Patents

Literature

53results about How to "Time adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

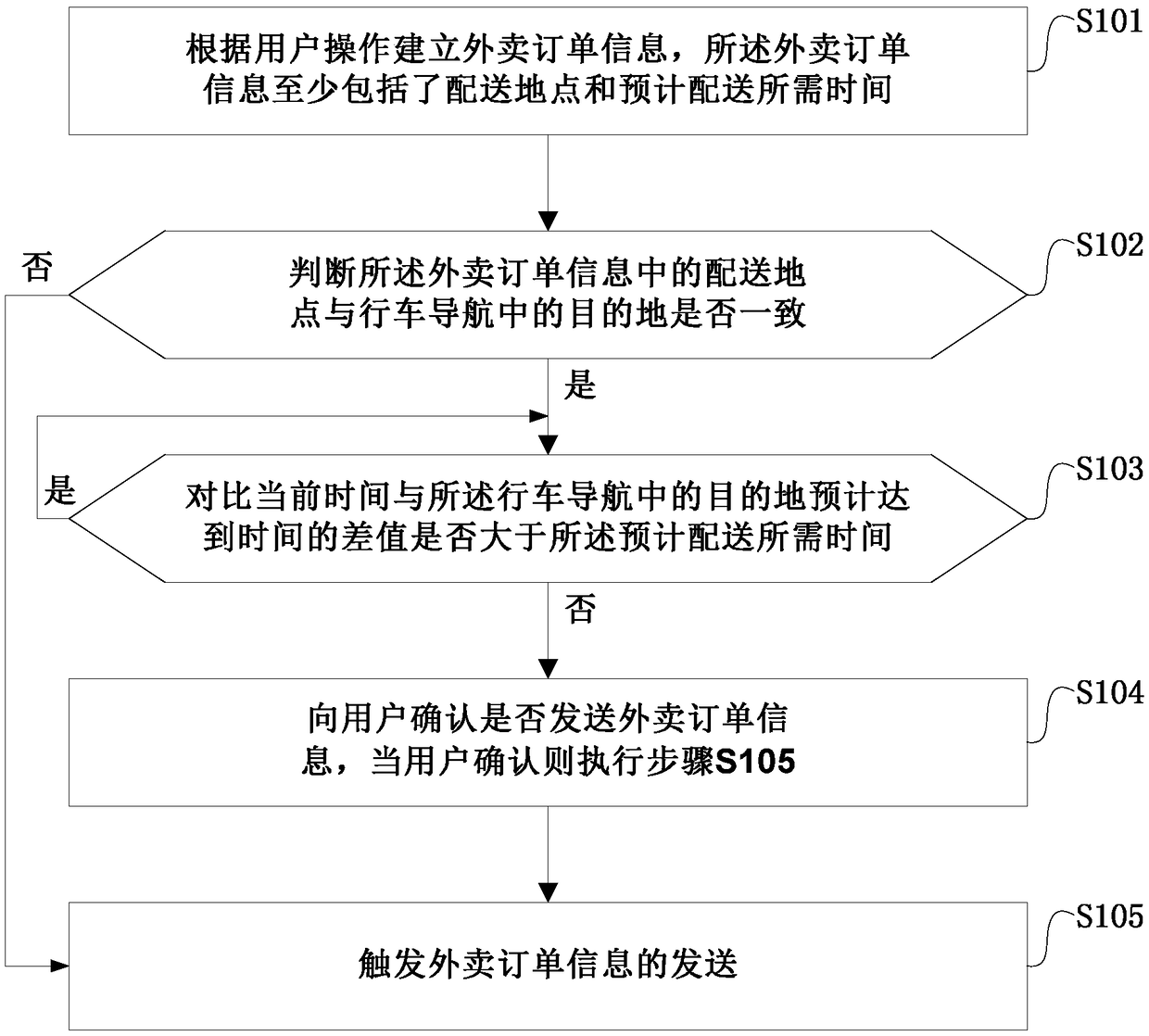

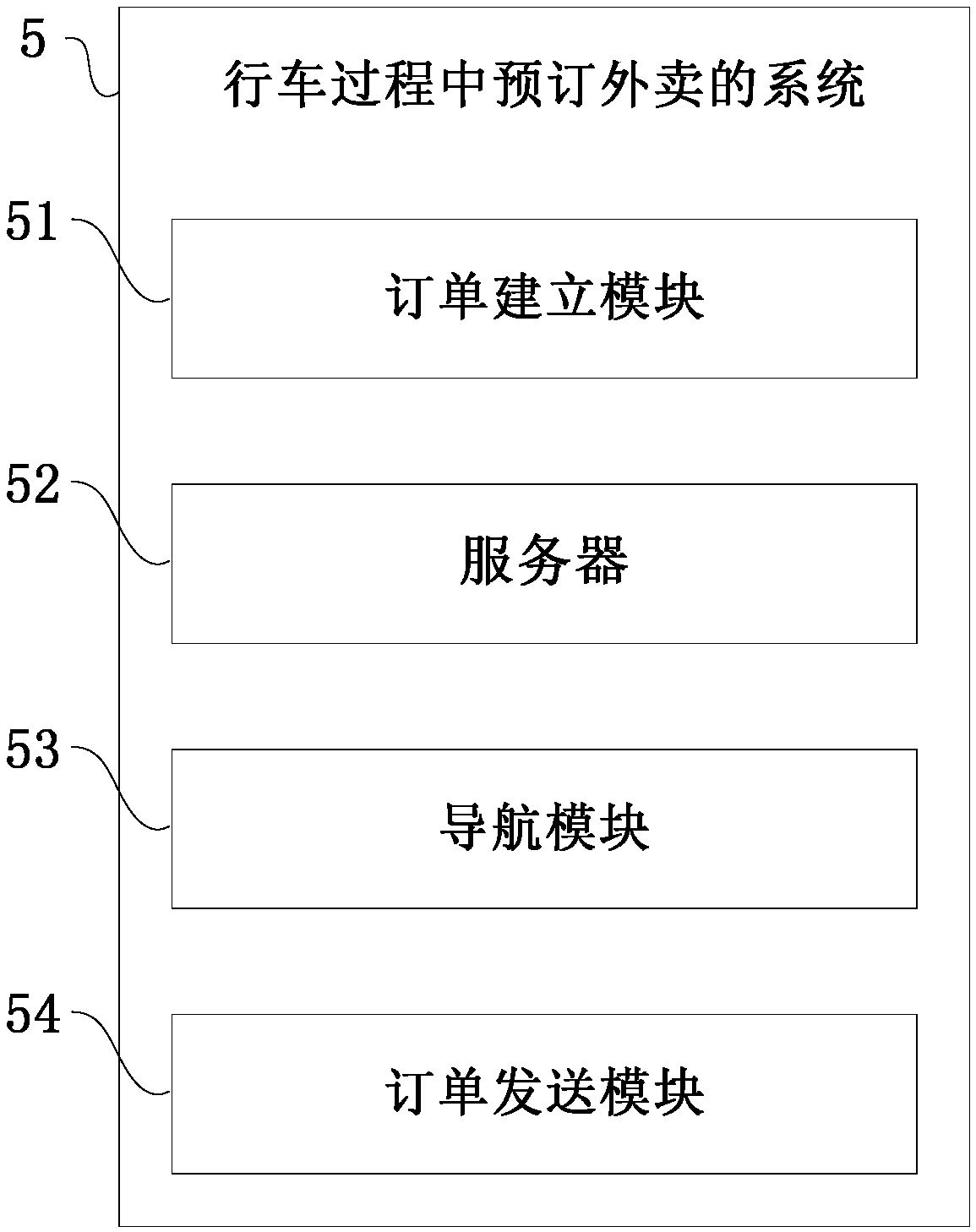

Method and system for ordering takeout during driving, apparatus and storage medium

InactiveCN109034951AConvenience guaranteedAvoid the problem of long waitsBuying/selling/leasing transactionsOrder formArrival time

The invention provides a method and system for ordering takeout during driving, an apparatus and a storage medium. The method comprises the following steps: establishing takeout order information according to a user operation, wherein the takeout order information at least comprises a distribution location and an estimated distribution time; when the delivery location in the take-out order information is consistent with the destination in the vehicle navigation, judging whether the difference between the current time and the estimated arrival time of the destination is greater than the estimated delivery time, and if not, triggering transmission of the delivery order information. The invention can timely adjust the time of ordering takeout according to the actual driving state, so as to ensure that the user can receive takeout in time, and meanwhile, the invention avoids the problem that the deliveryman delivering takeout waits for a long time, and ensures the convenience and timeliness of ordering takeout in the driving process.

Owner:AIWAYS AUTOMOBILE CO LTD

Rolled substrate for high temperature resistant smart card and method for making same

InactiveCN1603360AMeet the requirements of card making process, etc.Increase Vicat heat resistancePolyvinyl chlorideSmart card

A calendering substrate used for tolerance high-temperature smart card and its preparation method.In this invention,the vicat heat-resistant of PVC resin formulation is improved by adding the ABS resin in the PVC resin and make its softening point reach 90 DEG C + / - 2(vical A50-5kg).Comprehensiving the flame retardant better-rigid low-price characteristics of PVC and the anti-impact high vicat-softening point easy-processing characteristics of ABS,the SIM card calendering substrate has good printing performation which is suitable for making heat-resistant special card such as mobile phone SIM card.In order to prepare the substrate,it just need to modify the formulation of PVC and ABS and adjust the temperature roller speed and speed ratio time of the production process,but do not need to change the production equipment and device transformation of the common smart card.

Owner:上海达凯塑胶有限公司

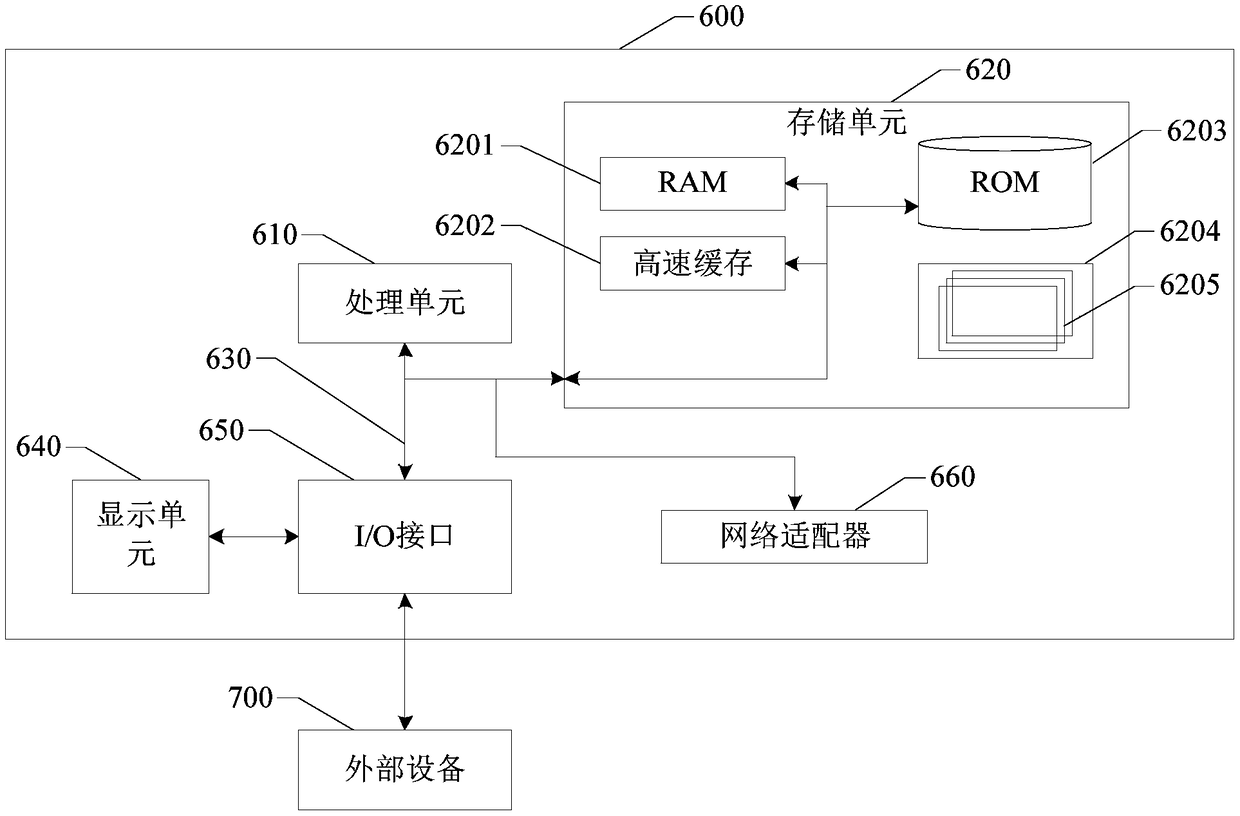

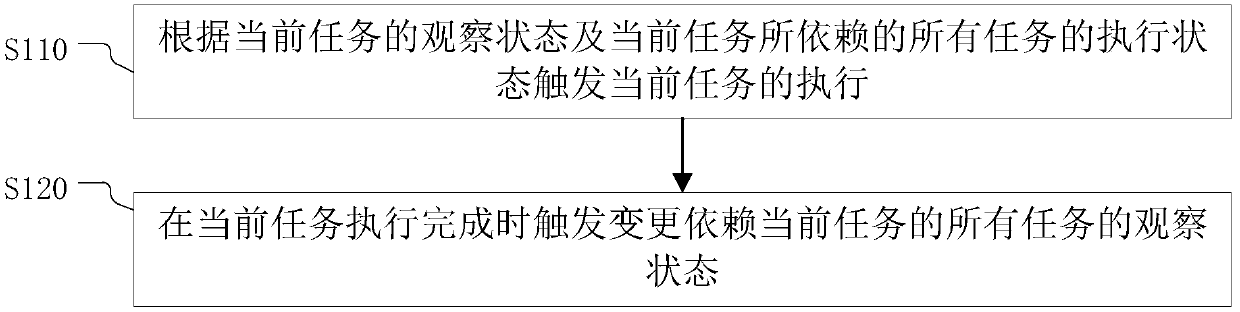

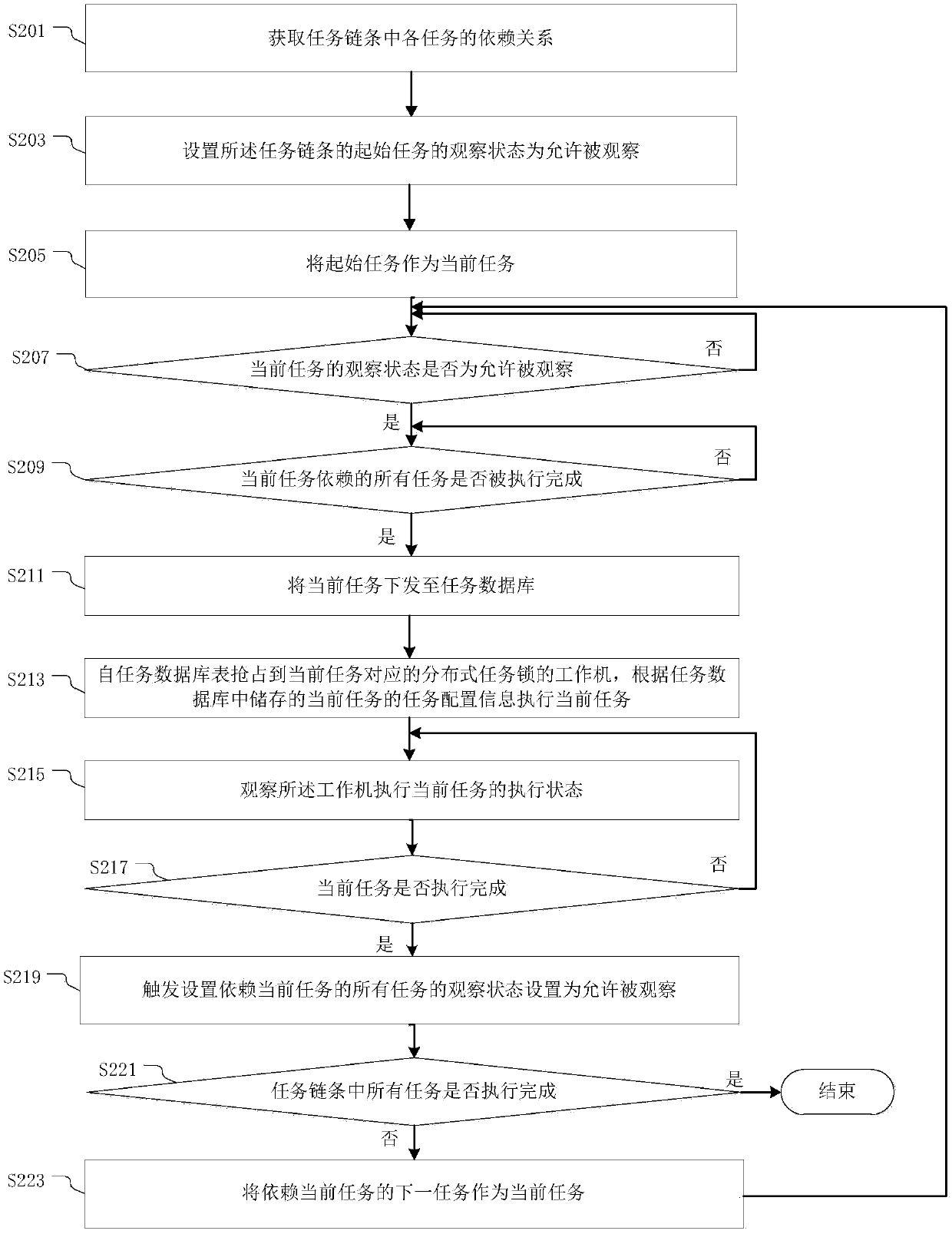

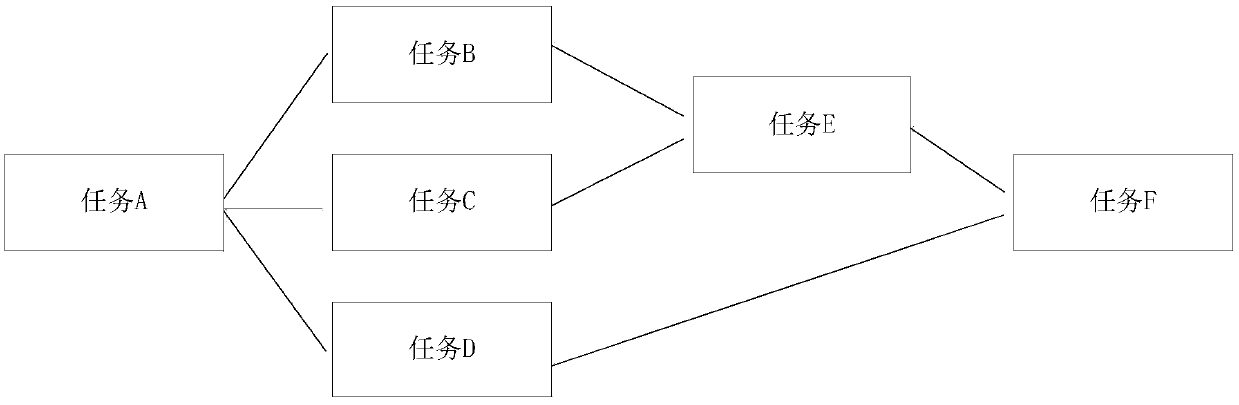

Distributed task scheduling method and device, electronic equipment and storage medium

