Environment-friendly type rotating drying system

A rotary drying, environmentally friendly technology, applied in the field of drying systems, can solve the problems of heat energy waste, low drying efficiency, environmental pollution, etc., and achieve the effect of automatic cleaning, ensuring stability, and fully lifting materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

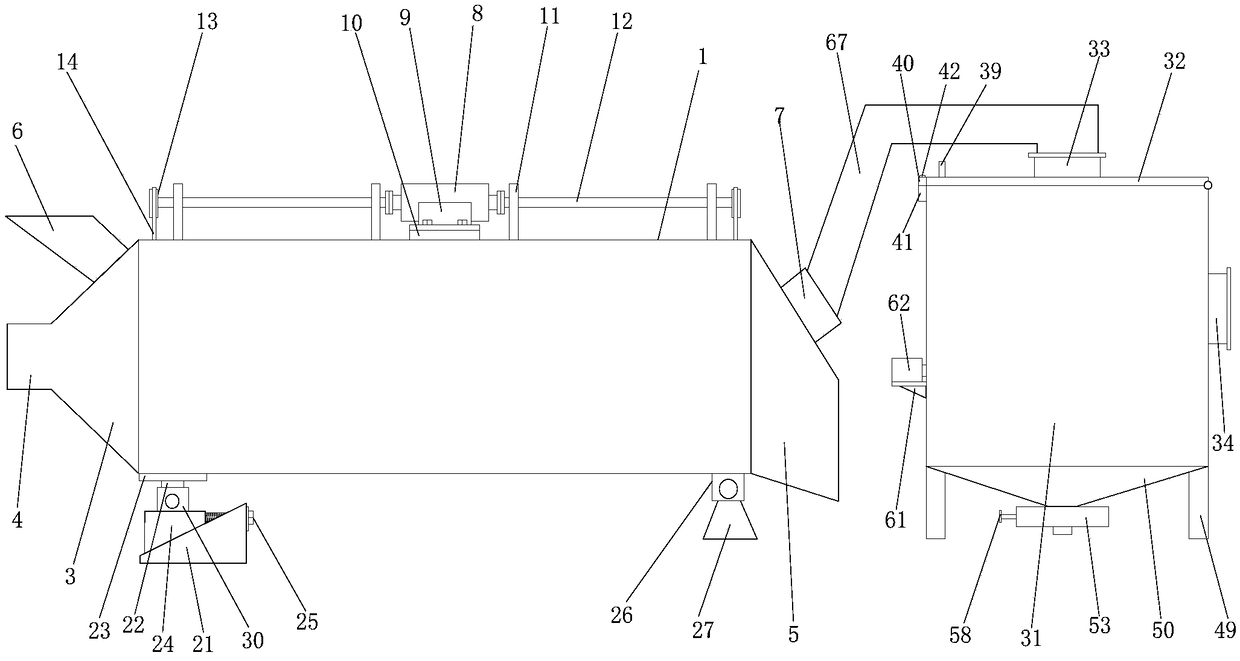

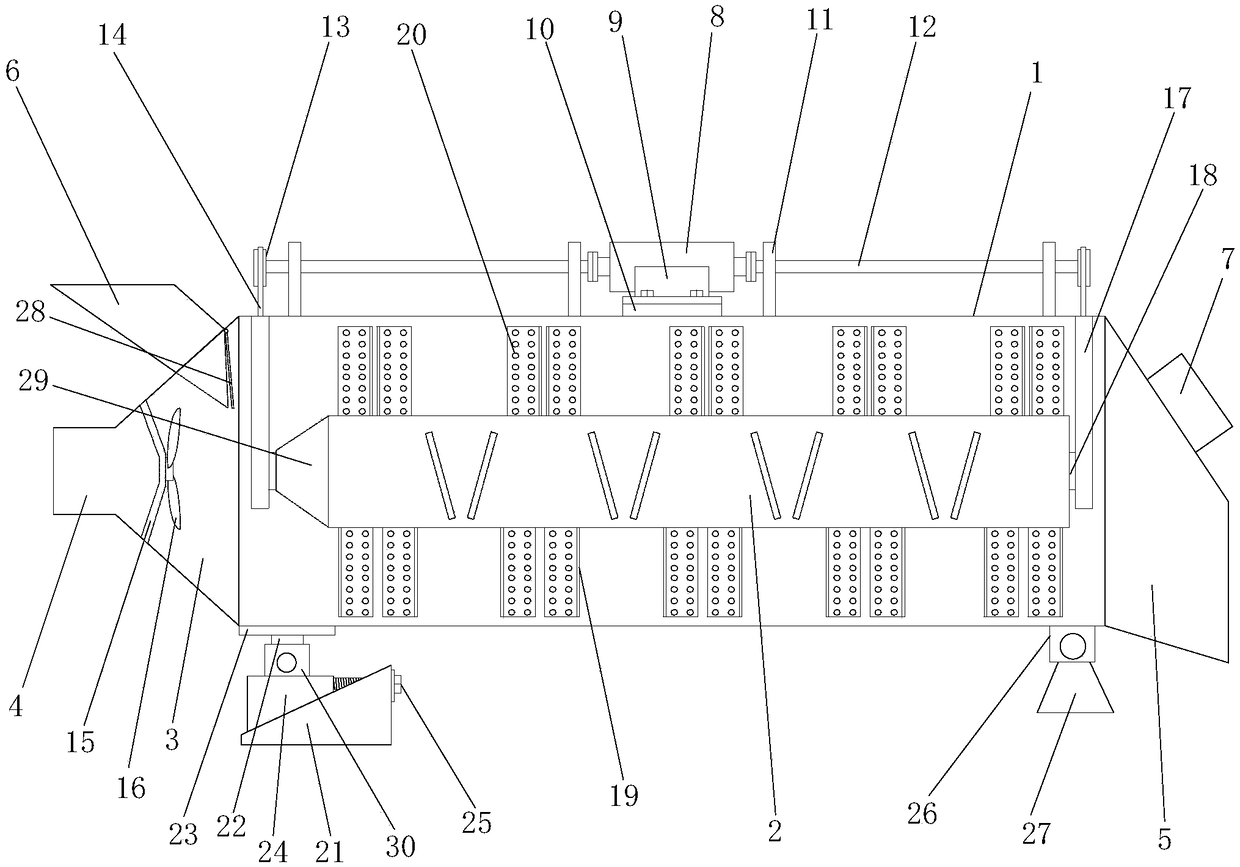

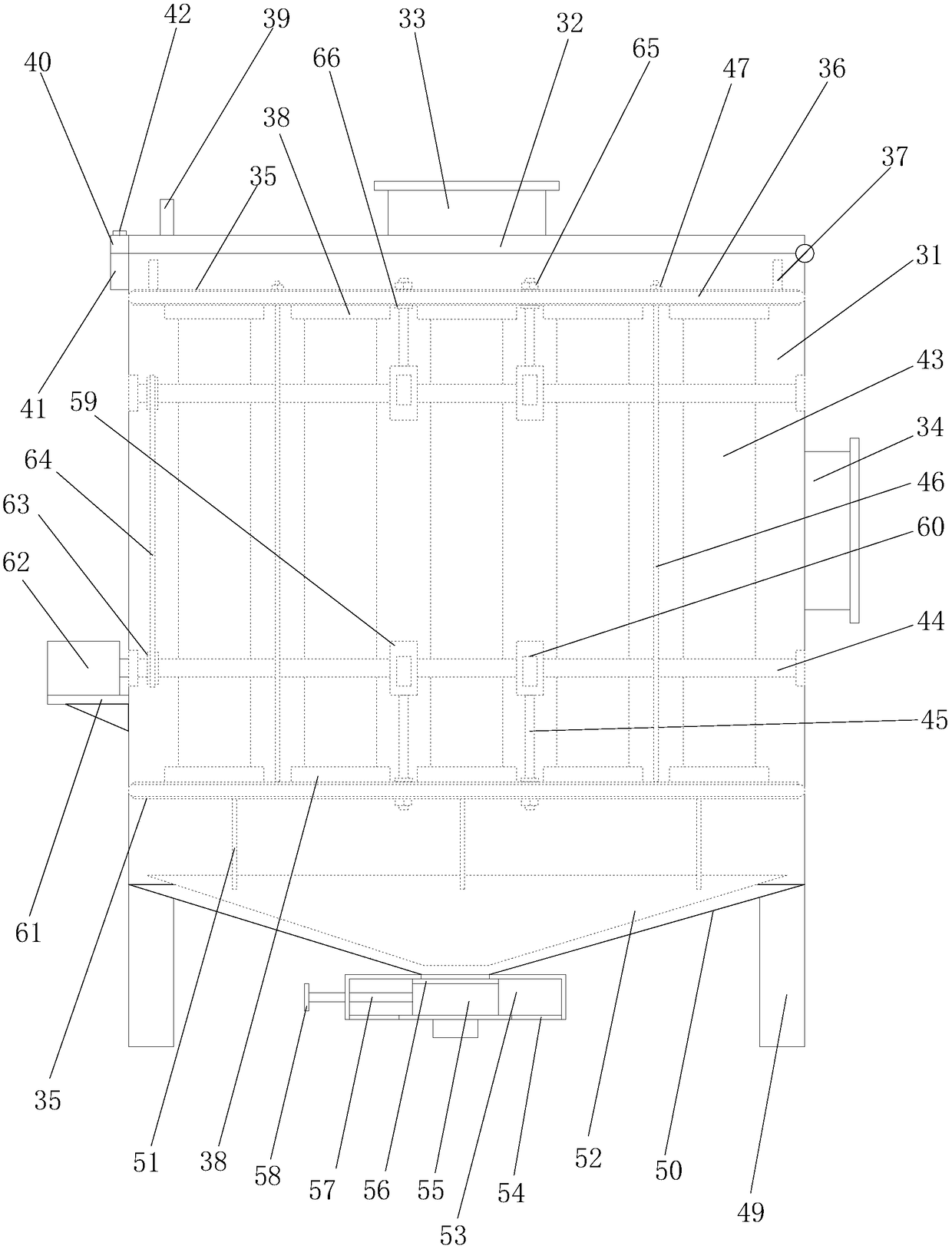

[0023] like Figure 1-3 As shown, the environmentally friendly rotary drying system disclosed by the invention includes: a rotary drum dryer and a self-cleaning filter element dust collector;

[0024]The rotary drum dryer includes a fixed cylinder 1, a rotary drum 2, a double-axis head drive motor 8, two drive shafts 12, an air inlet cone cover 3 and a discharge channel 5; the fixed cylinder 1 is installed horizontally, and An upper hinged seat 26 and a support plate 23 are respectively provided below both ends of the fixed cylinder 1; a lifting adjustment mechanism is installed below the support plate 23, which is used to adjust the left end of the fixed cylinder 1 to be higher than the right end of the cylinder; the upper hinge The seat 26 is hingedly installed on the lower hinged seat 27; the double-axis head drive motor 8 is fixedly installed on the center of the upper side of the fixed cylinder 1 through the motor bracket 9; The left and right sides of the motor 8, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com