A continuous catalytic upgrading reaction system for microalgae liquefied oil

A technology of liquefied oil and mass reaction, which is applied in the preparation of liquid hydrocarbon mixture, processing of hydrocarbon oil, petroleum industry, etc., to achieve the effect of low investment and operating costs, lower energy consumption and operating costs, and saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

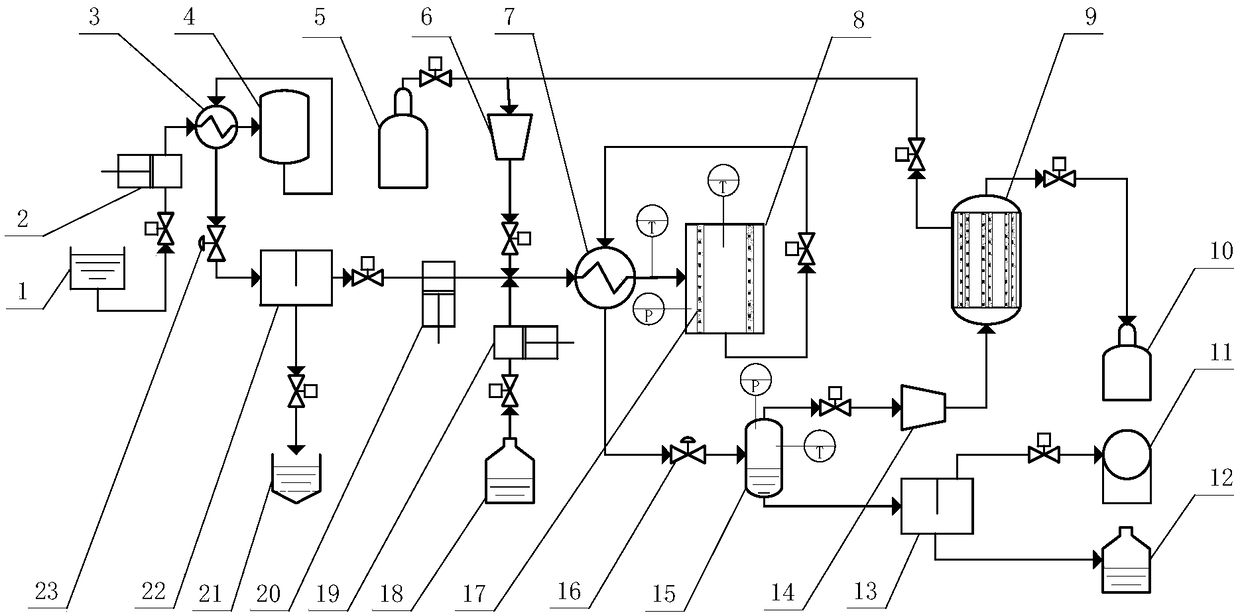

[0048] A continuous catalytic upgrading reaction system for microalgae liquefied oil, comprising a hydrothermal liquefaction reaction unit, a hydrothermal liquefaction separation unit, a catalytic upgrading reaction unit, a catalytic upgrading separation unit, and an oil storage tank 11;

[0049] Among them, the hydrothermal liquefaction reaction unit is connected with the hydrothermal liquefaction separation unit; the hydrothermal liquefaction separation unit is connected with the catalytic upgrading reaction unit; the catalytic upgrading reaction unit is connected with the catalytic upgrading separation unit; the catalytic upgrading separation unit is connected with the oil storage tank 11 connections;

[0050] Wherein, the catalytic upgrading separation unit includes a gas-liquid separator 15 and a quality upgrading centrifuge 13; the feed port of the gas-liquid separator 15 is connected with the catalytic upgrading reaction unit, and the liquid phase outlet of the gas-liqui...

Embodiment 2

[0058] A continuous catalytic upgrading reaction system for microalgae liquefied oil based on Example 1, wherein the catalytic upgrading reaction unit includes a hydrogen gas storage bottle 5, a water storage tank 18, a liquefied oil high-pressure pump 20 and a catalytic upgrading reaction unit device 8; where,

[0059] The feed port of the liquefied oil high pressure pump 20 is connected to the oil phase discharge port of the liquefied centrifuge 22;

[0060] The discharge port of the liquefied oil high-pressure pump 20 is connected with the feed port of the catalytic upgrading reactor 8 through a pipeline;

[0061] The hydrogen storage bottle 5 is connected to the first supercharger 6 through a pipeline; the first supercharger 6 is connected to the pipeline between the liquefied oil high pressure pump 20 and the catalytic upgrading reactor 8;

[0062] The water storage tank 18 is connected to the water tank high-pressure pump 19; the water tank high-pressure pump 19 is conn...

Embodiment 3

[0072] A continuous catalytic upgrading reaction system based on the microalgae liquefied oil of embodiment 1 or 2, wherein the hydrothermal liquefaction reaction unit includes an algae pulp high-pressure pump 2 and a hydrothermal liquefaction reactor 4,

[0073] The discharge port of the algae slurry high-pressure pump 2 is connected with the feed port of the hydrothermal liquefaction reactor 4;

[0074] The outlet of the hydrothermal liquefaction reactor 4 is connected to the inlet of the liquefaction centrifuge 22 through a pipeline, and a liquefaction back pressure valve 23 is arranged on the pipeline.

[0075] The liquefaction back pressure valve 23 can maintain the pressure in the hydrothermal liquefaction reactor 4, so that the hydrothermal liquefaction reaction can continue.

[0076] Wherein, in a feasible implementation manner, the hydrothermal liquefaction reaction unit further includes a liquefaction preheater 3, and the liquefaction preheater 3 has an algal pulp si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com