PendingCN110858158AReduce waiting timeReduce production accidentsProgram initiation/switchingOperating systemDistributed computing

The invention provides a distributed task scheduling method and device, electronic equipment and a storage medium. The distributed task scheduling method comprises the steps of triggering execution ofa current task for each task of a task chain according to an observation state of the current task and execution states of all tasks on which the current task depends according to a sequence of dependency relationships of the tasks in the task chain; and triggering to change the observation states of all tasks depending on the current task when the execution of the current task is completed. Themethod and the device provided by the invention can improve the task execution efficiency.

Owner:JINGDONG TECH HLDG CO LTD

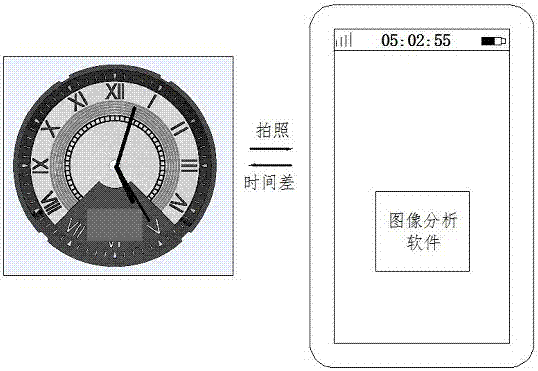

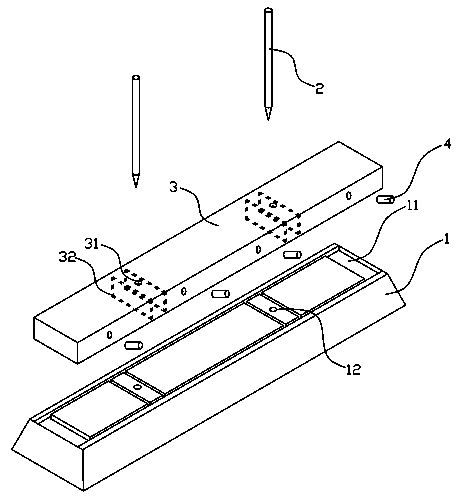

System capable of synchronize time of watch by image identification

ActiveCN107024860ATime adjustmentCharacter and pattern recognitionRadio-controlled time-piecesData transmissionImage analysis

A system capable of synchronize the time of a watch by the image identification comprises the watch, the watch comprises a movement, and the moment comprises a pointer and a dial. The pointer is connected with a stepping motor, the moment also comprises a controller connected with the stepping motor, and the system also comprises a mobile phone. The mobile phone comprises an image analysis software, and the image analysis software can start a lens of the mobile phone to shoot the dial of the moment and analyze a shot image to obtain the display moment of the dial. The mobile phone comprises a microprocessor, and the image analysis software can call the microprocessor to compare the display moment and the actual time when the image is obtained to obtain the time difference. The mobile phone can send the time difference to the watch via a wireless communication module, and the controller receives the time difference sent by the mobile phone and can adjust the pointer. By the above technical scheme, a user just needs to use the mobile phone to shoot the dial and transmit the processed data to the watch, so that the watch can synchronize and adjust the time automatically.

Owner:颍上县祥盛建设管理有限公司

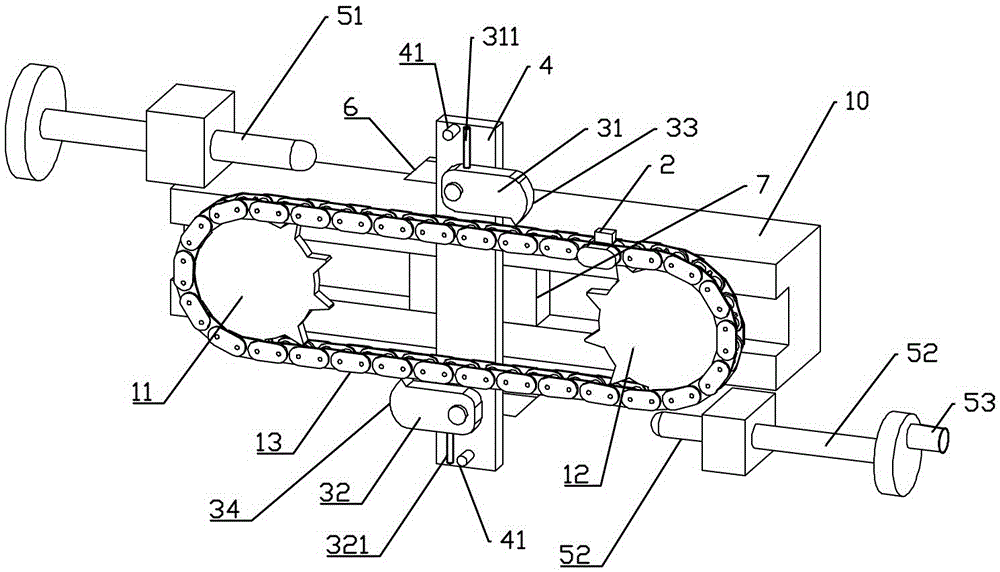

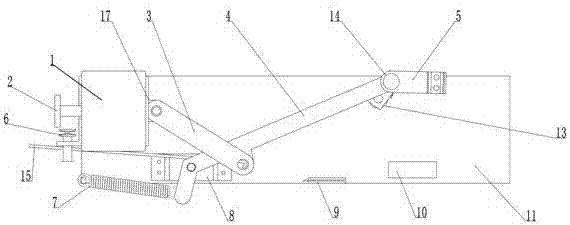

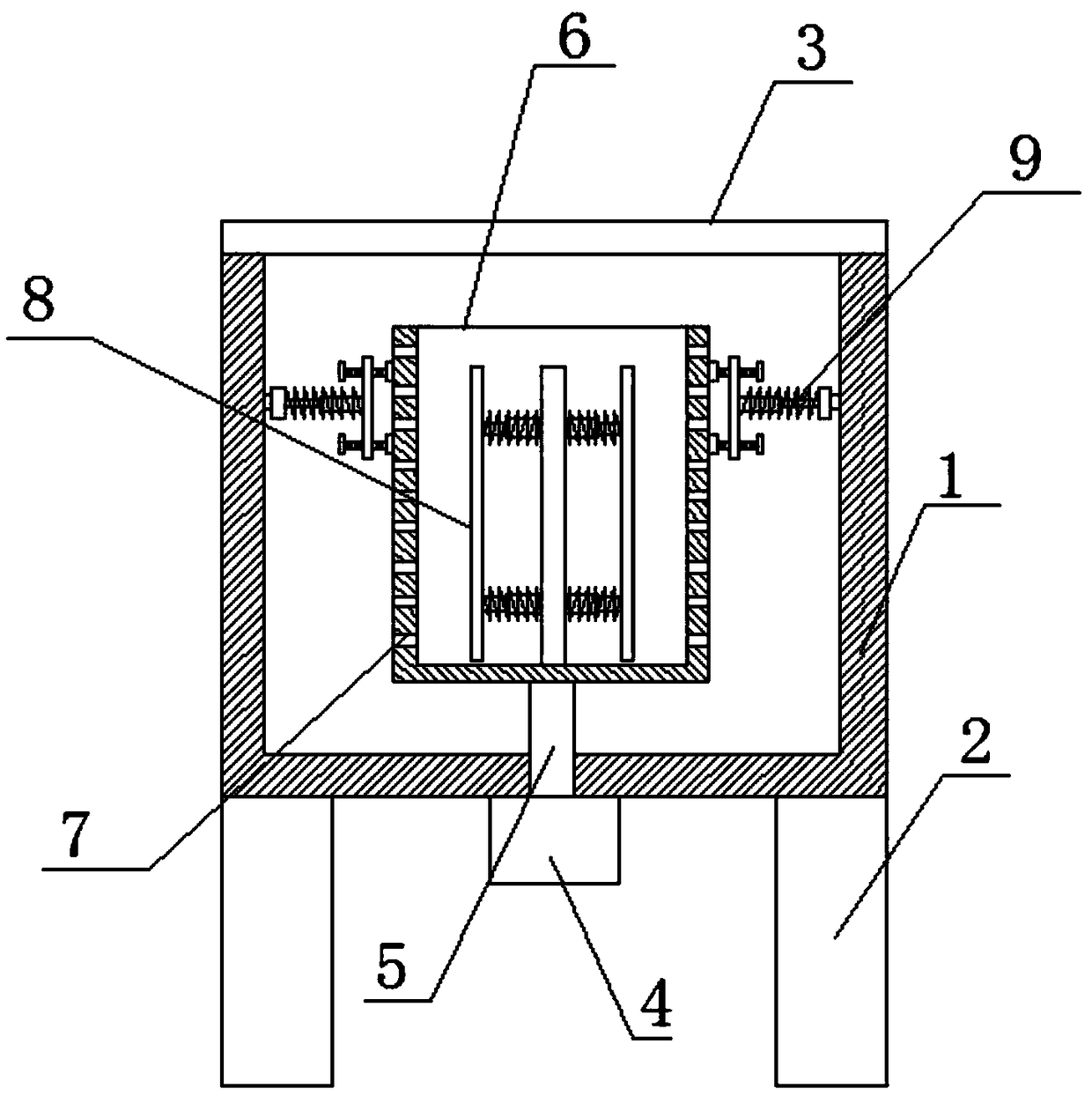

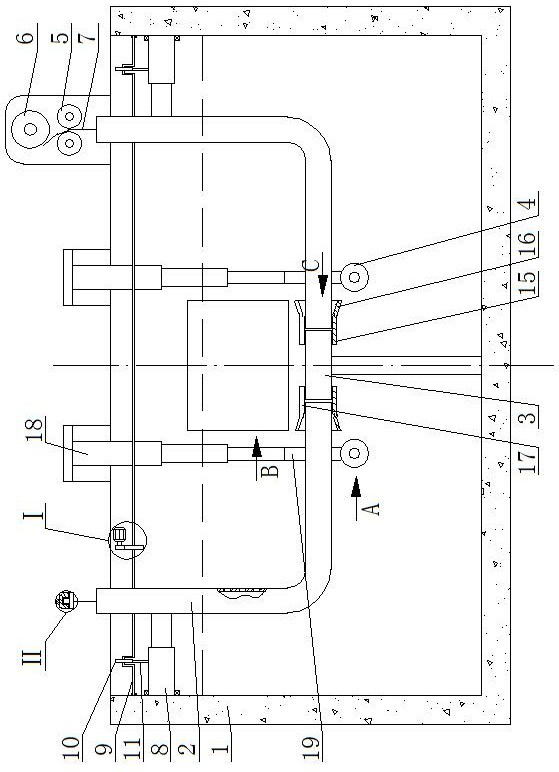

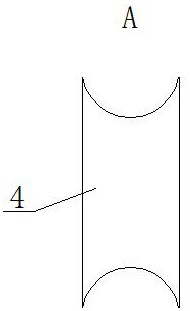

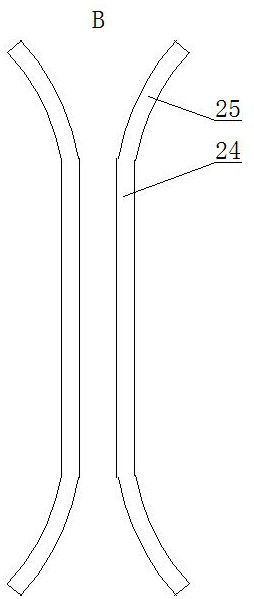

Cutting machine with adjustable staying duration

The invention relates to a transmission mechanism of a paper cutting device, in particular to a cutting machine with an adjustable staying duration. The cutting machine comprises a rack, a motor, a transmission mechanism and a cutting knife. The transmission mechanism comprises a drive chain wheel, a driven chain wheel, a transmission chain, a driven mechanism, a first stop rod, a second stop rod and a cutter. The drive chain wheel is equal to the driven chain wheel in size. The driven mechanism comprises a sliding block, a driven rod, a first triggering claw and a second triggering claw. The motor is connected with the drive chain wheel. The transmission chain is arranged outside the drive chain wheel and the driven chain wheel in a sleeving manner. A triggering block is fixed to the transmission chain. The invention aims at providing the purely-mechanical cutting device of which the cutting knife can stay for a period of time after primary cutting is finished.

