Reclaimed material drying apparatus

A drying device and recycled material technology, which is applied in roads, road repairs, roads, etc., can solve problems such as large agglomerates, difficult removal of asphalt, and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

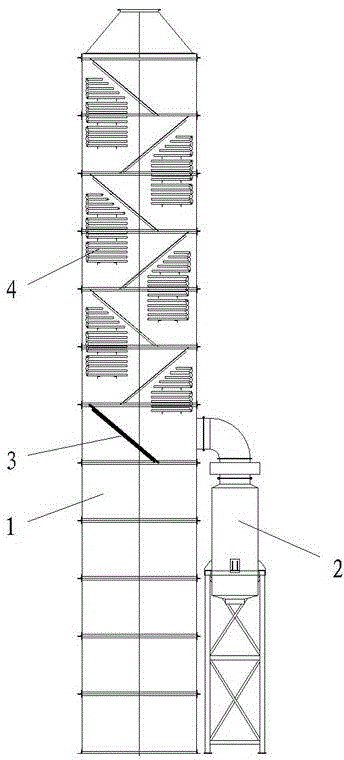

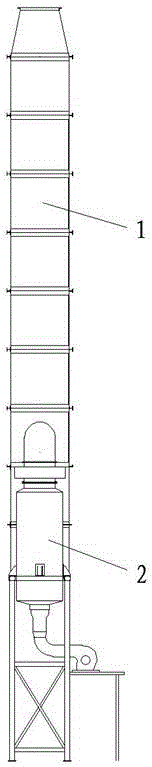

[0008] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but does not constitute any limitation to the present invention. figure 1 with figure 2 Shown, the present invention comprises hot blast stove 2 and the drying furnace 1 that is connected with hot blast stove 2, is provided with slideway in drying furnace 1, and radiator 4 is housed on the inner wall of drying furnace 1, and the drying furnace 1 The cross section is rectangular, and the slideways are two sets of oppositely staggered and downward-sloping slides 3 fixed on the inner wall, and the radiator 4 is located on the inner wall below the slides 3 .

[0009] When working, the crushed waste asphalt is input from the feed port on the top of the drying furnace 1, and the waste asphalt falls onto the slide board 3, and slides back and forth on two sets of opposite slide boards 3, and blows from the hot blast stove 2 in the process. The incomi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com