Patents

Literature

44 results about "STARCH WHEAT" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wheat starch is a gluten-free wheat flour that is made primarily of starch. It is often mixed with tapioca starch to make dough in a boiling water process.

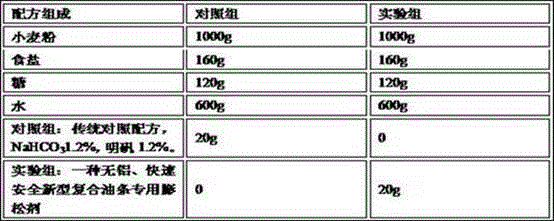

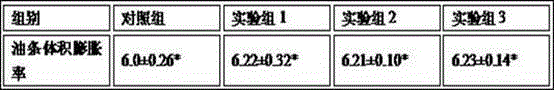

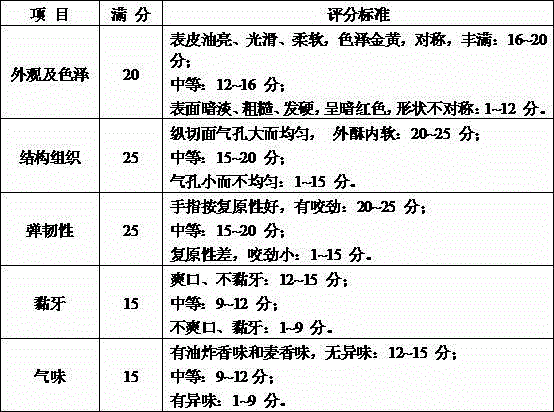

Novel aluminum-free, quick and safe special composite fried bread stick leavening agent

The invention discloses a novel aluminum-free, quick and safe special composite fried bread stick leavening agent which consists of the following raw materials in percentage by weight: 12%-18% of ammonium hydrogen carbonate, 12%-18% of sodium bicarbonate, 8%-12% of gluconic acid-sigma-lactone, 4%-7% of DL- tartaric acid, 4%-6% of calcium carbonate, 4%-6% of sodium pyrophosphate, 2%-5% of sodium dihydrogen phosphate, 2%-5% of calcium dihydrogen phosphate, 1%-2% of potassium hydrogen tartrate, 0.22%-0.76% of citric acid, 0.22%-0.76% of malic acid, 0.18%-0.56% of glucose oxidase, 0.16%-0.45% of pentosanase, 0.16%-0.25% of fungus alpha-amylase, 0.06%-0.22% of lipase, 10%-18% of salts, 10%-18% of modified starch, wherein the modified starch is one of modified corn starch, modified wheat starch, modified potato starch, modified sweet potato starch and modified cassava starch, wherein the moisture content of the modified starch is lower than 8%, the mass of the modified starch is 1%-3% the total mass of the flour. The special bread stick leavening agent disclosed by the invention can be used for quickly preparing an aluminum-free fried bread stick with a safe and bulk effect through a normal fried bread stick preparation process.

Owner:河南省熙康食品有限公司

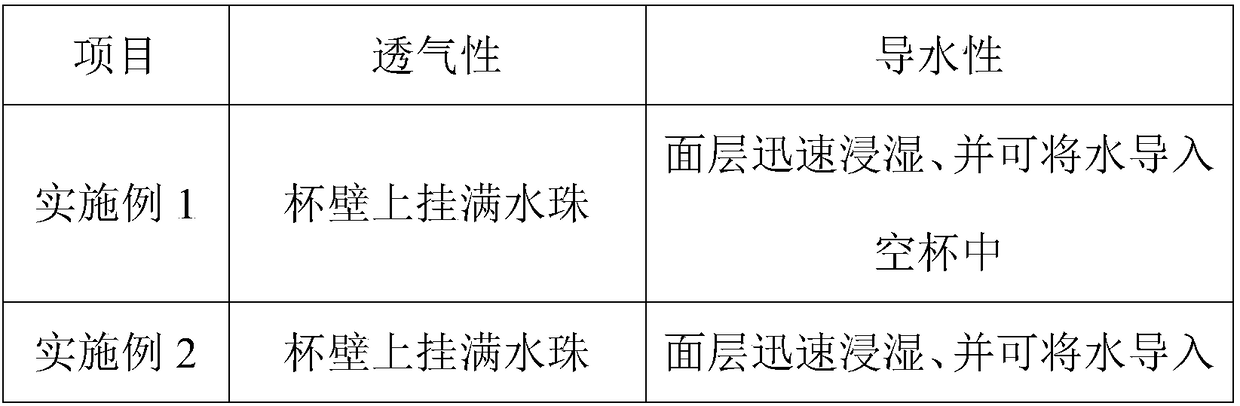

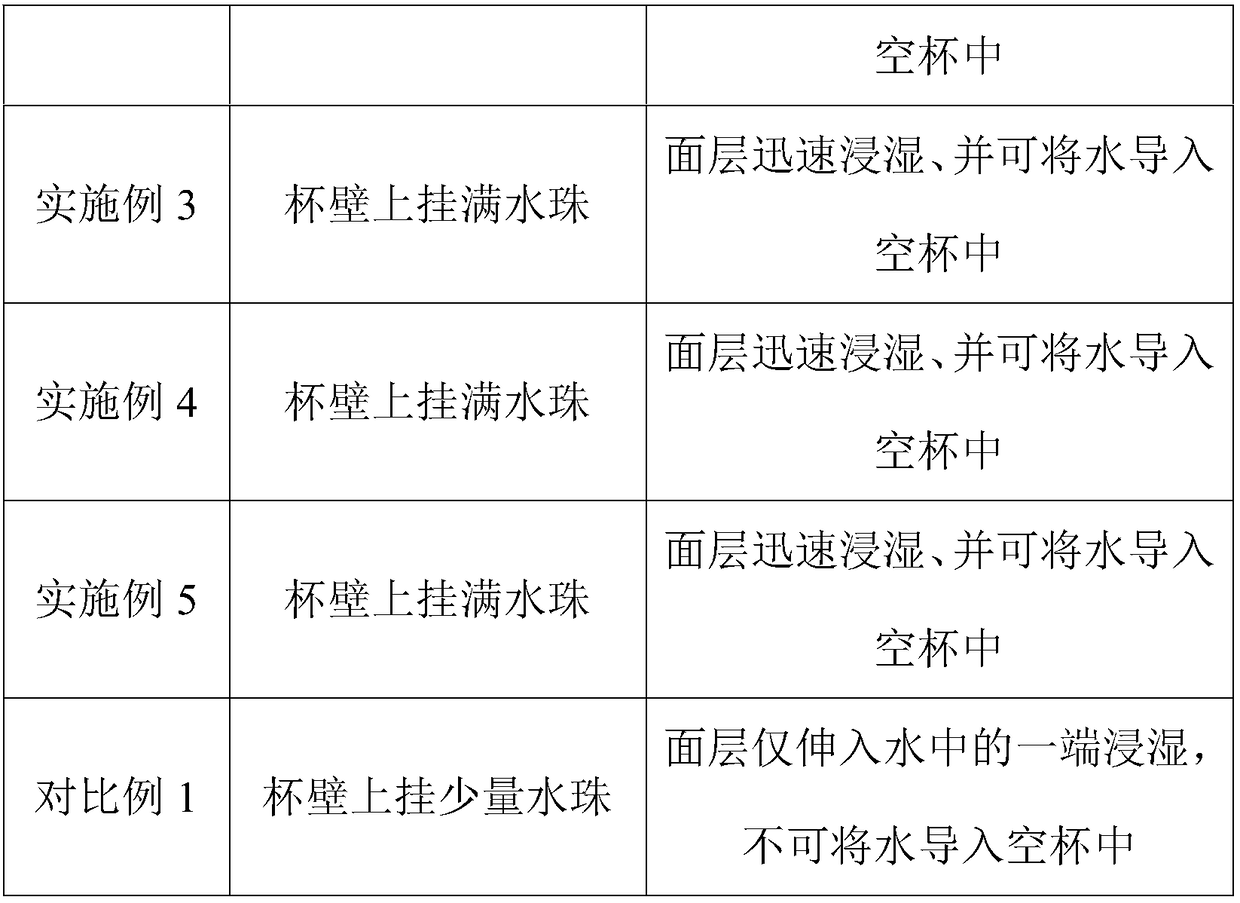

Water-resistant antibacterial bamboo fiber non-woven fabric surface layer and preparation method thereof

InactiveCN108360146APreserves natural antibacterial propertiesImprove hydrophilicityNon-woven fabricsChemistryWoven fabric

The invention discloses a water-resistant antibacterial bamboo fiber non-woven fabric surface layer and a preparation method thereof and belongs to the technical field of sanitary towel material preparation. The surface layer is prepared from, by weight, 90-96% of bamboo fibers, 2.5-5% of soybean protein fibers, 2.0-3.0% of corn protein fibers, 0.5-1.6% of sugarcane fibers, 0.2-0.8% of potato starch, 0.2-8% of wheat starch and 1-2.5% of water, wherein the materials above are subjected to mixing, heating, stirring, water-jetting and other processes to manufacture the surface layer. The surfacelayer contains no any additive component and is environmentally friendly and healthy; by adding natural plant fibers, starch and the like into the bamboo fibers, the hydrophobicity and softness of thebamboo fiber non-woven fabric surface layer are enhanced, and therefore the air breathability and water conducting performance are excellent.

Owner:湖南俏妃卫生用品有限公司

Starch wheat compound enzyme and method of applying same in preparation of starch wheat and vital gluten

The invention relates to an enzyme preparation or a biological preparation applied in the processing industry of starch wheat and specifically to a starch wheat compound enzyme. The starch wheat compound enzyme is prepared by uniformly mixing the following raw materials expressed in mass percent: 10 to 15% of cellulose, 15 to 30% of xylanase, 5 to 15% of mannanase, 5 to 10% of pectase and 30 to 60% of wheat flour. The invention also relates to a method of applying the compound enzyme in preparation of starch wheat and vital gluten. The method comprises a Martine production process and is characterized in that during making of dough, a wheat compound enzyme is added into water used for making the dough, addition amount of the wheat compound enzyme is 0.01% to 0.03% of the amount of the wheat flour, then the wheat compound enzyme and the water are uniformly mixed under stirring and finally a prescribed amount of flour is added to make the dough. Compared with the traditional Martine production process, the method provided in the invention has the following advantages: separation of starch from vital gluten can be accelerated, water consumption in making the dough and in washing can be reduced, production yield of vital gluten can be increased by 4.2 to 5%, and water consumption in the method is reduced by about 20%.

