in from the upper portion of the slag cooler, evenly flow downwards, and sweep past a heat exchange plate tube, and heat is transferred to water in the plate tube through a plate wall or tube wall. Cold water flows in a channel in the plate or tube, cross flow or adverse flow is formed between the cold water and the flowing direction of the furnace slag, and entering water is heated to form steam to be discharged out from an upper header. The cooled slag particles are discharged from an outlet in the lower portion. The flowing speed of the slag particles can be adjusted according to the louver type furnace slag outlet baffle at the lower portion of the slag cooler. The water cooling type slag cooler is simple and compact in heat exchange structure, running operation is convenient, the waste heat using efficiency is higher, and secondary losses of heat are avoided.

Owner:TONGJI UNIV

Metallurgical furnace slag thickness control device

The invention relates to the technical field of metallurgy, in particular to a metallurgical furnace slag thickness control device, which comprises a furnace wall and a slag hole external water jacket, wherein the furnace wall is provided with a fireproof slag outlet wall body; a water-cooling component is embedded between the furnace wall and the fireproof slag outlet wall body; the fireproof slag outlet wall body is provided with an upper slag hole and a lower slag hole; the slag hole external water jacket is positioned in the water-cooling component and is further positioned on the external surface of the fireproof slag outlet wall body; the slag hole external water jacket comprises a first slag hole, a second slag hole and a third slag hole; the first slag hole and the second slag hole are synchronously communicated with the upper slag hole; and the third slag hole is communicated with the lower slag hole. By using the metallurgical furnace slag thickness control device provided by the invention, the in-time and reasonable control of the thickness of a furnace slag layer can be achieved according to an on-site furnace practice; the residence time of furnace slag in a metallurgical furnace is regulated; the loss of a metal in furnace slag due to the completion extent of a chemical reaction and mechanical inclusion is decreased; the recovery rate of the metal is improved; the processing cost is saved; the service life of the slag holes can be effectively prolonged; and further, the maintenance is convenient.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

