Method for continuously preparing alkenyl succinic anhydride by microchannel reactor

A technology of microchannel reactor and alkenyl succinic anhydride, which is applied in the direction of chemical instruments and methods, chemical/physical/physical chemical reactors, chemical/physical/physical chemical processes, etc., can solve the problem of increasing catalyst removal procedures and pipeline length , can not be carried out continuously, etc., to achieve the effect of saving the process of catalyst recovery, continuous and efficient reaction, and reducing manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

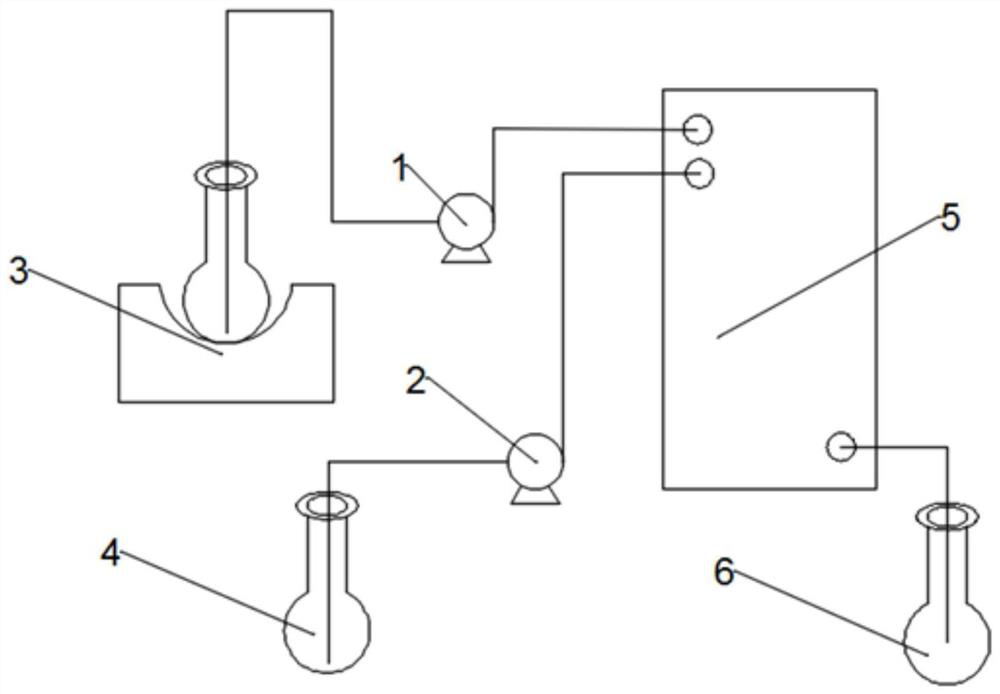

Method used

Image

Examples

Embodiment 1

[0022] This embodiment provides a method for continuously preparing alkenyl succinic anhydride in a microchannel reactor, which specifically includes the following steps:

[0023] Step 1) heat-melt maleic anhydride in a reaction tank, and the heat-melt temperature is 75° C. to obtain a hot-melt maleic anhydride;

[0024] Step 2) by two metering pumps, the maleic anhydride hot melt and the sixteen internal olefins obtained in step 1 are pumped into the microchannel reactor simultaneously, wherein the mol ratio of the maleic anhydride and the sixteenth internal olefins is 1 : 1, the material of the microchannel reactor is silicon carbide;

[0025] Step 3) react in a microchannel reactor, the reaction temperature is 220°C, the reaction residence time is 0.5min, and the reaction pressure is 0.7MPa;

[0026] Step 4) After the reaction, the discharged product was purified by vacuum distillation to obtain alkenyl succinic anhydride as an oily amber liquid with a yield of 70%.

Embodiment 2

[0028] This embodiment provides a method for continuously preparing alkenyl succinic anhydride in a microchannel reactor, which specifically includes the following steps:

[0029] Step 1) heat-melt maleic anhydride in a reaction tank, and the heat-melt temperature is 75° C. to obtain a hot-melt maleic anhydride;

[0030] Step 2) by two metering pumps, the maleic anhydride hot melt obtained in step 1 and octadecylidene are pumped into the microchannel reactor simultaneously, wherein the mol ratio of maleic anhydride and octadecadene is 2.5 : 1, the material of the microchannel reactor is Hastelloy;

[0031] Step 3) react in a microchannel reactor, the reaction temperature is 240°C, the reaction residence time is 3min, and the reaction pressure is 0.1MPa;

[0032] Step 4) After the reaction, the discharged product was purified by vacuum distillation to obtain alkenyl succinic anhydride as an oily thick amber liquid with a yield of 75%.

Embodiment 3

[0034] This embodiment provides a method for continuously preparing alkenyl succinic anhydride in a microchannel reactor, which specifically includes the following steps:

[0035] Step 1) heat-melt maleic anhydride in a reaction tank, and the heat-melt temperature is 75° C. to obtain a hot-melt maleic anhydride;

[0036] Step 2) by two metering pumps, the maleic anhydride hot melt obtained in step 1 and the carbon dodecacene are pumped into the microchannel reactor simultaneously, wherein the mol ratio of the maleic anhydride and the carbon dodecacene is 2 : 1, the material of the microchannel reactor is stainless steel;

[0037] Step 3) react in a microchannel reactor, the reaction temperature is 270°C, the reaction residence time is 2min, and the reaction pressure is 0.2MPa;

[0038] Step 4) After the reaction, the discharged product was purified by vacuum distillation to obtain alkenyl succinic anhydride as an oily thick amber liquid with a yield of 78%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com