Owner:BAIYIN SINO BIOTECH

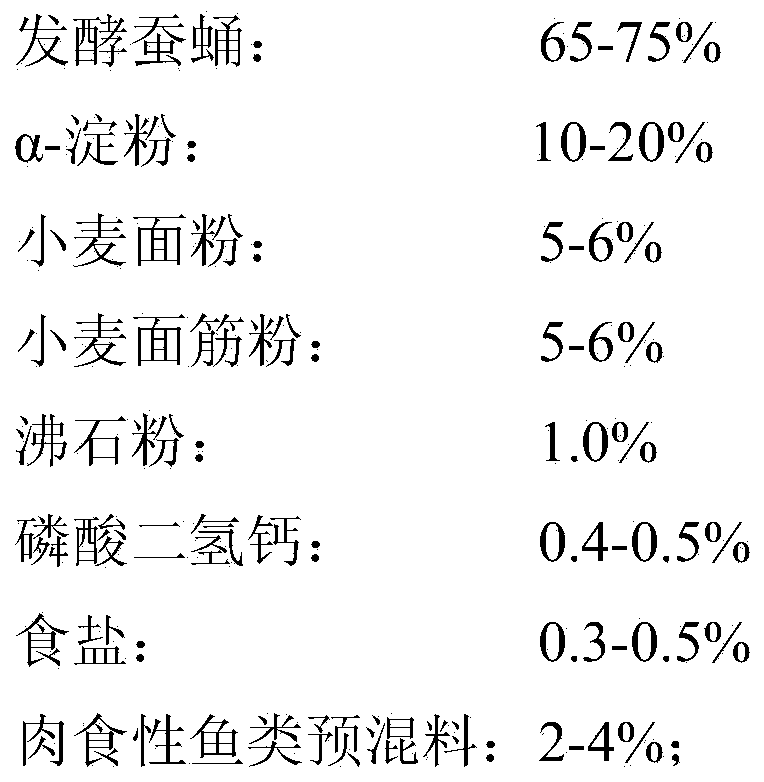

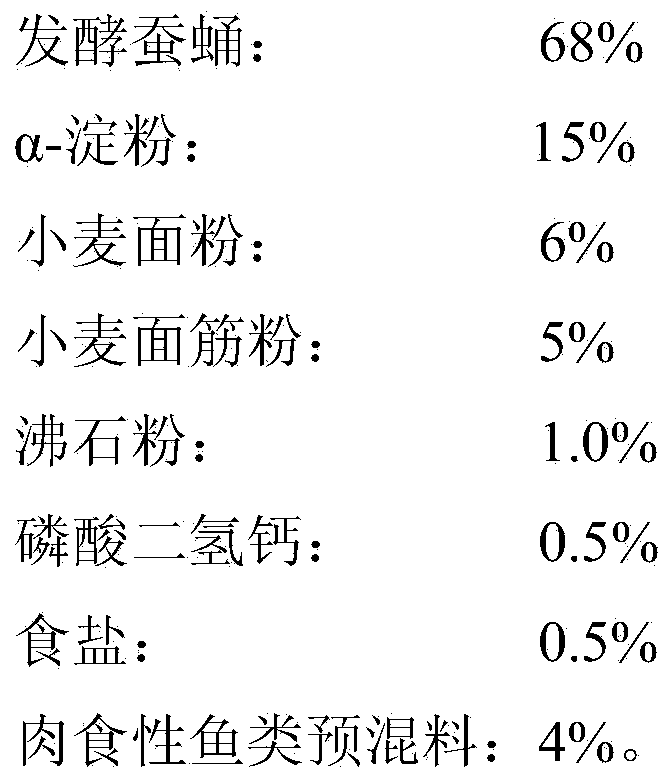

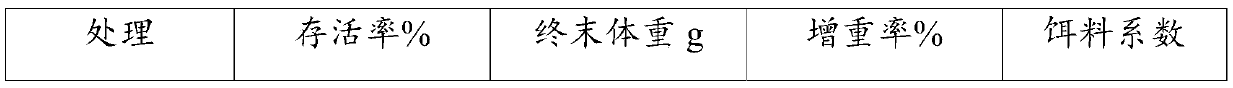

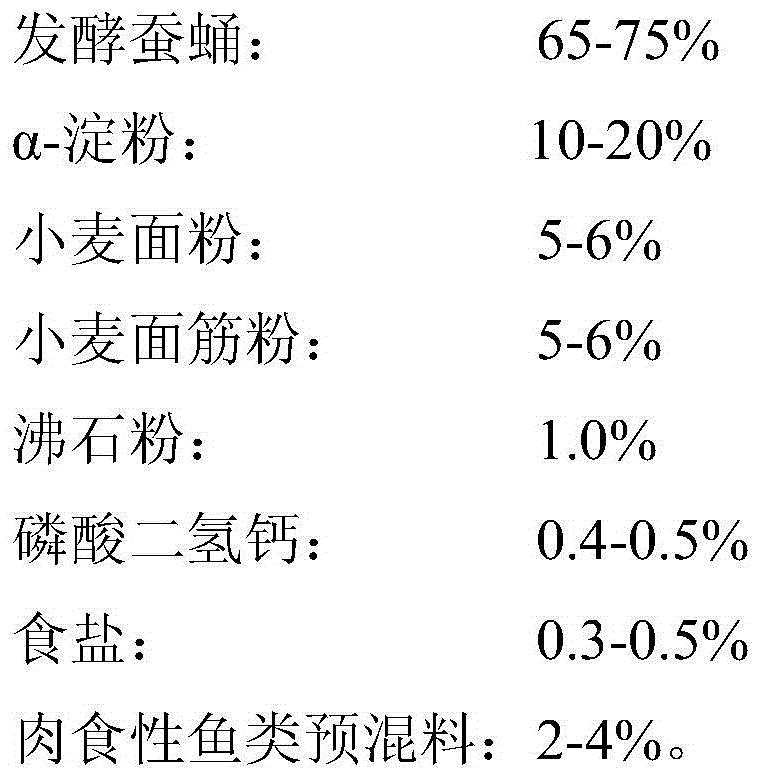

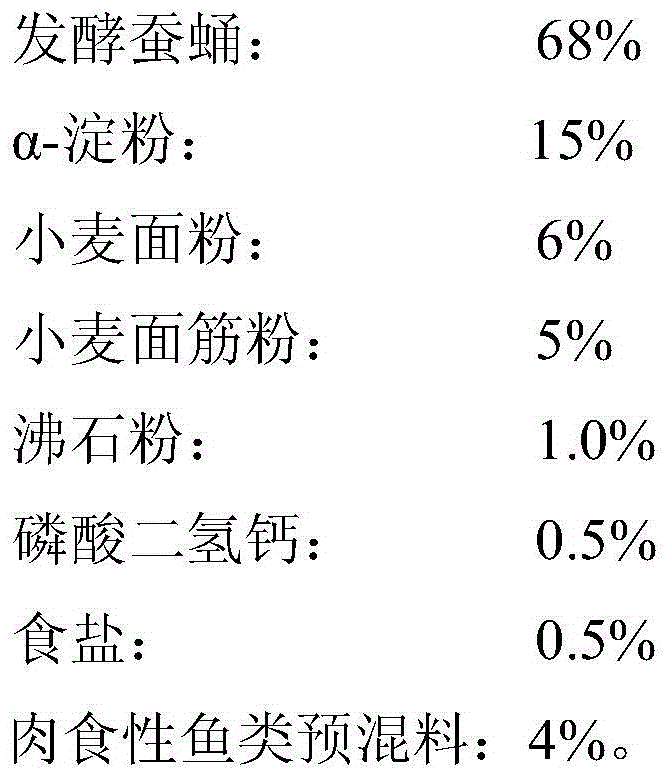

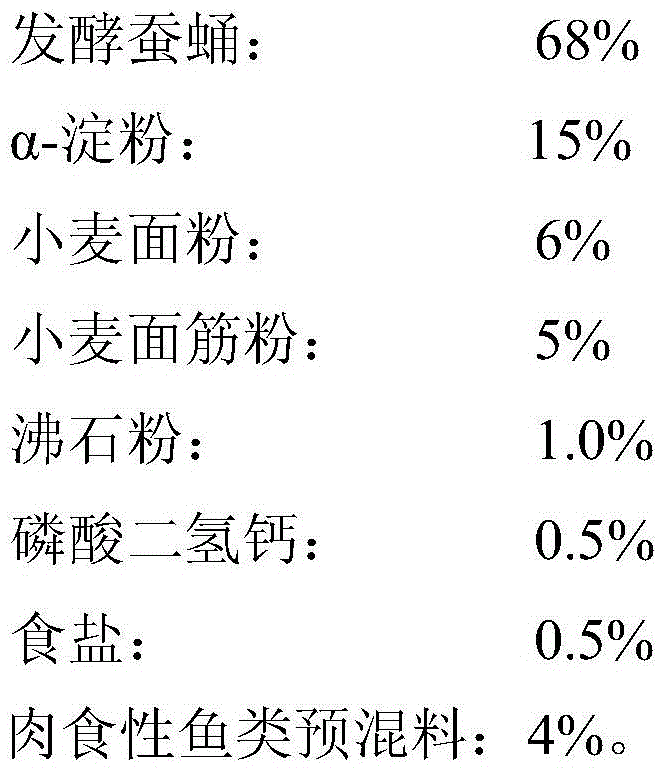

Marble goby compound feed containing fermented silkworm chrysalis and use thereof

ActiveCN104171492AImprove survival rateIncrease growth rateClimate change adaptationAnimal feeding stuffChemistryCalcium biphosphate

The present invention discloses a marble goby compound feed containing fermented silkworm chrysalis and a use thereof. The compound feed does not contain fish meal, and comprises fermented silkworm chrysalis, alpha-starch, wheat flour, wheat gluten flour, zeolite powder, calcium biphosphate, salt and premix for carnivorous fish. The fermented silkworm chrysalis is prepared by adding mixed meal into the silkworm chrysalis, inoculating microbe, adding carbon sources and inorganic salts, fermenting and culturing the mixture. The microbe is a mixed bacterio-liquid containing bacillus subtilis, bacillus acidi lactic and yeast. According to the present invention, the marble goby compound feed does not contain any fish meal and fish meat products, is produced from fermented silkworm chrysalis, can completely replace pure live fish and ice fish for breeding, increases survival rate and growth rate of marble goby, improves quality of fish meat, significantly increases the economic benefits of aquaculture, and promotes the sustained, healthy and stable development of marble goby aquaculture.

