Cutting machine with adjustable staying duration

A cutting machine and long-term technology, applied in metal processing and other directions, can solve the problems of easy damage, difficult maintenance of electrical control devices, etc., and achieve the effect of convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

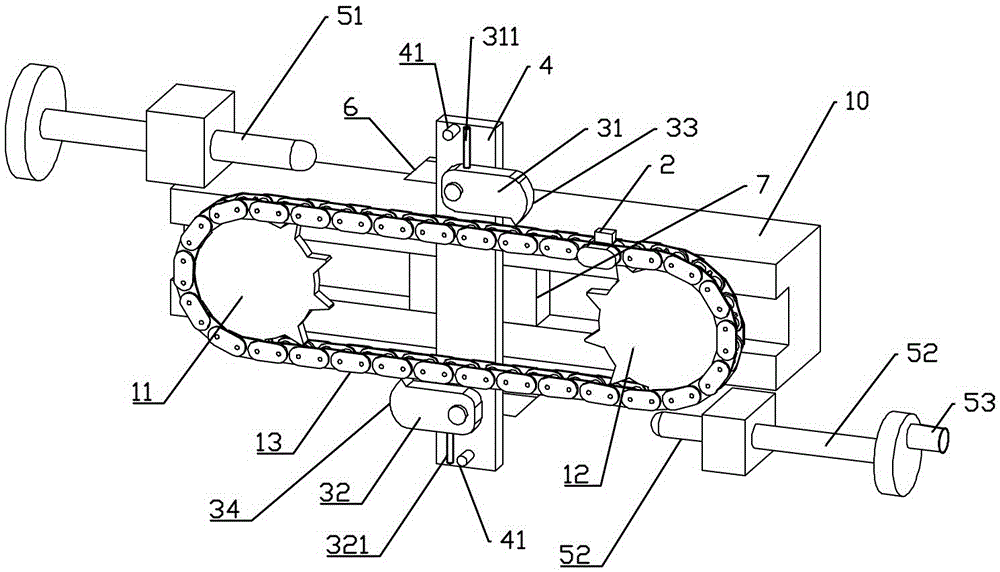

[0014] The reference numerals in the accompanying drawings of the description include: frame 10, driving sprocket 11, driven sprocket 12, transmission chain 13, trigger block 2, slide block 7, driven lever 4, first trigger claw 31, second Trigger pawl 32, first stop lever 51, second stop lever 52, slope 6, first trigger surface 33, second trigger surface 34, first limit lever 41, first swing lever 311, second limit Rod 42 , second swing rod 321 , rotating handle 53 .

[0015] Such as figure 1 The shown cutting machine with adjustable dwell time includes a frame 10, a motor, a transmission mechanism and a cutting knife, wherein the transmission mechanism includes a driving sprocket 11, a driven sprocket 12, a transmission chain 13, a driven mechanism, a second One stop lever 51, the second stop lever 52 and the cutter, the driving sprocket 11 and the driven sprocket 12 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com