Wet-type chemical desulfurization regeneration tank

A technology of chemical desulfurization and regeneration tank, which is applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve the problems of reduced stirring effect, no height adjustment function, and inability to control the residence time of hydrogen sulfide-containing absorbing liquid, etc., so as to improve the stirring effect. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

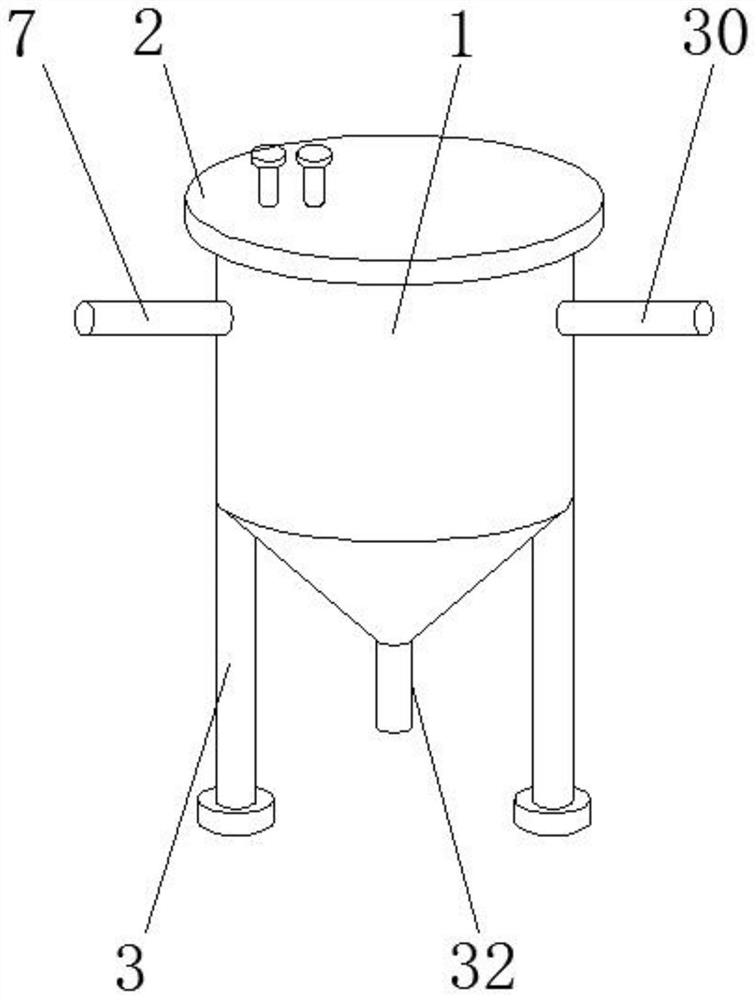

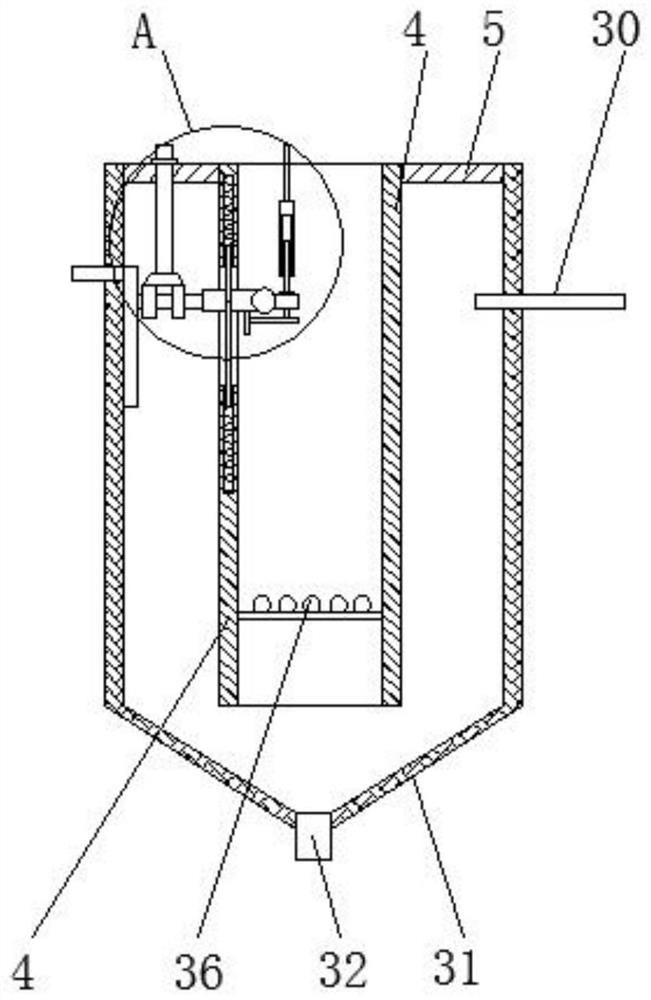

[0028] Such as Figure 1-6 As shown, the wet chemical desulfurization regeneration tank according to the embodiment of the present invention includes a reaction tank 1, the top of the reaction tank 1 is provided with a sealing cover 2, and the bottom of the reaction tank 1 is provided with a number of evenly distributed support feet 3 , the reaction tank 1 is provided with an inner tank 4, and the inner tank 4 is connected to the reaction tank 1 through a number of evenly distributed support rods 5.