Owner:佛山市顺德美塘农业科技开发有限公司

Soybean protein and edible glutinous rice starch floor glue and preparation method thereof

InactiveCN105567117AExcellent low temperature elasticityImprove stress resistanceNon-macromolecular adhesive additivesProtein adhesivesBiotechnologyPotato starch

The invention discloses a soybean protein and edible glutinous rice starch floor glue and a preparation method thereof. The floor glue comprises deionized water, soybean proteins, sweet rice flour, corn starch, rice flour, coix seed powder, cassava starch, wheat starch, potato starch, fish gelatin, cellulosic ethanol, sodium lignosulfonate, xanthan gum, acetyl tributyl citrate, ethyl acetate, sodium benzoate and ethylene glycol. A result of -30 ~ -50 DEG C refrigeration cycle 3-time freeze thaw test shows that the preserving rate of the adhesiveness and the peeling strength is 85-95%, the formaldehyde content is 0.01-0.2g / kg, and the adhesion stress is 60-70kPa.

Owner:南星家居科技(湖州)有限公司

Glass fiber-containing highly waterproof air filter paper and making method thereof

InactiveCN104005272AImprove efficiencyHigh wet stiffnessNon-fibrous pulp additionSynthetic cellulose/non-cellulose material pulp/paperPolyvinyl alcoholAir filter

The invention discloses a glass fiber-containing highly waterproof air filter paper. The glass fiber-containing highly waterproof air filter paper is made by using the following raw materials, by weight, 46-48 parts of a Bambusa textilis pulp, 52-54 parts of a mulberry bark pulp, 1-2 parts of dried oleander leaf, 0.7-0.9 parts of oleic acid, 0.4-0.5 parts of flaxseed gum, 0.3-0.5 parts of starch wheat, 3-4 parts of montmorillonite, 1-2 parts of cerium oxide, 1-2 parts of chopped glass fiber, 1-2 parts of molybdenum dioxide, 5-7 parts of polyamine epichlorohydrin resin, 3-5 parts of a vinyl acetate-acrylic emulsion, 0.3-0.4 parts of polyvinyl alcohol, 0.2-0.4 parts of a paraffin emulsion, 1-2 parts of an assistant and a proper amount of water. Cerium oxide added in the invention has a catalysis performance and can purify air; the addition of the chopped glass fiber improves the waterproof performance; and the assistant added in the invention is safe and environmentally-friendly, and forms tiny apertures on the surface of filter paper, so the adsorptivity is increased, and the filter paper has a waterproof property. The filter paper has the advantages of small filtering resistance, high efficiency, waterproof property, moisture resistance, and high wet stiffness.

Owner:BENGBU DEMO FILTRATION TECH

Poecilia reticulata feed and preparation method and application thereof

InactiveCN109907186APromote growth and developmentPromote reproductionClimate change adaptationAnimal feeding stuffBetaineAstaxanthin

The invention belongs to the technical field of freshwater fish breeding feed and particularly relates to a Poecilia reticulata feed and a preparation method and application thereof. The Poecilia reticulata feed comprises white fish powder, red fish powder, krill powder, fermented soybean meal, beer yeast, wheat germ, corn gluten meal, squid meal, soya bean lecithin, spiral seaweed, astaxanthin, monocalcium phosphate, choline chloride, glycine betaine, fish oil, edible salt, a complex enzyme preparation, alpha-starch, wheat flour, taurine, a mineral prefix and a vitamin prefix. The Poecilia reticulata feed is adaptable to the digestive physiological characteristics of Poecilia reticulata and palatable, can improve growth and reproduction performance of the Poecilia reticulata remarkably ata lower cost and is good in breeding effect, thereby creating high economic benefit.

Owner:DALIAN OCEAN UNIV

Dyeing waste water treating agent and preparation method thereof

InactiveCN105600852AEasy to prepareEasy to handleWater contaminantsWater/sewage treatment by ion-exchangeCross-linkWaste treatment

The invention provides a preparation method of a dyeing waste water treating agent, comprising the following steps: (1) mixing bentonite, corn starch and wheat starch uniformly, adding water and extruding into particles 1-2mm in diameter; (2) calcining the particles obtained in step (1) for 5-7h, cooling to room temperature; (3) mixing the calcined particles with an acrylamide solution and stirring; (4) adding an initiator into the mixture system to initiate polyreaction, then adding a cross-linking agent to initiate cross linking reaction to obtain a mixture; and (5) baking the mixture in step (4) to obtain the dyeing waste water treating agent. The dyeing waste water treating agent provided by the invention fully utilizes the expandability and absorbability of the bentonite, has strong absorption on chroma, phosphorus, heavy metal ions, organic matters and the like, and can be used as a purifying agent in waste water treatment.

Owner:TAICANG JINDA PRINTING & DYEING CO LTD

Preparation method of rice seedling matrixes

InactiveCN106105861AThe substrate has good ventilation and water retention performanceHelp seedling emergenceBio-organic fraction processingExcrement fertilisersSludgeCompost

The invention relates to a preparation method of rice seedling matrixes, belonging to the agricultural field.The method comprises following steps: combining river sludge, chicken manure and self-prepared puffed vermiculite powder, mixing with crushed needle pine barks, diluting heavy metal in river sludge and obtaining combined material, carrying out compost treatment, inoculating earthworms till compost material turns into earthworm manure and mixing with self-prepared acidified and fermented starch wheat such that rice seedling matrixes can be prepared. The preparation method of rice seedling matrixes has following beneficial effects: ventilation and water retention are good so that seedlings can sprout out rapidly; allowable weight of matrixes are low and high nutrients are obtained so that seeding survival rate is increased; decomposable substance is included so that soil pollution is avoided and the environment is protected.

Owner:丁玉琴

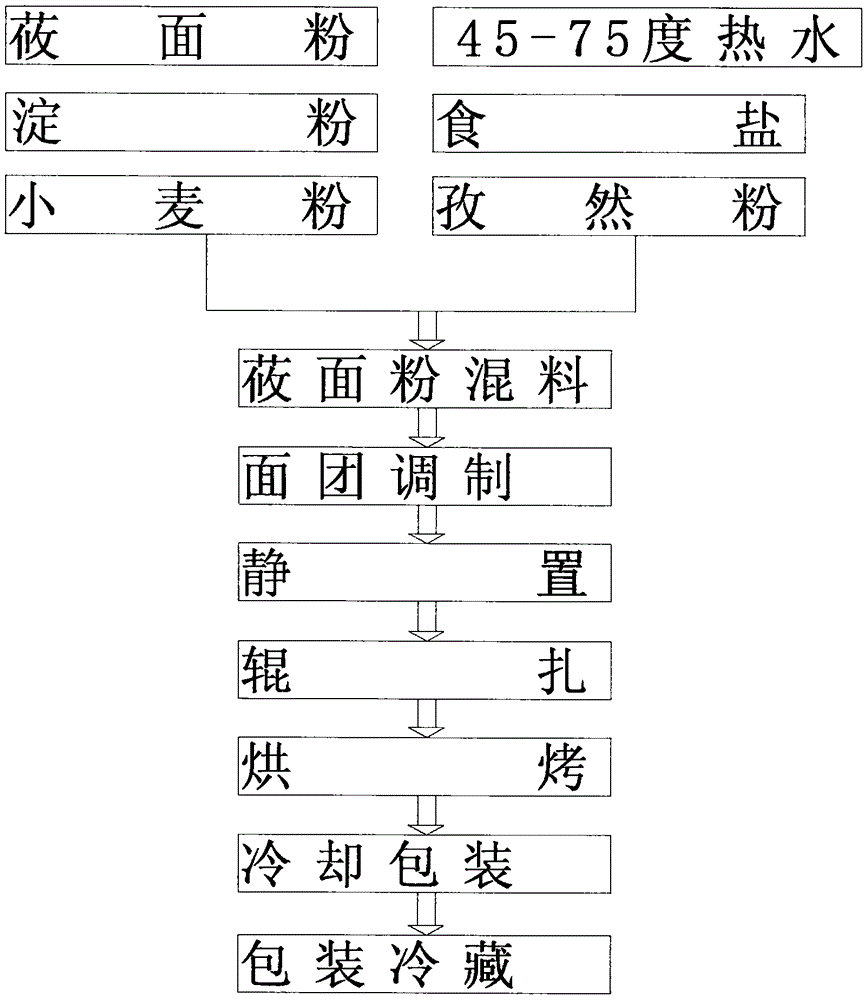

Oat flour biscuit production method

InactiveCN106165716ASolve the problem of edible cookiesReduce intakeDough treatmentBakery productsSugar intakeDisease

An oat flour biscuit production method is provided. Oat flour biscuits are produced by the following raw materials and formula including 45-75 DEG C hot water, 60%-85% of oat flour, 3%-7% of starch, 5%-8% of wheat flour, 1%-10% of salt and 1%-10% cumin. The method comprises the steps of (1) material compounding and mixing; (2) dough preparing; (3) standing; (4) rolling; (5) baking; (6) cooling and packing; and (7) packing and storing. Sugar intake of a human body is decreased while nutrient elements and energy which are normally required by the human body are provided, diabetics are assisted to control blood glucose, the blood glucose level is not increased, so that patient conditions are controlled, and the recovery purpose is achieved. The oat flour biscuits are nutrient-rich and high in satiety, and are suitable for all people to eat. Finally, the biscuits eaten by the people having the diseases of the same kind such as hyperglycemia, insulin disorder and diabetes are provided.

