Automatic wire binding device for straw baler

A straw bale and automatic technology, applied in agricultural machinery and implements, application, packaging, etc., can solve the time-consuming and labor-intensive problems of tying wires, and achieve the effect of improving efficiency and eliminating low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

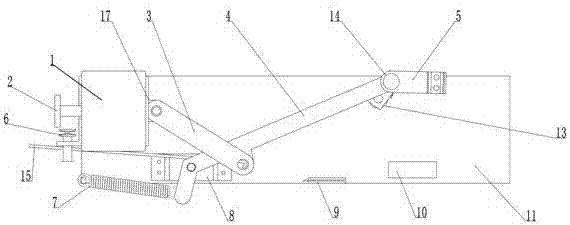

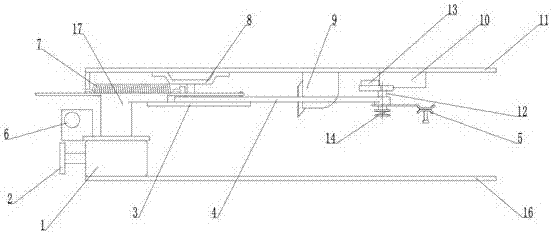

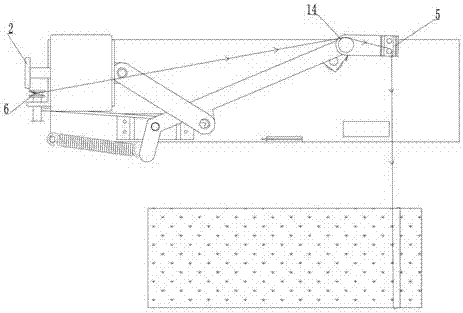

[0016] An automatic wire-tying device for a bale machine, matched with the bale machine, including a reducer fixed on a fixed plate and a wire-binding guide device, a cam is installed on the reducer, and the top of the cam is connected with the tail end of the connecting rod. The other end of the connecting rod is connected to the middle shaft of the support rod, and there is a movable shaft at the rear of the support rod connected to the fulcrum shaft on a fixed connection plate; the front end shaft of the support rod is connected to a crimping box; the cam rotates Drive the support rod to rotate along the fulcrum axis, thereby driving the crimping box to realize left and right reciprocating swing; a secant knife rest is provided at the position of the fixed plate corresponding to the full winding of the winding; the axial end of the crimping box is provided with a limit wheel, There are corresponding limit blocks on the fixed plate at the highest and lowest points of the move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com