Hydrogenation method for quickly circulating fluidized silicon tetrachloride

A silicon tetrachloride, fast cycle technology, applied in the direction of halogenated silicon compounds, halogenated silanes, energy input, etc., can solve the problem of gas-solid contact conditions to be improved, low single-pass conversion rate of silicon tetrachloride, silicon tetrachloride treatment Quantity limitation and other problems, to achieve the effect of easy large-scale industrial production, reduced process energy consumption, and large operation flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

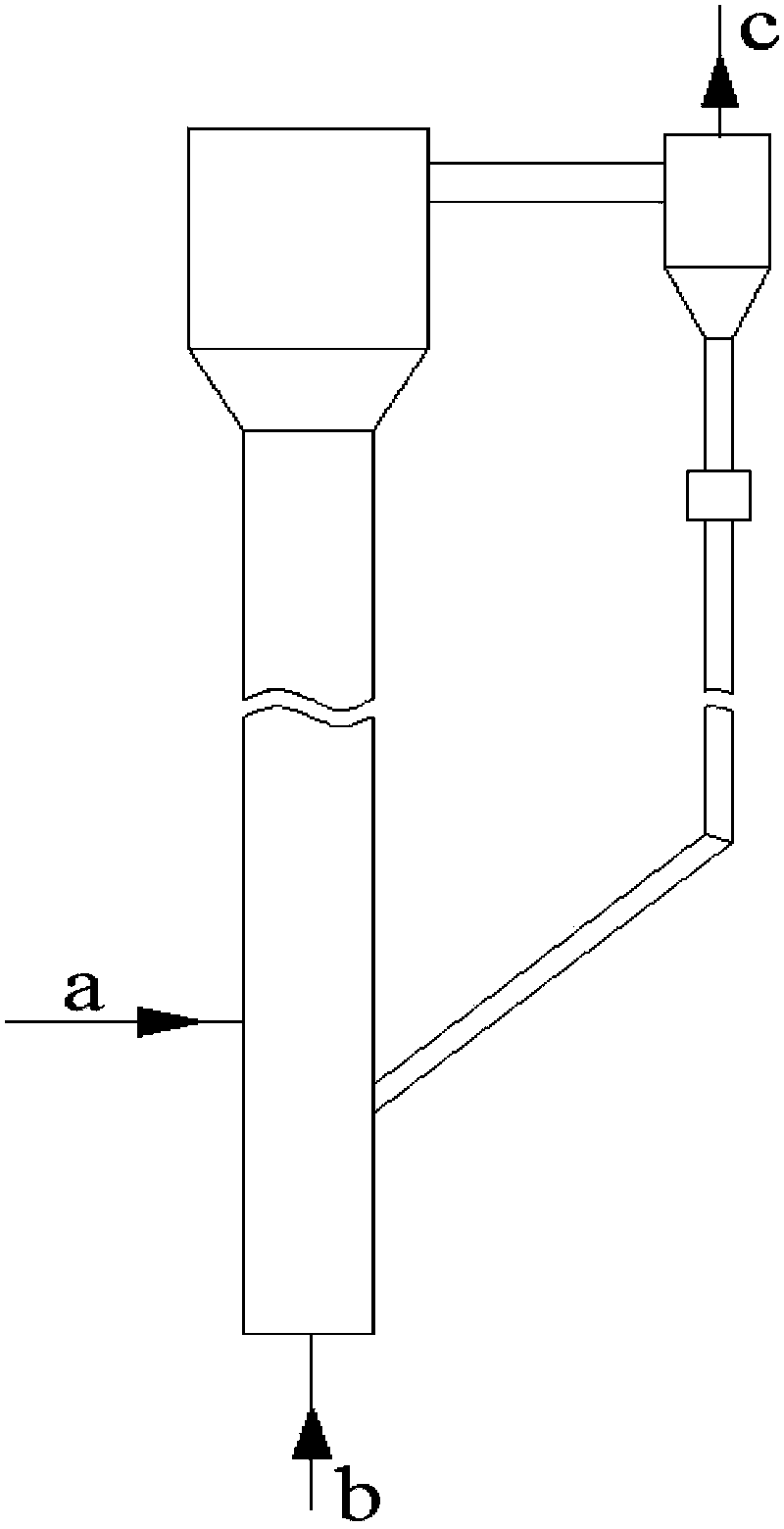

[0025] The accompanying drawing is a fast circulating fluidized bed hydrogenation reactor for silicon tetrachloride, a is the inlet for silicon powder, b is the inlet for silicon tetrachloride and hydrogen, and c is the