Owner:任旭明

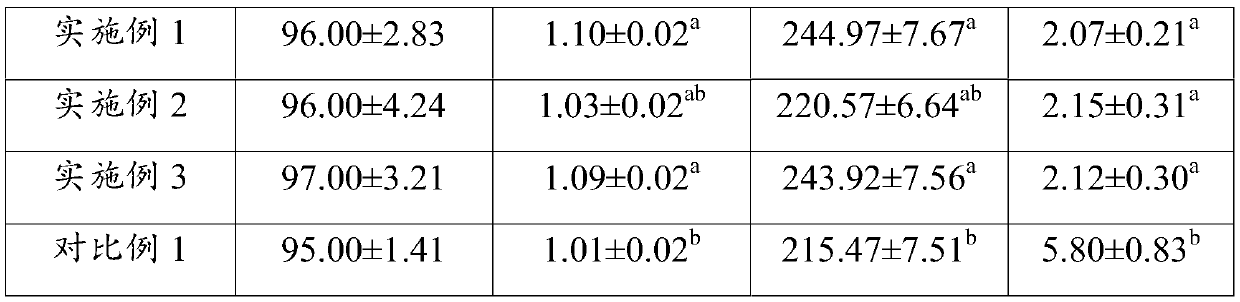

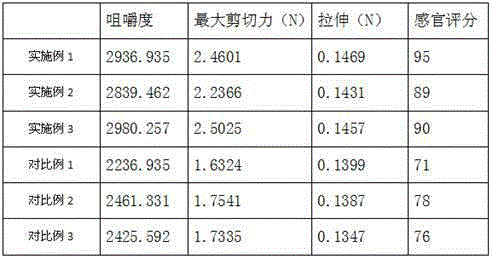

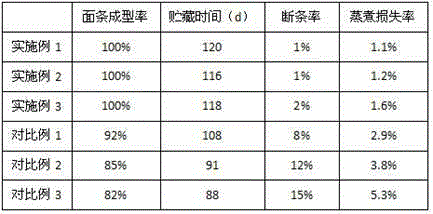

Semi-dried low-protein noodle and preparation method of the semi-dried low-protein noodle

ActiveCN105010997AReasonable collocationFit for consumptionFood preservationInorganic compound food ingredientsBiotechnologyCellulose

The invention provides a semi-dried low-protein noodle and a preparation method of the semi-dried low-protein noodle. The semi-dried low-protein noodle comprises the following raw materials: flour, alpha-modified starch, wheat starch, sodium carboxymethyl cellulose, phosphate, lactitol, glucomannan, sodium alginate, medicinal and edible plant powder and edible alcohol. The semi-dried low-protein noodle prepared by the invention is rational in raw material collocation, low in protein content, rich in nutrients, convenient to cook and eat, strong in noodle flavor, chewy and suitable for the patients with diabetes and nephropathy to eat. The preparation method of the semi-dried low-protein noodle provided in the invention has few manufacturing procedures and reserves the nutrients in the raw materials to the maximum; the noodle product prepared by the preparation method is long in storage period and small in sensory quality difference to the traditional wheat flour noodles, so that the semi-dried low-protein noodle can be easily accepted by the consumers.

Owner:INST OF AGRO FOOD SCI & TECH SHANDONG ACAD OF AGRI SCI

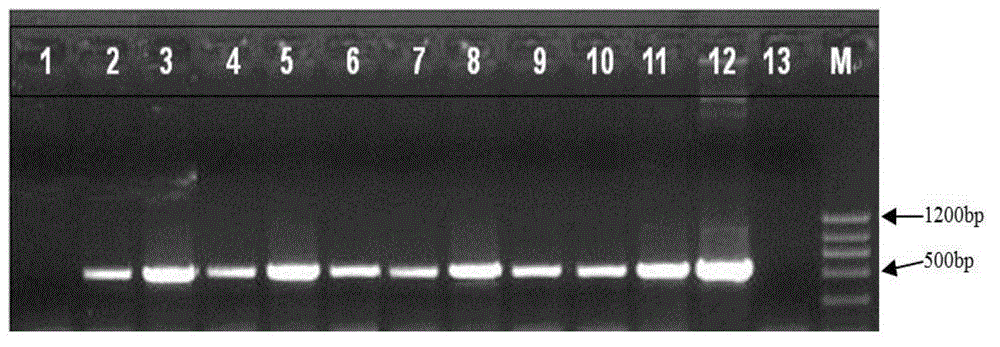

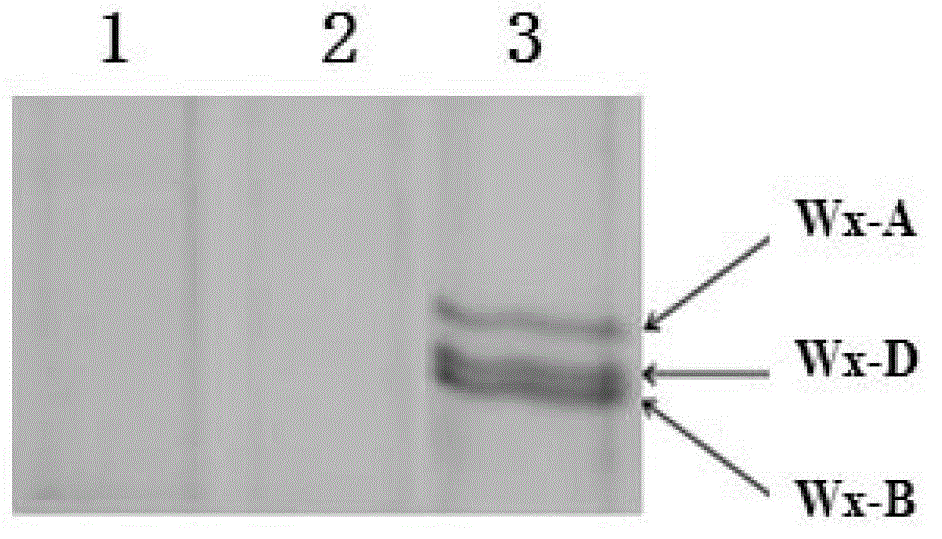

New method for formulation of full waxy starch wheat germplasm

InactiveCN102747100AComprehensive agronomic traits are goodBacteriaVector-based foreign material introductionGranule-Bound Starch SynthaseAgricultural science

The invention discloses a method for cultivation of full waxy wheat. The method for cultivation of full waxy wheat provided in the invention includes the following step of: inhibiting the expression of GBSS (granule-bound starch synthase) I gene in target wheat to obtain the full waxy wheat. The inhibition of expression of the GBSS I gene in the target wheat is realized by transferring a DNA fragment as shown in formula "SEQforward-X-SEQbackward" into the target wheat. Specifically, the SEQforward is the top 288 nucleotides in sequence 1 of a sequence table; the SEQbackward is in reverse complement with the SEQforward; the X is a spacer sequence between the SEQforward and the SEQbackward, and in sequences, the X is not complementary with and the SEQforward and the SEQbackward. Experiments prove that the wheat GBSS I gene can be silenced through a transgene silencing technology (RNAi) to obtain a GBSS I gene expression-inhibiting full waxy wheat new germplasm, and the transgenic material has excellent comprehensive agronomic characters, thus being able to be directly used for selective breeding of wheat low-amylose new strains (varieties) or be used as a patent material of breeding.

Owner:INST OF CEREAL & OIL CROPS HEBEI ACAD OF AGRI & FORESTRY SCI

Cold fresh noodle special for diabetic nephropathy and preparation and storage method thereof

ActiveCN104920974AReduce qualityImprove qualityFood ingredient as anti-freezing agentFood preservationBiotechnologyCellulose

The present invention relates to a cold fresh noodle special for diabetic nephropathy and a preparation and storage method thereof, and belongs to the technical field of noodle processing. The cold fresh noodles use flour, alpha modified starch, wheat starch, sodium carboxymethyl cellulose, phosphate, lactitol, trehalose, and medical and edible plant powder as raw materials, and is special because of the additions of lactose and trehalose. The lactose and trehalose are coordinated to be used as antifreezes, and can play the functions of enhancing the antifreezing capacity and improving the water retention rate. The preparation method of the cold fresh noodle is as follows: a final fermentation step is added at room-temperature after the dough kneading step, which makes the tense and hardened dough relax; and the gas generated inside the fermented dough can adjust the gluten network structure of the dough, increase the plasticity and make the dough easy to be shaped, and the prepared noodles have enhanced extensibility and are not easy to be cracked. The storage method of the cold fresh noodle is as follows: the cold fresh noodles are frozen at -80 to -70 DEG C for 15-45 min, then refrigerated at -10 to -15 DEG C. The storage method has lower freezing temperature and shorter freezing time, and thus effectively enhances the freezing efficiency and shortens the processing period.

Owner:INST OF AGRO FOOD SCI & TECH SHANDONG ACAD OF AGRI SCI

Method for preparing maca-containing boiling-free snow skin mooncake premixed flour

InactiveCN106173824AImprove staminaImprove disease resistanceFood ingredient functionsSorbitan monostearateCarrageenan

The invention discloses a method for preparing maca-containing boiling-free snow skin mooncake premixed flour. The premixed flour comprises the following raw materials: 500-600 parts of glutinous rice, 100-150 parts of starch wheat, 60-100 parts of maca fresh fruit, 20-30 parts of honey powder, 30-40 parts of white sugar, 1-3 parts of sorbitan monostearate, 10-15 parts of glyceryl monostearate, 2-5 parts of carrageenan, 2-5 parts of pectin, and 50-80 parts of water. The premixed flour is rich in high-unit nutrients, can be used for producing the snow skin mooncakes without re-blending, and the snow skin mooncake can be eaten when opened.

Owner:韦越仕

A kind of bamboo shoot shell fish compound feed containing fermented silkworm chrysalis and its application

ActiveCN104171492BImprove survival rateIncrease growth rateClimate change adaptationAnimal feeding stuffBiotechnologyFresh fish

The present invention discloses a marble goby compound feed containing fermented silkworm chrysalis and a use thereof. The compound feed does not contain fish meal, and comprises fermented silkworm chrysalis, alpha-starch, wheat flour, wheat gluten flour, zeolite powder, calcium biphosphate, salt and premix for carnivorous fish. The fermented silkworm chrysalis is prepared by adding mixed meal into the silkworm chrysalis, inoculating microbe, adding carbon sources and inorganic salts, fermenting and culturing the mixture. The microbe is a mixed bacterio-liquid containing bacillus subtilis, bacillus acidi lactic and yeast. According to the present invention, the marble goby compound feed does not contain any fish meal and fish meat products, is produced from fermented silkworm chrysalis, can completely replace pure live fish and ice fish for breeding, increases survival rate and growth rate of marble goby, improves quality of fish meat, significantly increases the economic benefits of aquaculture, and promotes the sustained, healthy and stable development of marble goby aquaculture.

Owner:佛山市顺德美塘农业科技开发有限公司

Manufacturing process of low-temperature adhesive for bonding corrugated boards

InactiveCN111592831ARaise the curing deformation temperatureLow cure deformation temperatureNon-macromolecular adhesive additivesMacromolecular adhesive additivesPotato starchMelamine formaldehyde resin

The invention relates to a manufacturing process of a low-temperature adhesive for bonding corrugated boards. The manufacturing process comprises the following steps: firstly, sequentially adding 10-15% of corn starch; 5%-10% of wheat starch; 5%-10% of potato starch and 3%-8% of glutinous rice flour and uniformly mixing; taking out 30% of the mixture, adding 15% of pre-gelatinized starch or pre-gelatinized corn flour, and uniformly mixing; then adding 5%-10% of modified compound protein, 3%-8% of vinyl acetate and 3%-6% of melamine formaldehyde resin; then adding 1%-2% of sodium hydroxide and1%-3% of water-soluble resin; then adding 2%-3% of dry filler, 1%-2% of hot melt resin and 1%-3% of water-soluble resin; adding 5% of the mixture of the hot-melt resin and the light dry filler into the mixture obtained in the third step; and finally, adding the balance of deionized water, and uniformly stirring. The low-temperature adhesive prepared by the process is good in waterproofness, the development requirements of flexibility, corrosion resistance and elasticity of an adhesive film are met, and the quality of a produced product can be improved by 30% in the aspects of physical properties and flatness.