Owner:DINGSHENG CORP

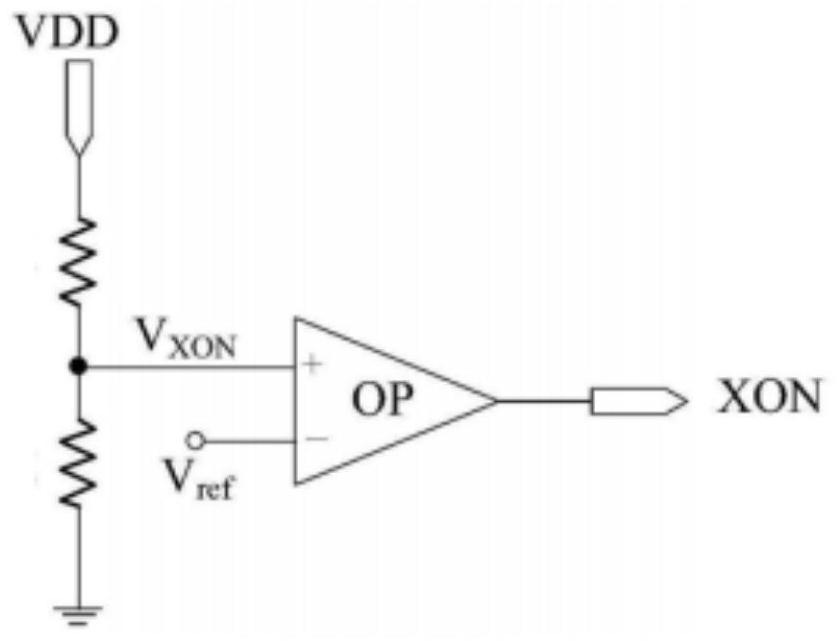

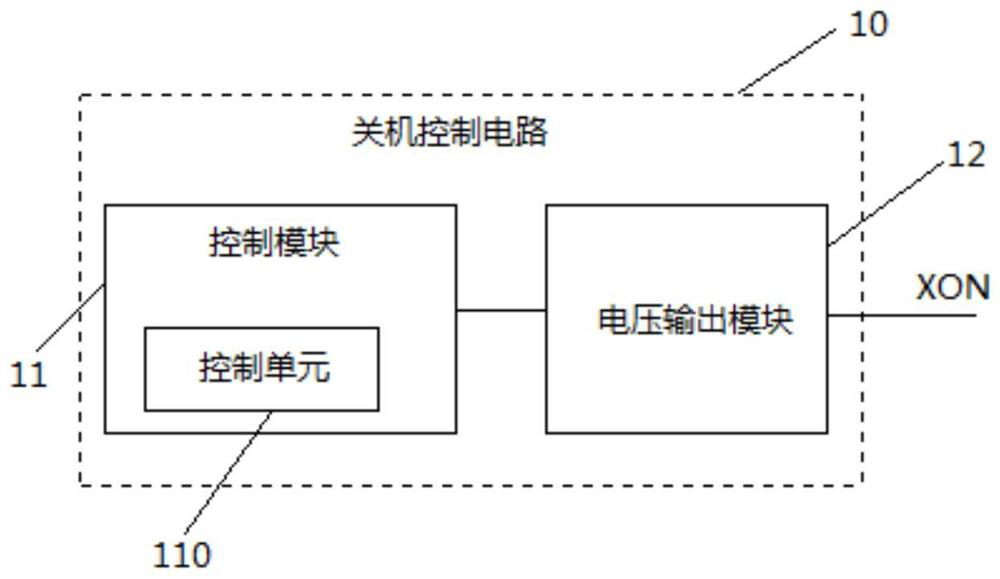

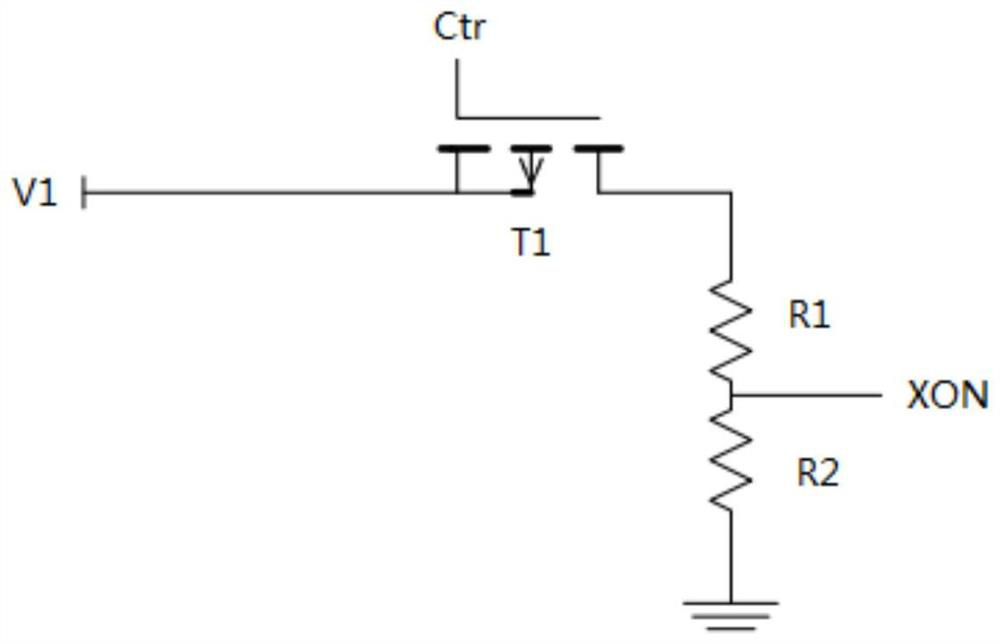

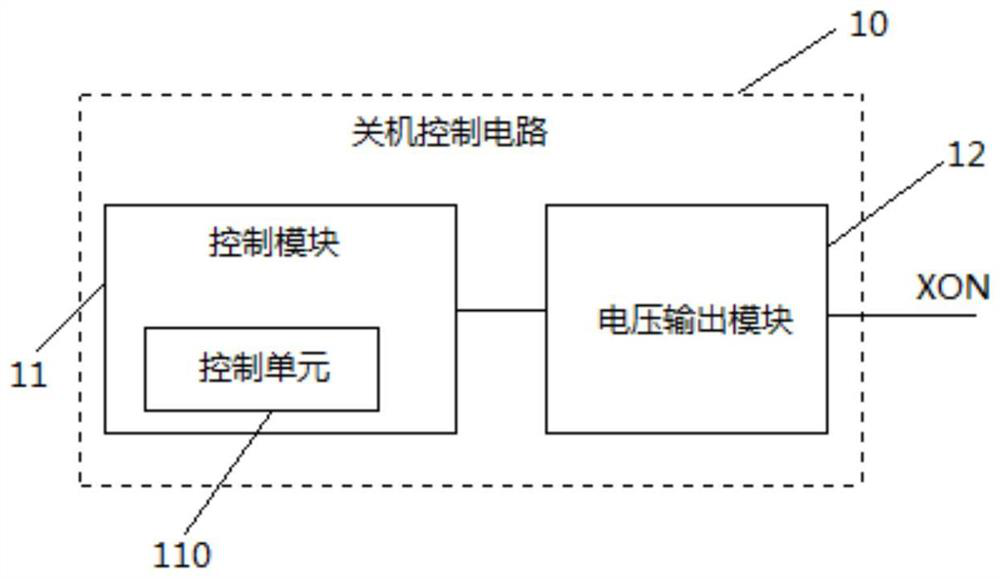

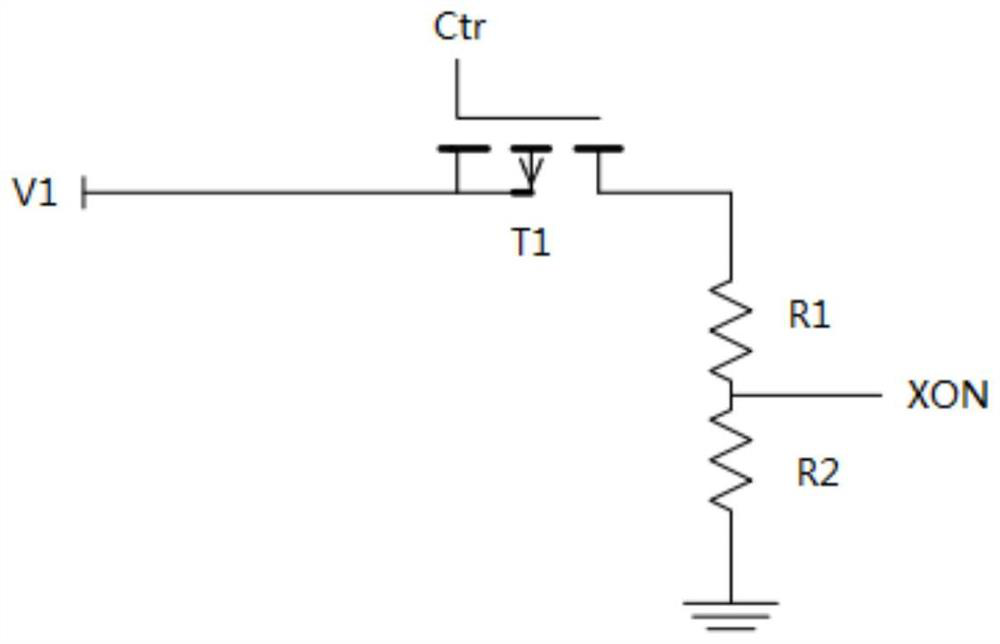

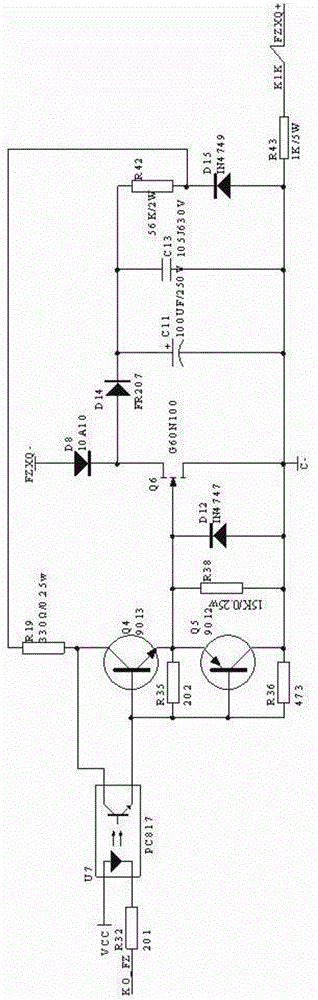

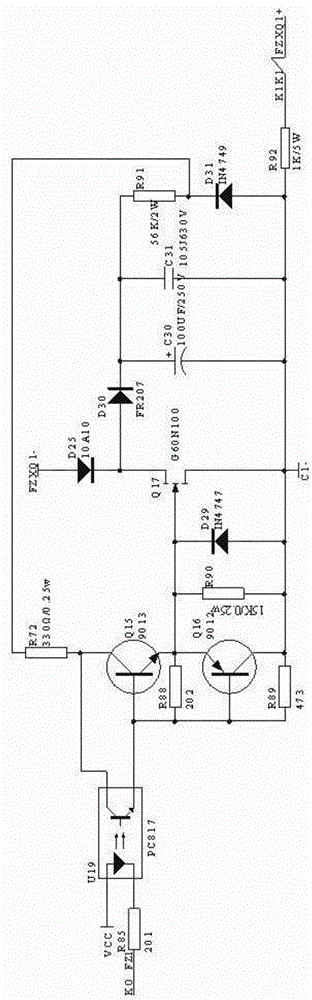

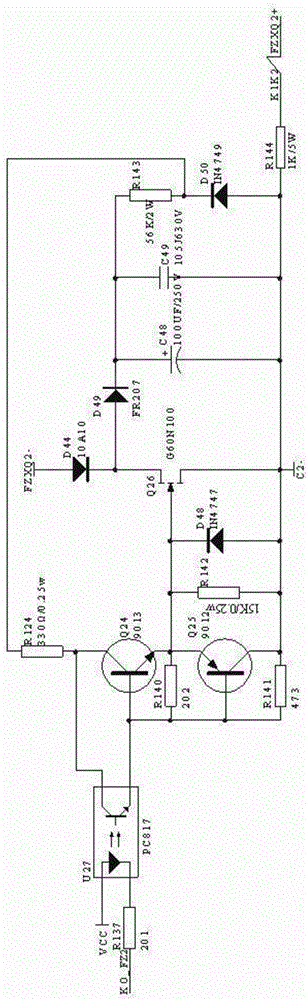

Shutdown control circuit, shutdown control method and display device

ActiveCN112735346ATime adjustmentExtension of timeStatic indicating devicesControl signalControl engineering

The invention relates to a shutdown control circuit, a shutdown control method and a display device. The shutdown control circuit comprises a control module and a voltage output module, wherein the control module comprises a control unit, and the control unit is used for starting timing after detecting that a front-end system stops transmitting data, and outputting an effective trigger signal after a preset time is up, so that the control module outputs an effective control signal; and the voltage output module is used for outputting an effective shutdown control signal according to the effective control signal, and the effective shutdown control signal is used for controlling the driving circuit to release residual charges of a pixel unit in the display device during shutdown. When the display device is shut down, the time for the pixel units to release the residual charges can be effectively prolonged, the shutdown residual image phenomenon is better eliminated, the time for the pixel units to release the residual charges can be effectively adjusted, and the product quality is improved.

Owner:KUSN INFOVISION OPTOELECTRONICS

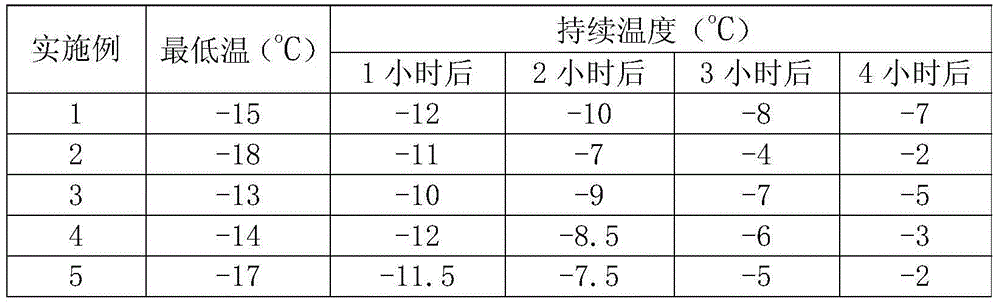

Chemical ice pack and preparation method thereof

InactiveCN104893675AExtended service lifeSlow down the dissolution rateHeat-exchange elementsAluminium sulfateAlcohol

The invention discloses a chemical ice pack and a preparation method thereof. The chemical ice pack is prepared by adopting the following components in parts by weight: 40 to 50 parts of ammonium nitrate, 70 to 80 parts of aluminum potassium sulfate dodecahydrate, 2 to 5 parts of sodium carboxymethylcellulose, 4 to 9 parts of ethyl alcohol, 15 to 30 parts of sodium chloride and 1 to 4 parts of sodium hydroxide. The preparation method of the chemical ice pack comprises the following steps: weighing each component according to the weight proportion, adding and stirring measured sodium carboxymethylcellulose in half of aluminum potassium sulfate dodecahydrate at a speed of 200 to 300 r / min, heating to 80 to 90 DEG C, stopping the heating when the solution is transparent, and naturally cooling the solution to the room temperature to obtain a solution A; sequentially adding ammonium nitrate, the rest aluminum potassium sulfate dodecahydrate and ethyl alcohol under the stirring state to obtain a solution B; finally sequentially adding sodium hydroxide and sodium chloride into the solution B, uniformly stirring, and encapsulating by utilizing a bag. The chemical ice pack is long in refrigerating time.

