A method for preparing complex amino acids by deep enzymatic hydrolysis of soybean protein

A compound amino acid and soybean protein technology, which is applied in the field of deep enzymatic hydrolysis of soybean protein to prepare compound amino acids, to achieve the effects of improving the sensitivity of enzymatic hydrolysis, increasing the degree of degradation, and increasing the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

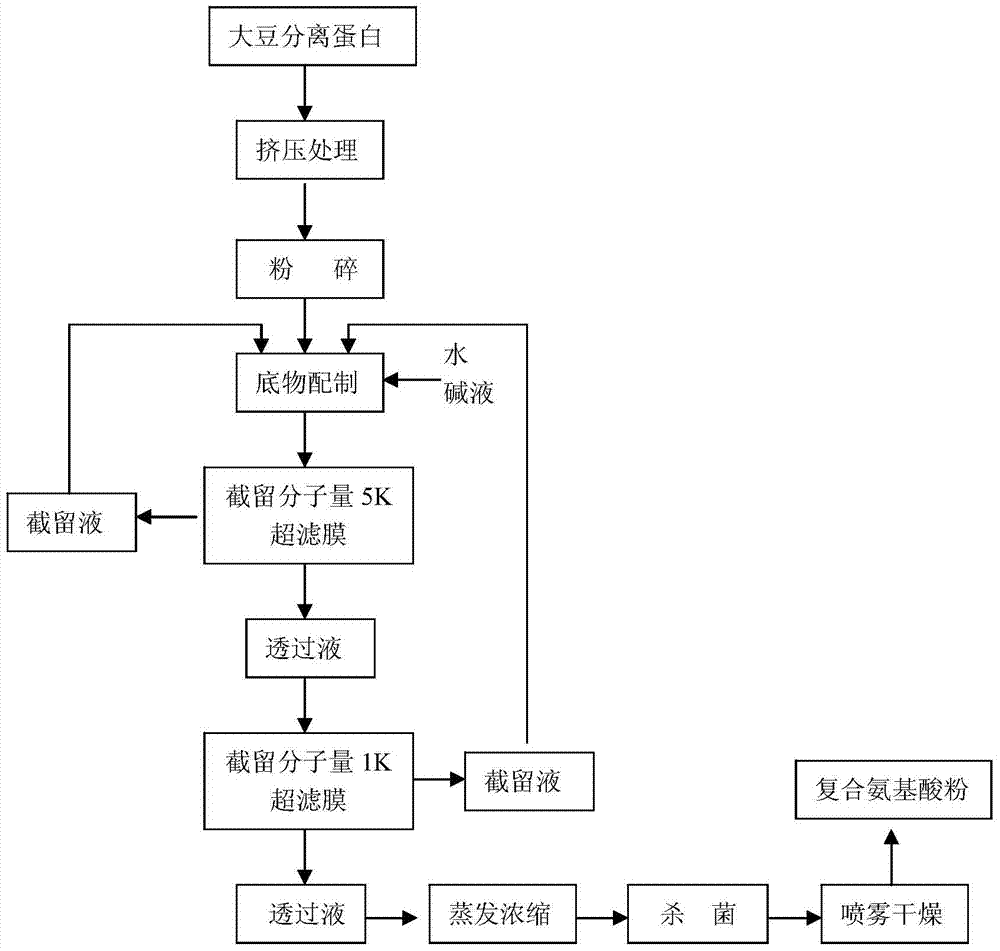

[0043] The operation process is as figure 1 Shown:

[0044] (1) Raw material moisture adjustment: add deionized water to 100kg soybean protein isolate raw material (on a dry basis, the protein content is 92.6%), stir and disperse evenly, so that the water content is 20% (w / w);

[0045] (2) Extrusion pretreatment: use a twin-screw extruder with an extrusion temperature of 100°C, a die hole diameter of 20mm, and a screw speed of 110r / min to extrude soybean protein. After extrusion, use a high-speed pulverizer to crush The extruded soybean protein is crushed to 60 mesh;

[0046] (3) Dispersion and hydration of soybean protein: the soybean protein powder after pulverization is prepared as a soybean protein solution with a mass percentage of 5% with deionized water, and the soybean protein solution is dispersed and hydrated (shear speed is 2000rpm, time 15min), the temperature was raised to 50°C, and the pH value was adjusted to 8.5 with sodium hydroxide solution;

[0047] (4) S...

Embodiment 2

[0050] (1) Raw material moisture adjustment: add deionized water to 100kg of soybean protein isolate raw material (on a dry basis, with a protein content of 92.6%), stir and disperse evenly, so that the water content is 25% (w / w);

[0051] (2) Extrusion pretreatment: use a twin-screw extruder with an extrusion temperature of 95°C, a die hole diameter of 15mm, and a screw speed of 100r / min to extrude soybean protein. After extrusion, use a high-speed pulverizer to crush The extruded soybean protein is crushed to 40 mesh;

[0052] (3) Dispersion and hydration of soybean protein: the soybean protein powder after crushing is prepared as 8% soybean protein solution by mass percentage with deionized water, and the soybean protein solution is dispersed and hydrated (shear speed is 3000rpm, time 10min), the temperature was raised to 45°C, and the pH value was adjusted to 8.0 with sodium hydroxide solution;

[0053] (4) Soybean protease membrane reaction based on ultrafiltration separ...

Embodiment 3

[0056] (1) Raw material moisture adjustment: add deionized water to 100 kg of soybean protein isolate raw material (on a dry basis, with a protein content of 92.6%), stir and disperse evenly, so that the water content is 30% (w / w);

[0057] (2) Extrusion pretreatment: use a twin-screw extruder with an extrusion temperature of 105°C, a die hole diameter of 25mm, and a screw speed of 120r / min to extrude soybean protein. After extrusion, use a high-speed pulverizer to crush The extruded soybean protein is crushed to 80 mesh;

[0058] (3) Dispersion and hydration of soybean protein: the soybean protein powder after crushing is prepared as a 10% soybean protein solution by mass percentage with deionized water, and the soybean protein solution is dispersed and hydrated (shear speed is 2500rpm, time 15min), the temperature was raised to 55°C, and the pH value was adjusted to 8.5 with sodium hydroxide solution;

[0059] (4) Soybean protease membrane reaction based on ultrafiltration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com