outlet for product gas. The size of the reactor is as follows: the diameter and height of the reactor cylinder are 50mm and 3m respectively, and the diameter and height of the cylinder of the enlarged part are 150mm and 300mm respectively.

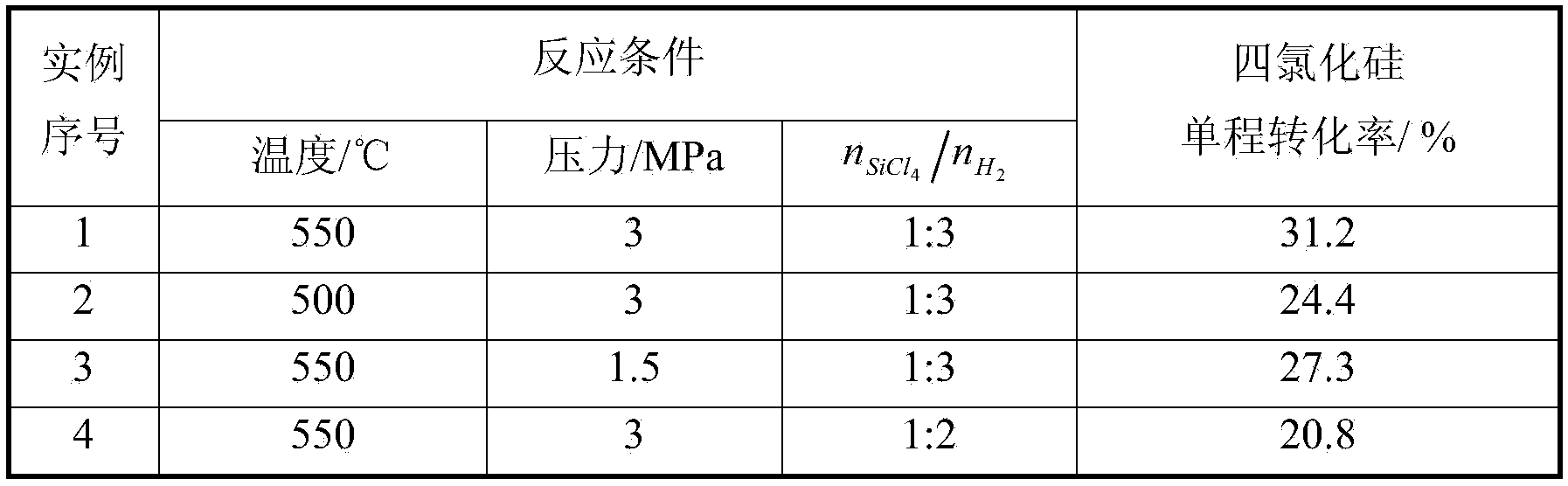

[0026] The silicon powder is added at one time to a height of 0.8m. First, 300°C nitrogen gas is passed through for 10 minutes to dry and activate. Then, silicon tetrachloride and hydrogen are continuously transported into the hydrogenation reactor after pressurization and electric heating for reaction. The product gas is condensed, and the content of trichlorosilane and silicon tetrachloride in the condensed liquid product is determined. Table 1 lists the per-pass conversion of silicon tetrachloride hydrogenation under var...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com