Owner:SHENZHEN HUILONG ENVIRONMENTAL PROTECTION SCI& TECH CO LTD

Manufacturing method of fragrant crispy pleurotus eryngii strips

InactiveCN105029382ATo promote metabolismBeautiful and fragrantFood ingredient functionsFood preparationBiotechnologySucrose

The invention discloses a manufacturing method of fragrant crispy pleurotus eryngii strips, and belongs to the field of food processing. The method is characterized in that an adopted recipe comprises the following ingredients including fresh pleurotus eryngii, 20 percent of yam starch, 25 percent of wheat starch, 15 percent of spiced salt, 8 percent of spicy thirteen-spices, 3 percent of cumin powder, 5 percent of cane sugar, 2 percent of monosidum glutamate and a proper amount of edible oil. A processing technological process comprises the flow processes of raw material sorting, cleaning, hot soaking, dewatering, forming, mixed power mixing, oil frying and packaging. The manufacturing method has the beneficial effects that the surface of a product is shallow golden yellow; the pleurotus eryngii bodies have slight elasticity; the fragrant crispy feeling is proper; the color, the flavor and the smell are good; the expected taste of the pleurotus eryngii is realized; the flavor is unique and good; the product contains rich nutrition, can be easily digested, and also contains rich protein and other nutrition substances; the human body metabolism can be favorably improved; the constitution is enhanced; the effects of tonifying yin and qi, delaying senescence, losing fat and lowering the blood pressure are achieved; the eating is convenient; the fragrant crispy pleurotus eryngii strips are suitable for both old people and young people.

Owner:吴蓓蓓

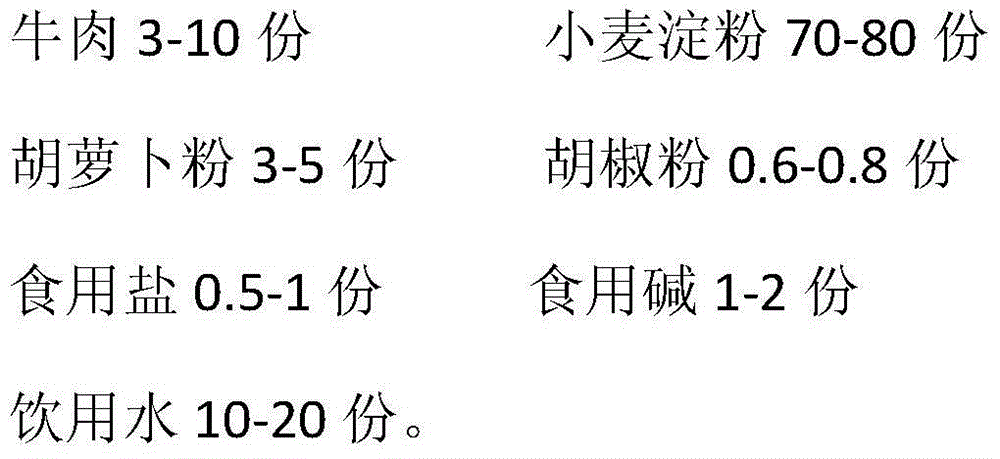

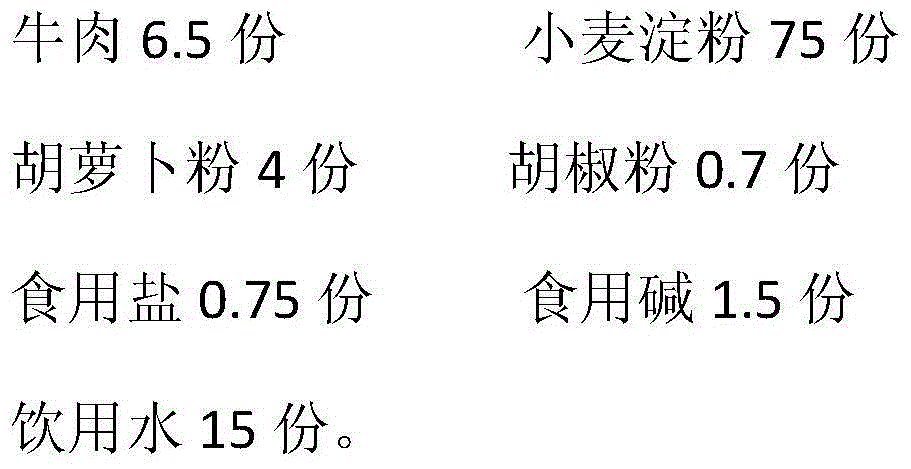

Ready-to-eat beef noodles

The present invention discloses ready-to-eat beef noodles, which comprises the following raw materials in part by weight: 3-10 parts of beef, 70-80 parts of starch wheat, 3-5 parts of carrot powders, 0.6-0.8 part of powdered peppers, 0.5-1 part of edible salt, 1-2 parts of edible alkali, and 10-20 parts of drinking water. The beef noodles are rich in nutrition and convenient to eat.

Owner:周琪

Multiple-grain puffed foods and making method thereof

InactiveCN109363084AHigh in dietary fiberOvercoming the deficiency of low dietary fiberFood ingredient functionsWheat germSugar

The invention discloses multiple-grain puffed foods. The multiple-grain puffed foods comprise the following raw materials in parts by weight of 20-35 parts of fine bran, 0-30 parts of coarse bran, 5-10 parts of rice bran, 6-10 parts of wheat germs, 9-16 parts of tapioca starch, 0-26 parts of corn starch, 0-36 parts of wheat starch, 4-6 parts of sugar and 0.5-1.5 parts of salt. The multiple-grain puffed foods preferably comprise 20 parts of the fine bran, 5 parts of the coarse bran, 5 parts of the rice bran, 10 parts of the wheat germs, 13 parts of the tapioca starch, 26 parts of the corn starch, 15 parts of the wheat starch, 5.5 parts of the sugar, and 0.5 part of the salt. The invention further discloses a preparation method of the multiple-grain puffed foods. The fine bran, the coarse bran, the rice bran and the wheat germs are introduced to puffed foods, the average rate of the content of bran raw materials is 40% or above, and dietary fibers and minerals are greatly increased. Thetapioca starch, the corn starch and the wheat germs are added, so that the shaping degree, the crisp degree and the mouth feel of the puffed foods are greatly increased; and through various taste changes, the multiple-grain puffed foods can meet requirements of different crowds, and the multiple-grain puffed leisure foods being healthy, delicious, rich in nutrients and good in mouth feel can be obtained.

