Metallurgical furnace slag thickness control device

A technology of thickness control and metallurgical slag, which is applied in the field of metallurgy, can solve the problems that the thickness cannot be adjusted at any time, the degree of metal reaction cannot be guaranteed, and the residence time of slag cannot be well controlled, so as to reduce losses and improve metallurgy. The recovery rate and the effect of saving processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

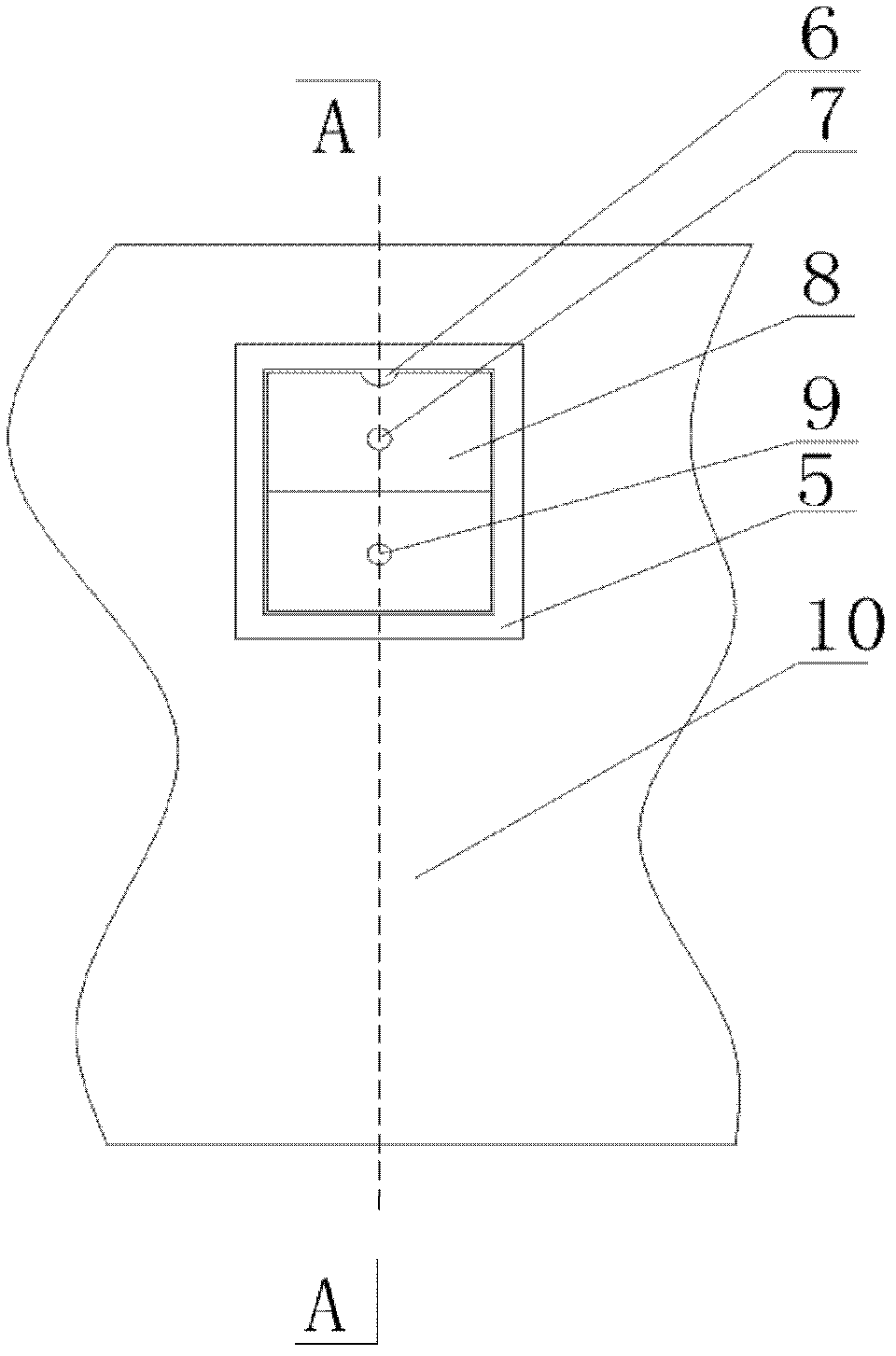

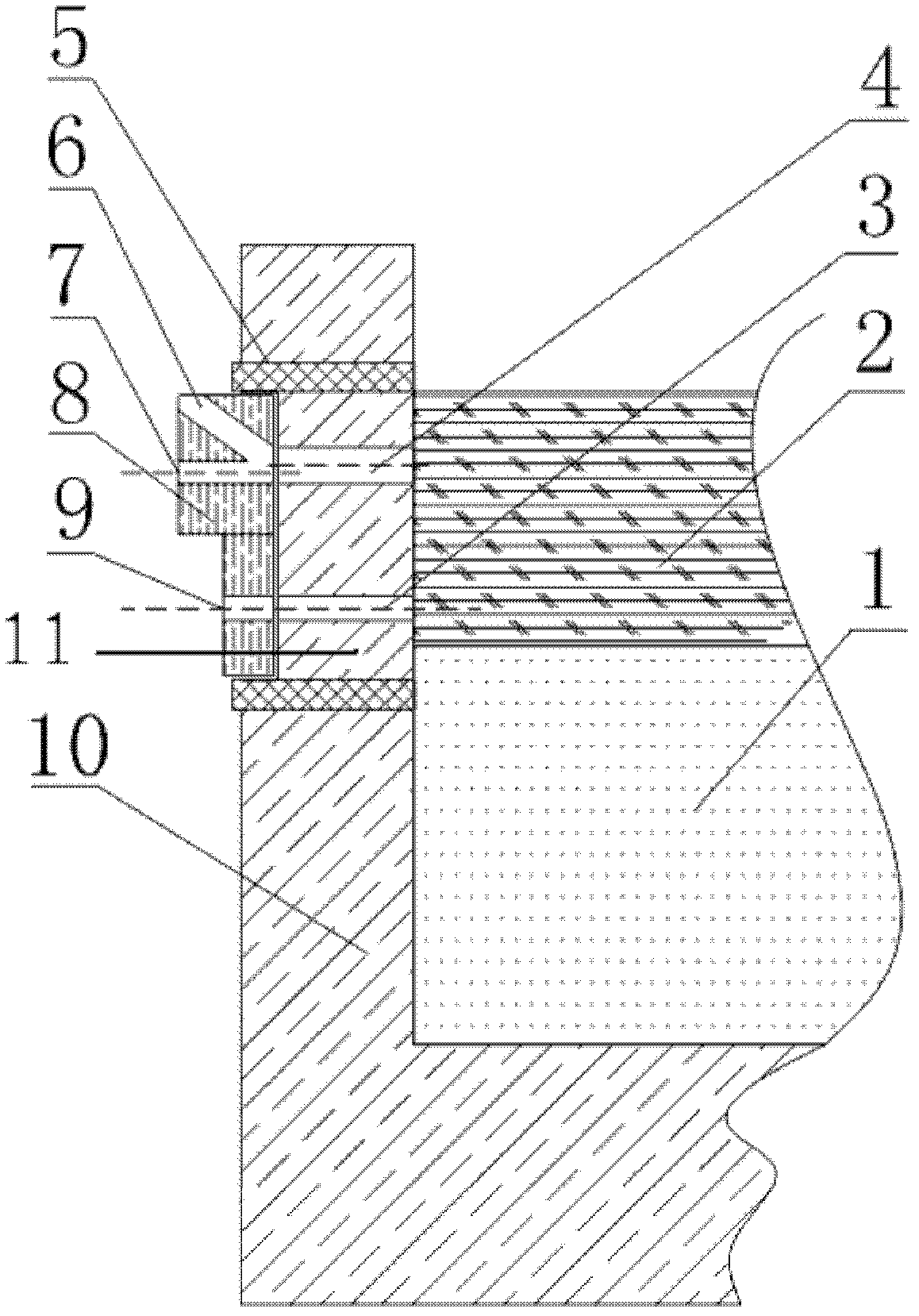

[0025] The metallurgical slag thickness control device of the present invention is used in lead-oxygen-enriched flash smelting production. During normal production, the siphon-type first slag port 6 is used for continuous slag discharge, so that the thickness of the slag layer is constant. When the production parameters are adjusted, the second slag port 7 and the third slag port 9 of the straight type can be used for intermittent slag discharge, and the thickness of the slag layer can be flexibly controlled by holding back the slag discharge. In the case of poor slag type in the furnace, the third slag port 9 located at the lowest position can be used to promptly discharge the slag in the furnace, and then form a new slag layer thickness meeting the technological requirements through intermittent slag discharge.

[0026] The metallurgical slag thickness control device provided by the present invention can realize timely and reasonable control of the thickness of the slag layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com