Method for preparing compound amino acid through extensive enzymatic hydrolysis of soybean protein

A technology for compound amino acids and soybean protein, which is applied in the field of compound amino acid preparation by in-depth enzymatic hydrolysis of soybean protein, and achieves the effects of improving the sensitivity of enzymatic hydrolysis, improving the yield and improving the degree of degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

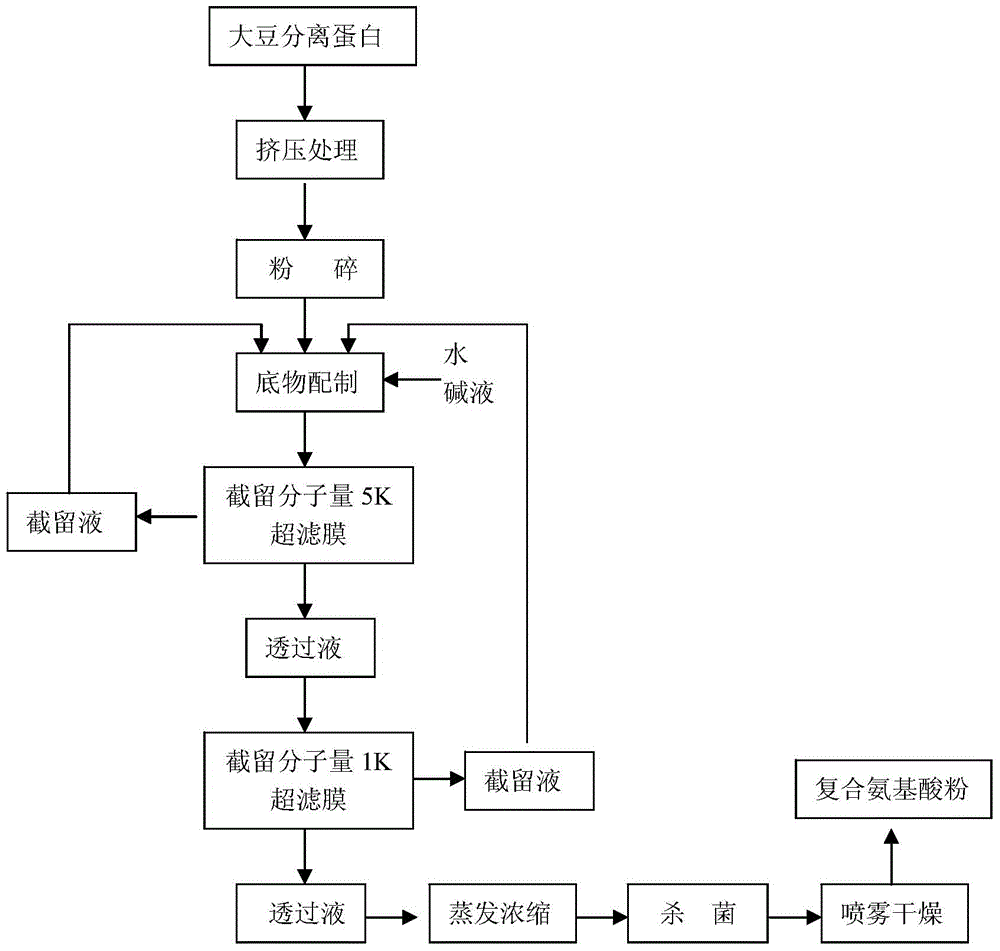

[0043] The operation process is as figure 1 Shown:

[0044] (1) Raw material moisture adjustment: add deionized water to 100kg soybean protein isolate raw material (on a dry basis, the protein content is 92.6%), stir and disperse evenly, so that the water content is 20% (w / w);

[0045] (2) Extrusion pretreatment: use a twin-screw extruder with an extrusion temperature of 100°C, a die hole diameter of 20mm, and a screw speed of 110r / min to extrude soybean protein. After extrusion, use a high-speed pulverizer to crush The extruded soybean protein is crushed to 60 mesh;

[0046] (3) Dispersion and hydration of soybean protein: the soybean protein powder after pulverization is prepared as a soybean protein solution with a mass percentage of 5% with deionized water, and the soybean protein solution is dispersed and hydrated (shear speed is 2000rpm, time 15min), the temperature was raised to 50°C, and the pH value was adjusted to 8.5 with sodium hydroxide solution;

[0047] (4) S...

Embodiment 2

[0050] (1) Raw material moisture adjustment: add deionized water to 100kg of soybean protein isolate raw material (on a dry basis, with a protein content of 92.6%), stir and disperse evenly, so that the water content is 25% (w / w);

[0051] (2) Extrusion pretreatment: use a twin-screw extruder with an extrusion temperature of 95°C, a die hole diameter of 15mm, and a screw speed of 100r / min to extrude soybean protein. After extrusion, use a high-speed pulverizer to crush The extruded soybean protein is crushed to 40 mesh;

[0052] (3) Dispersion and hydration of soybean protein: the soybean protein powder after crushing is prepared as 8% soybean protein solution by mass percentage with deionized water, and the soybean protein solution is dispersed and hydrated (shear speed is 3000rpm, time 10min), the temperature was raised to 45°C, and the pH value was adjusted to 8.0 with sodium hydroxide solution;

[0053] (4) Soybean protease membrane reaction based on ultrafiltration separ...

Embodiment 3

[0056] (1) Raw material moisture adjustment: add deionized water to 100 kg of soybean protein isolate raw material (on a dry basis, with a protein content of 92.6%), stir and disperse evenly, so that the water content is 30% (w / w);

[0057] (2) Extrusion pretreatment: use a twin-screw extruder with an extrusion temperature of 105°C, a die hole diameter of 25mm, and a screw speed of 120r / min to extrude soybean protein. After extrusion, use a high-speed pulverizer to crush The extruded soybean protein is crushed to 80 mesh;

[0058] (3) Dispersion and hydration of soybean protein: the soybean protein powder after crushing is prepared as a 10% soybean protein solution by mass percentage with deionized water, and the soybean protein solution is dispersed and hydrated (shear speed is 2500rpm, time 15min), the temperature was raised to 55°C, and the pH value was adjusted to 8.5 with sodium hydroxide solution;

[0059] (4) Soybean protease membrane reaction based on ultrafiltration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com