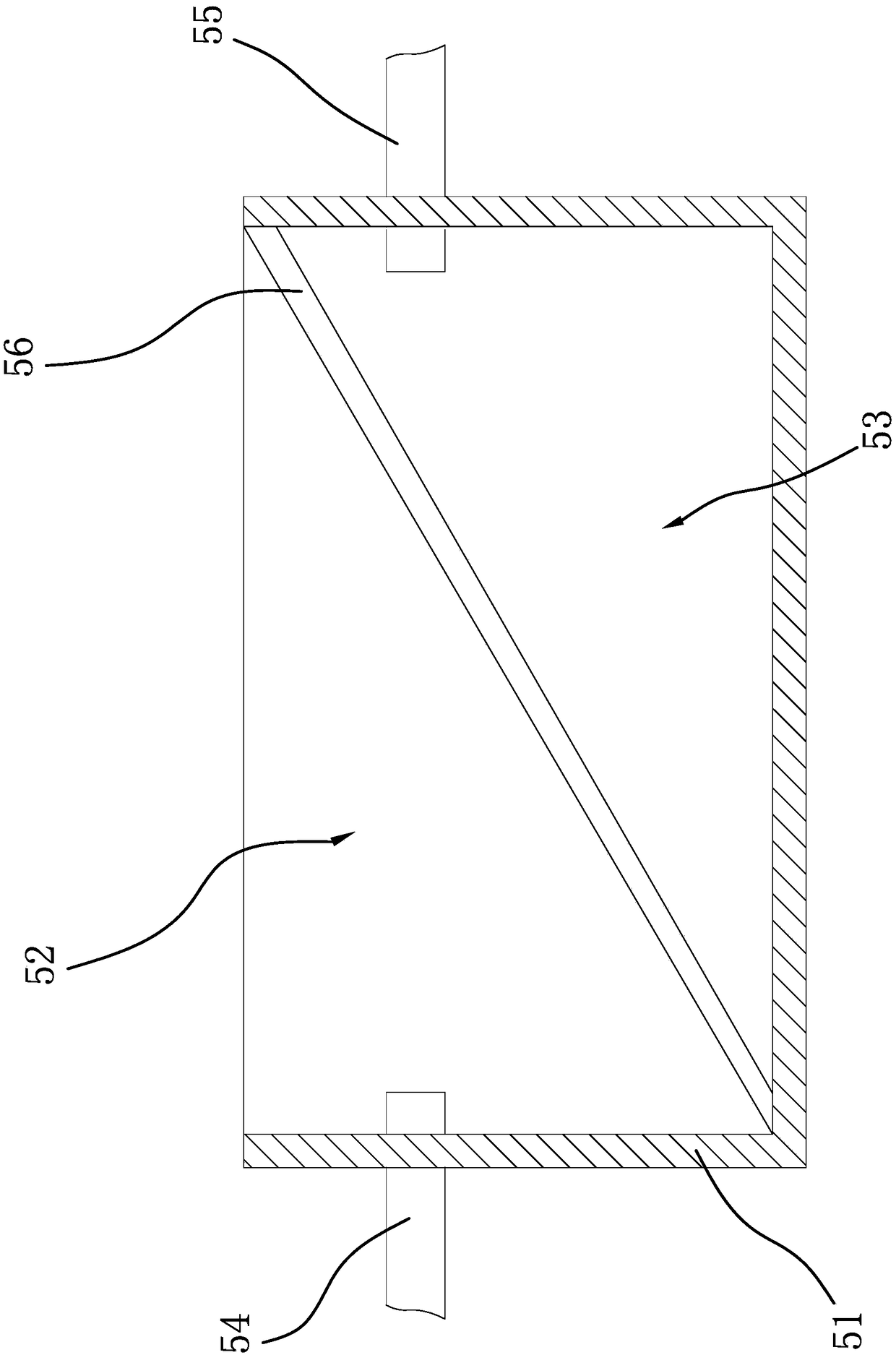

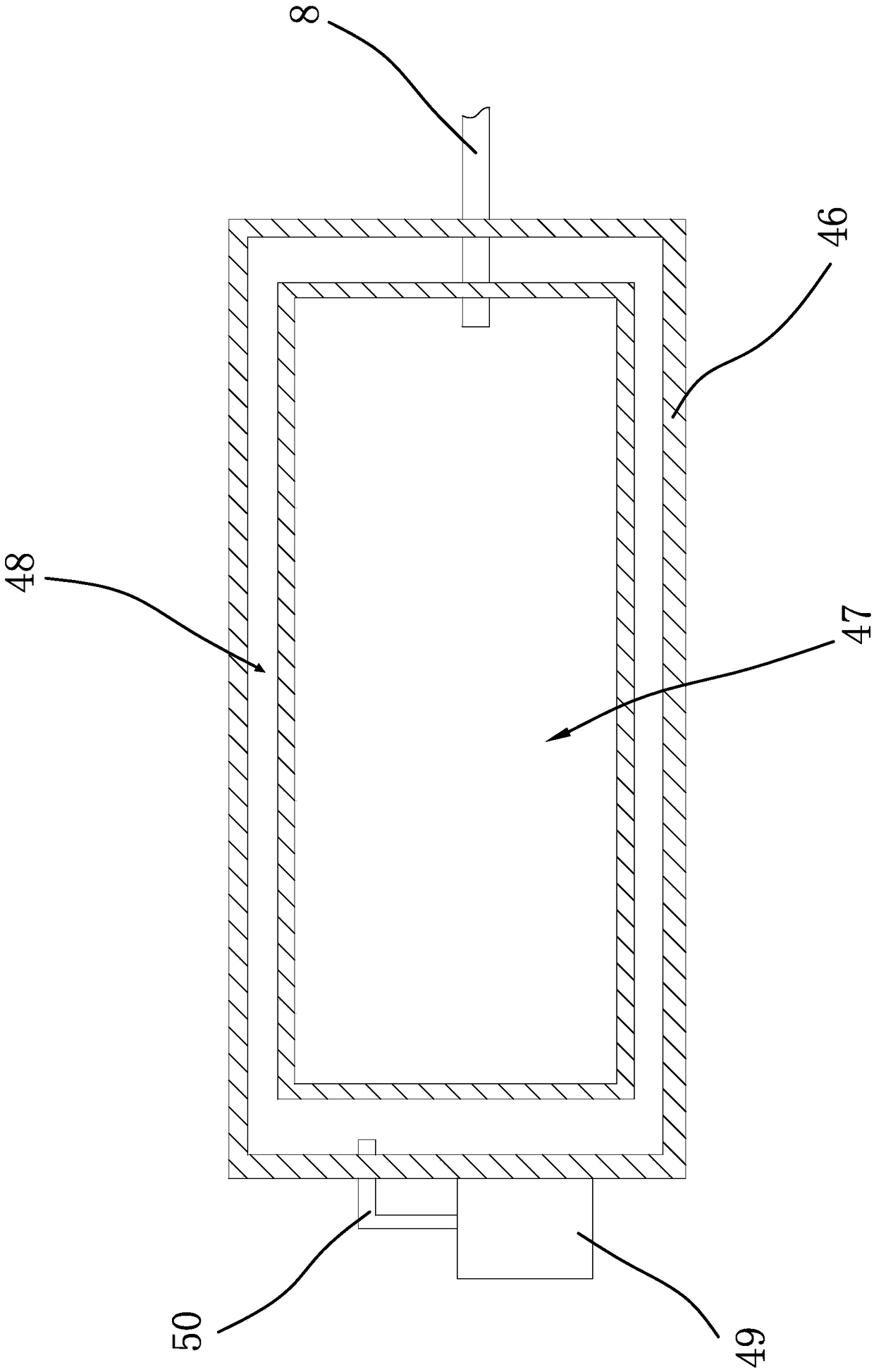

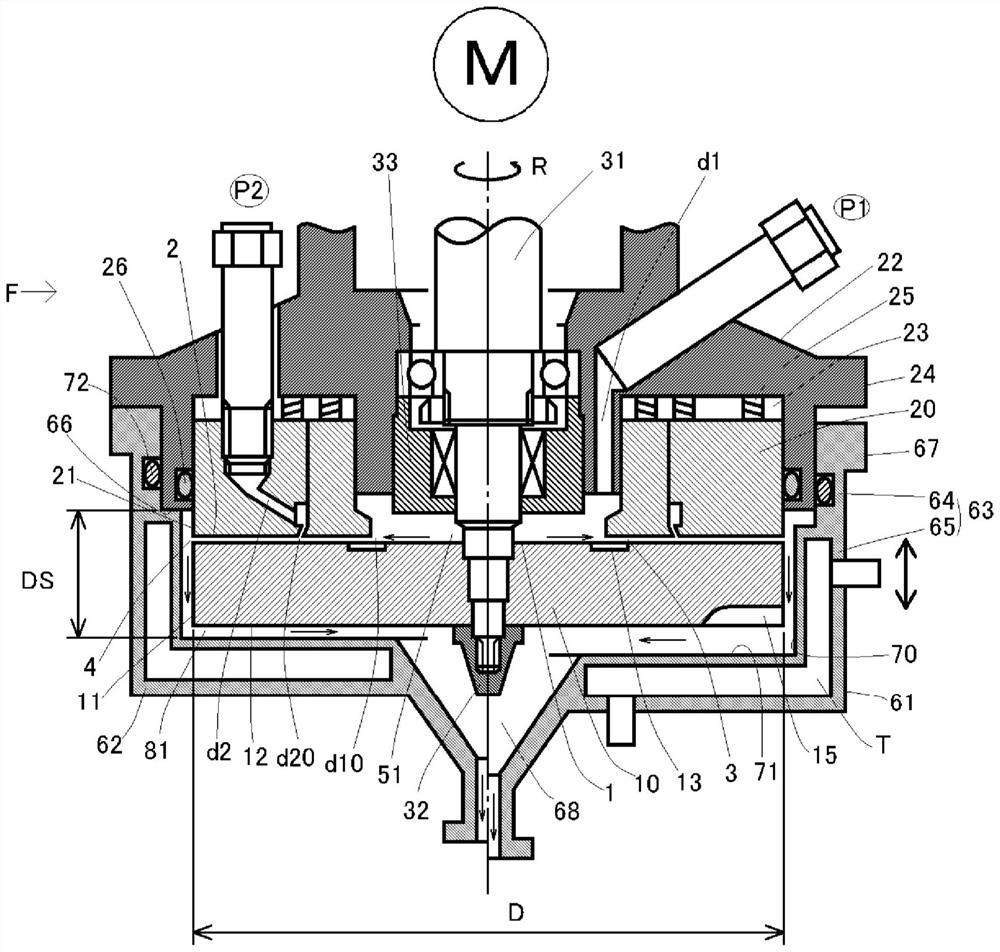

