Preparation method and denitration process of flue gas denitration catalyst

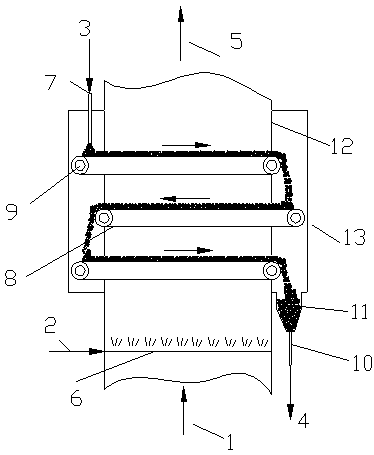

A denitrification catalyst and flue gas technology, applied in the direction of catalyst carriers, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of fouling and blockage of the heat exchange tube layer, low catalyst utilization rate, complicated operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

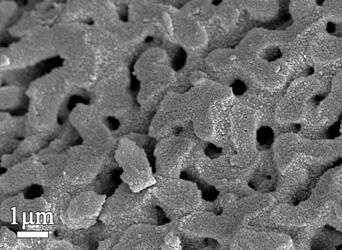

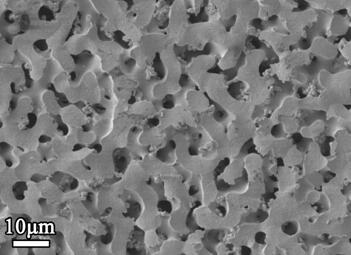

Embodiment 1

[0049] Mix water, absolute ethanol, aluminum chloride, and polyethylene glycol evenly, and then add pyridine to form a gel. The contents of each component of the mixture are by weight: water 14%, ethanol 12%, aluminum chloride 25% , polyethylene glycol (molecular weight 2000) 7%, pyridine 42%. After mixing evenly, the resulting mixed product was dropped into an oil column at 25°C to form gel microspheres, and then the material was placed in a closed container, and compressed air was slowly introduced at a rate of 0.01 MPa / min until it reached an equilibrium of 8 MPa. Aging at 30°C for 10 hours, and slowly releasing the pressure to normal pressure at 0.1 MPa / min. The aged mixture was then soaked in ethanol for 48 hours. After soaking and removing the liquid phase, it was dried at 40° C. until the product no longer lost weight. Then bake at 600°C for 6 hours, and then cool to room temperature to obtain the alumina microspheres. The average macropore diameter of the alumina micr...

Embodiment 2

[0051] Mix water, absolute ethanol, aluminum chloride, and polyethylene glycol evenly, and then add pyridine. The contents of each component of the mixture are by weight: 15% water, 15% ethanol, 35% aluminum chloride, polyethylene glycol Diol (molecular weight 4000) 5%, pyridine 30%. After mixing evenly, the obtained mixed product was dropped into an oil column at 25°C to form gel microspheres, and then the material was placed in a closed container, and compressed air was slowly introduced at a rate of 0.05 MPa / min until it reached an equilibrium of 8 MPa. Aging at 40°C for 7 hours, then slowly release the pressure to normal pressure at a rate of 0.1MPa / min. Then soak the aged mixture with ethanol for 48 hours, after soaking and removing the liquid phase, dry at 50° C. until the product no longer loses weight significantly. Then bake at 650°C for 5 hours, and then cool to room temperature to obtain alumina microspheres. The average macropore diameter of the alumina microspher...

Embodiment 3

[0053] Mix water, absolute ethanol, aluminum chloride, and polyethylene glycol evenly, and then add pyridine to form a gel. The contents of each component of the mixture are by weight: water 34%, ethanol 26%, aluminum chloride 20% , polyethylene glycol (molecular weight 6000) 3%, pyridine 17%. After mixing evenly, the resulting mixed product was dropped into an oil column at 25°C to form gel microspheres, and then the material was placed in a closed container, and compressed air was slowly introduced at a rate of 0.02 MPa / min until it reached a balance of 6 MPa. Aging at 30°C for 12 hours, then slowly release the pressure to normal pressure at a rate of 0.5 MPa / min. The aged mixture was then soaked in ethanol for 48 hours. After soaking and removing the liquid phase, it was dried at 40° C. until the product no longer lost weight. Then calcined at 850°C for 3 hours, and then cooled to room temperature to obtain alumina microspheres. The average macropore diameter of the alumin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com