Kitchen waste integrated sorting machine and method

A technology of food waste and sorting machine, which is applied in the direction of chemical instruments and methods, solid separation, and separation of solids from solids with airflow, which can solve the problems of unenclosed operating equipment, environmental pollution, time-consuming and labor-intensive, etc. Achieve the effect of stable operation, low speed and large diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

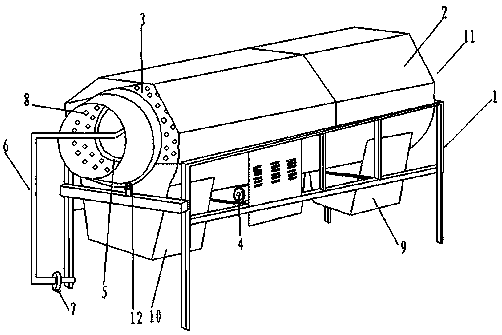

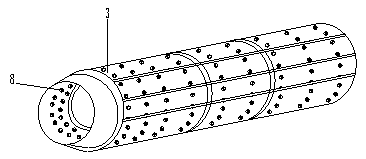

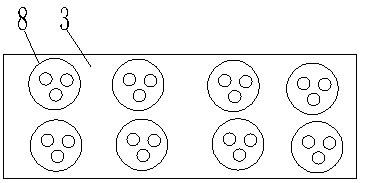

[0032] see figure 1 , 2 , an integrated sorting machine for food waste, including an organic base 1, a screen cylinder 3 is arranged on the base 1; an outer cover 2 is provided outside the screen cylinder 3; Rotate on the upper side of the sieve cylinder 3; a fan 7 is provided on the base below the entrance side of the front part of the screen cylinder 3, and the fan 7 communicates with the air duct 6, and the air outlet of the air duct 6 extends into the screen cylinder 3 from the entrance of the sieve cylinder 3 The inner wall of the sieve cylinder 3 is fixed with a material guide spiral plate 5; the inner wall of the sieve cylinder 3 is provided with a sieve hole; the bottom of the outer cover 2 is provided with a swill recovery box one 9 and a swill recovery box two 10; the sieve cylinder 3 tail is a soli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com