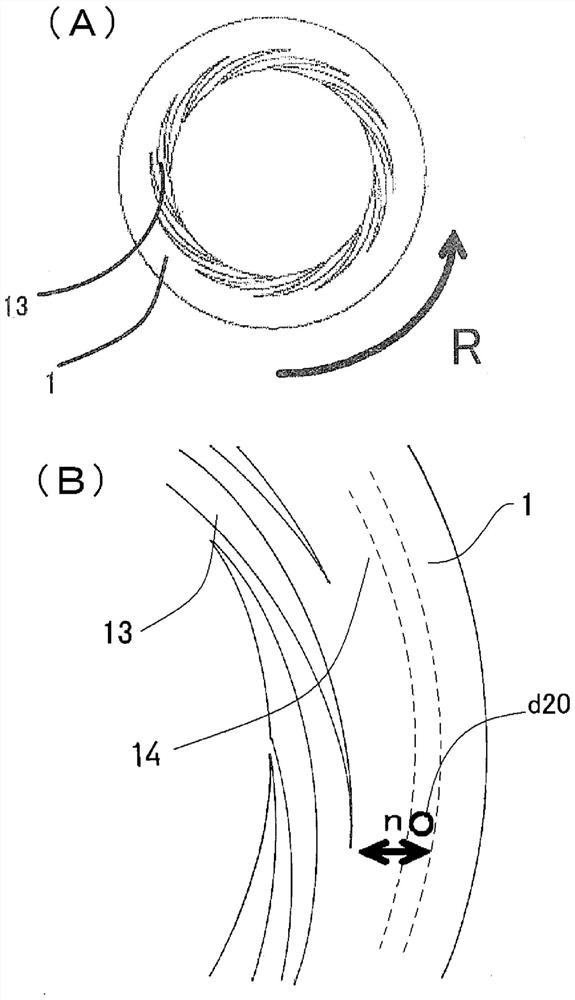

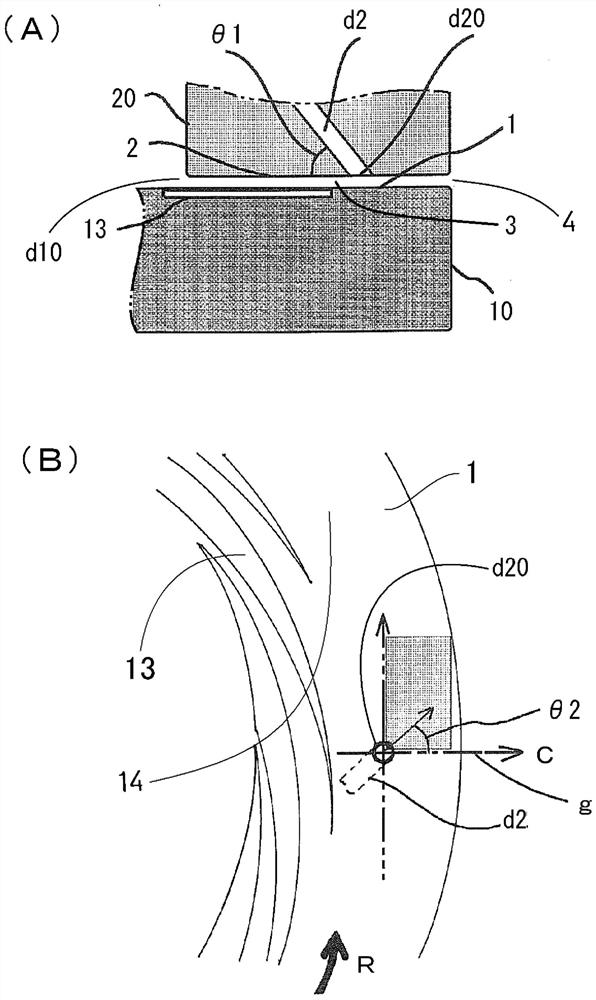

Fluid treatment device

PendingCN113226537AAdjust densityAdjust dwell timeRotary stirring mixersTransportation and packagingEngineeringMechanics