Owner:北京市粮食科学研究院有限公司

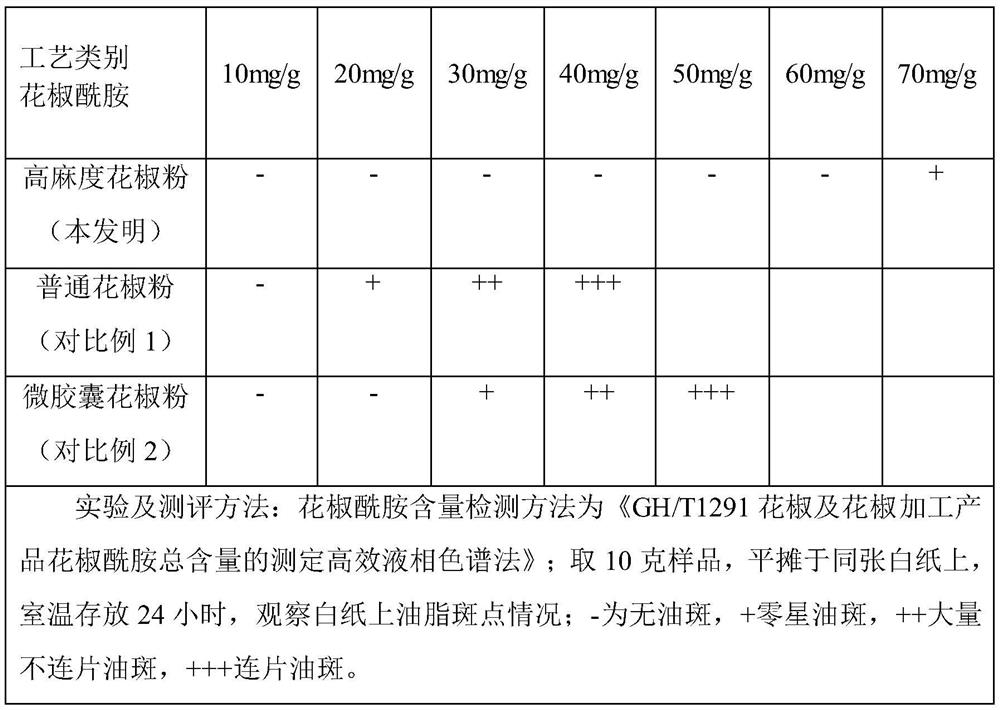

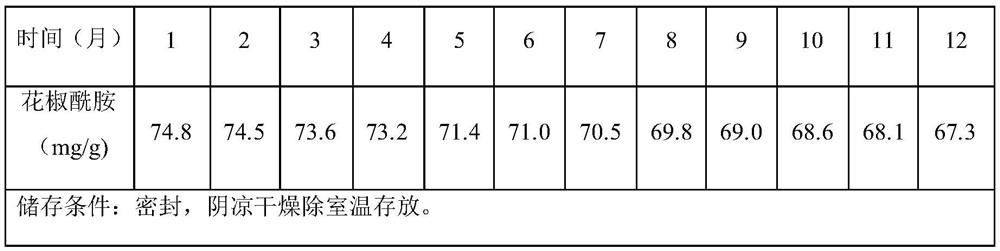

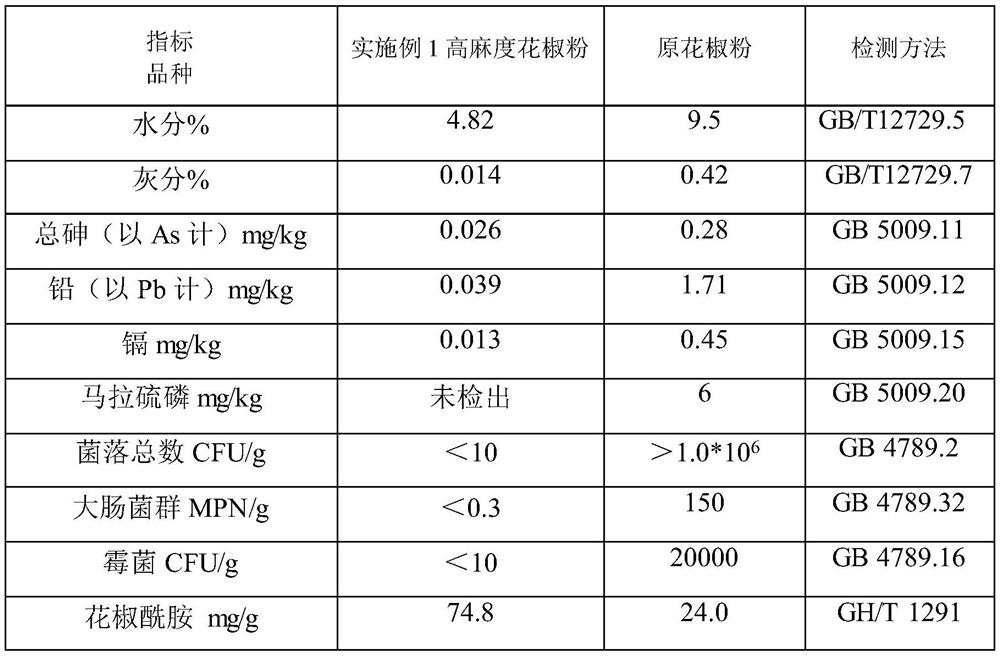

Preparation method of high-numb-degree Chinese prickly ash powder

ActiveCN113383941AReduce security risksImprove stabilitySugar food ingredientsBiotechnologyPotato starch

The invention provides a preparation method of high-numb-degree Chinese prickly ash powder, and relates to the technical field of deep processing of agricultural products. The method comprises the following step of mixing high-numb-degree Chinese prickly ash oleoresin with carrier granules, wherein the carrier granules are made from any one of corn starch, potato starch, wheat starch, cassava starch, maltodextrin and glucose. The content of xanthoamide (numb-degree substances) in the Chinese prickly ash powder prepared by the method disclosed by the invention can reach about 70mg / g, and is equivalent to 2-4 times of that of original plant powder; the content of the xanthoamide is stable, and is not influenced by the production place, the variety and the year environment of Chinese prickly ash, so that standardized and quantitative use of food processing enterprises is facilitated; and the Chinese prickly ash powder does not contain plant fibers, pesticide residues, microorganisms, heavy metals and the like, and is safe, controllable and low in food safety risk.

Owner:NANYANG ZHANGZHONGJING SUPER KITCHEN

Starch wheat compound enzyme and method of applying same in preparation of starch wheat and vital gluten

Owner:BAIYIN SINO BIOTECH

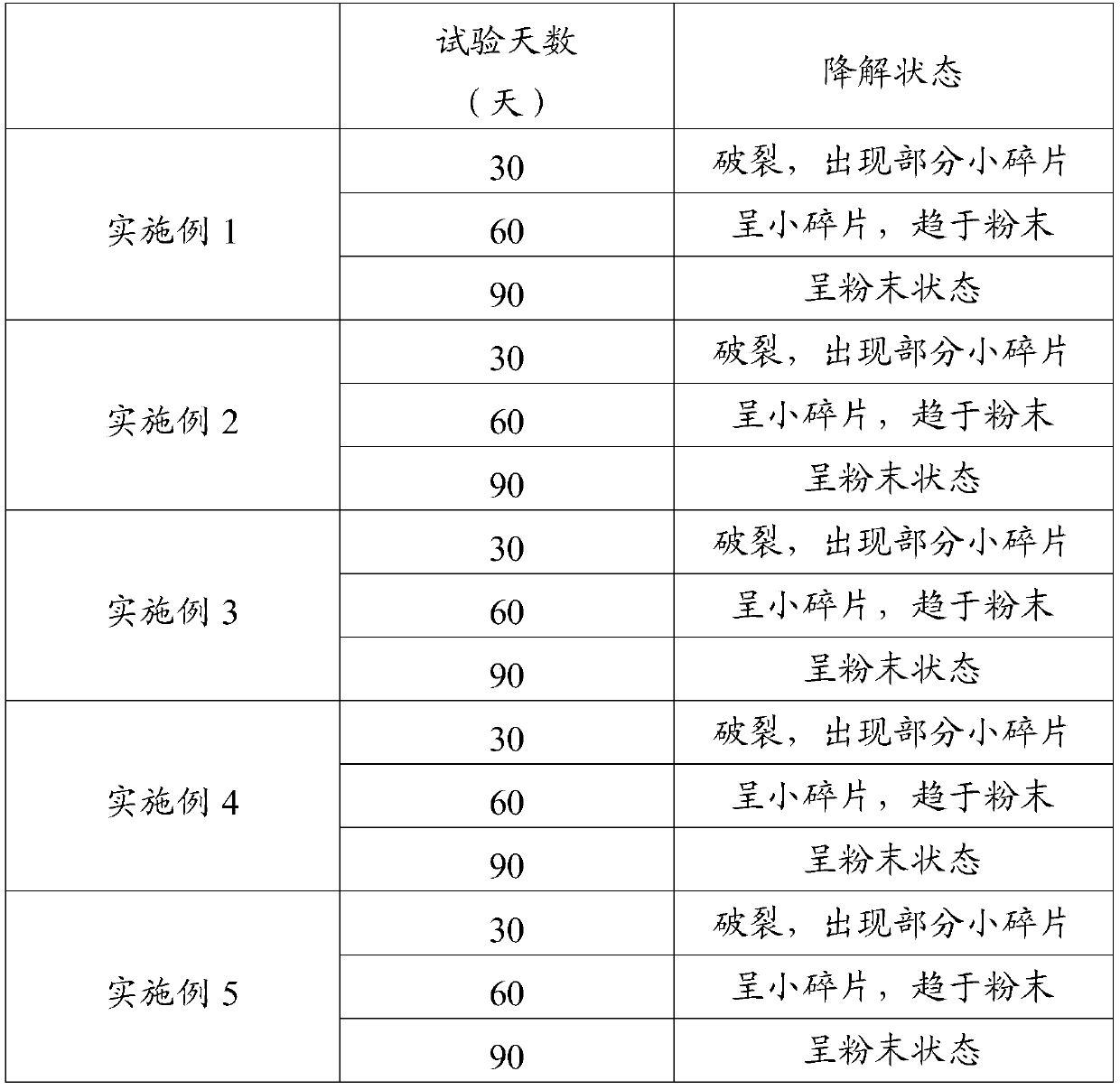

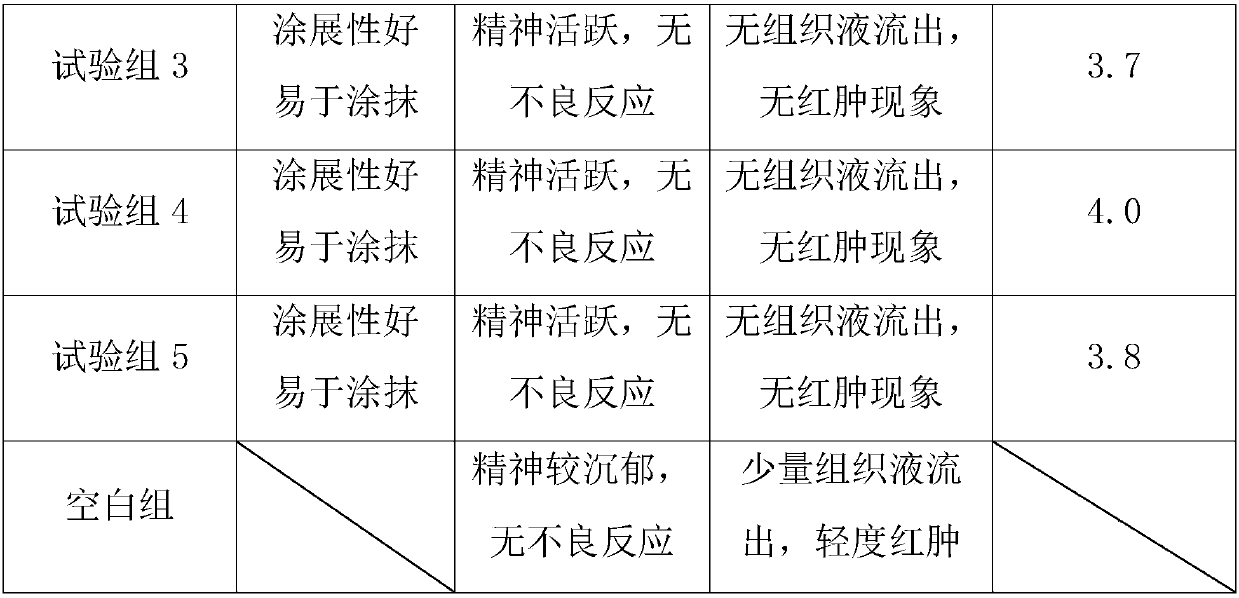

Biodegradable bacteriostatic film with high mechanical properties and preparation process thereof

The invention discloses a biodegradable antibacterial film with high mechanical properties and a preparation process thereof. The biodegradable antibacterial film is prepared from polyethylene, polylactic acid, deformed starch, wheat straw, wood fiber, Pullulan oxidized polyethylene wax, polysorbate, a toughening agent, bamboo charcoal powder, a heat stabilizer, milled long-grain glutinous rice flour, Chinese medical stone, kaolin, anhydrous sodium sulfate, coconut shell powder, poly(butylene succinate) and polyester fibers. The prepared film has a degrading function and high degradation efficiency, so the problem that conventional plastic films are difficult to degrade and pollute the environment is overcome; the film is also endowed with good antibacterial effect and tensile strength, sothe film can elongate under the stretching by external force, is increased in the elongation at break and is protected from dimensional changes caused by the increase of temperature. In addition, thepreparation process of the invention is simple in operation, high in production efficiency, convenient for processing and molding, endows a film product with antibacterial and environmental protection effects, and can be used for industrial large-scale production.