Owner:黄琳

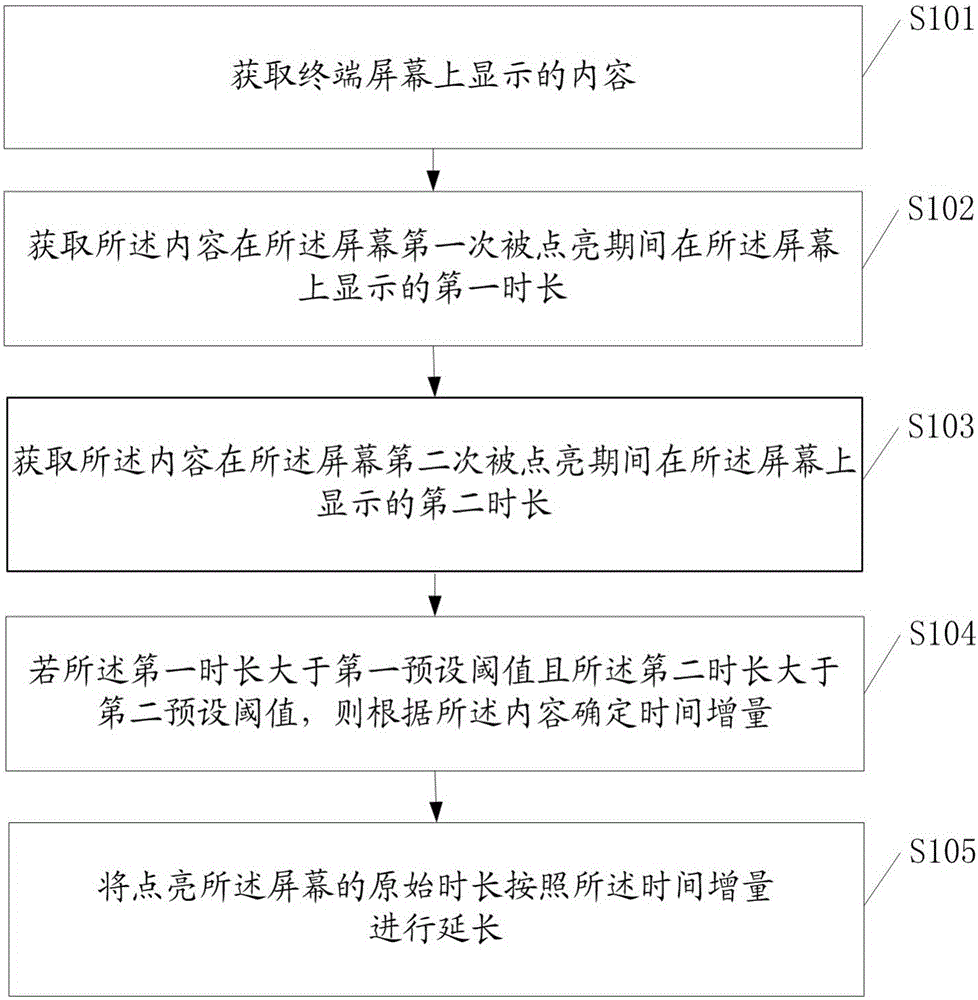

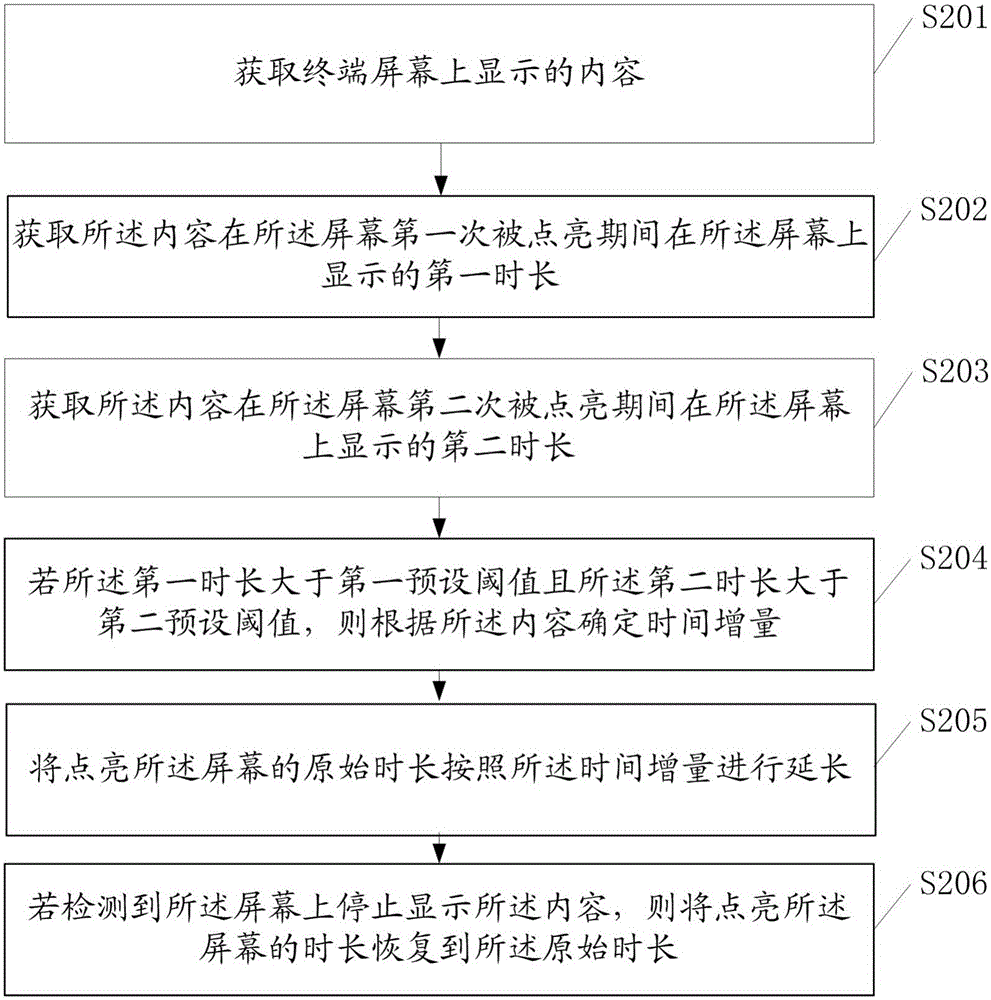

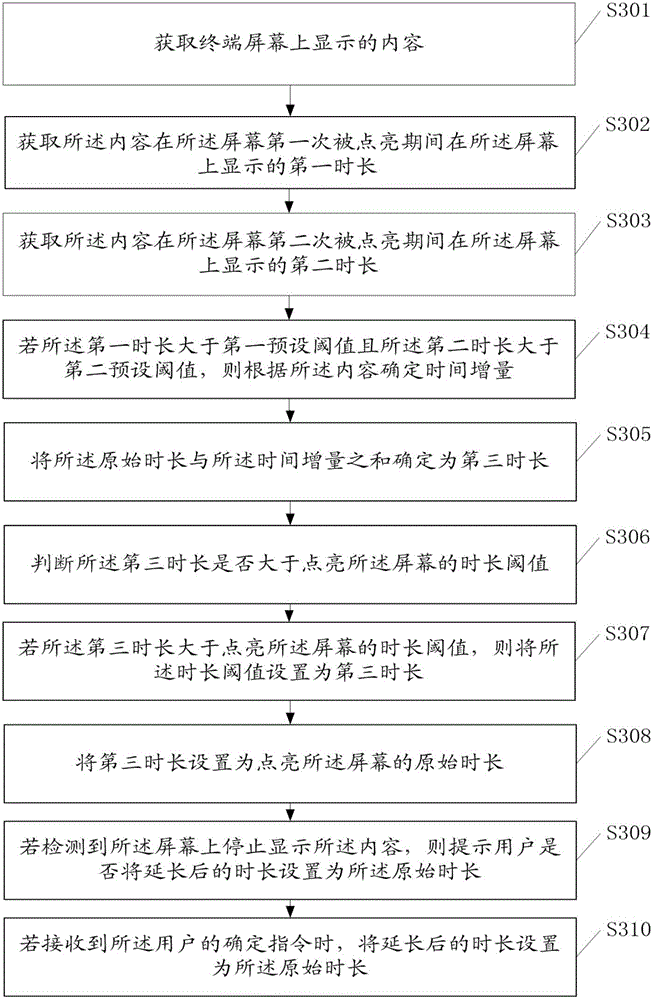

Duration adjusting method and terminal

InactiveCN106155520AImprove reading experienceTime adjustmentInput/output processes for data processingPhysical medicine and rehabilitationContent determination

The invention provides a duration adjusting method and a terminal. The method includes the steps that content displayed on a terminal screen is acquired; first duration of display of the content on the screen when the screen is turned on for the first time is acquired; second duration of display of the content on the screen when the screen is turned on for the second time is acquired; if the first duration is longer than a first preset threshold value and the second duration is longer than a second preset threshold value, time increments are determined according to the content; original duration for turning on the screen is prolonged according to the time increments. Thus, it can be known that by means of the technical scheme, screen turning-off time can be adjusted, and therefore the reading experience of a user is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

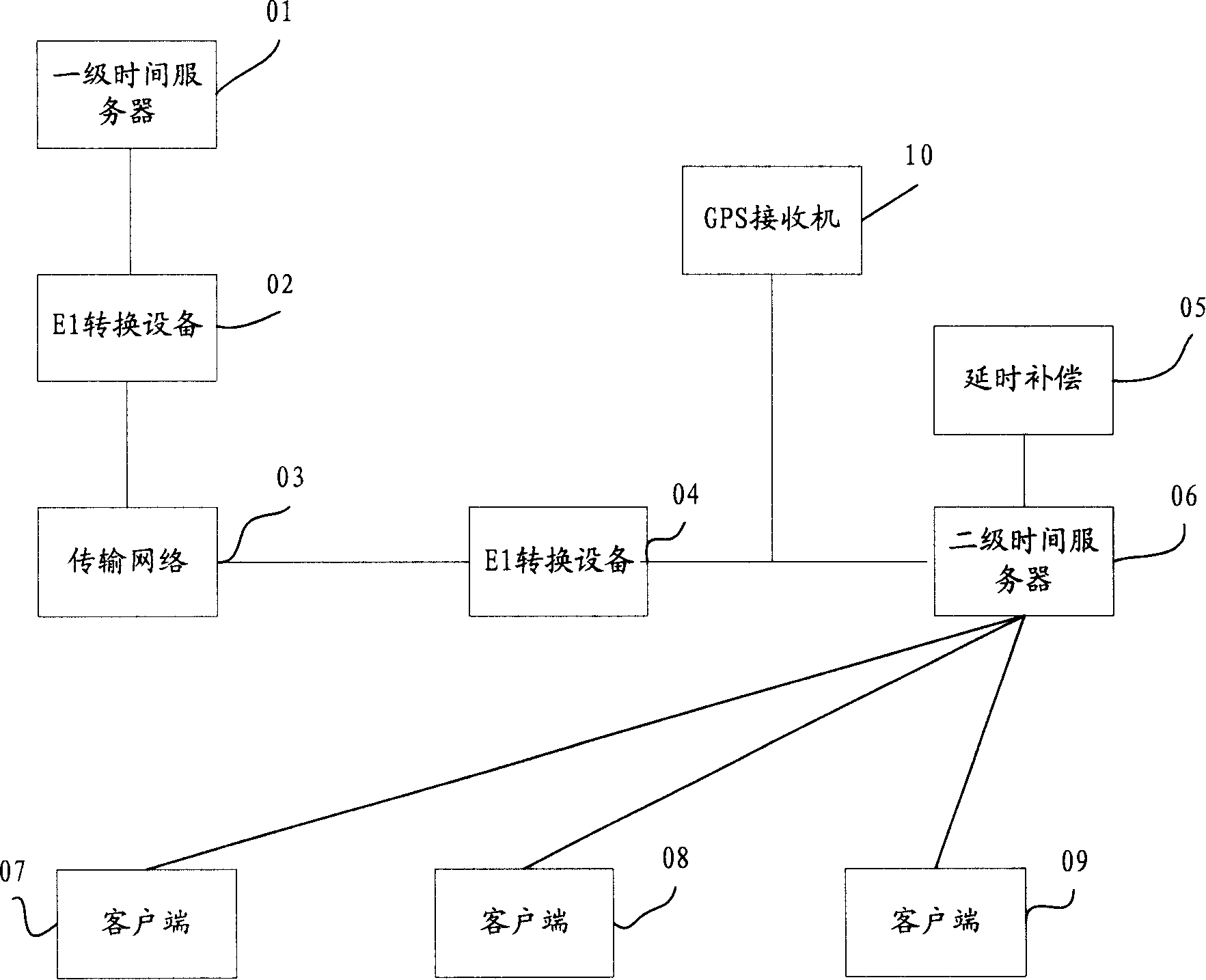

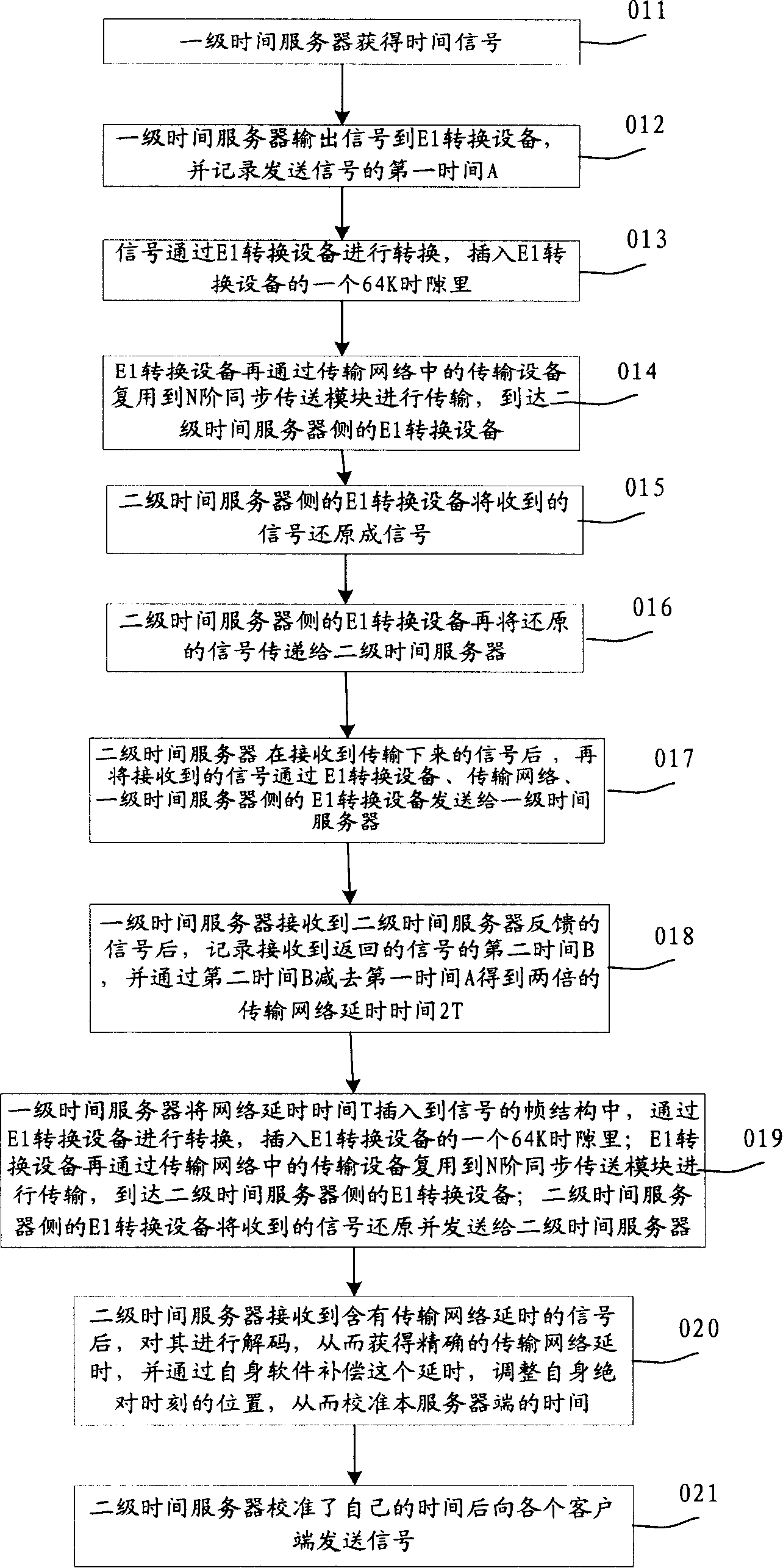

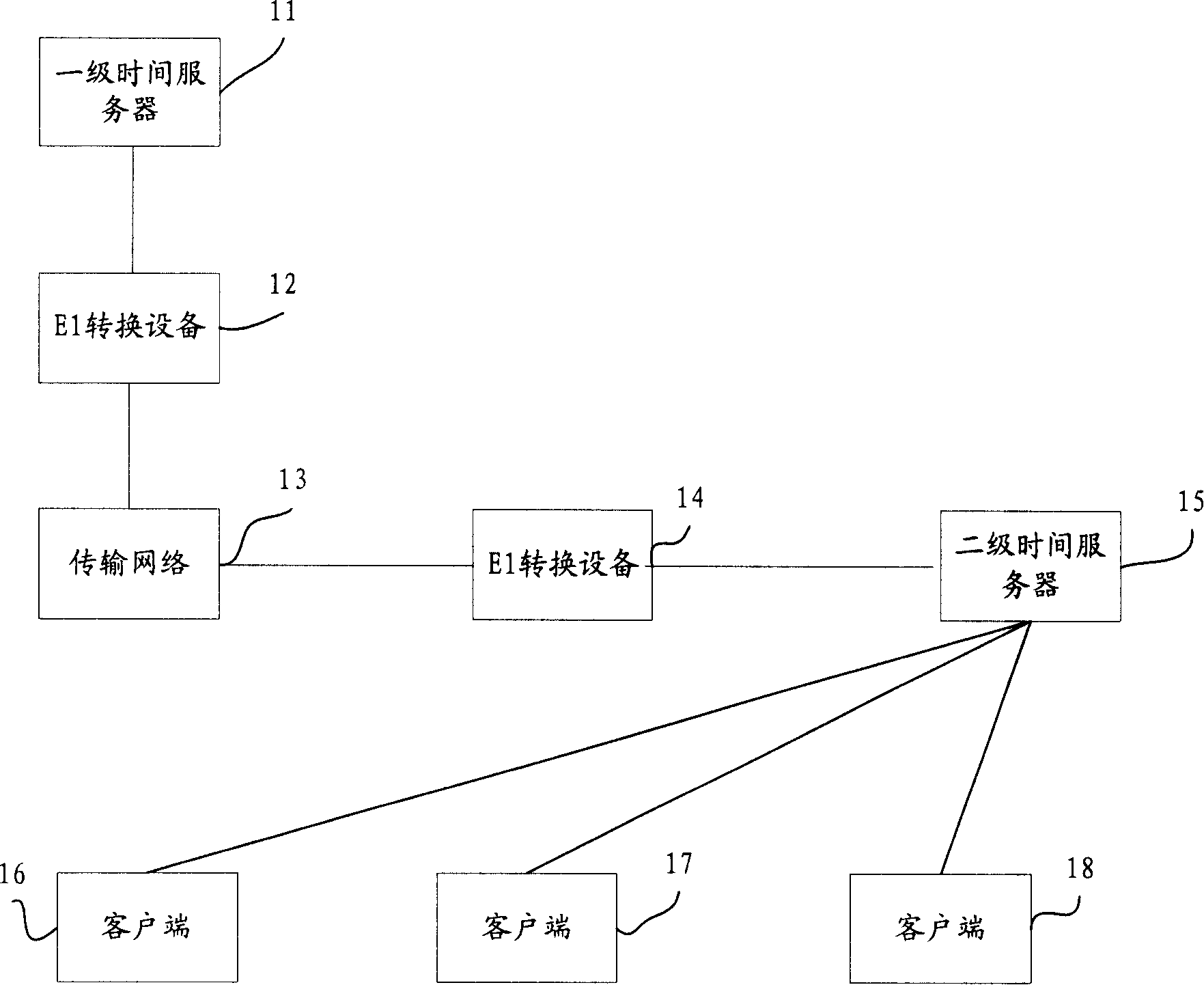

Method and system for adjusting network time

InactiveCN101170353ATime adjustmentAvoid inconvenienceTime-division multiplexRadio transmission for post communicationTransmission networkReal-time computing

The invention provides a method for adjusting network time, which includes the following steps: a Grade I time server obtains the delayed time of transmission network, and sends the time to a Grade II time server which adjusts the own time thereof to the coordinated universal time through the received delayed time of transmission network. The invention also provides a system for adjusting network time. The system includes an obtaining unit and an adjusting unit.