Embodiment 2

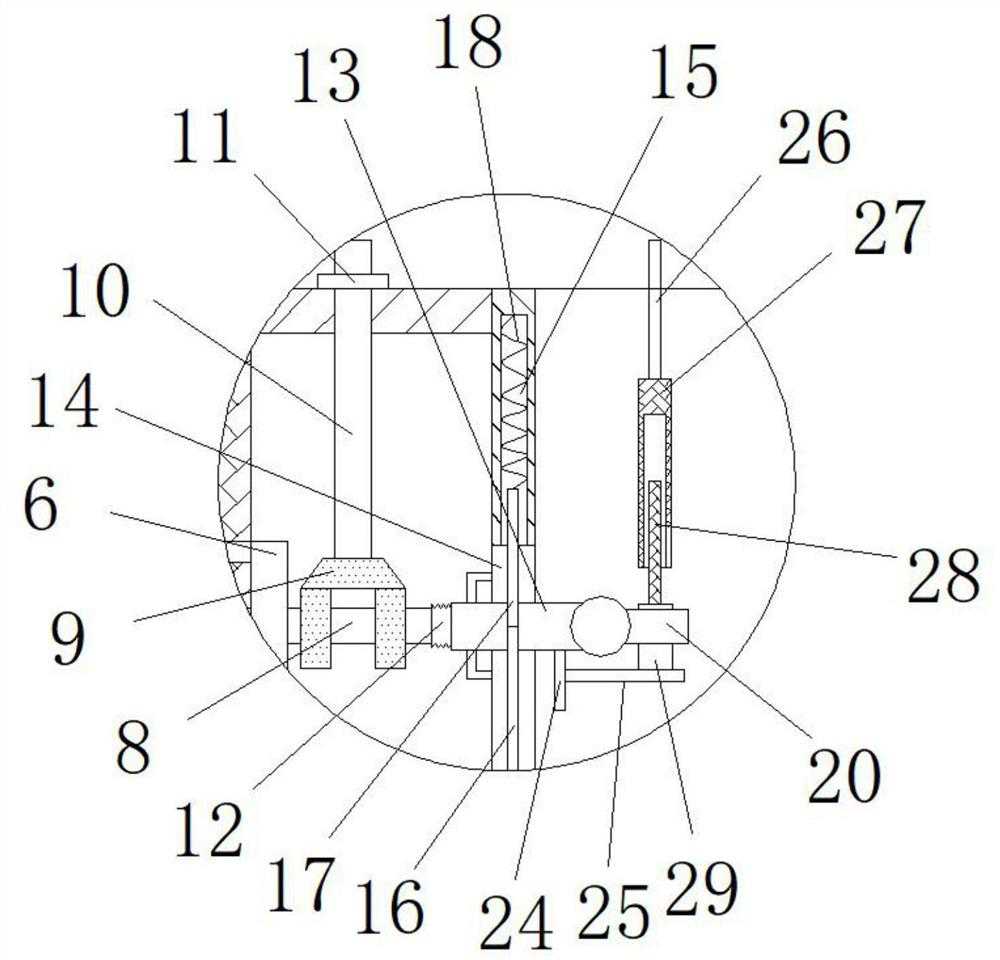

[0030] Such as Figure 1-6 As shown, the wet chemical desulfurization regeneration tank according to the embodiment of the present invention includes a reaction tank 1, the top of the reaction tank 1 is provided with a sealing cover 2, and the bottom of the reaction tank 1 is provided with a number of evenly distributed support feet 3 , the reaction tank 1 is provided with an inner tank 4, the inner tank 4 is connected to the reaction tank 1 through a number of evenly distributed support rods 5, and a height adjustment box 6 is provided on one side of the reaction tank 1 The top of one side of the height adjustment box 6 is provided with an absorption lye inlet pipe 1 extending to the outside of the reaction tank 1, and the other side of the height adjustment box 6 is provided with an absorption lye inlet pipe 2 8. The two 8 sets of the absorbing lye inlet pipe are provided with a clamp 9 that matches it, and the top end of the clamp 9 is provided with a connecting rod 10 that...

Embodiment 3

[0032] Such as Figure 1-6 As shown, the wet chemical desulfurization regeneration tank according to the embodiment of the present invention includes a reaction tank 1, the top of the reaction tank 1 is provided with a sealing cover 2, and the bottom of the reaction tank 1 is provided with a number of evenly distributed support feet 3 , the reaction tank 1 is provided with an inner tank 4, the inner tank 4 is connected to the reaction tank 1 through a number of evenly distributed support rods 5, and the other side top of the reaction tank 1 is provided with a Regenerated lye outlet pipe 30 inside, the bottom end of the reaction tank 1 is provided with a cone bucket 31, and the bottom end of the cone bucket 31 is provided with a discharge pipe 32, which can concentrate and collect the sediment, and facilitate the deposition of the sediment The height adjustment box 6 includes a bar-shaped box body 33, and the top of the bar-shaped box body 33 is provided with a number of evenly d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com