Oat flour biscuit production method

A production method and biscuit technology, applied in the direction of dough processing, baking, and the function of food ingredients, etc., can solve the problems that are unfavorable to the health of diabetic patients and the improvement of their condition, and achieve the reduction of sugar intake in the body, rich nutrition, and full stomach strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

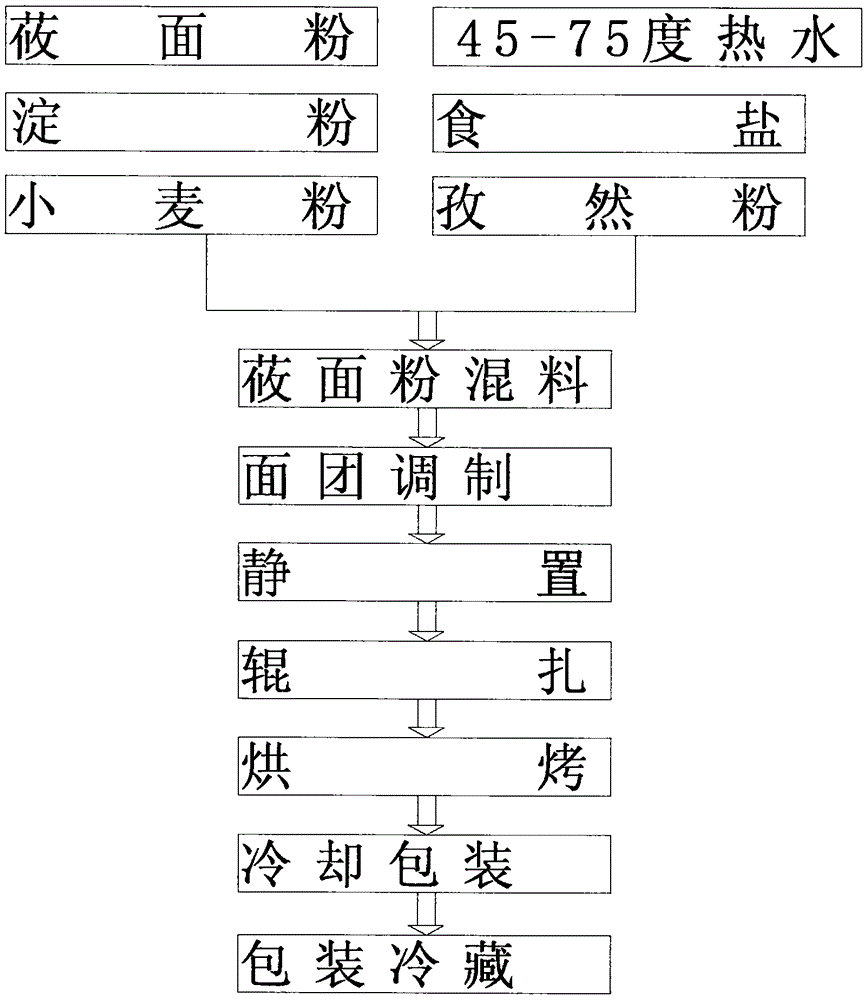

[0019] See the process of biscuit making figure 1 , a kind of oat noodle biscuit making method, comprises the following steps:

[0020] Step 1: batching and mixing;

[0021] Step 2: Dough preparation;

[0022] Step three: stand still;

[0023] Step 4: rolling;

[0024] Step five: Baking;

[0025] Step 6: cooling and packaging;

[0026] Step 7: Pack and store.

[0027] Among them, in step 1, the basic raw materials and the basic ratio are: use 45-75 degrees hot water, 60%-85% oatmeal flour, 3%-5% starch, 5%-7% wheat flour, 1%-10% Table salt, 1%-10% cumin.

[0028] In step 2, after weighing the various raw materials according to the formula and their proportions in step 1, add oat flour, green pea flour, starch, wheat flour, and salt to an appropriate amount of hot water at a temperature of 45-75 degrees and mix evenly , made into dough or batter;

[0029] In step 3, depending on the type of biscuits to be made, the time for standing or not standing, the general time fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com