Owner:HUAWEI TECH CO LTD

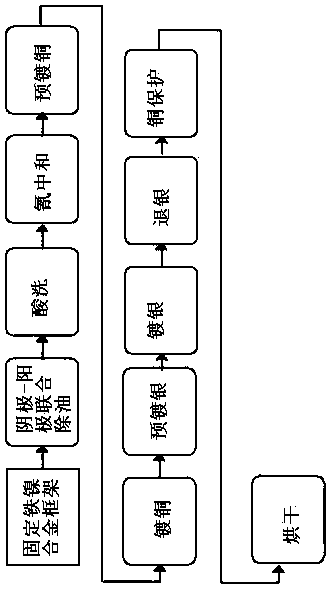

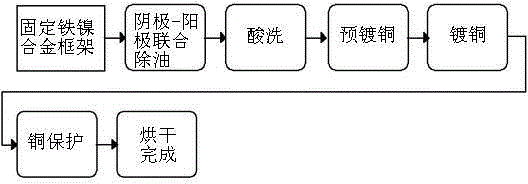

Method for electroplating copper and sliver on iron-nickel alloy frame

The present invention discloses a method for electroplating copper and sliver on an iron-nickel alloy frame. The method is characterized by comprising: 1, fixing an iron-nickel alloy frame; 2, carrying out cathode-anode combined degreasing; 3, carrying out acid washing; 4, carrying out cyanogen neutralization; 5, pre-plating copper; 6, plating copper; 7, pre-plating silver; 8, plating silver; 9, deplating sliver; 10, carrying out copper protection; and 11, drying, and taking the iron-nickel alloy frame from the bracket so as to complete the electroplating process. According to the present invention, the method has advantages of good electroplating effect and low cost.

Owner:TAIZHOU HUALONG ELECTRONICS

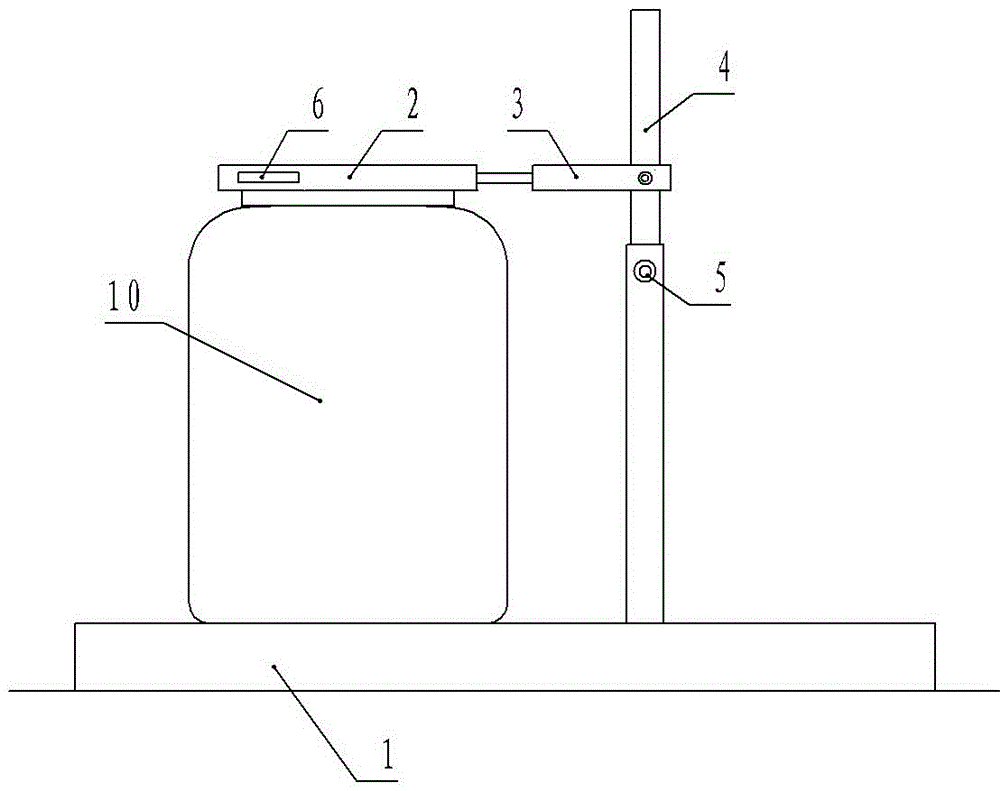

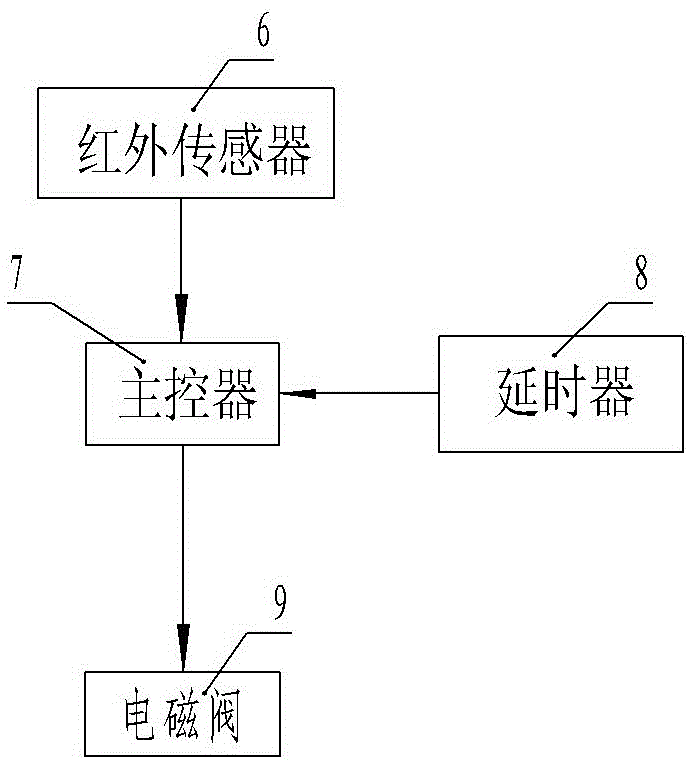

Medicamgent bottle opening and closing device and control method thereof

InactiveCN106214482AImprove cleanlinessRealize automatic controlPharmaceutical containersMedical packagingInformation controlElectricity

The invention discloses a medicament bottle opening and closing device and a control method thereof and belongs to the technical field of medical instruments. The device comprises a base and a supporting rod erected on the base, a cylinder transversely extending and controlled through an electromagnetic valve is arranged on the supporting rod, and a sealing cap for closing an opening of a medicament bottle is arranged at the extending end of the cylinder; an infrared sensor is arranged on the sealing cap and electrically connected with the electromagnetic valve through a controller, and the controller comprises a time delay unit connected with a main controller. The control method includes that the infrared sensor senses human infrared information and transmits the same to the main controller, and the main controller after receiving the information controls the electromagnetic valve to drive the cylinder to retract to open the opening of the medicament bottle; at the same time, the main controller outputs a signal to the time delay unit, and when the time delay unit reaches preset time, the time delay unit outputs a signal to the main controller to control the electromagnetic valve to enable the cylinder to extend to an original position to close the opening of the medicament bottle. By the medicament bottle opening and closing device and the control method, the problems of inconvenience in manual operation and unhealthiness of a medicament due to long-time opening of the medicament bottle can be solved.

Owner:郭翠莲

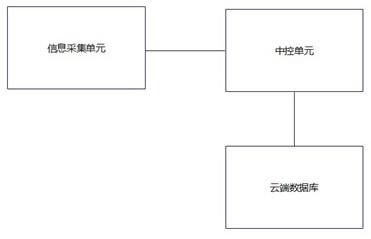

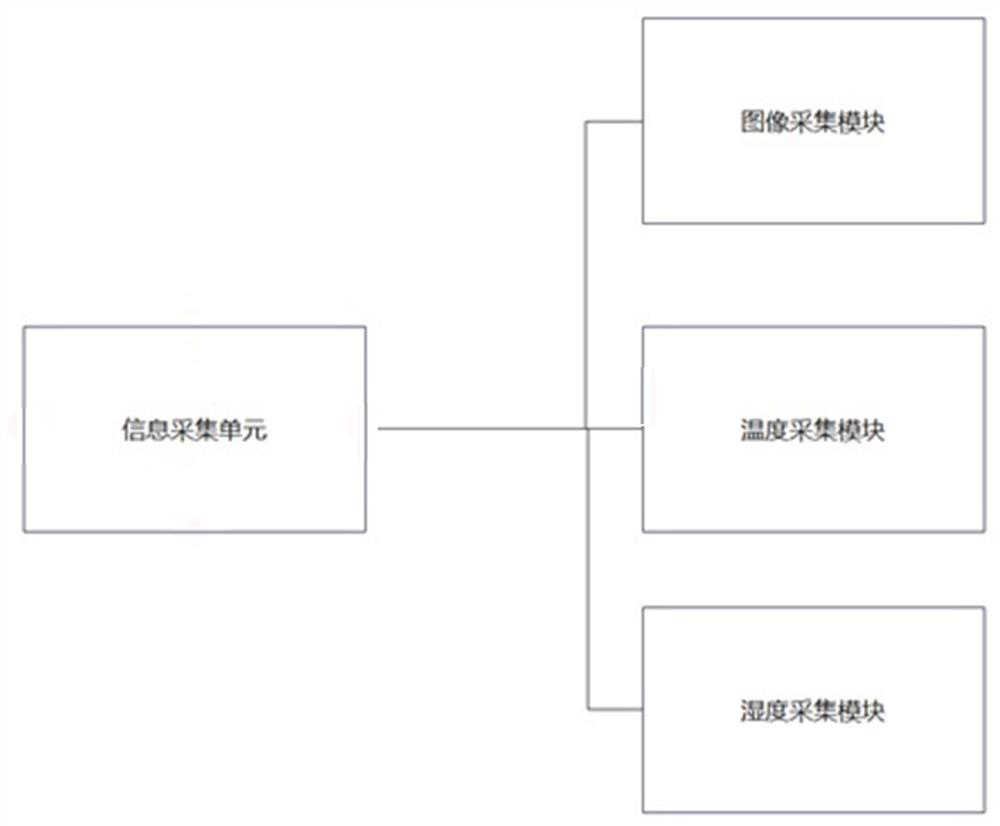

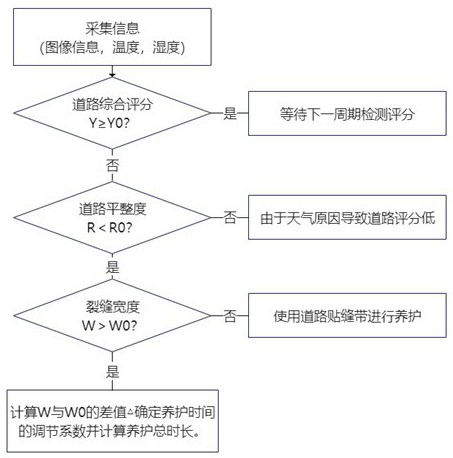

Evaluation monitoring platform based on road maintenance

ActiveCN114878796AImprove maintenance effectExtended service lifeImage enhancementImage analysisRoad surfaceInformation acquisition

The invention relates to the technical field of road maintenance, in particular to an evaluation monitoring platform based on road maintenance. The flatness, the humidity and the temperature of a road surface are monitored in real time through the information acquisition unit and the central control unit, corresponding data are analyzed and compared to comprehensively score the road, the crack degree of the road is analyzed according to the road scoring condition, and the maintenance time and the maintenance mode are determined. The road surface condition and the crack condition are accurately analyzed, the problems that inconvenience is brought to traffic by manual on-site detection and the safety of workers is poor in manual detection are solved, the labor cost and the time cost needed by the manual on-site detection mode can be reduced, and the influence of road maintenance on urban traffic is reduced; according to the invention, reinspection is carried out on the maintained pavement and periodical detection is carried out on the daily road pavement, so that the road maintenance effect can be improved, and the service life of the road is further prolonged.

Owner:唐山陆达公路养护有限公司

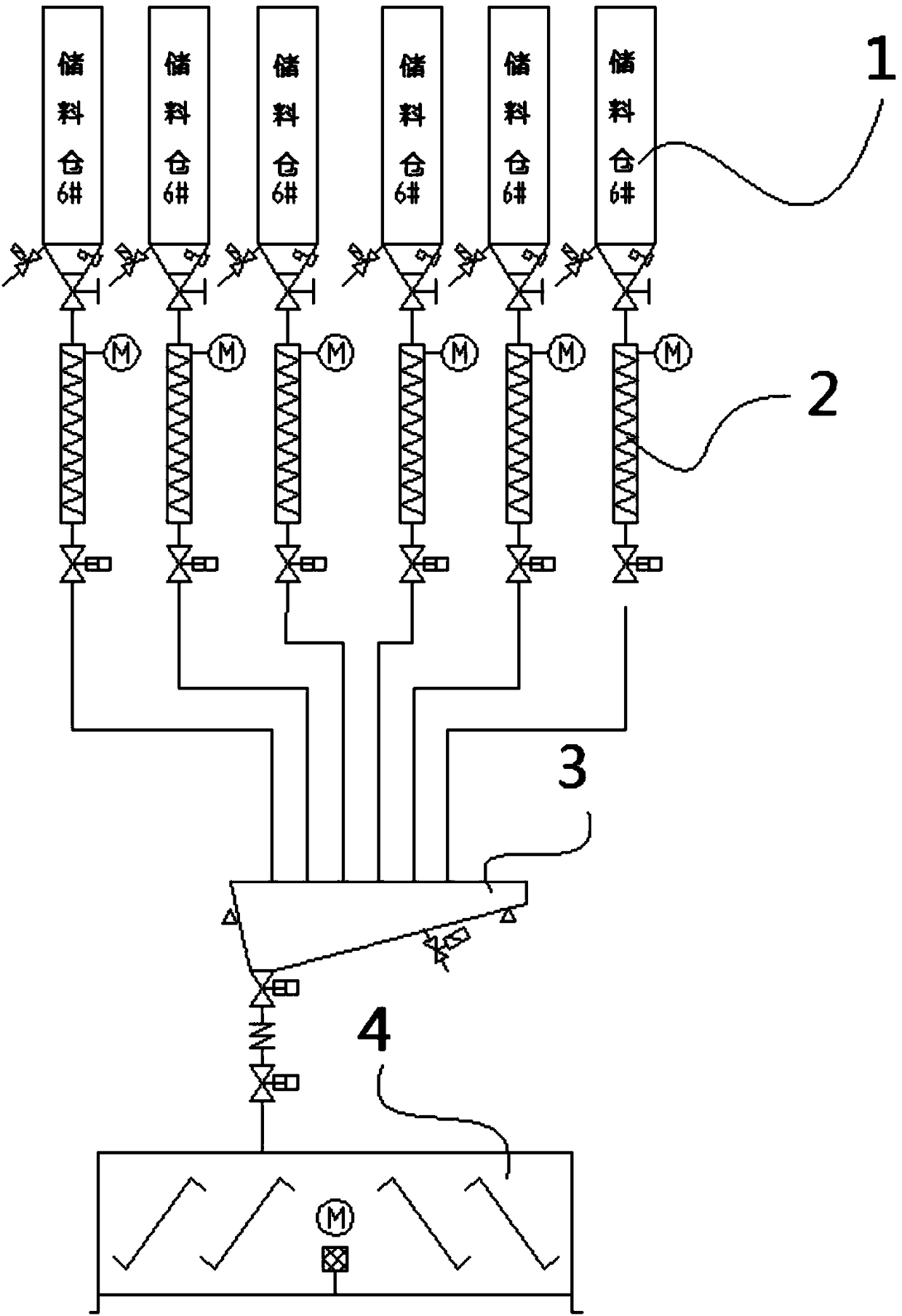

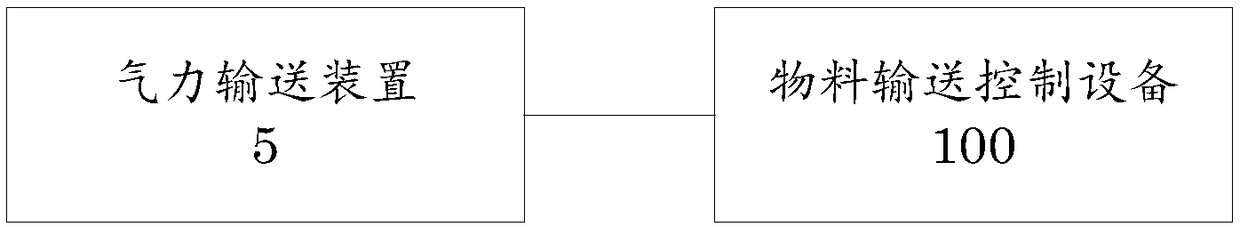

Material conveying control method, device and system

InactiveCN108262860ATime adjustmentFlexible locationSold ingredients supply apparatusProduction lineVolumetric Mass Density

The embodiment of the invention provides a material conveying control method, a material conveying control device and a material conveying system. The device comprises a receiving device for receivingweight, density and conveying distance of materials to be conveyed and a control device for determining an initial conveying pressure according to the weight, density and conveying distance of the materials to be conveyed, and controlling a pneumatic conveying device to convey the materials to be conveyed at the initial conveying pressure. Through the above technical scheme, by adopting the pneumatic conveying device, the position arrangement between a material conveying end and a receiving end can be more flexible, and the pneumatic conveying device can also adjust conveying speed of the materials by adjusting conveying pressure, so that the time of the material conveying can be flexibly adjusted to more flexibly meet production line requirements for production efficiency.

Owner:ZOOMLION HEAVY IND CO LTD

Method for watch time checking by image identification

InactiveCN106990711ATime adjustmentCharacter and pattern recognitionRadio-controlled time-piecesData transmissionTime difference

A method for watch time checking by image identification comprises the following steps of 1, performing image obtainment of a dial of a watch; 2, analyzing an obtained image to obtain a display time when the dial is subjected to image obtainment; 3, comparing the display time in the step 2 with an actual time obtained by an image in the step 1 to obtain a time difference; and 4, according to the time difference in the step 3, adjusting the pointer of the watch. Through the above technical scheme, users only need to use the phone to take pictures of the dial, the processed data can be transmitted to the watch, and the watch can automatically adjust the time.

