A kind of denitrification catalyst and its preparation method and low temperature denitrification process

A denitrification catalyst and low-temperature denitrification technology, applied in the field of flue gas denitrification, can solve the problems of high investment and operating costs, long process, corrosion, etc., and achieve the effect of reducing investment and operating costs, reducing follow-up processes, and prolonging the operation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

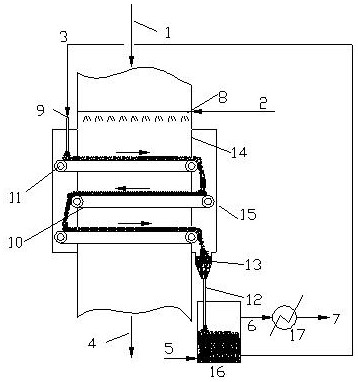

Method used

Image

Examples

Embodiment 1

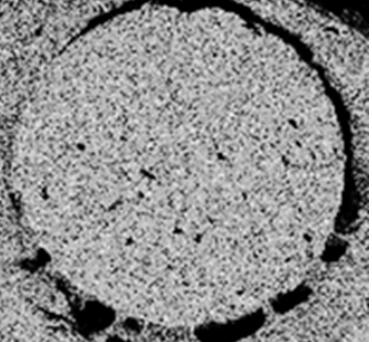

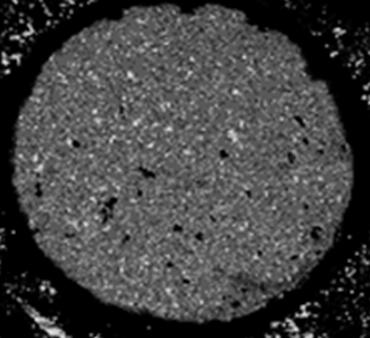

[0043] Immerse 150 grams of furfuryl alcohol solution into 100 grams of γ-alumina powder in an equal volume, and dry it in the shade at room temperature for a certain period of time, so that the two can be stirred into non-bonded agglomerate particles. The composition of the furfuryl alcohol solution is: furfuryl alcohol 10wt%, ethanol / water 0.1. Then move the agglomerate particles into the extruder, then slowly add 35ml of 3.0wt% dilute nitric acid (containing 0.04g of sulfuric acid), fully knead into a plastic body with suitable hardness, and then extrude into strips. After drying overnight at room temperature, the extrudate was dried at 110°C for 4 hours. Put the dried sample in a high-temperature furnace, raise the temperature to 350°C, and keep the temperature at this temperature for 6 hours, then pass in nitrogen gas and continue to heat up to 600°C, keep it at this temperature for 10 hours, and obtain a carbon-containing alumina carrier after natural cooling . The alu...

Embodiment 2

[0045] Impregnate 150 grams of furfuryl alcohol solution into 100 grams of γ-phase alumina powder in equal volumes, and dry in the shade at room temperature for a certain period of time, so that the two can be stirred into non-bonding agglomerate particles. The composition of furfuryl alcohol solution is: furfuryl alcohol 20wt%, ethanol / water 0.5. Then move it into extruder, then slowly add 50ml of 3.5wt% dilute nitric acid (containing 0.06g of sulfuric acid), fully knead into a plastic body, and then extrude into strips. After drying overnight at room temperature, the extrudate was dried at 110°C for 4 hours. Put the dry sample in a high temperature furnace, raise the temperature to 300°C, and keep it at this temperature for 4 hours, then pass in nitrogen gas and continue to heat up to 650°C, keep it at this temperature for 6 hours, and get a carbon-containing alumina carrier after natural cooling . The alumina carrier was impregnated with an equal volume of impregnating so...

Embodiment 3

[0047] Immerse 185 grams of furfuryl alcohol solution into 100 grams of γ-phase alumina powder in an equal volume, and dry it in the shade at room temperature for a certain period of time, so that the two can be stirred into non-bonded agglomerate particles. The composition of furfuryl alcohol solution is: furfuryl alcohol 45wt%, ethanol / water 1. Then move it into extruder, slowly add 50ml of 4.0wt% dilute nitric acid (containing 0.08g of sulfuric acid), fully knead into a plastic body, and then extrude into strips. After drying overnight at room temperature, the extrudate was dried at 110°C for 4 hours. Put the dried sample in a high-temperature furnace, raise the temperature to 400°C, and keep the temperature at this temperature for 4 hours, then pass in nitrogen gas and continue to heat up to 600°C, keep it at this temperature for 3 hours, and obtain a carbon-containing alumina carrier after natural cooling . The alumina support was impregnated with an equal volume of imp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com