A fluid treatment device with a new configuration is provided. The fluid treatment device F is provided with an upstream treatment unit defined by treatment surfaces 1, 2 that rotate relative to each other, and a downstream treatment unit arranged downstream of the upstream treatment unit. The upstream treatment unit is configured such that, by passing the fluid to be treated into an upstream treatment space 3 defined by the treatment surfaces 1, 2, the fluid to be treated is subjected to upstream treatment. The downstream treatment unit is provided with a downstream treatment space 81 which performs the function of retaining and mixing the fluid to be treated by means of a labyrinth seal. An upstream outlet 4 of the fluid to be treated from the upstream treatment unit opens into the downstream treatment space 81, and the downstream treatment space 81 is configured to use the labyrinth seal to perform the function of controlling retention time. The downstream treatment space 81 is provided with narrow seal spaces 84, and retention spaces 83 arranged upstream of the seal spaces 84 and wider than the seal spaces 84, and the upstream outlet 4 opens to a retention space 83.

Owner:M TECH CO LTD

Sewage treatment method capable of realizing advanced nitrogen removal through combined biofilm process

ActiveCN102689986BAchieve denitrification performancePromote denitrification processTreatment with aerobic and anaerobic processesRetention timeWater quality

Owner:EAST CHINA UNIV OF SCI & TECH

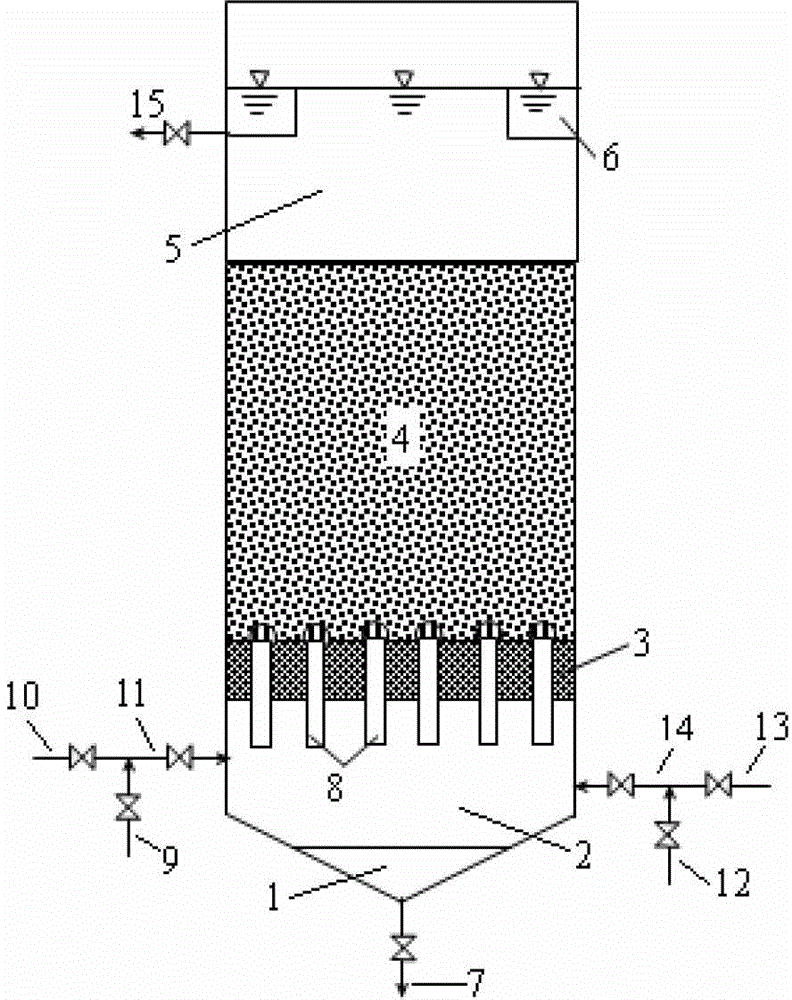

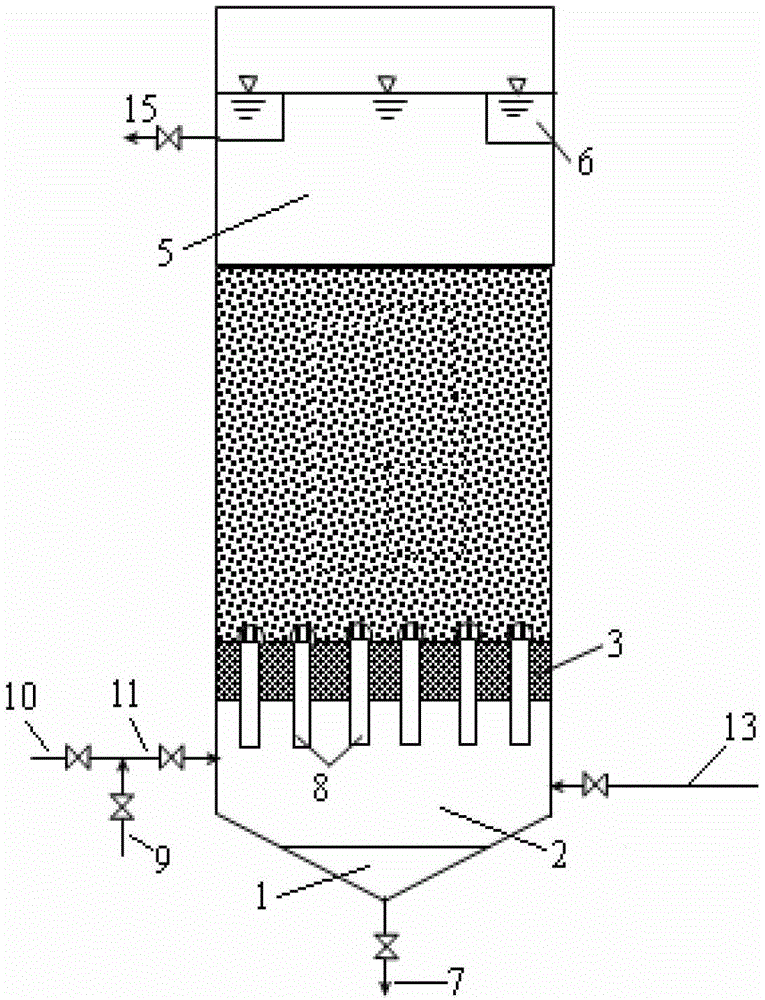

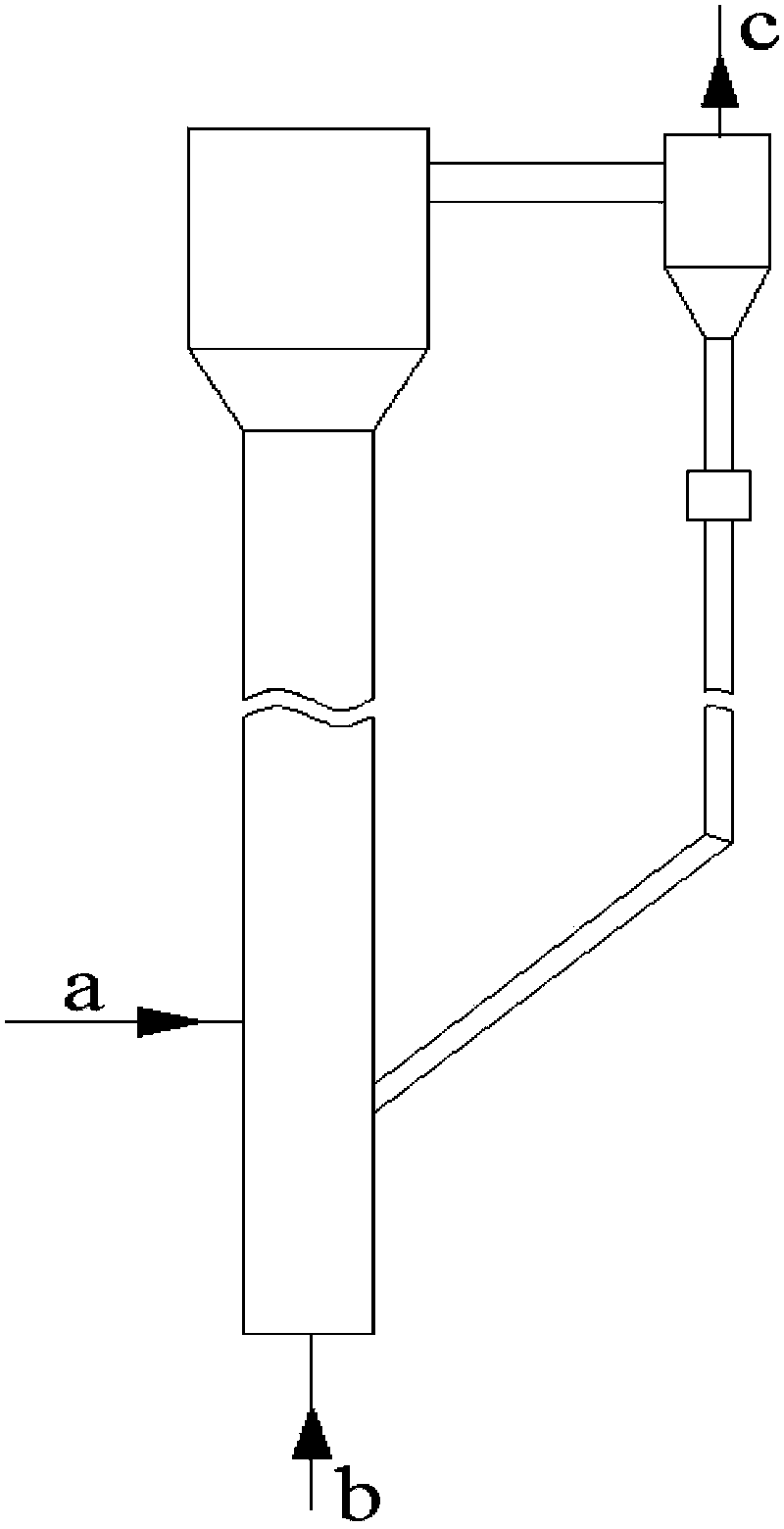

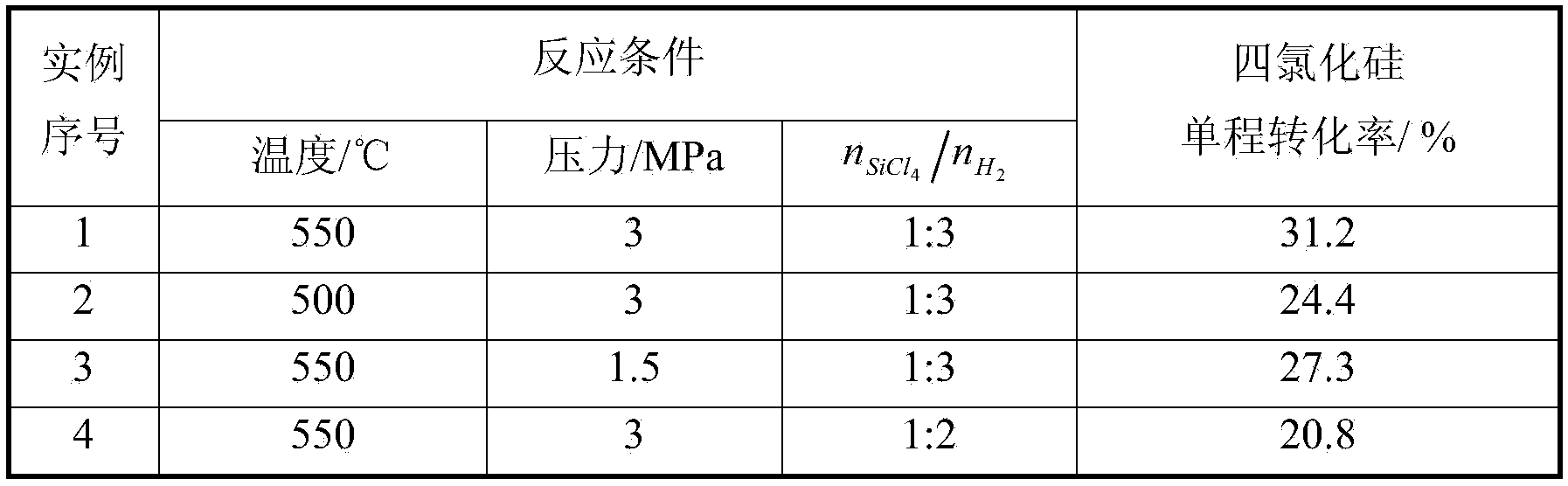

Hydrogenation method for quickly circulating fluidized silicon tetrachloride

InactiveCN102674369BLarge amount of processingFast mass transferEnergy inputHalogenated silanesChemistryPre treatment