Owner:GUANGDONG APPSCOMM

Plating method for iron-nickel alloy frame

InactiveCN105463539AImprove conductivityCompliant with production use standardsJewelleryCopper platingSemiconductor chip

The invention discloses a plating method for an iron-nickel alloy frame. The plating method comprises the following steps that 1, the iron-nickel alloy frame is fixed, specifically, the iron-nickel alloy frame is fixedly hung on a bracket; 2, cathode-anode combined degreasing is conducted; 3, pickling is carried out; 4, copper pre-plating is conducted; 5, copper plating is conducted, specifically, the iron-nickel alloy frame subjected to copper pre-plating treatment is put into a copper sulfate electrolytic solution to be used as a cathode, a copper plate serves as an anode, and a power source is connected; after copper plating is finished, the iron-nickel alloy frame is washed by clear water for the third time; 6, copper protecting is carried out, specifically, the bracket is put in a copper protective agent solution, and it is ensured that the iron-nickel alloy frame is immersed into the solution entirely; a layer of colorless and transparent thin film is formed on the surface of the iron-nickel alloy frame; and 7, drying is carried out, specifically, the iron-nickel alloy frame is taken down from the bracket, and the plating process is completed. The iron-nickel alloy leading wire frame obtained through the plating method has the advantages that the conductive performance is good, and the production and use standards of a semiconductor chip are met.

Owner:TAIZHOU HUALONG ELECTRONICS

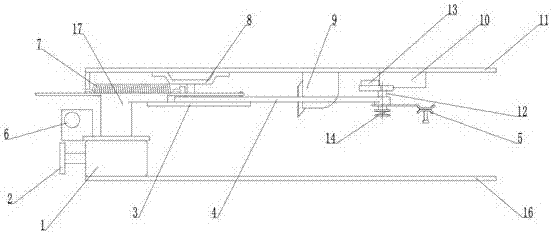

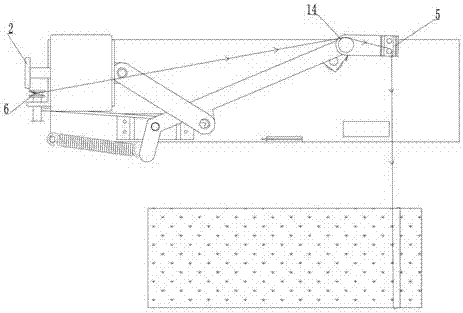

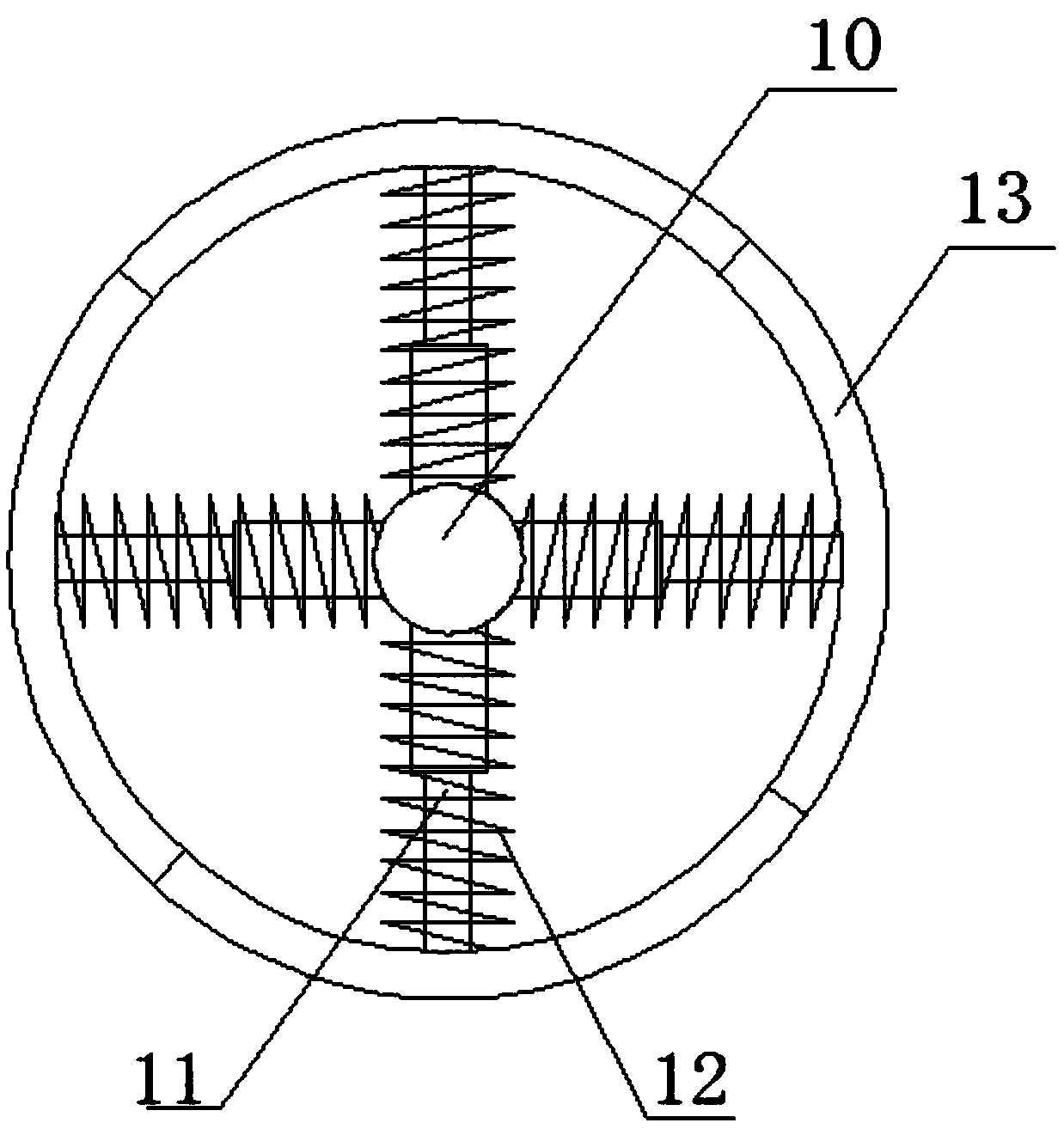

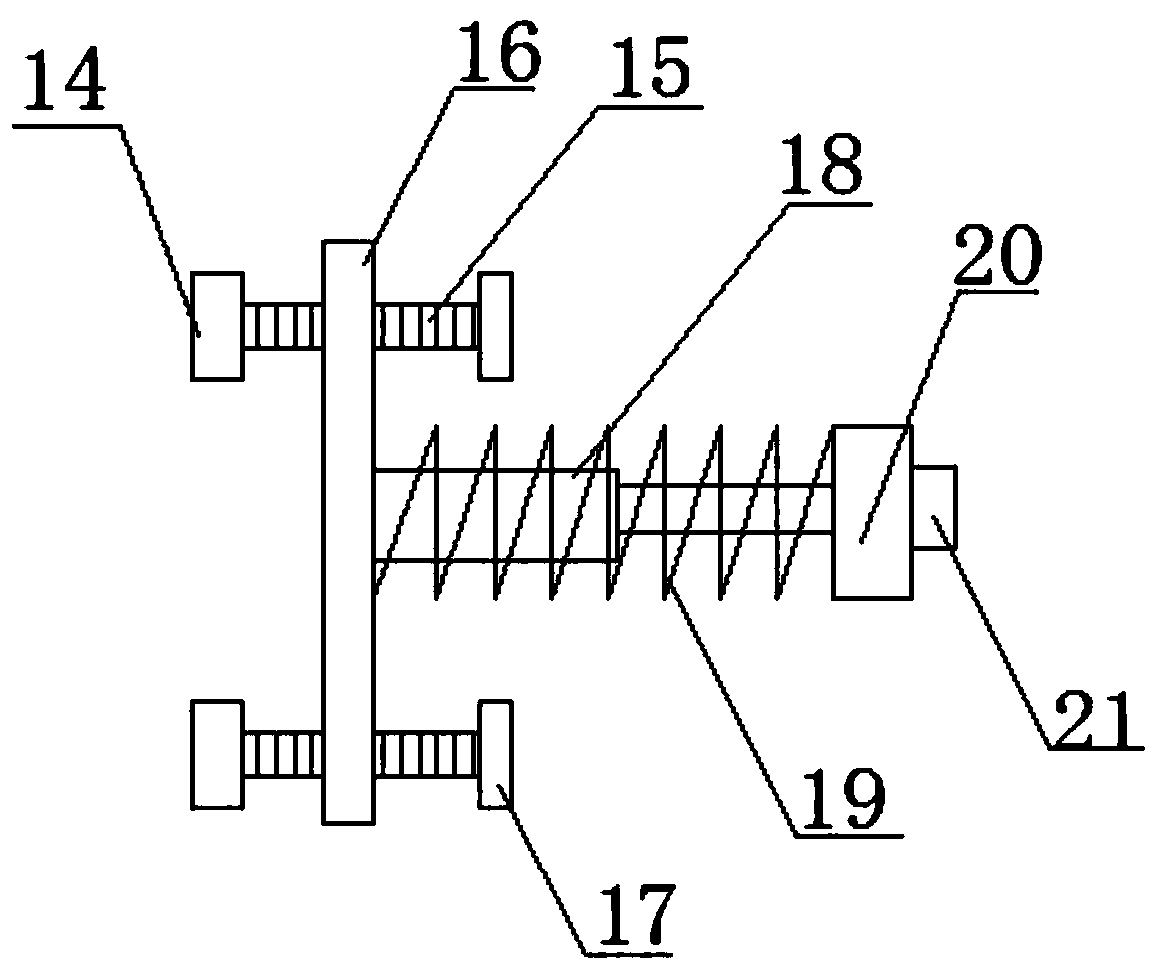

Automatic wire binding device for straw baler

The invention relates to an automatic wire binding machine for a straw baler. The automatic wire binding machine is matched with the straw baler and comprises a speed reducer fixed on a fixing plate and a bound wire unwinding device, wherein a cam is mounted on the speed reducer; the top of the cam is connected with a tail end shaft of a connecting rod; the other end of the connecting rod is connected with a middle shaft of a support rod; a fulcrum is also arranged on a rear part of the support rod; a movable shaft is connected with the fixing plate; a front end part shaft of the support rod is connected with a wire pressing box; the cam is rotated to drive the support rod to rotate about a fulcrum shaft, so as to drive the wire pressing box to swing to the left and right; a knife holder for cutting wires is arranged at a position at which the corresponding fixing plate is wound with the wires. The invention has beneficial effects of binding the wires automatically and effectively eliminating problems of low operating efficiency, overlong time and easy personal injury present when net ropes need to be cut off manually during traditional wire binding. The device is mounted on the straw baler to conveniently adjust wire binding time as needed, so as to improve efficiency.

Owner:曲阜鑫联重工机械制造有限公司

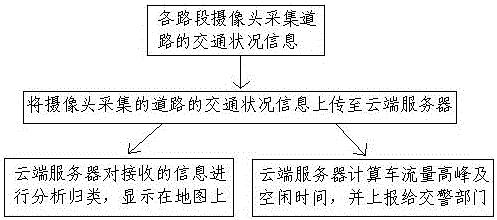

Traffic condition detection method based on big data

InactiveCN106097716ASave travel timeEase traffic pressureDetection of traffic movementReal-time computingRoad traffic

The invention discloses a traffic condition detection method based on big data, which belongs to the technical field of computer big data. The traffic condition detection method based on big data of the present invention comprises the following steps: S1: collect the traffic condition information of the road through the camera on the road; S2: upload the road traffic condition information collected by the camera to the cloud server; S3: the cloud server receives The road traffic status information is analyzed and classified, and displayed on the map. The traffic condition detection method based on big data of the invention can display the road traffic condition on the map in real time, and the traveler can clearly understand the traffic condition of the road section, and choose the appropriate travel section according to the actual situation, thereby alleviating the road traffic pressure, which has great advantages. Good promotion and application value.

Owner:INSPUR GROUP CO LTD

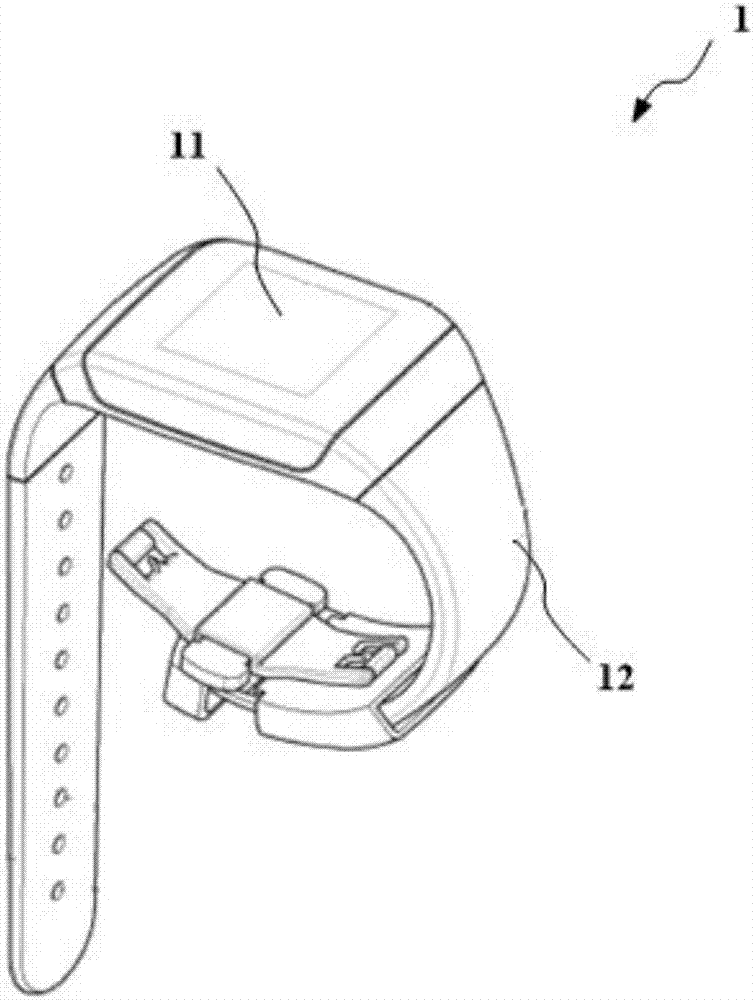

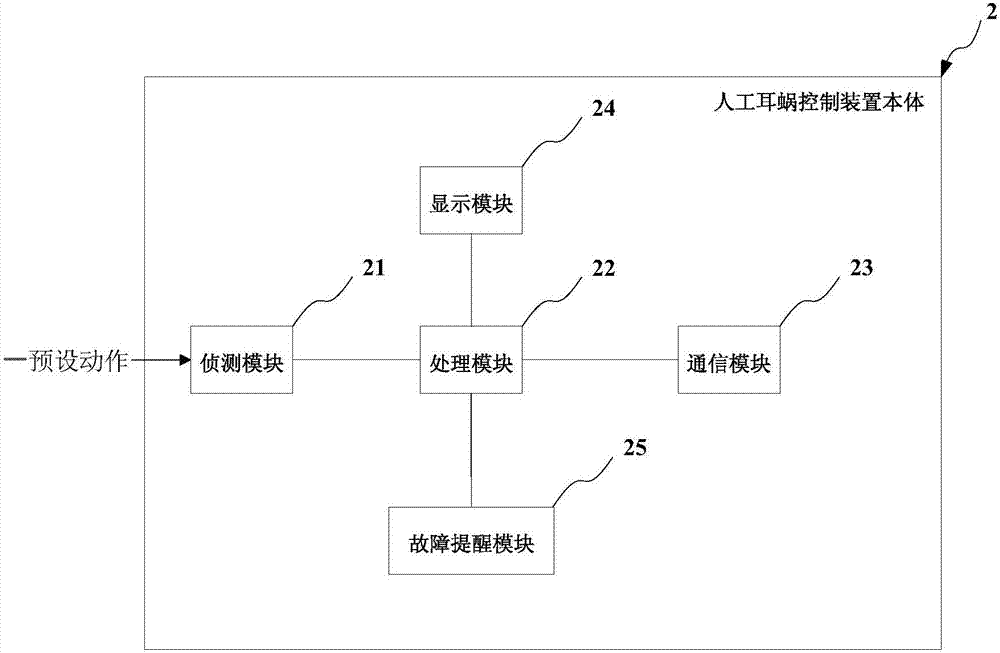

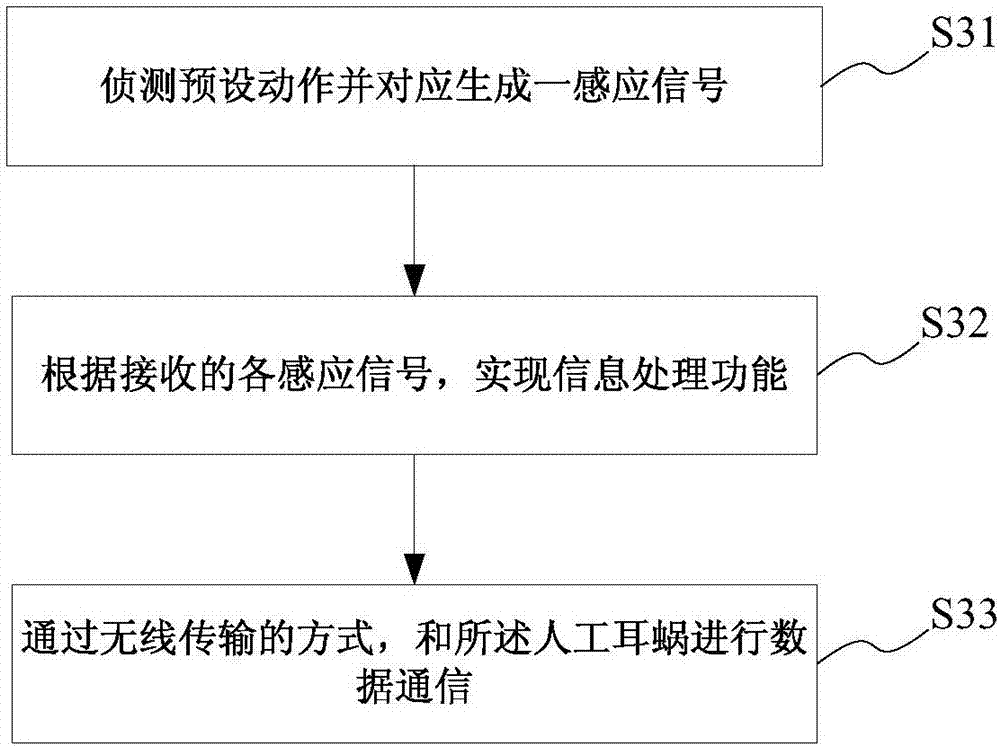

Artificial cochlea control device and method

InactiveCN107213550AReal-time monitoring of running status informationVolume adjustmentElectrotherapyArtificial respirationHuman bodyEngineering

The invention provides an artificial cochlea control device and method. The artificial cochlea control device is used for realizing wireless communication with an artificial cochlea to realize control on the artificial cochlea. The artificial cochlea control device comprises an artificial cochlea control device body and a fixing body which is arranged on the artificial cochlea control device body and is used for being worn on a human body. The artificial cochlea control device is advantaged in that the artificial cochlea can be controlled in a wireless mode through utilizing auxiliary equipment, the artificial cochlea control device is wearable, and intelligentization and light weight of artificial cochlea control are realized.

