Blast furnace slag sensible heat recovery slag cooler

A sensible heat recovery and slag cooler technology, which is applied in furnaces, waste heat treatment, furnace components, etc., can solve the problems of large equipment footprint, large pollutant discharge, and low efficiency of waste heat utilization, and achieve a small footprint , heat recovery efficiency improvement, the effect of improving heat recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

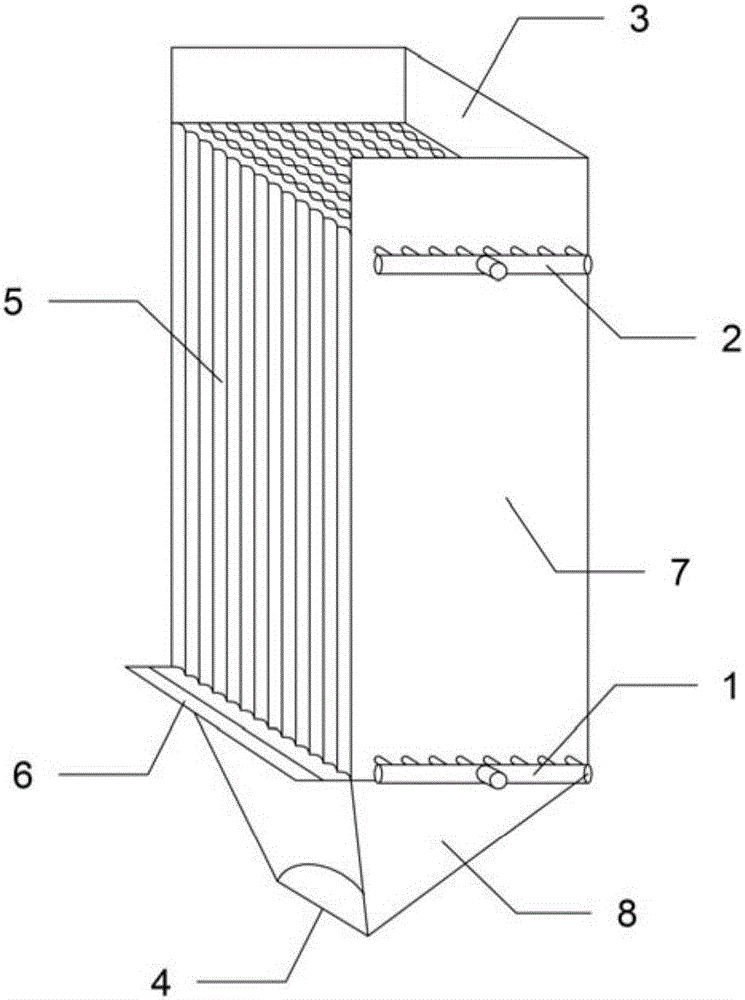

[0024] Embodiment 1: refer to figure 1 , a blast furnace slag sensible heat recovery slag cooler, comprising: cooling water inlet 1, steam outlet 2, slag inlet 3, slag outlet 4, plate and tube heat exchange core 5, louvered slag outlet baffle 6, shell and Insulation layer 7, slag outlet funnel 8.

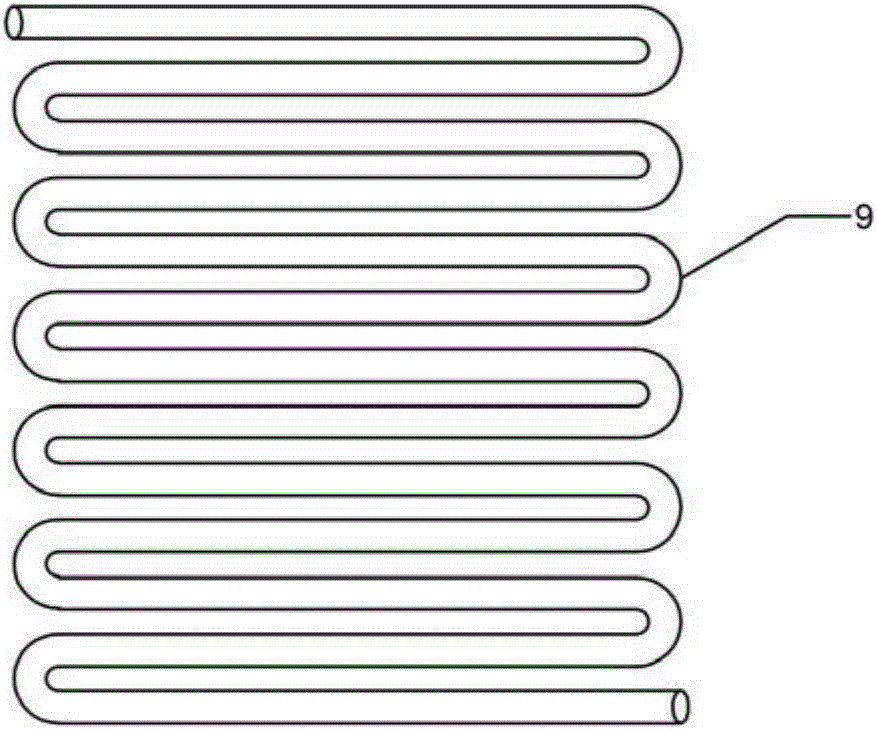

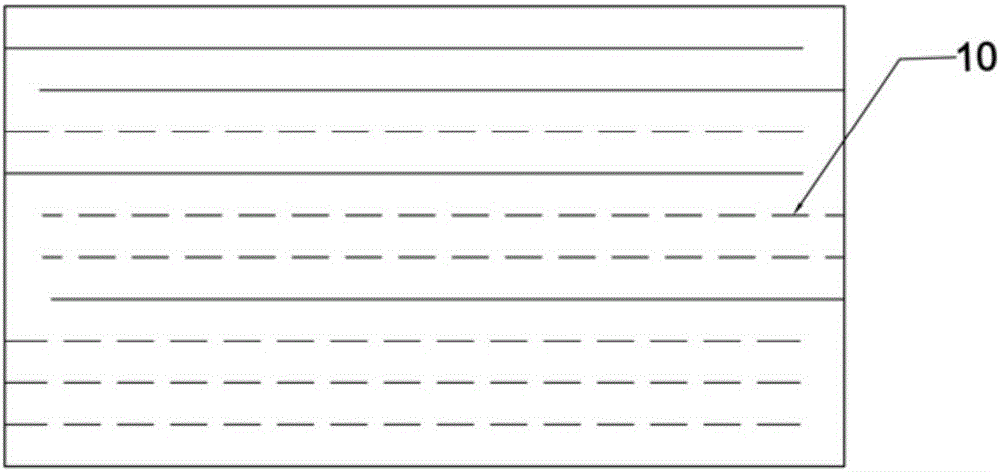

[0025] refer to figure 2 and 3 , the heat exchange core 5 of the slag cooler includes all plate and tube types, the cooling water channel is inside the plate or tube, and the high temperature slag channel is outside the plate tube.

[0026] refer to Figure 4 The louver-type slag outlet baffle 6 is a louver-type speed control device with a gear 12 that can be driven by a motor to rotate the baffle 11, and the retention of slag in the heat exchange core can be adjusted by changing the rotation range and inclination of the baffle 11 time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com