Straw decomposing agent and preparation and application thereof

A technology of straw decomposing agent and straw powder, which is applied in the biological field, can solve the problems of incompletely decomposing straw and other problems, and achieve the effect of increasing the degree of amorphousness, fast speed and good activity of bacterial agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

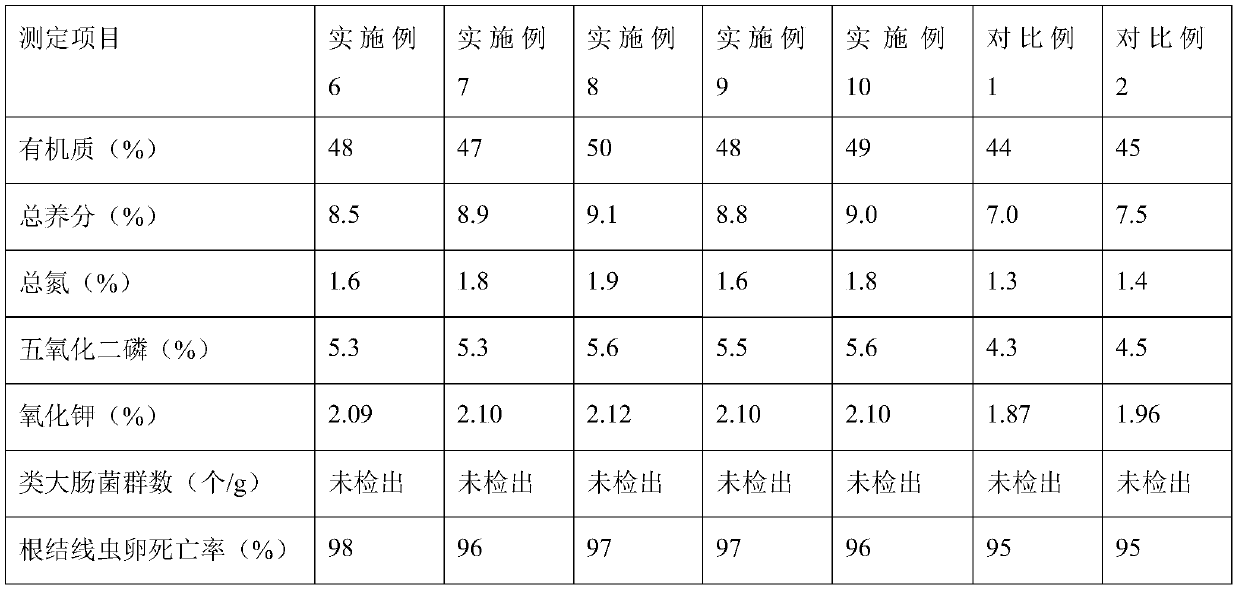

Examples

specific Embodiment approach

[0033] This embodiment provides a specific implementation of the straw decomposing agent, comprising the following steps:

[0034] Get Aspergillus niger 1.5g (viable bacteria concentration is 5×10 10 CFU / g), Aspergillus oryzae 0.5g (viable bacteria concentration is 10×10 10 CFU / g), Neurospora 1g (the live bacteria concentration is 10×10 10 CFU / g), Aspergillus flavus 1g (viable bacteria concentration is 10×10 10 CFU / g), Trichoderma 1g (viable bacteria concentration is 10×10 10 CFU / g), Streptomyces 1g (viable bacteria concentration is 10×10 10 CFU / g), Lactobacillus 1g (the concentration of live bacteria is 10×10 10 CFU / g), respectively add distilled water 4g to make bacterial agent suspension, then mix homogeneously with de-starch wheat bran, 30g corn bran and 8g pectin powder through high temperature and high pressure sterilization, described de-starch wheat bran, corn bran and pectin powder with a particle size of 400-600 μm, fermented at 26°C for 48 hours, and then ferme...

Embodiment 2

[0037] This embodiment provides a specific implementation of the straw decomposing agent, comprising the following steps:

[0038] Get Aspergillus niger 3g (viable bacteria concentration is 8×10 10 CFU / g), Aspergillus oryzae 1g (viable bacteria concentration is 8×10 10 CFU / g), Neurospora 1g (the live bacteria concentration is 8×10 10 CFU / g), Trichoderma 1g (viable bacteria concentration is 8×10 10 CFU / g), Streptomyces 1g (viable bacteria concentration is 9×10 10 CFU / g), Lactobacillus 1g (the concentration of live bacteria is 10×10 10 CFU / g), respectively add distilled water 6g to make bacterial agent suspension, then mix homogeneously with 25g de-starch wheat bran, 25g corn bran and 108g pectin powder through high temperature and high pressure sterilization, described de-starch wheat bran, corn bran and pectin powder with a particle size of 400-600 μm, fermented at 28°C for 12 hours, and then fermented at 20°C for 10 days to obtain the complex microbial agent I;

[0039] ...

Embodiment 3

[0041] This embodiment provides a specific implementation of the straw decomposing agent, comprising the following steps:

[0042] Get Aspergillus niger 2g (viable bacteria concentration is 5×10 10 CFU / g), Aspergillus oryzae 1g (viable bacteria concentration is 8×10 10 CFU / g), Neurospora 1g (the live bacteria concentration is 8×10 10 CFU / g), Aspergillus flavus 1g (viable bacteria concentration is 8×10 10 CFU / g), Trichoderma 3g (viable bacteria concentration is 8×10 10 CFU / g), Streptomyces 3g (viable bacteria concentration is 8×10 10 CFU / g), Lactobacillus 3g (the live bacteria concentration is 10×10 10 CFU / g), respectively add distilled water 5g to make bacterial agent suspension, then mix with 30g de-starch wheat bran, 20g corn bran and 12g pectin powder through high temperature and high pressure sterilization, described de-starch wheat bran, corn bran and pectin powder with a particle size of 400-600 μm, fermented at 26°C for 36 hours, and then fermented at 30°C for 8 da...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com