Owner:SHANGHAI LISTENT MEDICAL TECH CO LTD

Stably-operated cloth material spin-drying machine

InactiveCN108914462AAdjust the elasticityAvoid damageLiquid/gas/vapor removal by squeezingLiquid/gas/vapor removal by centrifugal forceEngineeringMechanical engineering

The invention discloses a stably-operated cloth material spin-drying machine. The stably-operated cloth material spin-drying machine comprises a machine body. An extrusion mechanism is arranged in theinterior of a spin-drying barrel. The extrusion mechanism comprises a rotary column. The rotary column is vertically installed in the middle in the interior of the spin-drying barrel. The outside ofthe rotary column is equipped with multiple first telescopic rods in the manner of longitudinal symmetry. The outer end of each first telescopic rod is equipped with an extrusion board. The outside ofeach first telescopic rod is equipped with an extension spring. The outside of the spin-drying barrel is provided with multiple balance devices. Each balance device comprises connecting seats which are installed outside the spin-drying barrel in the manner of longitudinal symmetry. Outsides of the connecting seats are rotatably connected with threaded rods. The two threaded rods are in threaded connection with support boards. The outer ends of the threaded rods are equipped with adjusting wheels. Outsides of the support wheels are equipped with second telescopic rods. Outer ends of the secondtelescopic rods are provided with wheel seats. Rotary wheels are arranged on the wheel seats. Outsides of the second telescopic rods are equipped with springs. The stably-operated cloth material spin-drying machine is simple in structure, convenient in application, good in spin-drying effect, high in spin-drying efficiency, strong in stability and long in service lifetime.

Owner:黄章溪

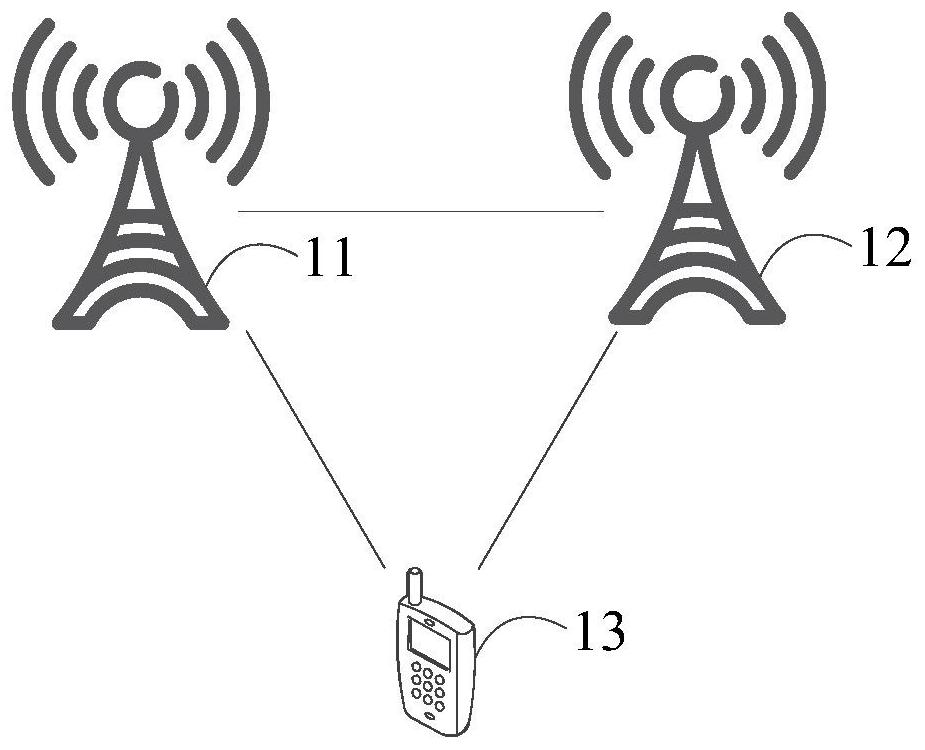

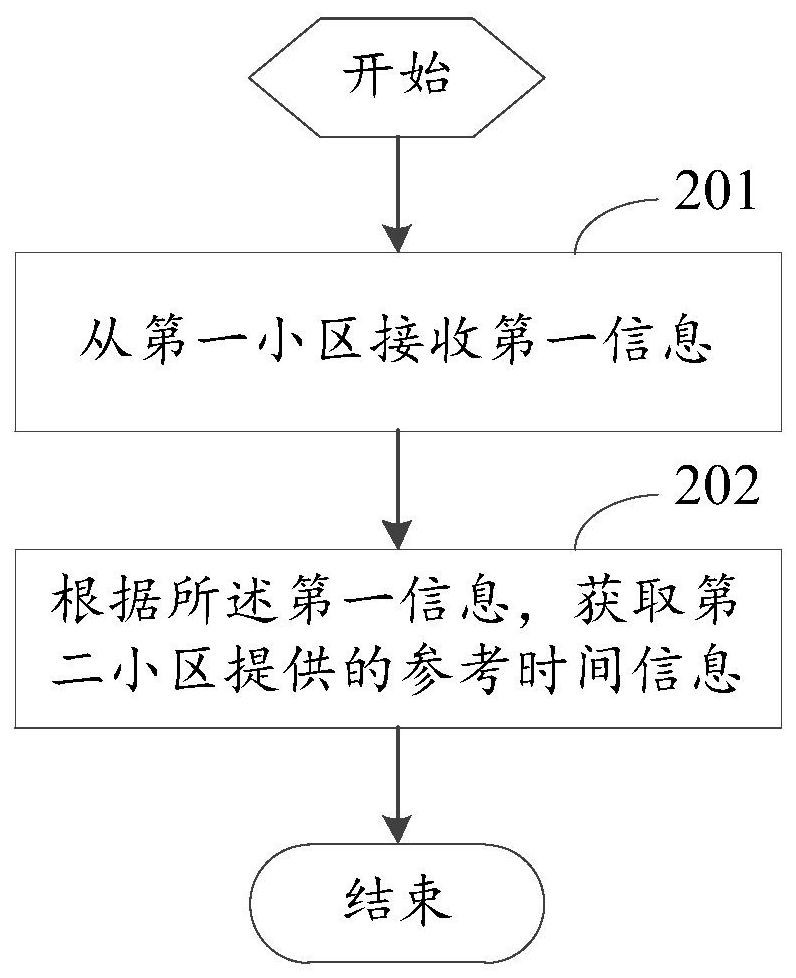

Method for acquiring reference time, and method and equipment for indicating reference time

Provided in an embodiment of the present invention are a method for acquiring a reference time, a method for indicating a reference time, and a device. The method comprises that a terminal receives first information from a first cell, wherein the first information is used for assisting the terminal in acquiring reference time information provided by a second cell, and the first cell is an independently working cell; and the terminal obtains reference time information provided by a second cell according to the first information, and the second cell is a neighbor cell of the first cell. In the embodiment of the invention, the first cell working independently sends the first information to the terminal, and the first information can assist the terminal in discovering the reference time information provided by the second cell, so that the terminal can adjust the time of the terminal side according to the reference time information provided by the second cell.

Owner:VIVO MOBILE COMM CO LTD

Bead wire processing equipment with high utilization rate of plating solution

ActiveCN112708841BMeet the needs of plating solutionTime equalizationCellsHot-dipping/immersion processesHand toolAqueduct

Owner:SHANDONG DAYE

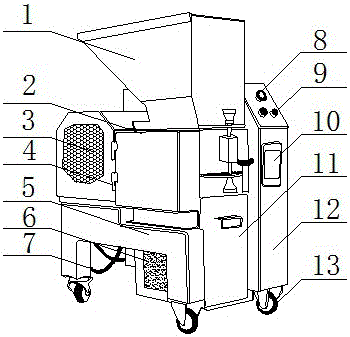

Crusher for producing toy

The invention discloses a crusher for producing a toy. The crusher comprises a rack and a sound insulation device arranged on one side of the rack; a hinge is arranged at the edge of the sound insulation device; a rotary wheel is arranged the bottom end of the rack; a control box is arranged on one side of the rotary wheel; a starting switch is arranged at the top of the control box; a switching button is arranged on one side of the starting switch; a display screen is arranged on one side of the switching button; a crushing groove is formed in one side of the display screen; a heat dissipation box is arranged on one side of the rack; a feeding hopper is arranged on one side of the heat dissipation box; a sieving box is arranged on the bottom side of the rack; a lead wire is arranged on one side of the sieving box. The crusher for producing the toy, provided by the invention, has complete structure functions, has a simple and easy structure and has a good sound insulation effect; the crushing rate of crushed objects, residual time and like can be directly identified; the crusher can be used for crushing different types of objects and can flexibly run and move randomly, so that extremely great convenience is provided for a production process of the toy.

Owner:蓝灿玉

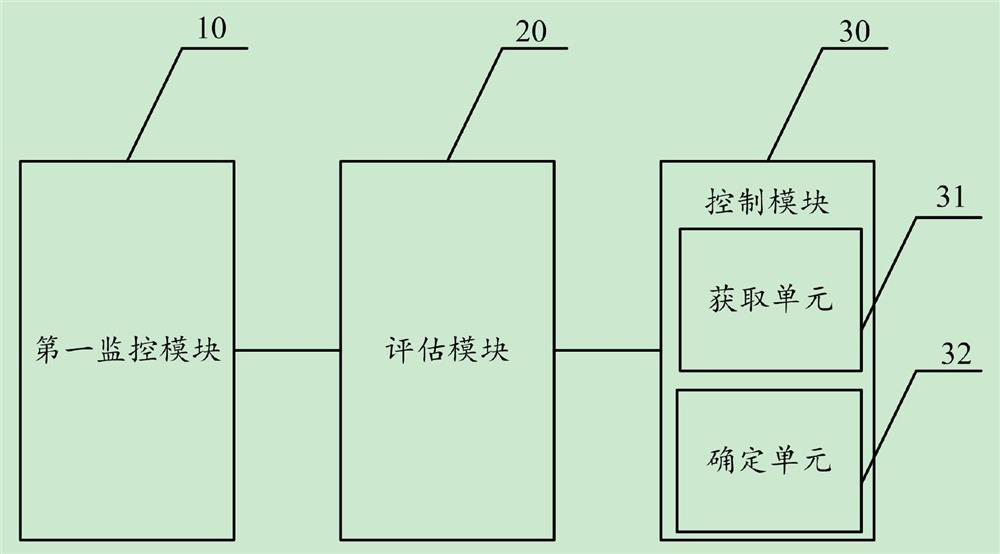

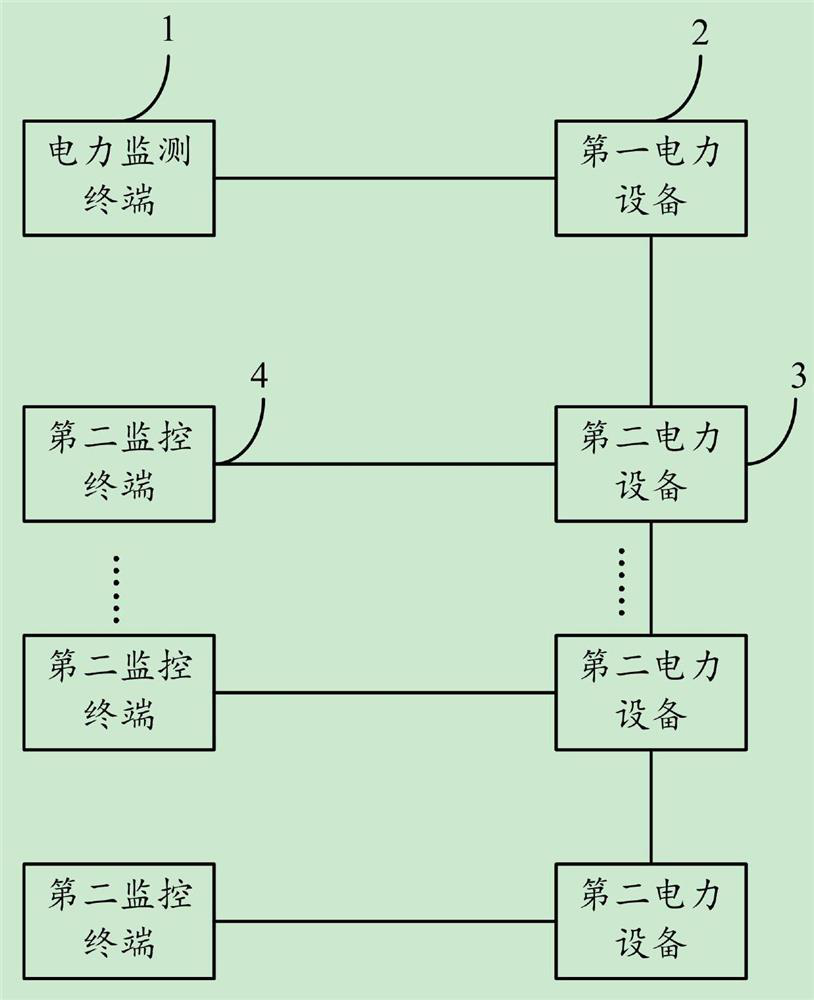

Power monitoring terminal and system

ActiveCN113675950BImprove security levelThe actual security level selection access time is extendedCircuit arrangementsInstrumentsEvaluation resultThe Internet

The present invention relates to a power monitoring terminal and system. The power monitoring terminal includes a first monitoring module for monitoring the state of a first power device; an evaluation module for forming an environment of the Internet of Things where the power device is located Perform evaluation and obtain evaluation results; a control module, connected to the evaluation module and the monitoring module, is used to select the access time of the first monitoring module according to the evaluation results obtained by the evaluation module, and at the access time Inside, the first monitoring module is connected to the first electric device, and the first monitoring module obtains the real-time status of the first electric device. The evaluation module evaluates the Internet of Things environment to determine the access time of the power monitoring terminal, which makes the access time more accurate, conforms to the actual Internet of Things environment, and improves the security of the power monitoring terminal.

