Plating method for iron-nickel alloy frame

An iron-nickel alloy and frame technology, which is applied in the field of iron-nickel alloy frame electroplating, can solve the problems of not meeting the use standard of semiconductor chips, unable to guarantee the performance of electrical conductivity, and difficult to improve the traction force, so as to achieve good copper plating effect and avoid poor conductivity. The best and the effect of reducing expenditure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

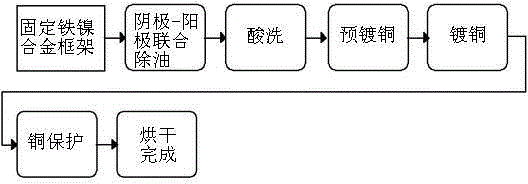

[0021] Such as figure 1 Shown, a kind of method for iron-nickel alloy frame electroplating, comprises the following steps:

[0022] Step 1: Fix the iron-nickel alloy frame; fix and hang the iron-nickel alloy frame on the bracket.

[0023] Step 2: Cathode-anode joint degreasing;

[0024] Place the bracket above the alkaline electrolyte, place the iron-nickel alloy frame in the alkaline electrolyte as the first electrode, and the metal plate as the second electrode, connect the power supply, and perform combined cathode-anode degreasing, degreasing time: cathode The degreasing time is 3.5-5min, and the anode degreasing time is 0.7-1.5min; the power source used in the cathode-anode joint degreasing step is the cathode-anode automatic switching power supply, and the cathode-anode joint degreasing step includes: advanced cathode Degreasing, and then anode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com