The invention relates to a hydrogenation method quickly for circulating fluidized silicon tetrachloride, and method comprises the following steps of: mixing pre-treated silicon power into a hydrogenation rector from the middle, wherein the pressure is 1-5MPa, and charging mixed gas of hydrogen and silicon tetrachloride with the preheating temperature of 400-600DEG C (the molar ratio is 1:(1-5)) into the hydrogenation rector from the bottom; in the hydrogenation rector, wherein the macroscopic tolerance is 0.2-4m / s; quickly fluidizing the silicon power; and carrying out the gas-solid separation on the product gas and the silicon power flowing out of the top of the reactor by a first-stage cyclone separator or a multi-stage cyclone separator, and reflowing the silicon power into the reactor by a circulating pipe, wherein the product gas passes through a waste heat recovery system, a condensation system and a separation system, the trichlorosilane is taken as a hydrogenated product, and the separated silicon tetrachloride and hydrogen can be recycled. The method has the advantages that the gas and the solid can be sufficiently contacted with each other, the heat and the mass can be quickly transferred, and the silicon tetrachloride is high in conversion per pass; a bed layer is even in temperature field, and the product is stable in quality; and the hydrogenation rector of a circulating fluidized bed is high in operation elasticity, high in capacity, and easy for realization of the large-scale production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Reclaimed material drying apparatus

InactiveCN104805755AReduce contact timeContact time adjustmentRoads maintainenceContact timeSlide plate

The invention discloses a drying apparatus difficultly adhering to a device and specially used for producing reclaimed waste asphalt. The apparatus comprises a hot-blast stove and a drying furnace connected with the hot-blast stove, a slide way is arranged in the drying furnace, the inner wall of the drying furnace is provided with heating radiators, the cross section of the drying furnace is rectangular, the slide way is two groups of relatively-interlacing downward-tilting slide plates fixed on the inner wall, and the heating radiators are positioned on the inner wall below the slide plates. The slide way adopts two groups of the relatively-interlacing downward-tilting slide plates, so the contact time of waste asphalt with the slide plates is shortened, thereby the adhesion of the waste asphalt to the slide way is difficult.

Owner:山西玉通机械设备有限公司

Wet-type chemical desulfurization regeneration tank

PendingCN113403118AEasy to installEasy to disassembleGaseous fuelsMechanical engineeringRotational flow

The invention discloses a wet-type chemical desulfurization regeneration tank which comprises a reaction tank, a sealing cover is arranged at the top end of the reaction tank, a plurality of uniformly distributed supporting legs are arranged at the bottom end of the reaction tank, an inner tank is arranged in the reaction tank, and the inner tank is connected with the reaction tank through a plurality of uniformly distributed supporting rods. The wet-type chemical desulfurization regeneration tank has the beneficial effects that through the arrangement of the connector and the angle adjusting pipe internally provided with a third spring, deformation is facilitated, and the folding phenomenon cannot occur after deformation; meanwhile, a threaded rod, a limiting sleeve, a limiting rod, a disc and supporting pieces are arranged, so that the angle adjusting pipe can deform and adjust the angle according to the diameter of the inner tank, rotational flow is formed in the water inlet process, and the stirring effect is improved; by arranging a folding pipe internally provided with a first spring, a second absorption alkali liquor inlet pipe is convenient to mount and dismount; and meanwhile, the connecting rod and the threaded sleeve are arranged, so that the height of the second absorption alkali liquor inlet pipe is convenient to adjust, and the height of the first absorption alkali liquor inlet pipe is not affected.

Owner:QINGDAO ZHONGKE HUATONG ENERGY ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com