Owner:江苏超能电力科技有限公司

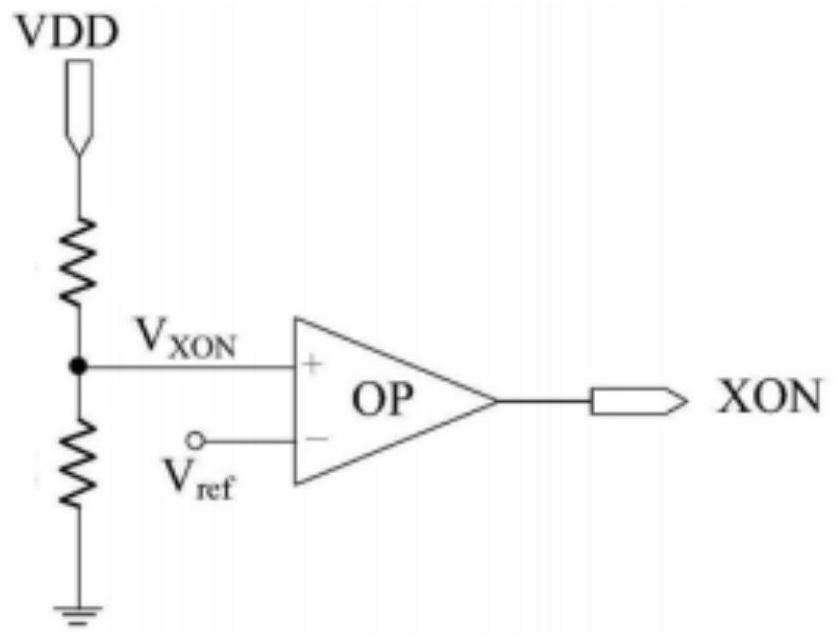

Shutdown control circuit, shutdown control method and display device

ActiveCN112735346BTime adjustmentExtension of timeStatic indicating devicesControl signalDisplay device

The present invention relates to a shutdown control circuit, a shutdown control method, and a display device, including a control module and a voltage output module; wherein, the control module includes a control unit, and the control unit is used to start timing after detecting that the front-end system stops transmitting data, and when it reaches After a preset time, an effective trigger signal is output for the control module to output an effective control signal; the voltage output module is used for outputting an effective shutdown control signal according to the effective control signal, wherein the effective shutdown control signal is used for shutting down The driving circuit is controlled in time to release the residual charge of the pixel unit in the display device. The application can effectively prolong the time for the pixel unit to release the residual charge when the display device is turned off, better eliminate the afterimage after shutdown, and can effectively adjust the time for the pixel unit to release the residual charge to improve the quality of the product.

Owner:KUSN INFOVISION OPTOELECTRONICS

Rolled substrate for high temperature resistant smart card and method for making same

Owner:上海达凯塑胶有限公司

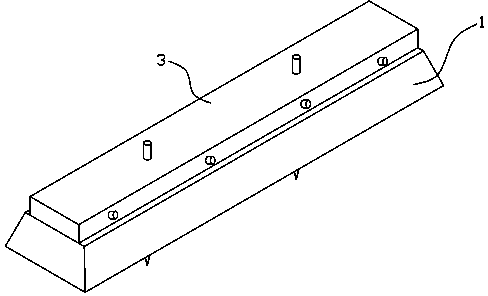

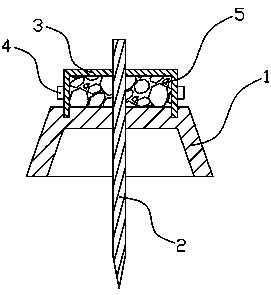

Benthic algae oriented reinforcing device

ActiveCN104322365APromotes enhanced growthQuick buildClimate change adaptationCultivating equipmentsCalcium biphosphateMetal strips

The invention discloses a benthic algae oriented reinforcing device. The benthic algae oriented reinforcing device comprises an anchor pile which is arranged on a wave proof base in a penetrating mode and the seawater corrosion resistant wave proof base; the wave proof base is an inverted arched structure; the wave proof base is provided with a main fixing hole which can accommodate penetration of the anchor pile; a sealing iron cover which is in an inverted groove shape is arranged close to the upper end of the anchor pile; an auxiliary fixing hole is formed in the sealing iron cover; the anchor pile can be arranged in the auxiliary fixing hole in a penetrating mode; iron wire fibers and filling base materials are arranged inside the sealing iron cover; the lateral side of the wave proof base is provided with a through hole; metal strips can be arranged inside the through hole according to requirements; the filling base materials comprise, by weight part, 80 to 90 parts of sea sand, 5 to 10 parts of river sand, 0.1 to 0.5 part of calcium phosphate and 0.15 to 0.1 part of copper sulfate. The benthic algae oriented reinforcing device has the advantages of directionally and rapidly constructing artificial algae farms having specific category advantages in a batch, repairing the seabed habitat and regulating low-quality microelement components according to the timing sequence.

Owner:ZHEJIANG OCEAN UNIV

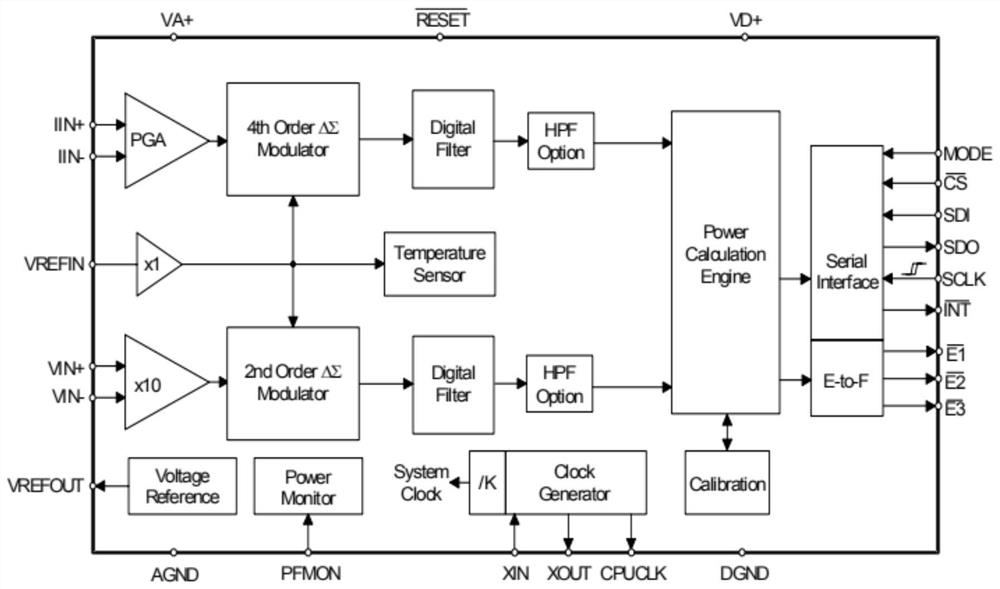

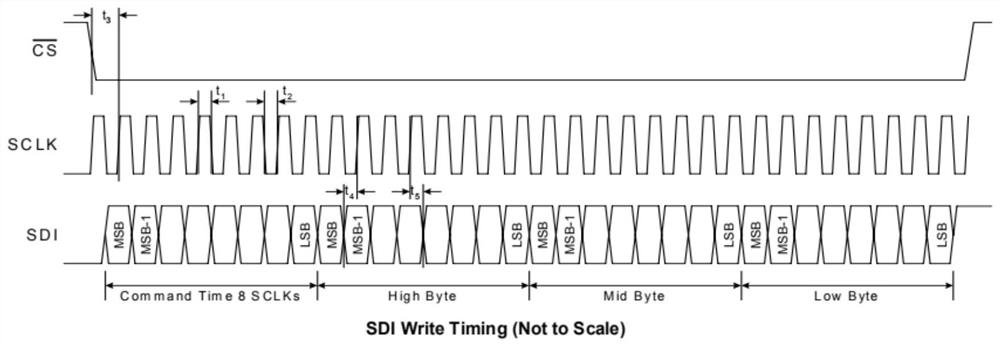

Control method for achieving independent zero crossing turn-off of three-phase current

InactiveCN104600665AReduce power lossAvoid electromagnetic interferenceEmergency protective arrangements for automatic disconnectionEngineeringField-effect transistor

The invention relates to a control method for achieving independent zero crossing turn-off of three-phase current. The method comprises the steps of treating three N channel insulated gate field effect tubes as a solid-state power controller in a three-phase current load circuit so as to enable complete independence of three-phase triggering loops; operating zero crossing turn-off logic of the current by the combination of an analog circuit and a digital circuit; outputting to driving circuits of the three independent N channel insulated gate field effect tubes; outputting transient DC high voltage through the driving circuits; the three-phase current is in a form of three independent analog channels; the digital signals are synchronously converted through three A / D converters; the three-phase N channel insulated gate field effect tubes are completely independent from each other. With the adoption of the method, the drop voltage and the power consumption can be obviously reduced, thus the AC current zero crossing turn-off can be achieved; the shortages of the original synchronous three-phase triggering are overcome, the power consumption of each phase vacuum tube can be obviously reduced, and the electromagnetic interface can be removed.

Owner:ELECTRIC LIGHT EXPLOSION PROTECTED TECHSHANGHAI

A method for time synchronization of watches through image recognition

InactiveCN106990711BTime adjustmentCharacter and pattern recognitionRadio-controlled time-piecesComputer graphics (images)Data transmission

A method for time-setting a watch through image recognition. The method includes the following steps: step 1, image acquisition of the dial of the watch; step 2, analyzing the acquired image to obtain the Describe the display time of the dial when the image is acquired; step 3, compare the display time in the step 2 with the actual time of the image acquisition in the step 1, and obtain the time difference; step 4, according to the step 3 In the time difference, adjust the hands of the watch. Through the above technical solution, the user only needs to take pictures of the dial with the mobile phone, and transmit the processed data to the watch, and the watch can automatically adjust the time.

Owner:GUANGDONG APPSCOMM CO LTD

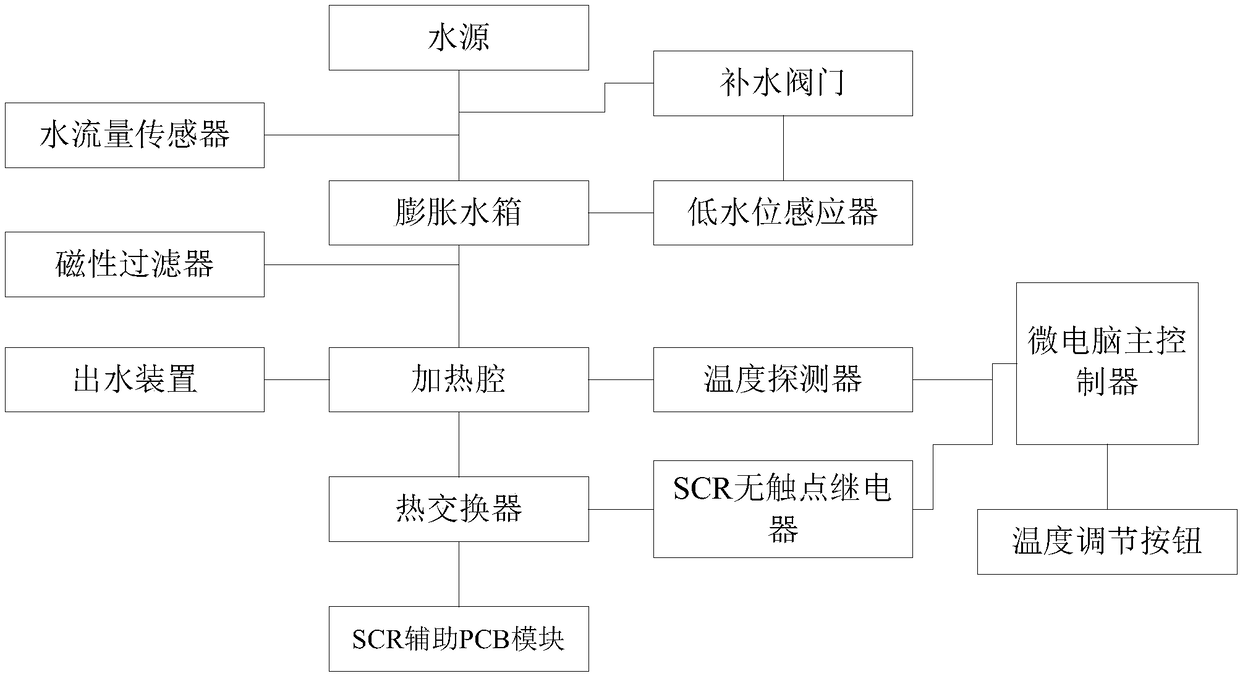

Gas equipment for heating running water

The invention discloses gas equipment for heating running water. The gas equipment comprises a water source and an expansion tank; the expansion tank is connected with the water source through a pipeline, and a water refilling valve and a water flow sensor are sequentially arranged on the pipeline for connecting the expansion tank and the water source, and the water refilling valve is controlled by a low-level sensor; the low-level sensor detects information of internal water level of the expansion tank, and has a threshold value H, and the refilling valve is turned on when the information ofwater level is lower than the threshold; the expansion water tank is connected with a heating cavity, a magnetic filter is arranged on a connecting pipe between the expansion tank and the heating cavity, a heat exchanger is arranged at the bottom of the heating cavity, and the heating cavity is connected with a water outlet unit; an SCR voltage regulating module is arranged in the heat exchanger,the heat exchanger is connected with a micro-computer master controller through an SCR contact-less relay, the micro-computer master controller detects temperature information of the heating cavity through a temperature detector, and an information input end of the micro-computer master controller refers to a temperature regulating button, and the SCR contact-less relay realizes on or off betweenthe heat exchanger and micro-computer master controller by regulating output voltage value.

Owner:成都星协科技有限公司

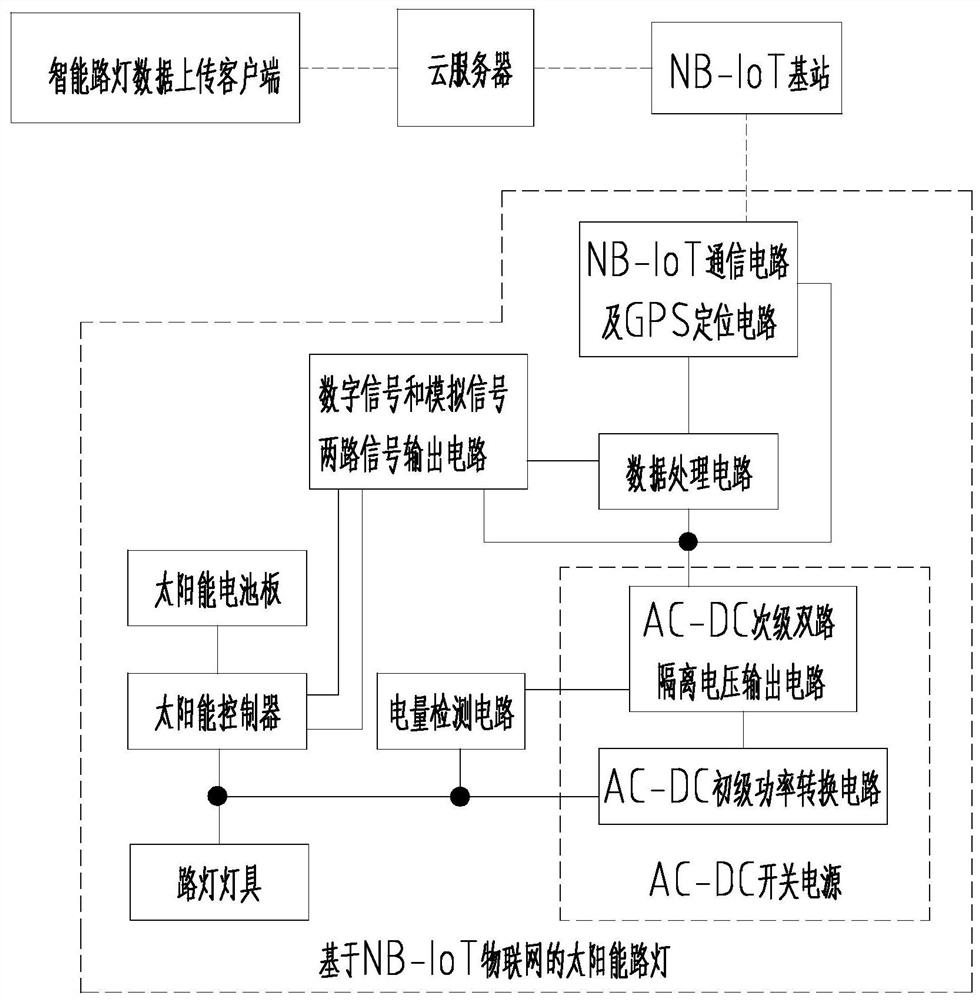

Intelligent solar street lamp control system based on Narrow Band Internet of Things (NB-IoT)

PendingCN112074058AVoltage regulationActive voltage controlElectrical apparatusEnergy saving control techniquesControl systemSolar street light

The invention relates to an intelligent solar street lamp control system based on the NB-IoT. The intelligent solar street lamp control system comprises an intelligent street lamp data uploading client, a cloud server, an NB-IoT base station and a plurality of solar street lamps based on the NB-IoT, wherein the intelligent street lamp data uploading client uploads pedestrian and vehicle flow dataof a road section in each time period every day; the cloud server receives, calculates and records pedestrian and vehicle flow data of each time section of the road section in recent n days and records the pedestrian and vehicle flow data as D1, D2, D3... Dm in sequence; the cloud server sends the pedestrian and vehicle flow data to each solar street lamp based on the NB-IoT through the NB-IoT base station; and each solar street lamp based on the NB-IoT comprises a solar cell panel, a solar controller, a street lamp body and an NB-IoT controller, and all the circuit modules are connected in amatched mode. According to the invention, the brightness of the street lamp bodies can be intelligently adjusted according to the road pedestrian volume condition of each time period.

Owner:FUJIAN JOY SOLAR TECHNOLOGY CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com