Owner:青岛永昌塑业有限公司

Water-based medical ultrasonic couplant and preparation method and application method thereof

InactiveCN108030934AGood water solubilityGood application effectAntipyreticAnalgesicsWater basedUltrasonography

The invention discloses a water-based medical ultrasonic couplant and a preparation method and an application method thereof, which belong to the technical field of the medical ultrasonic couplant. The water-based medical ultrasonic couplant comprises the following raw materials in parts by weight: 40-80 parts of liquidambar formosana hance, 30-50 parts of tree peony bark, 35-60 parts of Scutellaria baicalensis, 35-60 parts of Sophora flavescens, 40-80 parts of cactus, 50-80 parts of pine needle, 60-90 parts of oat, 50-90 parts of bamboo shavings, 45-65 parts of mushroom, 60-90 parts of freshand tender towel gourd, 20-50 parts of rose flower, 20-40 parts of perilla, 20-40 parts of lithospermum, 35-50 parts of fish pelargonium, 30-50 parts of bergamot, 20-40 parts of starch wheat, 5-20 parts of phycocyanin, and 5-10 parts of sodium polyacrylate. The prepared ultrasonic couplant employs water as a solvent and takes traditional Chinese medicine plant extract products as a main component,water-soluble performance is strong, smearing effect is good, washing difficulty after smearing is little, nontoxicity and innocuousness cannot be generated on human body, and no pollution is generated for environment.

Owner:AFFILIATED YONGCHUAN HOSPITAL OF CHONGQING MEDICAL UNIV

Formula and manufacturing technology of shark fin sponge cake

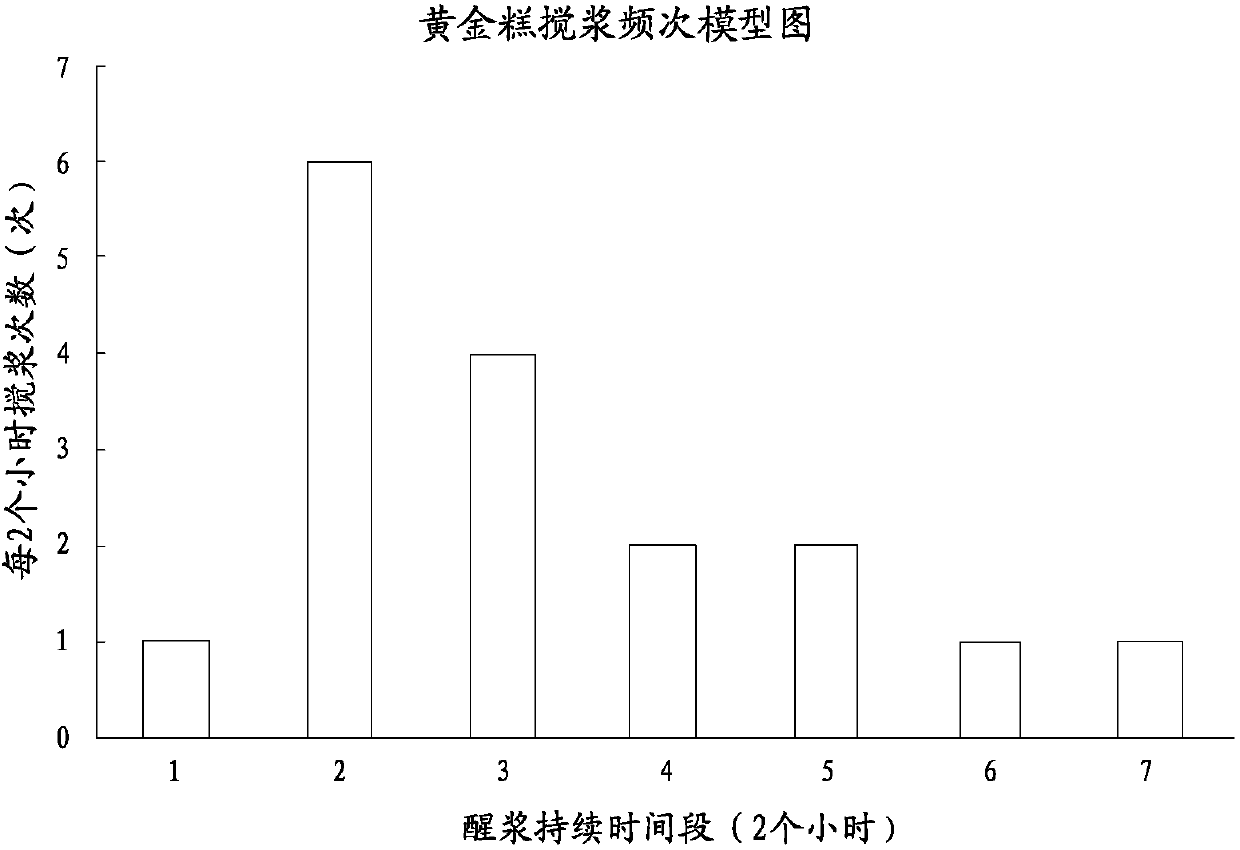

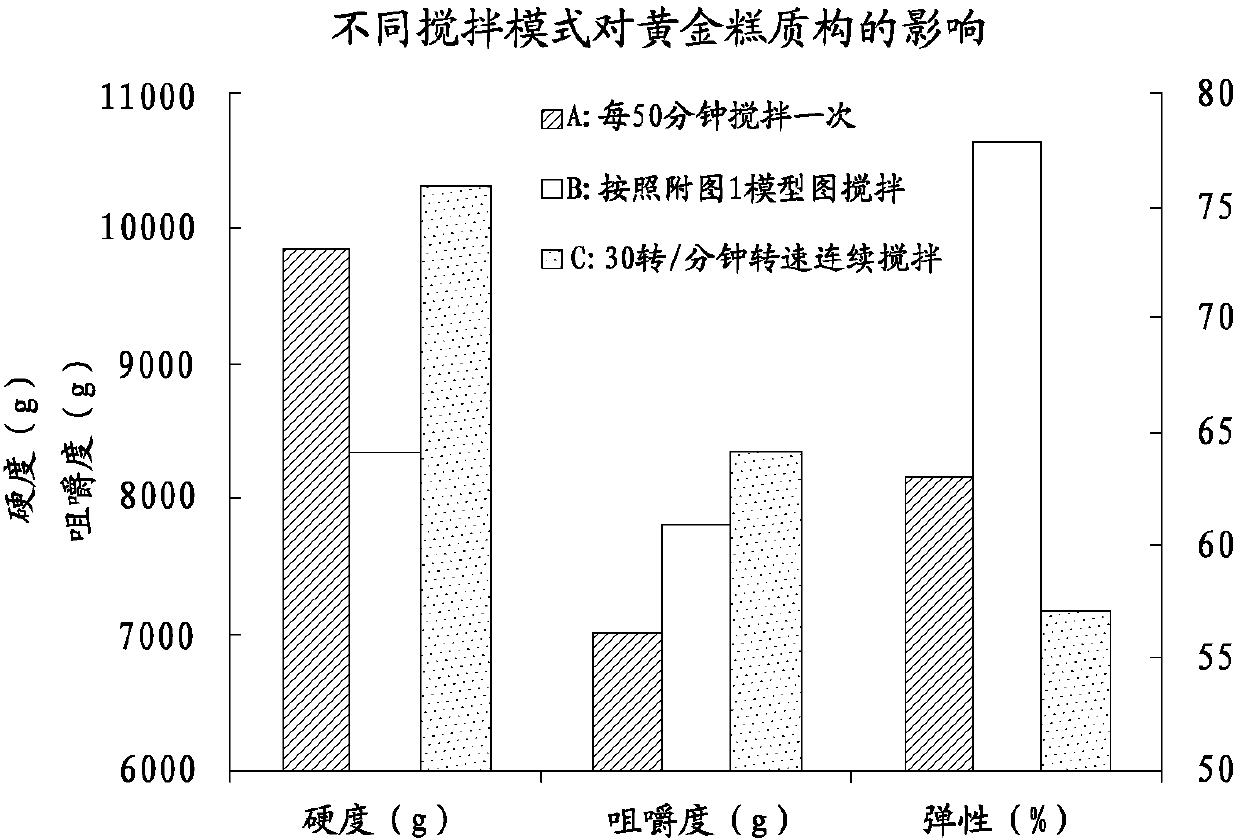

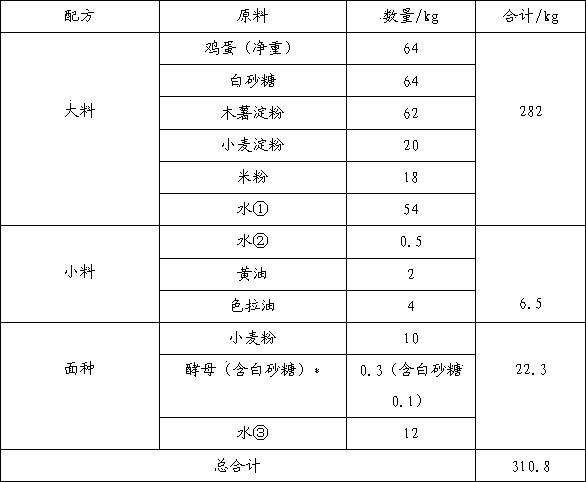

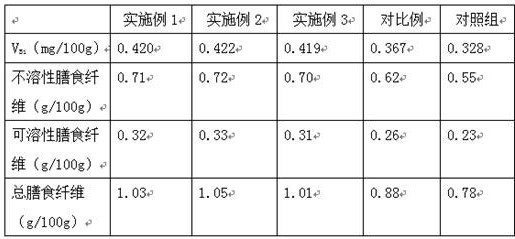

The invention discloses a formula of shark fin sponge cake and a manufacturing technology, suitable for industrial production, of the shark fin sponge cake. The shark fin sponge cake comprises, by weight, 18-25% of egg liquid, 17-23% of white granulated sugar, 17-21% of cassava starch, 5-8% of wheat starch, 4-7% of rice flour, 20-25% of water, 0.5-0.8% of butter, 1.1-1.5% of salad oil, 3-3.5% of flour and 0.06-0.07% of yeast. The manufacturing technology includes the steps of (a) batter manufacturing; (b) sourdough preparing; (c) batter rising (including stirring batter); (d) baking to be done. The manufacturing technology is characterized in that the batter is stirred according to a batter stirring frequency model in a reference attached map first in the batter rising process, according to braking of the shark fin sponge cake, open flames are adopted for braking the upper layer and the lower layer of the shark fin sponge cake in a sectional mode, and the sponge cake can be provided, wherein the surface of the sponge cake is slightly crisp, and uniform shark-fin-shaped pore tissues are formed in the interior. The shark fin sponge cake manufactured according to the formula and the manufacturing technology is fluffy and elastic, elasticity is high, and the shark fin sponge cake can be fried, baked and steamed for eating and more suitable for large-scale industrial production.

