Tower type pre-polycondensation reactor

A technology of precondensation and reactor, which is applied in the direction of chemical instruments and methods, components of pressure vessels, pressure vessels/vacuum vessels, etc. It can solve the problems of high equipment manufacturing cost, high operating cost, and high equipment height, and achieve good uniformity , increase the gas-liquid contact area, improve the effect of polymerization degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

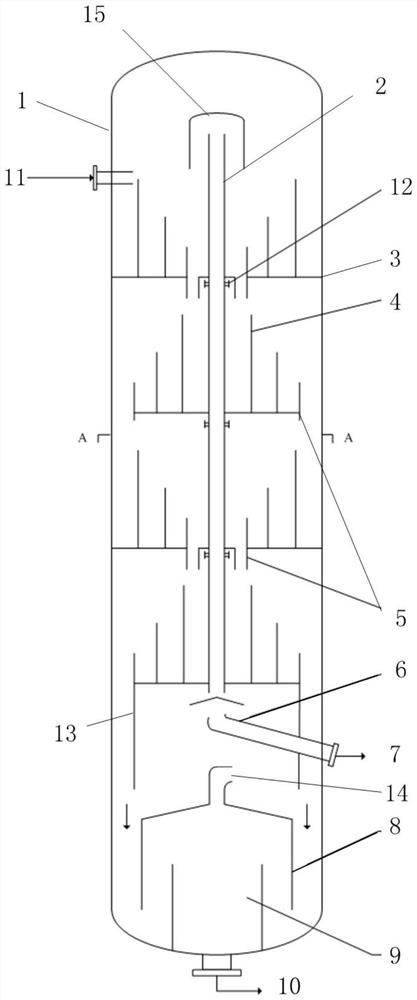

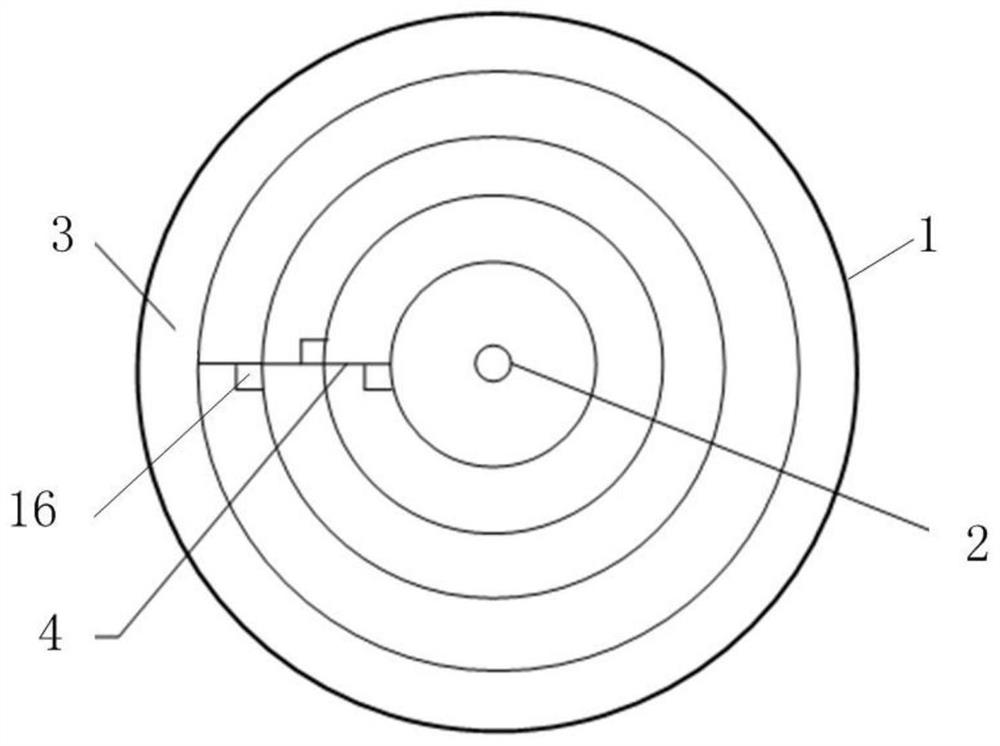

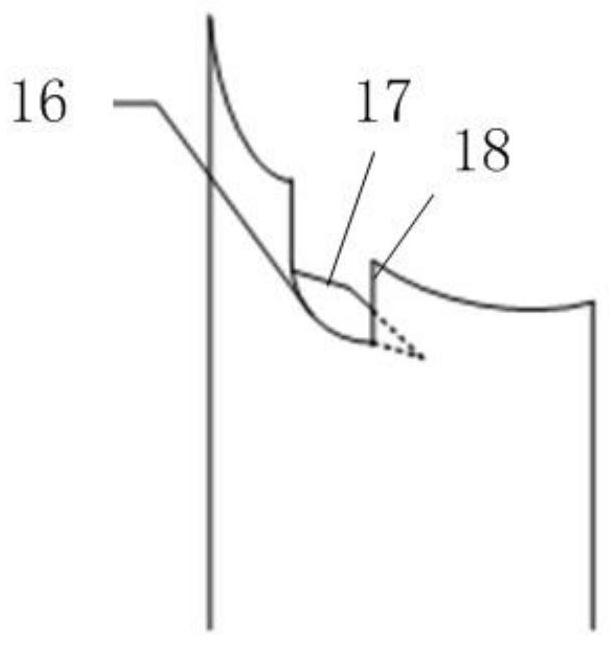

[0025] The technical solutions of the present invention will be further described below with reference to the accompanying drawings.

[0026] From the perspective of PET polyester polycondensation reaction mechanism, PET pre-polycondensation is to remove ethylene glycol small molecules from the ester under negative pressure positive reaction conditions, and continue transesterification between ethylene terephthalate monomers. reaction. Based on the reaction mechanism, the design of the pre-polycondensation reactor needs to start from the following points: 1. Heat and mass transfer. The polycondensation reaction is an exothermic reaction, but the latent heat and sensible heat required for the evaporation of a large amount of EG in the ester compound are greater than the reaction heat, so a large amount of heat is required when the ester compound just changes from positive pressure to negative pressure. In addition, increasing the mass transfer area of the material can effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com