Owner:WUXI HUASHUN MINSHENG FOOD

High-starch wheat seedling culturing method

InactiveCN104705027ARapid emergenceStrong seedlingsFertilising methodsPlant cultivationPeatDisease damage

Owner:QINGDAO XINRUNTU NURSERY STOCK SPECIALIZED COOP

Soft chocolate paste, and preparation method, application method and applications thereof

The invention provides a soft chocolate paste, and a preparation method, an application method and applications thereof, and belongs to the technical field of food. The soft chocolate paste is prepared from, by mass, 10-30 parts of chocolate, 8-15 parts of syrup containing sorbitol, 9-15 parts of cream, 10-19 parts of starch wheat, 0.8-3 parts of sweet rice flour, 0.1-0.8 part of carboxymethylcellulose sodium, 0.3-1.5 parts of hydroxypropyl distarch phosphate, 0.6-2 parts of glycerin and 2-9 parts of water. The soft chocolate paste can be stored in either a cold storeroom or a room temperaturestoreroom; the soft chocolate paste is not easy to soft and deform within a long time when a storage temperature is at 30 DEG C without being directly exposed under the sun, so that the soft chocolate paste has strong shaping effects; and the soft chocolate paste is good and smooth in glossiness, and fine and soft in taste.

Owner:王书朋

Processing technology for improving peeling rate of aleurone layer and wheat bran layer in wheat processing

PendingCN112244274ALarge poresStrong penetrating powerFood dryingFood ultrasonic treatmentBiotechnologyPorous starch

The invention discloses a processing technology for improving the peeling rate of an aleurone layer and a wheat bran layer in wheat processing, and relates to the technical field of wheat processing.The specific technology is as follows: 1) preparing porous starch; 2) performing acidolysis treatment on chitosan, and performing cross-linking with the porous starch to obtain cross-linked porous starch; 3) pretreating wheat; and 4) dispersing the cross-linked porous starch in white oil to obtain impregnation liquid, performing vacuum pressure impregnation treatment on the pretreated wheat, and then performing wheat wetting treatment again. According to the technology method provided by the invention, the peeling rate of the aleurone layer and the wheat bran layer in wheat processing can be increased, so that the aleurone layer and the wheat bran layer are easily peeled and separated, the content of the aleurone layer in flour can be increased, and the nutrition and the quality of the flour are improved.

Owner:安徽康美达面业有限责任公司

Transparent rice dumpling and method for making the same

The invention relates to transparent dumplings and process for making them, wherein the process comprises, mixing homogeneously cassava starch, potato starch, sweet potato starch, and wheat starch as blank peel flour, choosing sesame powder, groundnut kernel powder, pine nut meat powder, melon seeds meat powder, vegetable oil and sugar as stuffing to make ball-form, placing the stuffing in the blank peel powder, stirring homogeneously, digesting in water in repetition, finally freezing in a refrigerator to obtain the end product.

Owner:史国平

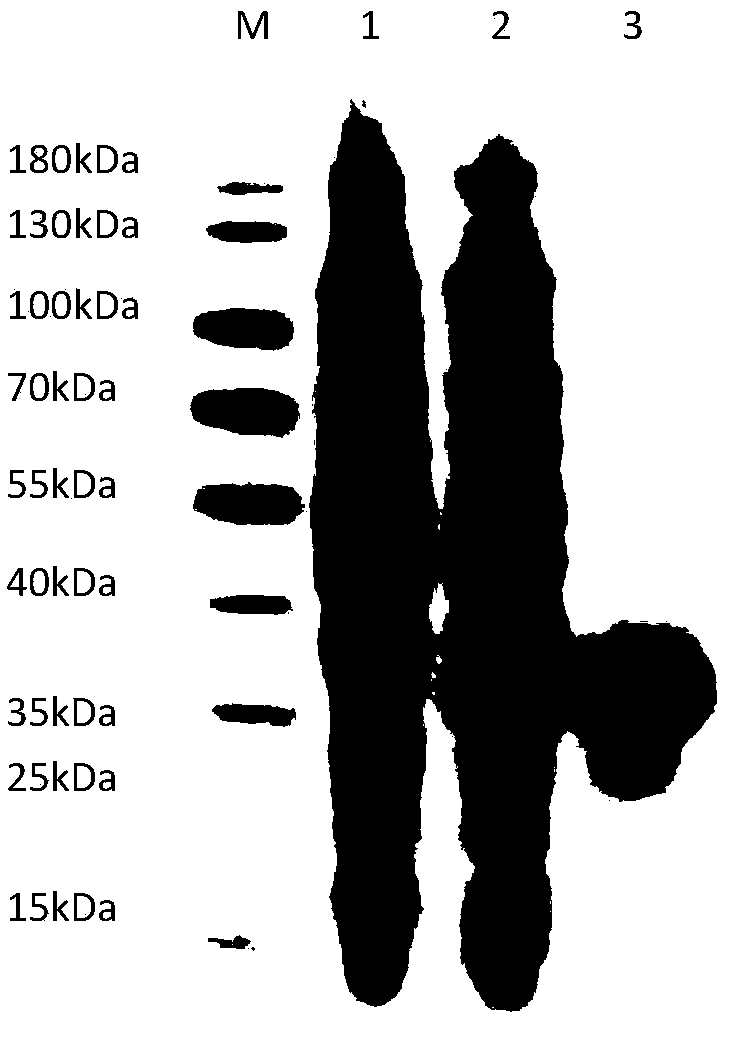

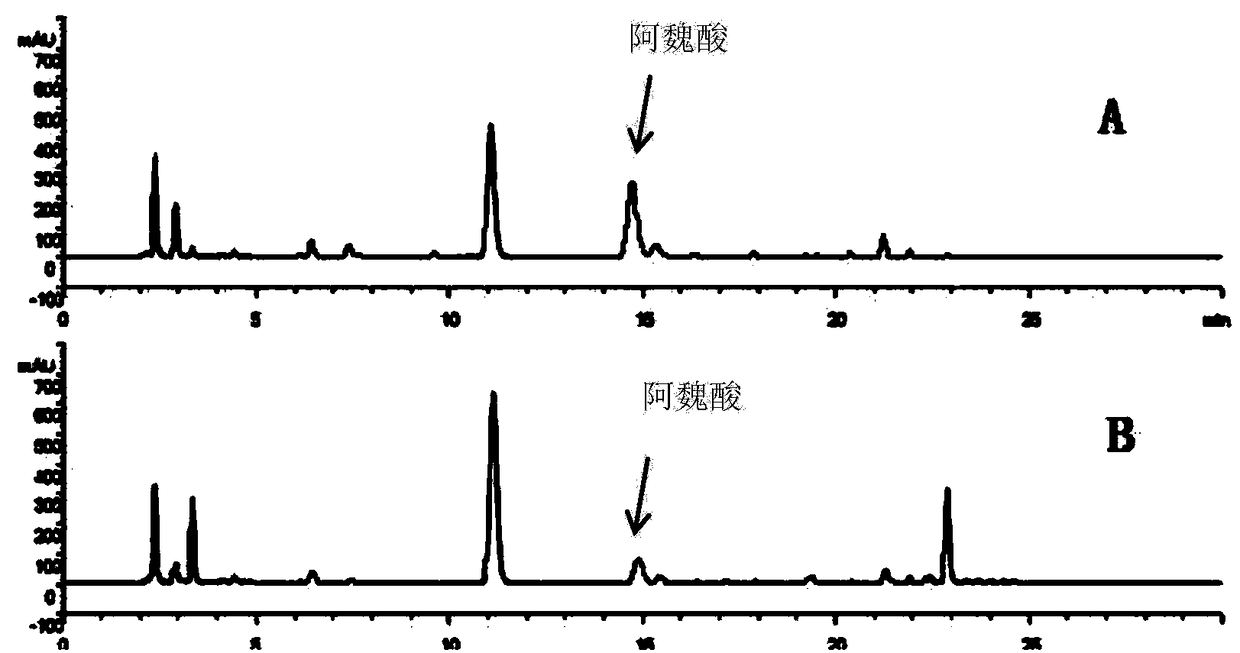

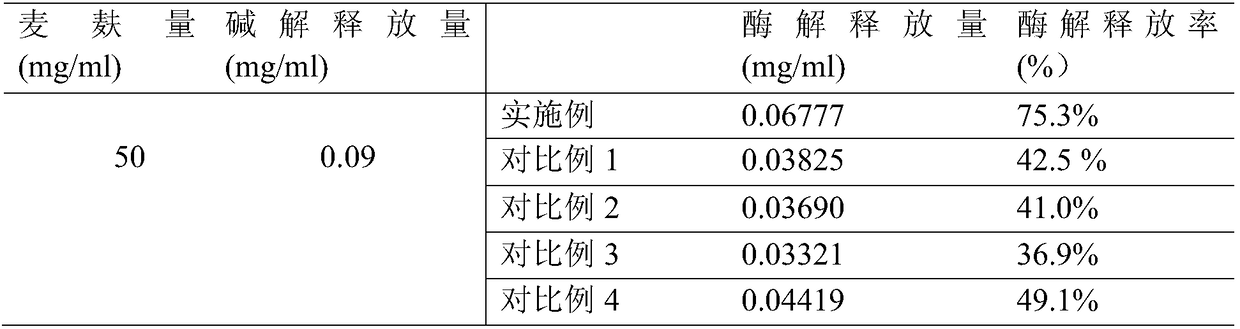

Aspergillus cristatus feruloyl esterase gene as well as engineering bacteria and application of thereof

The invention belongs to the field of genetic engineering, and in particular relates to an aspergillus cristatus feruloyl esterase gene as well as engineering bacteria and application thereof. The nucleotide sequence of the aspergillus cristatus feruloyl esterase gene is shown in SEQ ID No. 1. Feruloyl esterase encoded by the aspergillus cristatus feruloyl esterase gene has an amino acid sequenceshown in SEQ ID No. 2. The aspergillus cristatus feruloyl esterase gene provided by the invention can be used for in vitro generation of ferulic acid. Tests prove that the release rate of the ferulicacid in de-starch wheat bran suspension is 75.3%; the aspergillus cristatus feruloyl esterase gene enables the release rate of the ferulic acid to be much higher than other feruloyl esterase genes; therefore, a new enzyme source is provided for production of ferulic acid.

Owner:SHANDONG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com